With the development of biomedicine, micro/nano fabrication, nanostructured materials, environment protection equipment and so on, various nano manipulation functions are being required[1, 2], which include trapping, positioning, transfer, release, revolution, removal, concentration, assembly, sorting, etc. However, most of the above listed nano manipulation functions cannot be effectively and efficiently realized by the conventional actuating technology, which have limited driving form and operating principles [2]. To fulfill the demands, lots of strategies have been proposed and investigated. Based on the physical principles, they can be classified as optical [1, 3], magnetic[4], electric[5], mechanical[6], AFM[7], microfludic [8] and acoustic methods[9, 10, 11, 12, 13, 14, 15].

The ultrasonic nano manipulation utilizes sound induced flow or the acoustic streaming to manipulate nanoscale materials. In recent four years, the authors group proposed and realized a series of nano manipulation functions by means of controlled acoustic streaming. They include trapping, orientation, positioning, transfer and rotation of individual nanowires in deionized water, and concentration of nanowires and nanoparticles in deionized water [2, 9, 10, 11, 12, 13]. In 2014 and 2015, researchers in the USA reported the method of nano rotary driving based on acoustic streaming[14, 15].The ultrasonic nano manipulation has the features such as little selectivity to material properties of manipulated samples, little heat damage to manipulated samples, diversified manipulation functions, and no need to dispose MEMS or NEMS structures on the substrate. Although it has huge potential applications in the fields such as biomedicine, micro/nano fabrication, nanostructured materials, air filtration, etc., researches on the principle and structure design of these devices are still superficial and insufficient[2]. This paper reviews the progresses in principles, functions, structures and characteristics of the ultrasonic devices for nano manipulations.

2 Acoustic Streaming and Its AnalysesAt the present stage, the acoustic streaming which is a nonlinear effect of ultrasonic wave is the main means employed in the controlled ultrasonic nano manipulations[2].It can be generated by spatial gradient of the Reynolds stress and 2nd order sound pressure or by the collapse of acoustic bubbles. In the controlled nano manipulation, the former is mostly utilized[2], while the latter one can be utilized in the dispersion of nano samples in liquid[2, 16, 17]. For better and wider applications of acoustic streaming in nano manipulations, it is necessary to understand the dependency of acoustic streaming field in the devices on working and structural parameters. However, it is usually not easy to observe and measure the acoustic streaming field owing to its complicated geometrical shape and small size. Also, the typologies of acoustic fields in the existing computation models are quite different from that in the ultrasonic devices for nano manipulations[18, 19, 20, 21, 22]. Thus, the theoretical results based on these computational models cannot be applied to the analyses of acoustic streaming fields in nano manipulations.

We proposed and developed a numerical method, making use of a commercialized FEM software (COMSOL Multiphysics), to compute the acoustic streaming field conveniently and efficiently[18]. The computation process consists of three steps. In the first step, the sound field is solved with the coupled sound pressure, structural vibration and piezoelectricity modules. In the second step, vibration velocity and sound pressure of the sound field are used to calculate spatial gradients of the Reynolds stress and mean pressure, which generate the acoustic streaming, by the post processing functions of the software. In the last step, the acoustic streaming is solved by the fluidic dynamics module, with proper boundary conditions. The steady acoustic streaming satisfies the following equation:

| ${p_o}\left( {{{\overline u }_i}\partial {{\overline u }_j}/\partial {x_i}} \right) = {F_j}-\partial {\overline p _2}/\partial {x_j} + \eta {\nabla ^2}{\overline u _j}$ | (1) |

where ui is acoustic streaming velocity, repeated suffix i and j represent x, y and z in a 3D model; ρ0is the medium density in the undisturbed state; Fj is the gradient of the Reynolds stress which acts on the fluid as a driving force of the acoustic streaming, and ${\overline p _2}$is the time average of the 2nd order pressure or mean pressure. Fj is calculated by

| ${F_j} = -\partial \left( {\overline {{p_0}{u_i}{u_j}} } \right)/\partial {x_i}$ | (2) |

where ui is the vibration velocities in the sound wave, and the bar signifies the mean value over one period.${\overline p _2}$is calculated by

| ${\overline p _2} = {1 \over {2{p_o}{c_o}^2}}{B \over A}\left\langle {{p_1}^2} \right\rangle $ | (3) |

where p1 represents the 1st order sound pressure; < > represents the time average over one time period; c0 is the medium sound speed in the undisturbed state, and $B/A$ is the nonlinear parameter of the medium. The acoustic streaming also satisfies the continuity equation

| ${p_o}\partial {\overline u _i}/\partial {x_i} = 0$ | (4) |

Based on the computation method, the effective methods for controlling the acoustic streaming fields in the nano manipulation have been achieved [13, 23, 24]. Ultrasonic nano trapping and some ultrasonic rotary driving methods are based on a micro manipulation probe (MMP) with controlled vibration. At the root of the micro manipulation probe (or the vibration excited part), there are three orthogonal vibration components, which have different amplitudes and initial phases. According to our computation, the acoustic streaming pattern can be effectively controlled by the phase differences among these three orthogonal components, and by the vibration amplitude ratios of them.

3 Nano TrappingNanowire trapping in deionized water by ultrasound has been proposed and realized [9, 12].In the ultrasonic method, there are two working modes, i.e., the contact and noncontact trapping modes. In the former mode, the trapped nano sample is in contact with the micro manipulating probe[9]. In the latter one, the trapped nano sample is not in contact with the micro manipulating probe[12]. The contact trapping mode makes the transfer of a trapped sample convenient, and the noncontact mode enables the device to handle sticky samples.

