2. Geotechnical Research Institute, Hohai University, Nanjing 21098, China ;

3. Shanghai Municipal Engineering Design Institute (Set) Co., Ltd., Shanghai 200092, China ;

4. College of Mathematics, Physics and Information Engineering, Anhui Science and Technology University, Chuzhou 233100, China

The sludge deposition of rivers and lakes is more and more serious nowadays in China. For instance, according to preliminary statistics, the dredged sludge in Three Gorges Reservoir has amounted to 144 million tons from June 2003 to December 2012[1]. In order to improve the water quality, numbers of large-scale dredging projects which resulted in plentiful sludge have been carried out every year[2-5]. The problem of the sludge deposition of rivers and lakes in the nation claims our highest attention.

Placed in the mud field is one of the main measures to deal with the large amount of dredged sludge produced by rivers and lakes. However, owing to the high clay content and poor permeability of the sludge, it takes a few years or even longer to complete the consolidation only under the action of deadweight[6-9], which may occupy lots of fish ponds and ploughs for a long time. Therefore, the drainage facilities which can reduce the sludge moisture content and the yard area have been installed to accelerate the drainage of dredged sludge. Thousands of domestic projects adopted the vacuum pumping method[10], but drainage channels were soon be silted up due to the high clay content of dredged sludge in the conventional dewatering technique. The effectiveness of the conventional dewatering technique on dredged sludge was relatively poor[11].

After many years of experimental research, an effective dewatering technique on dredged sludge—the aeration vacuum rapid mud-water separating (AVMWS) technique has been successfully developed[12-13], which has been applied for national invention patent[14] and overcame the siltation problem when pumping in the high moisture content and the high clay content dredged sludge.

The filtration material is one of the main factors of affecting the mud-water separation in this technique. Geotextiles are widely used in civil engineering, hydraulic engineering and other dredging projects owing to the strong permeable ability[15]. They are used to eliminate the soil moisture, control the water level, prevent the flood and accelerate the dissipation of pore pressure and so on. Geotextiles commonly used in domestic and foreign projects are woven fabric, machine-woven fabric, non-woven fabric and some composite fabric. The pore diameter of geotextiles has a close relationship with the penetrating quality. Because of its larger porosity, non-woven fabric is widely considered as the most suitable geotechnical material for infiltration and drainage[16].

Based on the aeration vacuum rapid dewatering technique, acting force on the borders of geotextiles is the vacuum pressure and unstable airflow rather than hydraulic height. Meanwhile, the dredged sludge which has extremely high moisture content and nearly flow pattern is contacted with the fabric. So the dewatering process is different from the conventional penetration process. Therefore, it is necessary and meaningful to look for an ideal geotextile for separating mud with water under the action of aeration vacuum which can improve the technology of siltation prevention.

2 Conditions and MethodsThe dredged sludge in the test was taken from Baima Lake in Huaian, Jiangsu province, which is the east-route of South-to-North Water Diversion Project. Basic properties are shown in Table 1[17].

| Table 1 Physical character parameters of Baima Lake′s dredged sludge |

This test chose three types of woven and non-woven geotextiles which are commonly used in civil engineering, including two types of fabrics: more silk woven fabric and flat silk woven fabric. To distinguish, they are short for machine-woven fabric and woven fabric. Non-woven fabric is a needle-punched non-woven fabric which is short for non-woven fabric. In order to ensure the credibility, two sets of samples were prepared respectively and each set had similar effective pore diameter. Physical property parameters of two sets are shown in Table 2 and real materials are shown in Fig. 1.

| Table 2 Character parameters of geotextile |

|

Figure 1 Two sets of geotextiles used in the test |

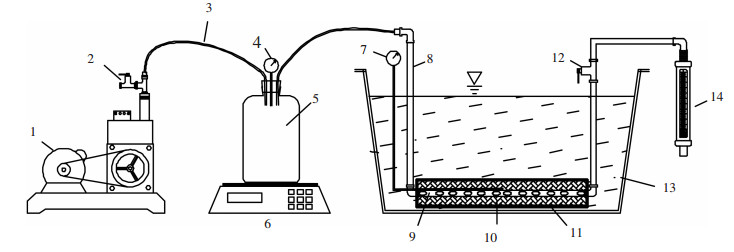

The equipment in the test is presented in Figs. 2 and 3[18]. The above geotextiles were wrapped on the surface of the filter tubes, and vacuum degree was measured by a vacuum hose circumscribed with a vacuum gauge which was stretched into the internal filter[19]. Ventilation rate was measured by the flow meter. Vacuum degree and ventilation rate could be regulated through the valve 2 and 12. Vacuum degree span was 5 kPa and increased evenly to 30 kPa within 15 min at the beginning of the test. Ventilation rate was also adjusted to 0.5 m3 within 15 min. Two conditions remained the same until the end and the test cycle was 30 h.

