Metal matrix composites (MMCs)are an important class of structural materials. Because it has lots of excellent characters, such as low density, high specific strength, increased wear resistance, higher service temperature and so on. And these make MMCs can fulfill some important requirements of the modern industry. In general, Metal matrix composites have better mechanical performance compared with conventional unity materials. Al-based composites are an important studied area due to their attraction for different industries and potential applications in the field of MMCs.

As a great nanoscale material, CNTs[1] exhibits a large aspect ratio and good mechanical, electrical and thermal properties[2-3] which make it exceed any other conventional material and considered as ideal candidates to reinforce composites materials in order to increase both stiffness and strength[4-6]. In order to achieve an optimum mechanical performance and good interfacial bonding between the reinforcement and the Al metal matrix, there are certain key requirements to be fulfilled as a uniform dispersion of the CNTs in the Al matrix. Several methods have been proposed and implemented to synthesize nanocrystalline matrix reinforced with CNTs, such as powder metallurgy[7-8], mechanical alloying (MA)[9-11], thermal spraying[12-13], spark plasma sintering[14-15], semi-solid powder processing[16-17] and friction stir processing[18-19]. Among the aforementioned methods, MA appears to be the best method to induce the dispersion of CNTs within metal matrix and it is easy to realize industrialization. MA is a technique that allows the introduction of the inforcement phase in the matrix by the repeated cycle of welding-fracture-welding of the particles involved in the process. The process can achieve homogeneous dispersion of the strengthening phase and the formation of supersaturated solid solutions. Additionally, a high dislocation density and a small sub grain size in the matrix can be obtained by MA. A number of research groups have devoted themselves to researching high-energy ball milling to fabricate the MWCNT/Al [7-13]. However, limited work were related to the effect of milling time and CNT concentration on mechanical property. They did not build the mathematical models which can indicate correlating the interactive of the process parameters.

The present investigation emphasizes the features of the development of comprehensive mathematical models for correlating the interactive and the higher order influences of the various predominant process parameters on ultimate tensile strength (UTS) and hardness of CNTs/Al2024 composites produced by MA. The investigation about the influence of MA process parameters is carried out through response surface methodology utilizing the relevant experimental data which are obtained by experiments. The adequacy of the developed mathematical model is also tested by the analysis of variance test(ANOVA). An attempt is made to obtain optimal process parameters for maximum UTS and hardness of CNTs/Al2024 composites produced by MA.

2 ExperimentalThe 2024 aluminum alloy (Al2024) powder with a mean particle size of 50 μm was used as the matrix phase. The chemical composition of Al2024 powder were 4.5Cu, 1.5Mg, 0.6Mn, 0.15Ti and 0.25Zn; balance Al (in wt %). For the reinforcement phase, multi-walled CNTs from Chengdu institute of organic chemistry was used. The size of CNTs was 30-50 nm in diameter and 10-20 μm in length. Al2024 powder and CNTs were used as the starting materials to produce CNTs/Al2024 composites through high-energy ball milling. CNTs/Al2024 composite was fabricated using five different levels of the following four factors: 1) milling time (1 h to 3 h); 2) rotational speed (600 r/min to 1000 r/min); 3) Mass fraction of CNTs (0% to 4%); 4) the ball-to-powder ratio (10:1 to 30:1).

CNTs/Al2024 composites powder was fabricated by high-energy ball milling. The grinding media was made from stainless steel and a process control agent (PCA) was stearic acid. The atmosphere of ball milling was Argon. Firstly, the powder mixture was pre-compacted under 1 100 MPa of pressure at room temperature to form cuboid( 30 mm ×5 mm × 5 mm) and then compacted samples were sintered during 2 h at 500 ℃ under Ar atmosphere with a heating rate of 5 ℃/min. Tensile tests on a UNITEK-94100 UTM machine were carried out at room temperature. The hardness of samples was measured by a LECO LM247AT Micro Hardness Tester after appropriate polishing procedure.

3 Mathematical Model DevelopmentIn order to find out the relationship between the process parameters and the mechanical properties, second-order polynomial response surface mathematical models can be considered as [20-21]

| ${{Y}_{u}}={{b}_{0}}+\sum\limits_{i=1}^{n}{{{b}_{i}}{{\chi }_{i}}+}\sum\limits_{i=1}^{n}{{{b}_{ii}}\chi _{i}^{2}+}\sum\limits_{i=1}^{n-1}{\sum\limits_{j=i+1}^{n}{{{b}_{ij}}{{\chi }_{i}}{{\chi }_{j}}}}$ | (1) |

where Yu is the corresponding response; χi, χj is the coded values of the high-energy ball milling parameters; b0 the constant coefficient; bi the linear coefficients; bij the interaction coefficients; bii the quadratic coefficients.