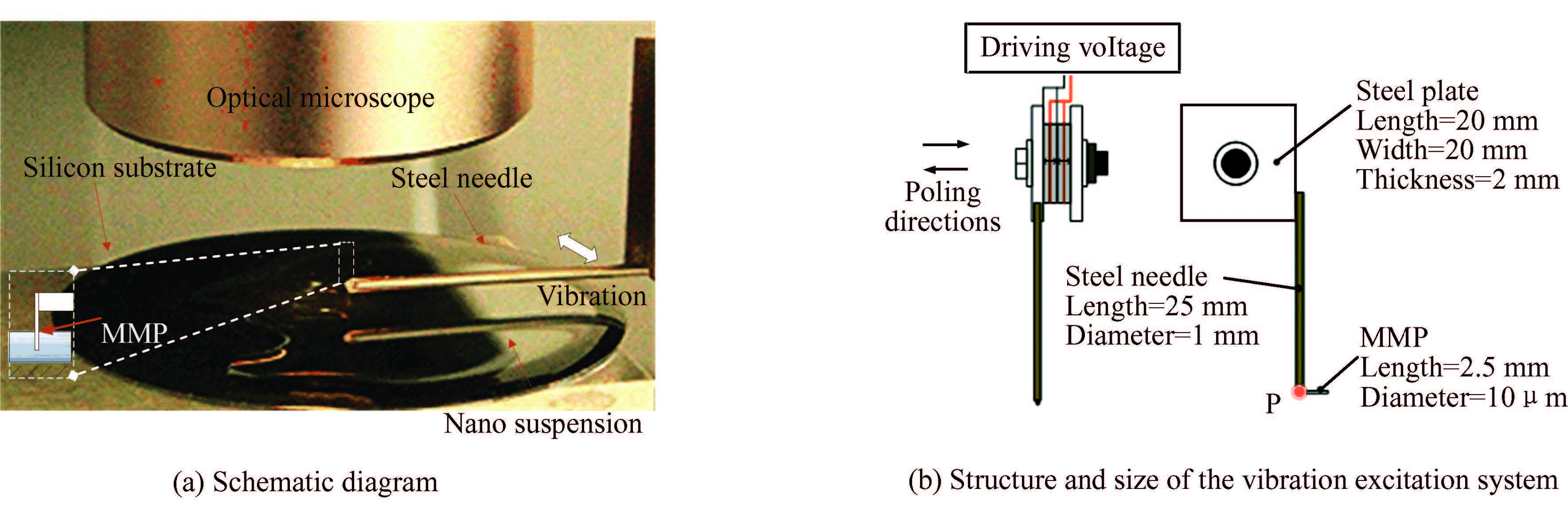

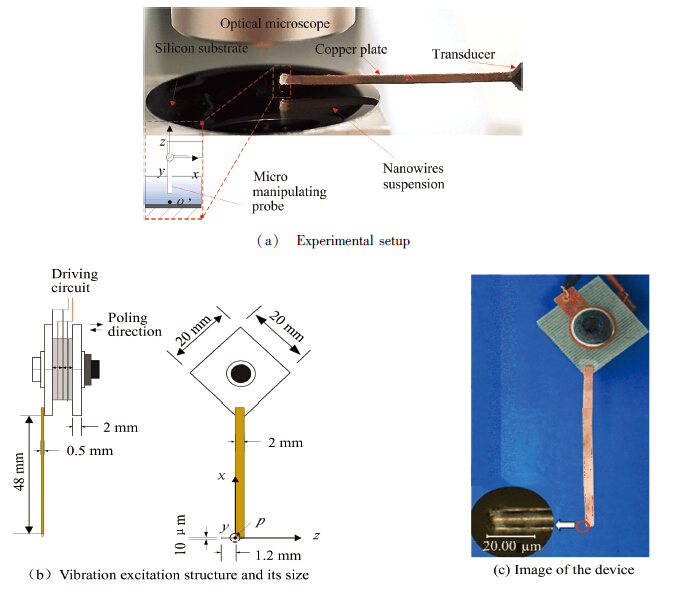

Fig.1 shows the experimental setup for the contact trapping of single nanowires in a layer of suspension film on the surface of a silicon substrate[9]. The experiment is conducted under an optical microscopy (VHX-1000, Keyence), as shown in Fig.1(a). In the experiments, a micro manipulating probe (MMP) which is made of fiberglass, and mechanically excited to vibrate by a perpendicular steel needle, is immersed into the suspension film. The MMP has uniform thickness of 10 μ m and total length of 2.5 mm. The suspension is composed of deionized water and dispersed silver nanowires (AgNWs) which have diameter of 100 nm and length up to several tens of microns. The distance between the MMP tip and silicon substrate is 10 μm approximately. Fig.1(b) shows the structure and size of vibration excitation system. The MMP is bonded on and excited by the tip of the steel needle which is mechanically driven by a sandwich type piezoelectric transducer. The steel needle is 25 mm long and 1 mm thick. The operating frequency of the transducer is about 135 kHz at which the steel needle vibrates flexurally. The resonance frequency of the sandwich transducer is 93 kHz; thus the manipulation system does not operate at resonance. More details of the device can be found in Refs. [2] and [9].

|

Figure 1 Experimental setup for the acoustic streaming based trapping of a single silver nanowire |

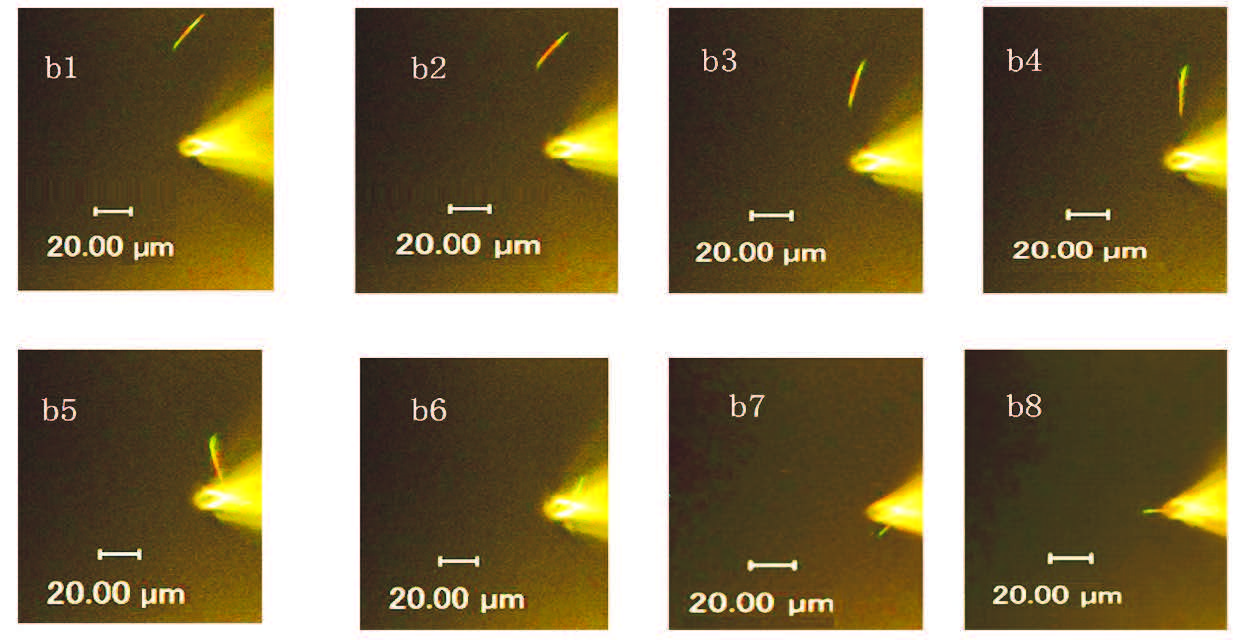

When the working frequency is around 135 kHz, and the MMP root's vibration amplitude is several ten microns, an AgNW at the interface between the substrate surface and water suspension film, can besucked and then trapped onto the MMP tip, as shown in Fig.2. The trapped nanowire is perpendicular to the direction of the lateral vibration of the MMP. Also, the maximum sucking distance, beyond which the AgNW cannot be sucked, is about 200-300 μm. The center of the trapped nanowire can be controlled by the phase differences among the three orthogonal vibration components of the MMP root. The trapped nanowire may be transferred to any desired location in the water suspension film by tuning the position of the MMP, which can be implemented by tuning the position of the transducer. The temperature rise around the vibrating fiberglass is less than 0.1℃ for the experimental driving voltages (< 30Vp-p).

|

Figure 2 Trapping of a single AgNW under the micro manipulation tip by the acoustic streaming in water |

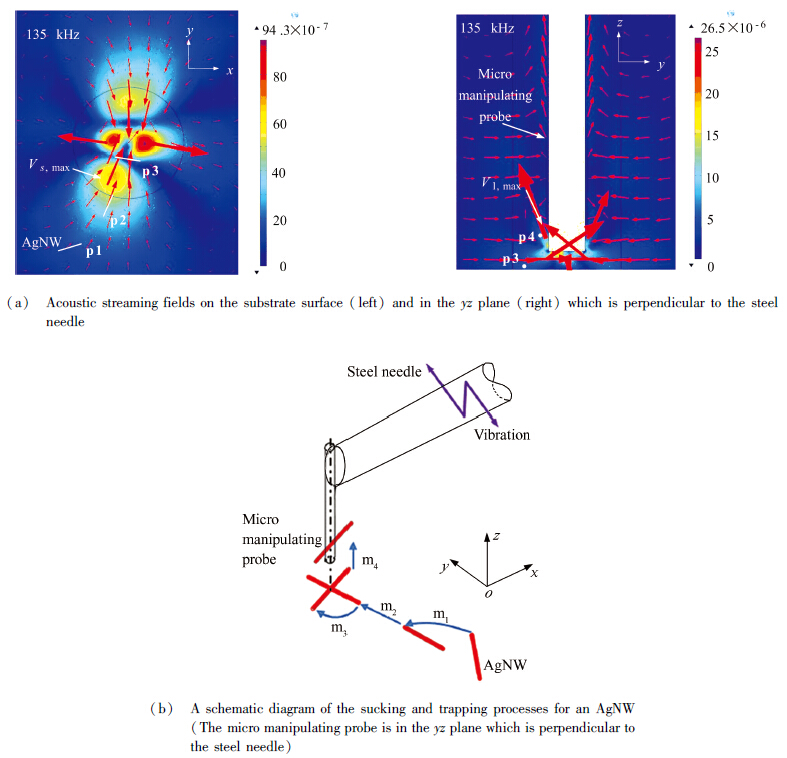

From the computed 3D acoustic streaming field in the device as shown in Fig.3(a), the mechanism of sucking and trapping the nanowire is revealed, as shown in Fig.3(b). The y-directional acoustic streaming (or the flow in the direction of the major lateral vibration of the steel needle) flushes the nanowire to the location under the MMP tip, while the x-directional acoustic streaming (or the flow perpendicular to the major lateral vibration of the steel needle) rotates the nanowire to the x-direction. When the nanowire reaches the location just under the MMP tip, the z-directional acoustic streaming lifts the nanowire up. After this, the y-directional acoustic streaming pushes the lifted nanowire onto the side of MMP tip. The 3D acoustic streaming field is generated by the MMP's vibration, and has a fixed relative position to the MMP. Thus the acoustic streaming field is mobile, and can be moved by tuning the position of the MMP, which is connected to the transducer. FEM computation of the 3D acoustic streaming shows that to generate a useful acoustic streaming field for the contact type nano trapping, the phase difference between the y (or x) and z vibration components must be close to ±90°, and the amplitude of the x (or y) vibration component must be small enough compared to another lateral vibration component.

|

Figure 3 Computed 3D acoustic streaming field employed by the contact type nanowire trapping |