Owing to wide ranges of the factors in the mechanical alloying process, it decides to use four factors with five levels and central composite rotatable design matrix is chosen to optimize the experimental conditions. This method is suitable for fitting a quadratic surface and it helps to optimize effective parameters with a number of experiments, and it also helps to analyze the interaction between the parameters [22]. This approach helps to understand how the change in the levels of parameters affects the response. The combination of the levels of the parameters leads to certain optimum response.

In this study, CNTs/Al2024 composites were prepared using high-energy ball milling method by varying the prepration variables using the CCD. The variables studied were 1) χ1, ball milling time; 2) χ2, rotational speed ; 3) χ3, Mass fraction of CNTs; 4)χ4, the ball-to-powder ratio.

The responses were ultimate tensile strength (UTS) and hardness of the CNTs/Al2024 composites. For each categorical variable, a 24 full factorial central composite design for the four variables, consisting of 16 factorial point, this consists of 2×4=8 axial points at γ=$ \mp $2 and a centre point at zero level repeated seven times n0 to estimate the error.

The codeand actual values of the parameters used in the present work are listed in Table 1. 31 experiments were conducted and the values (responses) of UST and hardness along with the design matrix are tabulated in Table 2. For analyzing the data, the fitness of the model was very much required. Checking accuracy of the models included test for significance of the regression model, test for significance on model coefficient and test for lack of it. For those purposes, analysis of variance (ANOVA) was performed.

| Table 1 Experiment parameter and levels |

| Table 2 Experimental design matrix and results |

3.1 Mathematical Model for Ultimate Tensile Strength(UST)

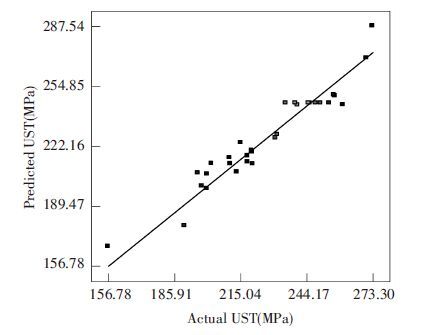

The test of significance of UTS was carried out by the quadratic model. The results of the quadratic model for UST were given in Table 3. From the ANOVA for response surface quadratic model of UST, the Model F-value of 13.81 implied that the model was significant. In this case, χ2, χ4, χ1χ2, χ2χ4, χ21, χ22, χ32 and χ42 were significant model terms. The other terms can be regarded not significant due to their probability values being more than 0.05. The values of R2 and adjusted R2 were 92.36% and 85.67%. It means that the regression model provides a complete relationship between the dependent and independent variables. Fig. 1 shows the predicted values versus the experimental values for UST. As can be seen, the predicted values obtained are quite close to the experimental values, indicating that the model developed is successful in capturing the correlation of the CNTs/Al2024 composites preparation variables to the UST. For UST, the quadratic model is selected as suggested by the software. The final empirical model in terms of coded factors is shown in Eq.(2):

| $\begin{align} & {{\sigma }_{b}}=245.50+9.16{{\chi }_{2}}+10.75{{\chi }_{4}}-6.04{{\chi }_{1}}{{\chi }_{2}}+7.74{{\chi }_{2}}{{\chi }_{4}}- \\ & 6.29\chi _{1}^{2}-4.83\chi _{2}^{2}-18.16\chi _{3}^{2}+5.14\chi _{4}^{2} \\ \end{align}$ | (2) |

| Table 3 Analysis of variance (ANOVA) for response surface quadratic model for UST |

|

Figure 1 Predicted vs. actual of UST |

3.2 Mathematical Model for Hardness

According to the sequential model sum of squares, the model was selected based on the highest order polynomials where the additional terms were significant and the model was not aliased. For the hardness, the quadratic and two factor interaction (2FI) were suggested by the software; however the quadratic was selected in this case due to the higher order polynomial. The final empirical model in the terms of coded factors after excluding the insignificant terms for the hardness is shown in Eq.(3):

| $\begin{align} & H=233.27+10.06{{\chi }_{2}}+22.07{{\chi }_{3}}-10.61{{\chi }_{1}}{{\chi }_{2}}- \\ & 7.74{{\chi }_{1}}{{\chi }_{4}}-7.23\chi _{1}^{2}-6.59\chi _{3}^{2}-5.90\chi _{4}^{2} \\ \end{align}$ | (3) |

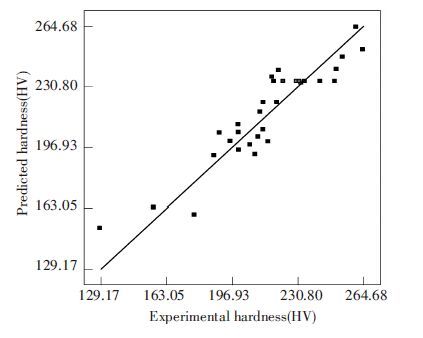

The adequacy of the model was further justified through analysis of variance (ANOVA). The ANOVA for the quadratic model of the hardness is listed in Table 4. From the ANOVA for response surface quadratic model of the hardness, the Model F-value of 6.58 implies that the model is significant. Values of Prob>F less than 0.05 indicate that the model terms are significant. In this case, χ2, χ3, χ1χ2, χ12 and χ32 are significant model terms whereas others terms are insignificant. Fig. 2 shows the predicted values versus the experimental values for hardness. It is observed that the predicted values obtained are quite close to the experimental values. So we think that the model is adequate for the hardness.

| Table 4 Analysis of variance (ANOVA) for response surface quadratic model for hardness |

|

Figure 2 Predicted vs. actual of hardness |

4 Results and Discussion 4.1 UST of the CNTs/Al2024 Composites

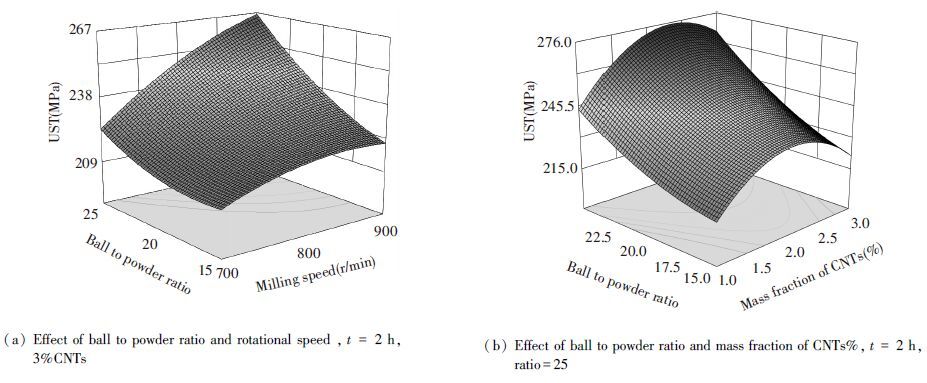

Based on the F-values(Table 3), both ball rotational speed and ball to powder ratio are found to have significant effects on the UST whereas milling time and Mass fraction of CNTs/% show the least effect on the UST. Fig. 3(a) shows the three-dimensional response surfaces which are constructed to show the effects ball to powder ratio and rotational speed on UST. As can be seen from Fig. 3(a), the UST increases with the increase in ball to powder ratio and rotational speed. The highest UST value is obtained when both the variables are at the maximum point within the range studied.

|

Figure 3 Three-dimensional response surface plot of the US |

The response surface plot of UST with respect to ball to powder ratio and mass fraction of CNTs is show in Fig. 3(b). The UST increases with the increase in mass fraction of CNTs within 1.0%-2.5% range. However, in range 2.5%-3.0% of the mass fraction of CNTs, the UST decreases with the increase in mass fraction of CNTs. The reason is that Carbon nanotubes can share the load of matrix in the process of tension, but when the mass fraction of CNTs is beyond 2.5%, CNTs will be agglomerate in matrix, that is, why the UST of CNTs/Al2024 composite decreases.