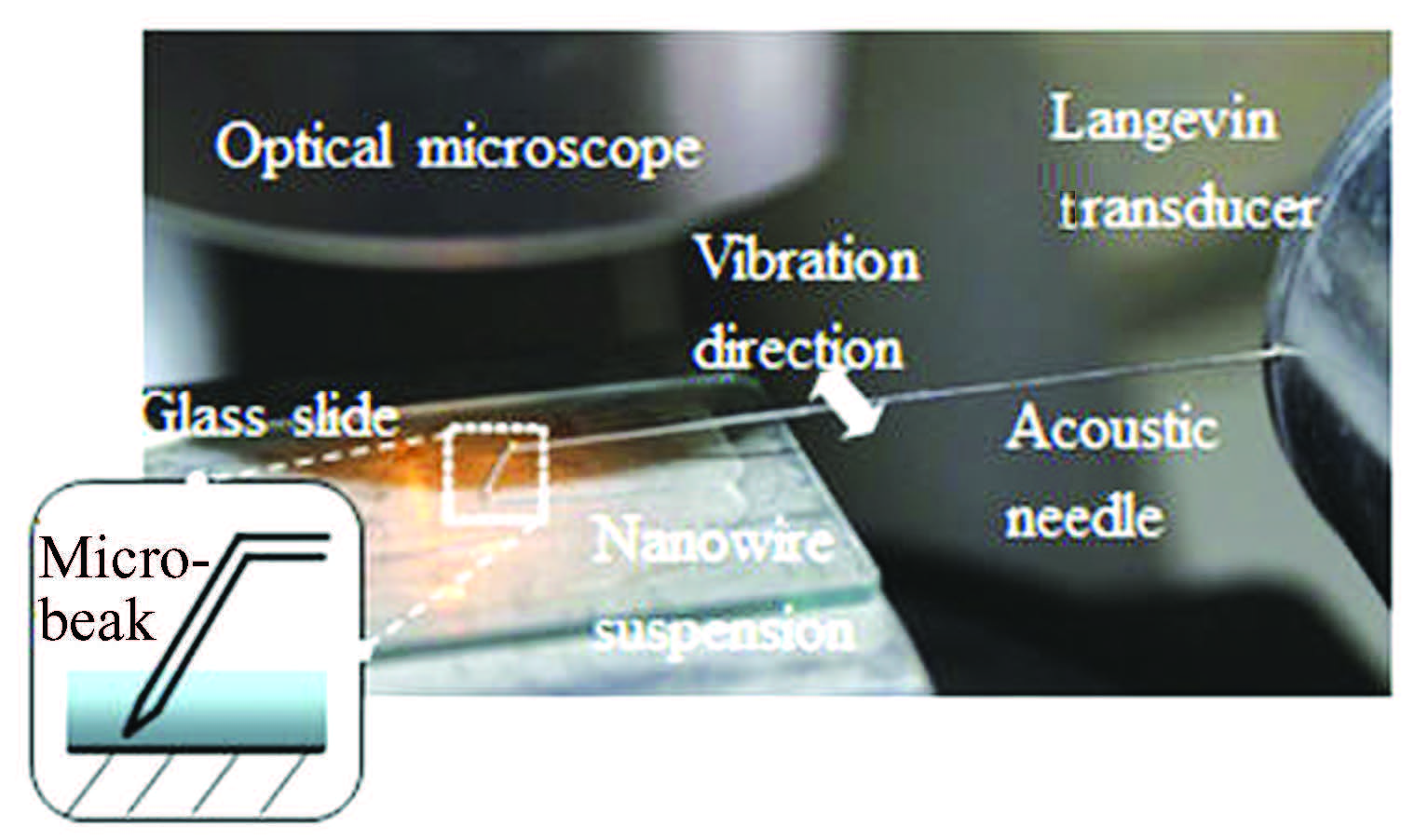

The noncontact trapping mode can be realized by reducing the acoustic streaming velocity in the height direction (or the z-direction). Fig.4 shows a device to generate such an acoustic streaming field[12]. In the device, a micro-beak is used as the MMP, and the Langevin transducer which has pure longitudinal vibration is used to excite the acoustic needle. The ultrasonic micro-beak can suck, align and trap a single silver nanowire in the water film on a substrate in a noncontact way, and the trapped nanowire can be transferred by tuning the position of the MMP or the transducer. The driving force on a manipulated nanowire is estimated to have an order of magnitude of 10-14 N.

In the above stated nano trapping, single nanowires or several nanowires are trapped by the acoustic streaming. Nonlinear effects of ultrasound can be also employed to capture massive submicro particles in air. It has been experimentally verified that the standing wave in an air gap with a thickness of a quarter of, half or one wavelength can capture submicron droplets in the air gap, and transfer the captured droplets onto the reflective and radiation surfaces[25].

|

Figure 4 A micro-beak-shaped manipulating probe in flexural vibration to generate an acoustic streaming field for the noncontact trapping mode |

4 Nano Rotation

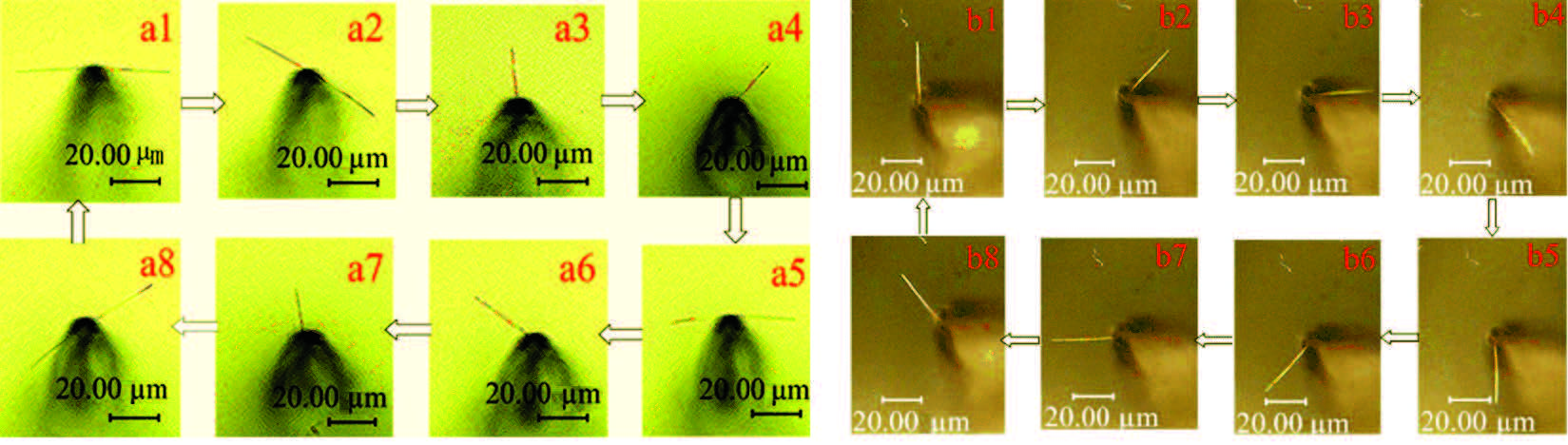

Micro eddies of acoustic streaming can be used to rotary drive a single nanowire or multiple nanowires. Fig.5 shows the experimental setup and device with a micro manipulating probe (MMP), for the rotary driving of a single AgNW in a layer of deionized water film with dispersed AgNWs on a silicon substrate[13]. The experimental setup and device are similar to those as shown in Fig.1, except that a copper plate, excited along the diagonal direction of the end plate of the transducer, is used to transmit the vibration energy to the MMP. The design is to generate the x- and y-directional vibration components at the root of the MMP with a phase difference of about 90°and to avoid a twisting vibration in the copper plate, in order to make the MMP oscillate elliptically[26]. The MMP, which is made of fiberglass, has a uniform diameter of 10 μm and total length of 3.2 mm. The AgNWs have a diameter of about 100 nm and length of several micrometers to several ten micrometers. The distance between the MMP tip and silicon substrate is about 10 μm.The operating frequency is around 137 kHz. As the resonance frequency of the transducer is about 93 kHz, the transducer does not operate at resonance, which makes the rotary drive more stable. During the operation, the nanowire center or end moves to the location directly under the MMP tip by the acoustic streaming field, and serves as the rotation center, as shown in Fig.6. The driving torque has an order of magnitude of 10-20 N·m. Stable angular speed of a rotating nanowire can be up to several radians per second, and the temperature rise at the manipulation spot is less than 0.1 in the experiments, in which the y-directional vibration amplitude at the MMP root is less than 100 nm. More details of the device can be found in Ref.[13].

|

Figure 5 Experimental setup and the ultrasonic device for rotary drive of a single AgNW in a layer of water film on a silicon substrate |

|

Figure 6 Two Image sequences to show the rotation of a single AgNW under the MMP tip in a layer of deionized water film on a substrate |

Recently, researchers in the USA reported a method that employs a high frequency standing wave sound field (several Mega Hertz) to rotate levitated nanorods around their longitudinal axes at a revolution speed up to several kHz or a surface linear speed up to several mm/s [14, 15]. Acoustic streaming eddies around the nanorods are believed to be the cause of the rotation. However, the position and speed control of the nanorods remains to be a big challenge in that method.

5 Nano ConcentrationAt the present stage, nanoscale materials in a droplet or layer of water suspension, deposited on the surface on a substrate, can be concentrated by two ultrasonic methods. One is to use a system consisting of an ultrasonic stage and a droplet (or a layer of liquid suspension) sitting on the center of the stage [10]. Another is to use a system consisting of a stationary substrate, a layer of liquid suspension on the substrate, and a vibrating needle immersed in the liquid suspension [11].