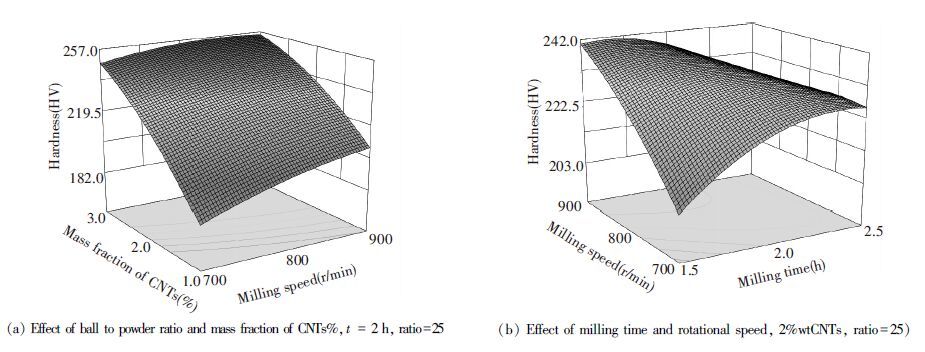

4.2 Hardness of the CNTs/Al2024 CompositesFor the hardness of CNTs/Al2024 composites in the other hand, the mass fraction of CNTs and rotational speed are found to have significant effects on it, with the F-values (Table 4) of 49.55, 10.32 respectively, while milling time and ball to powder ratio showed almost similar effects on the response, which are less significant compared to rotational speed and mass fraction of CNTs. The effects of mass fraction of CNTs and milling time on hardness are shown in Fig. 4(a). Hardness increases with the increase in mass fraction of CNTs and milling time. The highest hardness value is obtained when both the variables are at the maximum point within the range studied. This is due to the fact that the reinforcement acts as barrier during the migration of dislocation and also grain refining and on the other hand, during the sintered, Carbon nanotubes react with Al matrix formation Al4C3.

Fig. 4(b) depicts the effects of rotational speed and milling time on hardness. As can be seen, the hardness is found to increase with the increase in rotational speed and milling time. This main is due to the reason that with the increase of rotational speed and milling time, grain size will become refine.

|

Figure 4 Three-dimensional response surface plot of the hardness |

5 Optimization

Based on the developed second order response surface equations correlating the various high-energy ball milling process parameters with the UST and hardness values, optimality search was done. An analysis for the optimization of process parameter was carried out by response surface methodology optimization technique. The goal was to maximize the UST and the hardness, and the optimization experimental conditions were achieved by analysis of RSM. The one experimental condition with the highest desirability was selected to be verified. The CNTs/Al2024 composites prepared under the experimental conditions is given in Table 5, together with the predicted and experimental values for UST and hardness. Itis observed that experimental values obtained are in good agreement with the values predicted from model. The optimal process parameters for in high-energy ball milling of CNTs/Al2024 composites are 1.53 h milling time, 900 r/min rotational speed, mass fraction of CNTs 2.87% and Ball to powder ratio 25. UST can be achieved as high as 283.25 MPa and the hardness can be achieved as high as 256.8 HV.

| Table 5 Model validation |

6 Conclusions

CNTs/Al2024 composites have been successfully prepared by high-energy ball milling. Mathematical have been developed based on RSM approach.

The developed RSM based mathematical modeling hasthe potential to predict UST and hardness under various process parameters. The adequacy of the mathematical model is also tested through the analysis of variance(ANOV). The results of the analysis are justified and it is very fit the mathematical model.

The influence of the different process parameters of high-energy ball milling is displayed through surface plots. We can draw conclusions that the UST increases with the increase of ball to powder ratio and rotational speed. The UST increases with the increase in mass fraction of CNTs about within 1.0%-2.5% range. However, in range 2.5%-3.0% of the mass fraction, the UST decreases with the increase of mass fraction of CNTs. The hardness increases with the increase of mass fraction of CNTs and rotational speed.

From the analysis of the models, the optimal parameters are 1.53 h milling time, 900 r/min rotational speed, mass fraction of CNTs 2.87% and Ball to powder ratio 25. The maximum UST and hardness are 273.30 MPa and 261.36 HV, respectively, whereas the experimental values are 283.25 MPa and 256.8 HV, respectively.

| [1] |

Helical I S. Microtubules of graphitic carbon.

Nature,1991, 354 : 56-58.

( 0) 0)

|

| [2] |

Treacy M J, Ebbsen T W, Gibson J M. Exceptionally high Young's modulus observed for indi-vidual carbon nanotubes.

Nature,1991, 381 : 678-680.

( 0) 0)

|

| [3] |

Ruoff R S, Lorents D C. Mechanical and thermal properties of carbon nanotubes.

Carbon,1995, 33 : 925-930.

( 0) 0)

|

| [4] |

Aqeeli A N, Suarez M G. Development of new Al-based nanocomposites by mechanical Alloying.

Mater Sci Eng A,2008, 480 : 392-396.

( 0) 0)

|

| [5] |

Bakshi S R, Singh V, Seal S, et al. Aluminum composite reinforced with multiwalled carbon nanotubes from plasma spraying of spray dried powders.