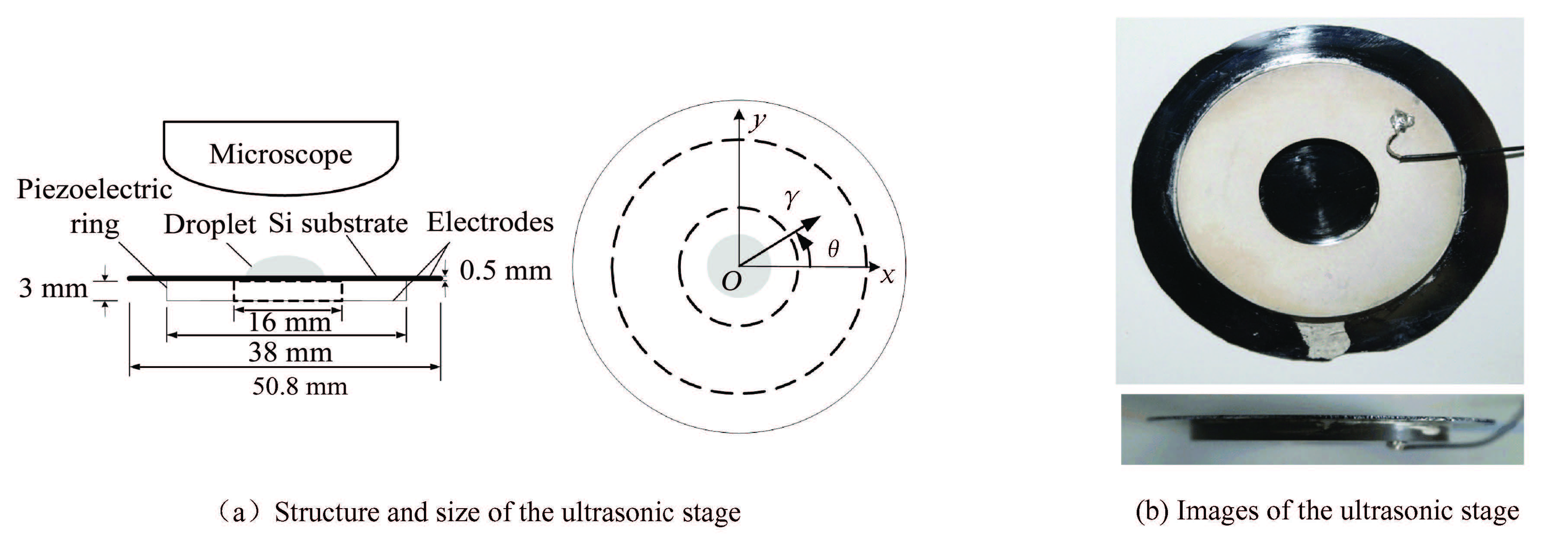

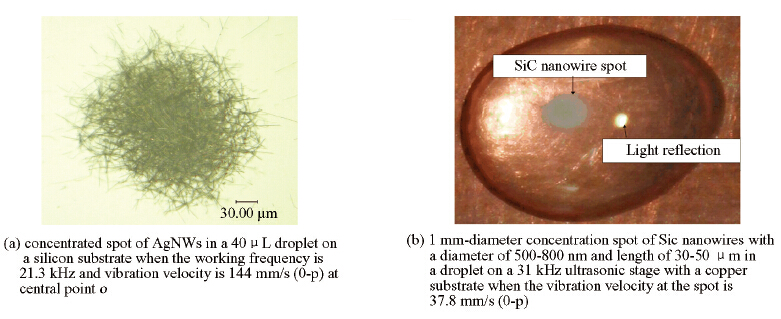

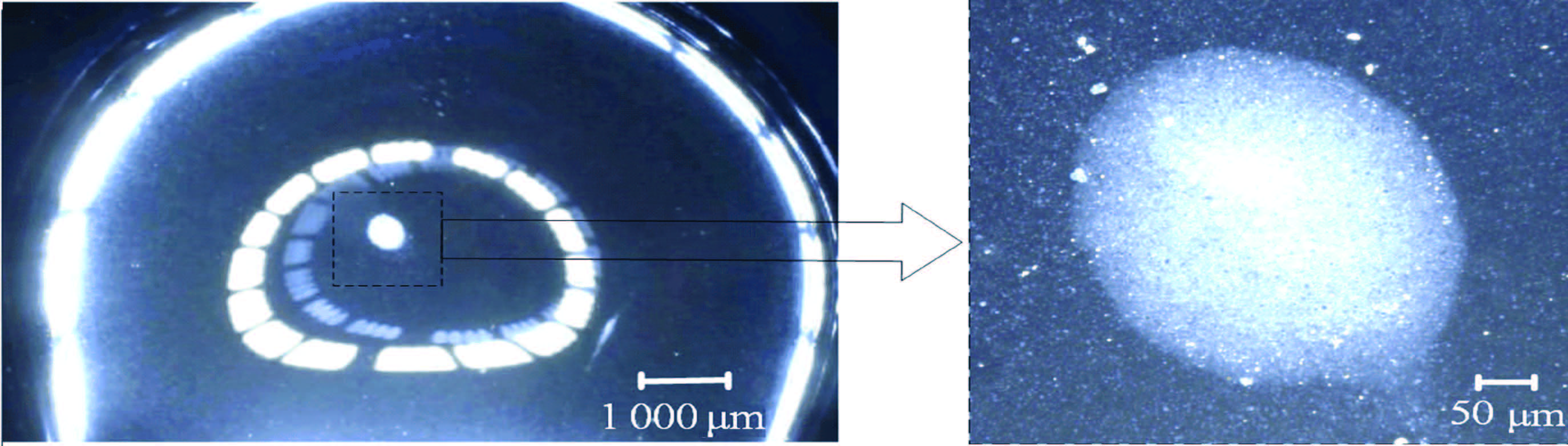

Fig.7 shows the structure and size of an ultrasonic stage for the concentration of AgNWs dispersed on the interface between a deionized water droplet and the stage surface. The stage consists of a circular silicon (or metal) substrate and a piezoelectric ring bonded onto the bottom of the silicon substrate by conductive adhesive. During the experiments, AgNW suspension with concentration of 0.01 mg/mL was dropped onto the center of the ultrasonic stage, and AgNWs in the droplet were observed by microscope (VHX-1000, Keyence) with the direction as shown in Fig.7(a). The diameter and length of the AgNWs are about 100 nm and 30 nm, respectively. The vibration mode of the ultrasonic stage is symmetric about the center approximately, and there is a vibration peak at the stage center o (x = 0, y = 0). The details of the device can be found in Ref. [10]. Fig.8(a) shows a concentrated spot of AgNWs in a 40 μL droplet on a silicon substrate after 15 min sonication. In the experiment, the working frequency is 21.3 kHz, and vibration velocity is 144 mm/s (0-p) at the stage center o. Other nano materials can be also concentrated on the ultrasonic stage. Fig.8(b) shows a 1 mm-diameter concentration spot of SiC nanowires with a diameter of 500-800 nm and a length of 30-50 μm in a 40 μL droplet on a copper substrate after 15 min sonication. In the experiment, the working frequency is 31 kHz, and the vibration velocity at the spot is 37.8 mm/s (0-p).