Surf Coat Technol,2009, 203 (6) : 1544-1554.

( 0) 0)

|

| [6] |

Wu Y, Kim G Y, Russell A M. Effects of mechanical alloying on an Al6061-CNT composite fabricated by semi-solid powder processing.

Mater Sci Eng A,2012, 538 (2) : 164-172.

( 0) 0)

|

| [7] |

George R, Kashyap K T, Rahul R, et al. Strengthening in carbon nanotube/aluminum(CNT/Al) composites.

Scripta Mater,2005, 5 (1) : 1159-1163.

( 0) 0)

|

| [8] |

Bustamante R P, Guel I E, Ant'unez-Flores W, et al. Novel Al-matrix nanocomposites reinforced with multi-walled carbonnanotubes.

Alloys Compd,2008, 450 (10) : 323-326.

( 0) 0)

|

| [9] |

Bustamante R P, Gomez C D, Guel I E, et al. Microstructural and mechanical characterization of Al-MWCNT composites produced by mechanical alloying.

Mater. Sci. Eng. A,2009, 502 : 159-163.

( 0) 0)

|

| [10] |

Esawi A M, Morsi K, Syed A, et al. The influence of carbon nanotube(CNT) morphology and diameter on the processing and properties of CNTreinforced aluminum composites.

Composites Part A,2011, 42 (8) : 234-243.

( 0) 0)

|

| [11] |

Stein J, Lenczowski B, Frety N, et al. Mechanical reinforcement of a highperformance aluminium alloy AA 5083 with homogenously dispersed multi-walled carbon nanotubes.

Carbon,2012, 50 (1) : 2264-2272.

( 0) 0)

|

| [12] |

Laha T, Agarwal A, Mckechnie T, et al. Synthesis and characterization of plasma spray formed carbon nanotube reinforced aluminum composite.

Mater. Sci. Eng. A,2004, 381 : 249-258.

( 0) 0)

|

| [13] |

Bakshi S R, Singh V, Seal S, et al. Aluminum composite reinforced with multi-walled carbon nanotubes from plasma spraying of spray dried powders.

Surf. Coat. Technol,2009, 203 : 1544-1544.

( 0) 0)

|

| [14] |

Wu Jianhua, Zhang Hailong, Zhang Yang, et al. Mechanical and thermal properties of carbon nanotube/aluminum composites by spark plasma sintering.

Material & Design,2012, 41 : 344-348.

( 0) 0)

|

| [15] |

Liao J Z, Tan M J, Sridhar I. Spark plasma sintered multi-wall carbon nanotube reinforced aluminum matrix composites.

Material & Design,2010, 31 : S96-S100.

( 0) 0)

|

| [16] |

Wu Yufeng, Gap-Yong Kim. Carbon nanotube reinforced aluminum composite fabricated by semi-solid powder processing.

Material Process Technol,2011, 211 (3) : 1341-1347.

( 0) 0)

|

| [17] |

Wu Yufeng, Gap-Yong Kim. Effects of mechanical alloying on Al 6061-CNT composite fabricated by semi-solid powder processing.

Mater. Sci. Eng. A,2012, 538 (5) : 164-172.

( 0) 0)

|

| [18] |

Liu Z Y, Xiao B L, Wang W G, et al. Singly dispersed carbon nanotube/aluminum composites fabricated by powder metallurgy combined with friction stir processing.

Carbon,2012, 50 (3) : 1843-1852.

( 0) 0)

|

| [19] |

Izadi H, Gerlich A P. Distribution and stability of carbon nanotubes during multi-pass friction stir processing of carbon nanotubes aluminum composites.

Carbon,2012, 50 : 4744-4749.

( 0) 0)

|

| [20] |

Tan I A, Ahmad A L, Hameed B H. Optimization of preparation conditions for activated carbons from coconut husk using response surface methodology.

Chemical Engineering Journal,2008, 137 (6) : 462-470.

( 0) 0)

|

| [21] |

Palanivel R, Koshy M P. Development of mathematical model to predict the mechanical properties of friction stir welded AA6351 aluminum alloy.

Journal of Engineering Science and Technology Review,2011, 4 : 25-31.

( 0) 0)

|

| [22] |

Azargohar R, Dalai A K. Production of activated carbon from Luscar char:experimental and modelling studies.

Micropor Mesopor Materials,2005, 85 : 219-225.

( 0) 0)

|

2016, Vol. 23

2016, Vol. 23