|

Figure 7 A nano concentration device consisting of an ultrasonic stage and droplet |

|

Figure 8 Concentration of nanoscale materials at the center of the ultrasonic stage |

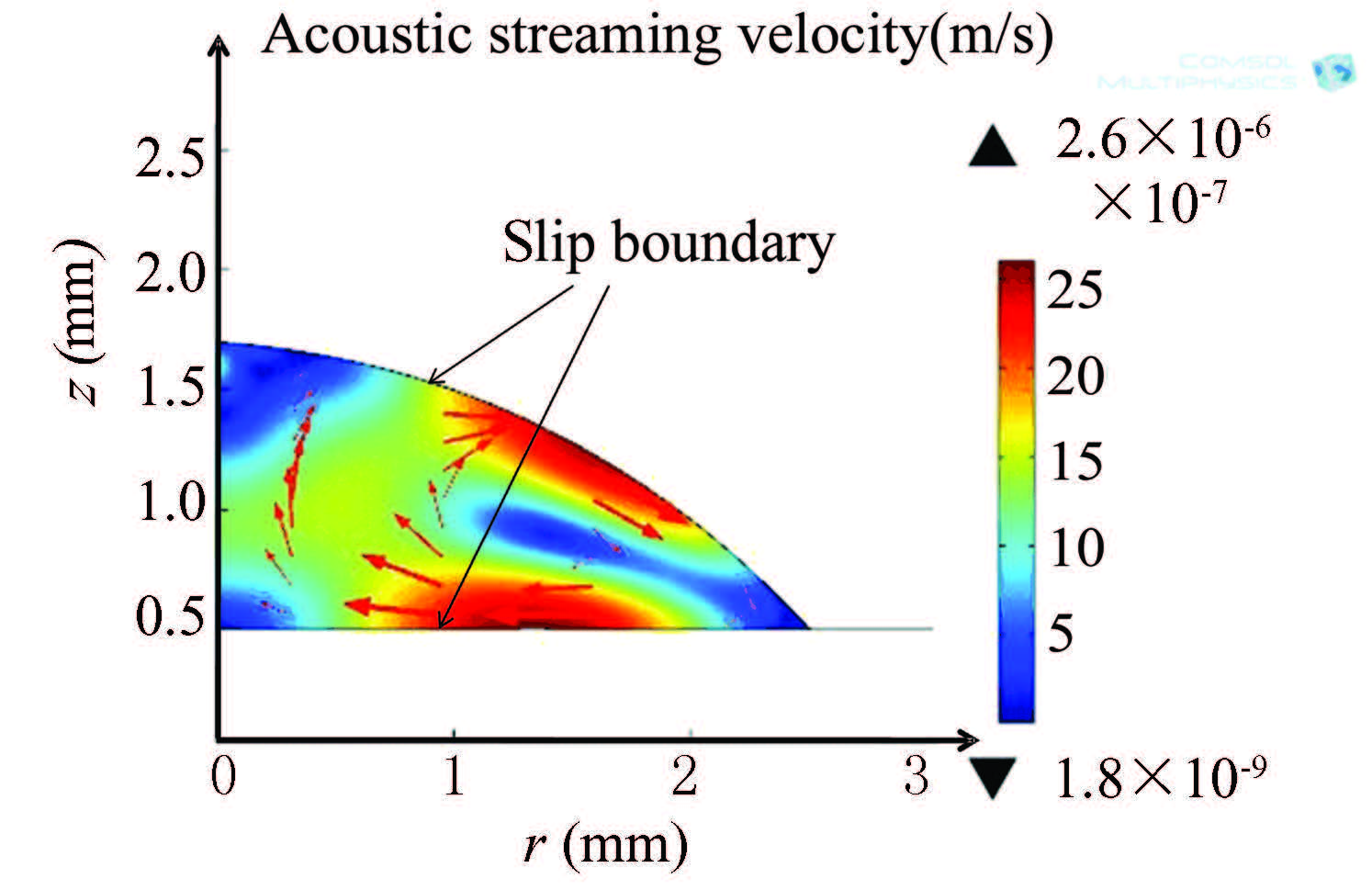

Fig.9 shows the computed acoustic streaming field in the droplet at the center of the ultrasonic stage. The eddies in the droplet flush the nano materials to the stage center, and make them accumulate at the stage center when the upward flow velocity is not high enough to lift the nano materials up[24].

|

Figure 9 Computed acoustic streaming field in the droplet at the center of the ultrasonic stage |

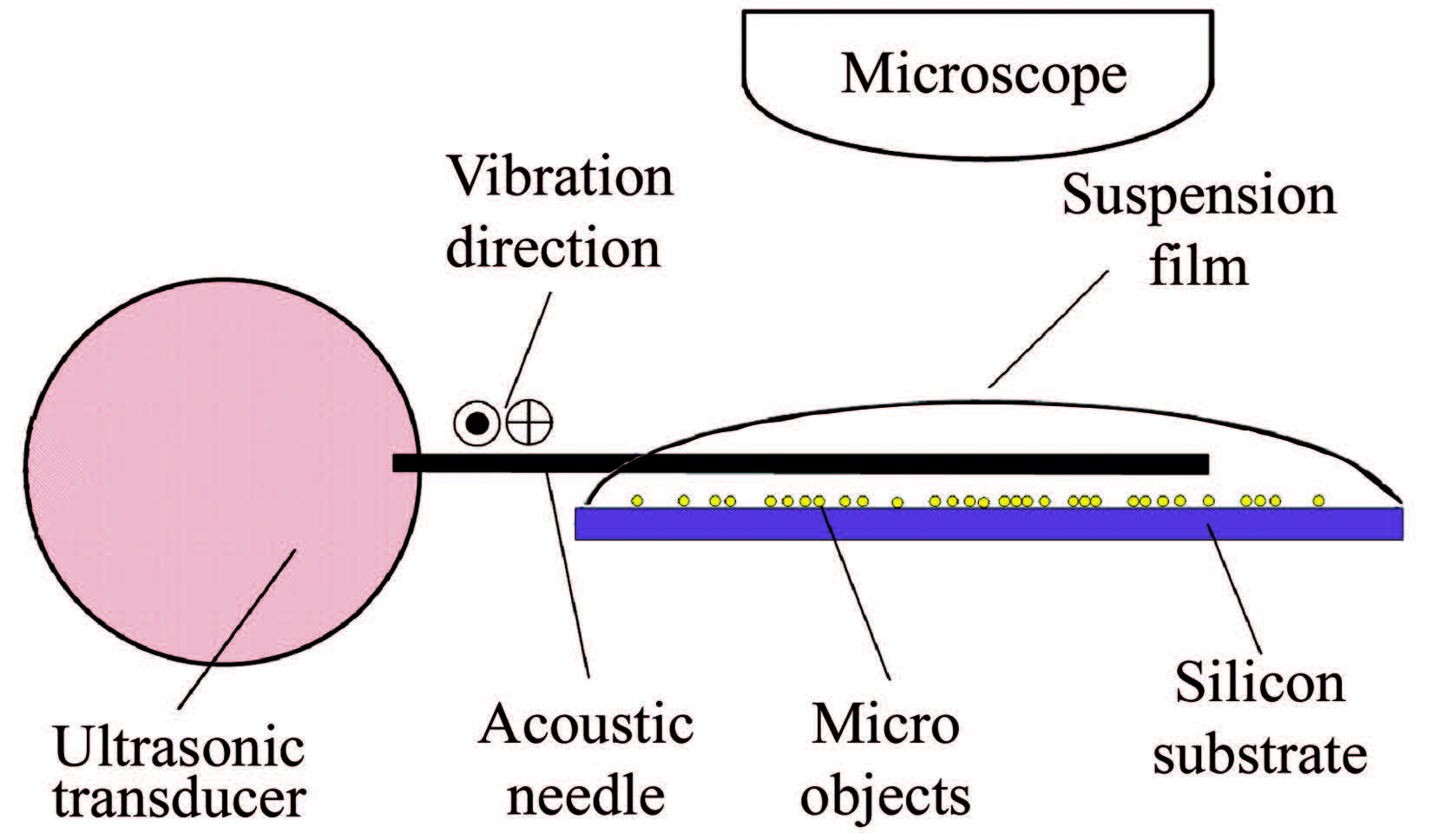

In the above stated method, the substrate is in vibration during the operation, which may cause inconvenience in some practical applications. To overcome this problem, the system consisting of a stationary substrate, a layer of liquid suspension on the substrate, and an acoustic needle immersed in the liquid suspension is proposed, as shown in Fig.10[11].

By controlling the acoustic streaming field around the acoustic needle, desired micro eddies can be generated to concentrate the nano materials in the liquid suspension. The acoustic streaming field can be controlled by vibration mode pattern of the acoustic needle inside the suspension film layer, and other parameters such as the distance between the acoustic needle and substrate. Fig.11 shows the concentration of 250 nm-diameter SiO2 particles in a droplet of deionized water, excited by an acoustic needle working at 108 kHz, after a 10 min sonication. The boundary of the concentration spot is very clear.

|

Figure 10 Schematic diagram of the ultrasonic nano concentration based on a system consisting of a stationary substrate, a layer of liquid suspension on the substrate, and a vibrating needle immersed in the liquid suspension |

|

Figure 11 Concentration of 250 nm-diameter SiO2 particles in a droplet of deionized water, excited by an acoustic needle working at 108 kHz |

At the present stage, the concentrated spots' diameter is less than 1 mm. For the practical application of nano assembling, efforts of scaling up the acoustic streaming eddies are needed.

6 Manipulation Function IntegrationThe contact trapping mode may cause the contamination of samples, and difficulty in releasing sticky samples although it makes the transfer of a trapped sample convenient. In the noncontact trapping mode, the transfer of a trapped nanowire may be blocked by nano objects on the transfer path. Thus it will be beneficial to practical applications to integrate the noncontact and contact nano trapping functions in one device. The contact and noncontact trapping modes have been integrated in one device[27].

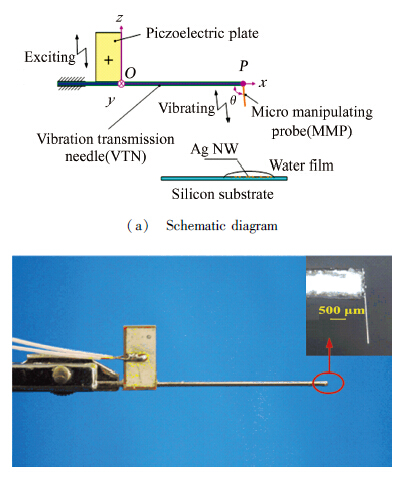

Fig.12 shows the experimental setup to implement the noncontact and contact-type trapping of individual nanowires by one device. The device is simply made up of the piezoelectric plate, vibration transmission needle (VTN) made of steel, and micro manipulating probe (MMP) made of fiberglass. The VTN is bonded along the narrow side of the piezoelectric plate.The MMP is bonded to the VTN's tip, and parallel to the piezoelectric plate. The resonance frequency of the device is about 136 kHz, at which the VTN vibrates flexurally. In the frequency range from 131.2 -132.2 kHz, the trapped nanowire is not in contact with the MMP, and it is in contact with the MMP in the frequency range from 133.9-134 kHz.

|

Figure 12 Experimental setup for the noncontact and contact-type trapping of a single silver nanowire |

The noncontact and contact trapping modes are realized by employing different acoustic streaming field patterns around the MMP. Our calculation shows that the difference in acoustic streaming fields in the noncontact and contact modes is caused by the change of the phase difference among the orthogonal vibration components at the MMP root. The use of a piezoelectric plate to excite the vibration of the VTN makes the function integration possible because the piezoelectric plate can vibrate in its length and width directions.

7 Nano AlignmentAlthough ultrasound based alignment of nanowires has been realized, it is only on a MEMS substrate or in a small droplet, thus on a small scale. Therefore, it is not very competitive in practical applications. The ultrasonic stage shown in Fig.7 actually has another function, that is, to align the nanowires on the substrate surface in the radial direction[10]. However, the method cannot control the spacing between the nanowires. Also, it is reported that the standing surface acoustic wave (SSAW) can quite effectively orientate the metalic nanowires on a piezoelectric substrate in a controlled way and with controlled nanowire spacing[28]. The method is based on the ac electric field generated by the piezoelectric substrate with the SSAW. However, scaling up the device and making it feasible on large size substrates with aligned nanowires are still a big challenge.

8 Ultrasonic Nano CuttingIn 2008, a Japanese research team proposed a method to use the relative motion between an AFM probe and vibrating stage to scratch the surface of a substrate to generate nano width channels[29]. The stage vibrates with a frequency of 9 MHz, and the width of the generated channels is several ten nanometers. Recently, a domestic research team utilized ultrasonic low-frequency (15-50 kHz) vibration of a micro cutter to cut micro-/nano-scale bio samples[30]. In the method, vacuum is used to fix the sample to be cut, and the micro cutter is ultrasonically excited by a multiplayer piezoelectric actuator, and vibrates elliptically. To make the methods more convenient in practical applications, ultrasonic nano cutting systems with simple and compact structures are desired.

9 ConclusionsThe experimental and theoretical work has demonstrated that the acoustic streaming can be utilized as an effective physical means to implement various nano manipulation functions. It has the features such as no selectivity to the material properties of manipulated samples, little heat damage to manipulated samples, diverse manipulation functions, simple and compact device structures, no MEMS or NEMS structure requirement on the substrate surface, etc. As an emerging actuating technology, the ultrasonic nano manipulation is facing lots of technological challenges such as the diversification of manipulation functions and manipulated samples, enhancement of manipulation functions, etc. Vibration control of the ultrasonic manipulators is one of the keys to solve these problems.

| [1] |

Ashkin A.

Optical Trapping & Manipulation of Neutral Particles Using Lasers. Singapore: World Scientific Publishing. 2006 .

( 0) 0)

|

| [2] |

Hu J.

Ultrasonic Micro/Nano Manipulations. Singapore:World Scientific Publishing. 2014 .

( 0) 0)

|

| [3] |

Ashkin A. Acceleration and trapping of particles by radiation pressure.

Phys. Rev. Lett,1970, 24 (4) : 156-159.

( 0) 0)

|

| [4] |

Tanase M, Bauer L A, Hultgren A, et al. Magnetic alignment of fluorescent nanowire.

Nano Lett,2001, 1 (3) : 155-158.

( 0) 0)

|

| [5] |

Castillo J, Dimaki M, Svendson W E. Manipulation of biological samples using micro and nano techniques.

Integr. Biol,2009, 1 (1) : 30-42.

( 0) 0)

|

| [6] |

Molhave K, Wich T, Kortschack A, et al. Pick-and-place nanomanipulation using microfabricated grippers.

Nature Nanotech,2006, 17 (10) : 2434-2441.

( 0) 0)

|

| [7] |

Sitti M, Aruk B, Shintani K, et al. Scaled teleoperation system for nano-scale interaction and manipulation.

Advanced Robotic,2003, 17 (3) : 275-291.

( 0) 0)

|

| [8] |

Lu M, Yang S, Ho Y, et al. Shape-controlled synthesis of hybrid nanomaterials via three-dimensional hydrodynamic focusing.

ACS Nano,2014, 8 (10) : 10026-10034.

( 0) 0)

|

| [9] |

Li N, Hu J, Li H, et al. Mobile acoustic streaming based trapping and 3-dimensional transfer of a single nanowire.

Phys. Lett,2010, 101 (9) : 093113.

( 0) 0)

|

| [10] |

Zhou Y, Hu J, Bhuyan S. Manipulations of Silver Nanowires in a Droplet on Low-Frequency Ultrasonic Stage.

IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control,2013, 60 (3) : 622-629.

( 0) 0)

|

| [11] |

Yang B, Hu J. Linear concentration of microscale samples under an ultrasonically vibrating needle in water on a substrate surface.

Sensors and Actuators B,2014, 193 : 472-477.

( 0) 0)

|

| [12] |

Li H, Hu J. Noncontact manipulations of a single nanowire using an ultrasonic micro-beak.

IEEE Transactions on Nanotechnology,2014, 13 (3) : 469-474.

( 0) 0)

|

| [13] |

Li N, Hu J. Sound controlled rotary driving of a single nanowire.

IEEE Transactions on Nanotechnology,2014, 13 (3) : 437-441.

( 0) 0)

|

| [14] |

Balk A L, Mair L O, Mathai P P, et al. , Kilohertz rotation of nanorods propelled by ultrasound, traced by microvortex advection of nanoparticles.

ACS Nano,2014, 8 (8) : 8300-8309.

( 0) 0)

|

| [15] |

Ahmed S, Gentekos D T, Fink C A, et al. Self-Assembly of nanorod motors into geometrically regular multimers and their propulsion by ultrasound.

ACS Nano,2014, 8 (11) : 11053-11060.

( 0) 0)

|

| [16] |

Leighton T G.

The Acoustic Bubble. San Diego: Academic Press. 1994 .

( 0) 0)

|

| [17] |

Abramov Oleg V.

High-Intensity Ultrasonics: Theory and Industrial Applications. Beijing:Gordon and Breach Science Publishers. 1998 .

( 0) 0)

|

| [18] |

Muller P B, Barnkob R, Jensen M, et al. A numerical study of microparticle acoustophoresis driven by acoustic radiation forces and streaming-induced drag forces.

Lab Chip,2012, 12 (22) : 4617-4627.

( 0) 0)

|

| [19] |

Lei J, Hill M, Glynne-Jones P. Numerical simulation of 3D boundary-driven acoustic streaming in microfluidic devices.

Lab Chip,2012, 14 (3) : 532-541.

( 0) 0)

|

| [20] |

Nama N, Huang P H, Huang T J, et al. Investigation of acoustic streaming patterns around oscillating sharp edges.

Lab Chip,2014, 14 (15) : 2824-2836.

( 0) 0)

|

| [21] |

Wada Y, Koyama D, Nakamura K. Acoustic streaming in an ultrasonic air pump with three-dimensional finite-difference time-domain analysis and comparison to the measurement.

Ultrasonics,2014, 54 (8) : 119-2125.

( 0) 0)

|

| [22] |

Sundin S M, Jensen T G, Bruus H, et al. Acoustic resonances in microfluidic chips: full-image micro-PIV experiments and numerical simulations.

Lab Chip,2007, 7 (10) : 1336-1344.

( 0) 0)

|

| [23] |

Tang Q, Hu J. Diversity of acoustic streaming in a rectangular acoustofluidic field. Ultrasonics , 2015,58: 27-34.

( 0) 0)

|

| [24] |

Zhu P, Hu J. Modeling and analysis of the droplet-ultrasonic stage system for nano concentration. Sensors and Actuators A, 2015, 225: 111-118.

( 0) 0)

|

| [25] |

Wang Y, Hu J. Ultrasonic removal of coarse and fine droplets in air. Separation and Purification Technology, 2015, 153: 156-161.

( 0) 0)

|

| [26] |

Wang X, Hu J. 3D FEM analyses of the ultrasonic transducer for controlled nanowire rotary driving. Applied Acoustics, 2015,103(Part B):157-162.

( 0) 0)

|

| [27] |

Wang X, Hu J. An ultrasonic manipulator with noncontact and contact-type nanowire trapping functions.

Sensors and Actuators A,2015, 232 : 13-19.

( 0) 0)

|

| [28] |

Chen Y, Ding X, Lin S, et al. Tunable nanowire patterning using standing surface acoustic waves.

ACS Nano,2013, 7 (4) : 3306-3314.

( 0) 0)

|

| [29] |

Iwata F, Ohara K, Ishizu Y, et al. Nanometer-scale manipulation and ultrasonic cutting using an atomic force microscope controlled by a haptic device as a human interface.

J. Appl. Phys.,2008, 47 (7) : 6181-6185.

( 0) 0)

|

| [30] |

Wang H, Sun L. Research on a micro-to-nano bio-manipulation device. 2103 International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale. Suzhou, 2013. 376-380.

( 0) 0)

|

2016, Vol. 23

2016, Vol. 23