|

1. vacuum pump 2. vacuum governor valve 3. plastic conduit 4. vacuum gauge 1 5. water collecting bottle 6. electronic scale 7. vacuum gauge 2 8. galvanized steel pipe 9. vacuum barrel 10. plastic blind drain 11. filter geosynthetic material (geotextiles)12. airflow governor valve 13. model box 14. glass rotameter Figure 2 Schematic diagram of lab model test device of aeration vacuum rapid mud-water separating(AVMWS) technique |

|

Figure 3 Lab model test device of aeration vacuum rapid mud-water separating(AVMWS) technique |

3 Comparison of Geotextile Types in Mud-water Separation 3.1 Cumulative Weight of Pumping Water

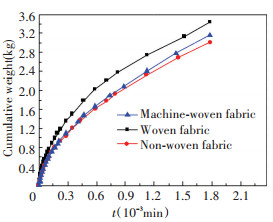

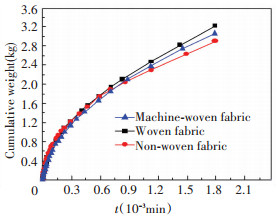

Figs. 4 and 5 show the cumulative weight of pumping water curve in saturated cylinders over time for two sets. As seen from them, the total water output of woven fabric is the maximum, followed by machine-woven fabric, non-woven fabric is the minimum. Taking the first set as an example, the total water output of woven fabric is up to 3 445 g and increases 14.3% compared with non-woven fabric.

|

Figure 4 Cumulative weight of pumping water curve over time for the first set of test |

|

Figure 5 Cumulative weight of pumping water curve over time for the second set of test |

3.2 Decrease of Moisture Content

Table 3 presents the comparison of the decrease of the average sludge moisture content in model box at the end of the test. As seen from the data, after 30 h of the mud-water separation, the decrease of moisture content of the non-woven fabric is the maximum, machine-woven fabric takes second place, non-woven fabric is the minimum. Taking the first set as an example, the decrease of the average sludge moisture content of woven fabric is 12.0% higher than non-woven fabric.

| Table 3 Decrease of the moisture content of different types of geotextiles after test |

3.3 Stable Pumping Speed

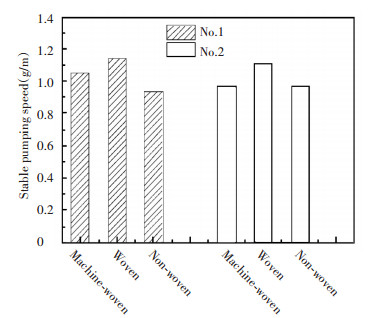

At the beginning of the test, the pumping speed was quite high and the fluctuation range also large under the action of vacuum and air flow. As time went by, the pumping speed decreased gradually and tended to be a stable value. According to the test, the pumping speed had been basically stable at the end of the test (30 h) and the change trends of the pumping speed of each set kept the same. Therefore, the stable pumping speed at the end of the test could be used to evaluate the sustainable pumping effect. As shown in Fig. 6, the sustainable pumping effect of woven fabric is the best (1.14 g/min), followed by machine-woven fabric (1.05 g/min), non-woven fabric remains the worst (0.93 g/min). Compared with non-woven fabric, the stable pumping speed of woven fabric increases 22.6% which is consistent with the former conclusion on the comparison of the cumulative weight of pumping water and the decrease of moisture content.

|

Figure 6 Comparison of stable pumping speed of different types of geotextiles |

3.4 Discussion

The above comparison of the cumulative weight of pumping water, the decrease of moisture content and the stable pumping speed shows that the effect on mud-water separation of woven fabric is the best, followed by machine-woven fabric, non-woven fabric remains the worst. The factors are the characteristic of the geotextile materials and the particularity of the aeration vacuum rapid mud-water separating technique. Reasons resulting in such phenomena are analyzed from three aspects.

3.4.1 Internal pore shape of geotextileThe woven fabric and machine-woven fabric in this test which belong to woven cloth are both weaved in warp and weft directions. The difference is that the material of woven fabric in warp and weft directions is lamina and machine-woven fabric is more silk yarn, which result in tiny thickness of woven and machine-woven fabric[20]. From Fig. 3, the cumulative weight of pumping water of woven is higher than the others, and it is because the pores of the drainage exist in the junction of two directions and the pore forms inside the fabric are almost linear pattern and the difference of the pore size can be ignored, so the soil particles are not easy to block in woven and machine-woven fabric pores. However, non-woven fabric is disorderly crisscrossed and composed of many loosely mixed fibers, and thickness is also higher than the others. The change of internal pore forms which are twists and turns is much more obvious so that the soil particles are more likely to block in fabric pores.

3.4.2 External characteristic of geotextileThe advantages in filtering measures are that non-woven fabric surface is rough and well contacted with the protected soil. In the aeration vacuum rapid mud-water separating technique, the existence of vacuum suction leads to the exceeding compact between fabrics and sludge. From Table 3, we can see that the decrease of the moisture content after test of woven is the maximum compared with. Personally speaking, such close contact is not beneficial for drainage which needs to be well solved. Soil particles are easy to adhere to prominent fibers on the surface of the non-woven fabric, which results in the deposition of small soil particles in the fabrics. From Table 3, we can see that the decrease of the moisture content of woven fabric is the maximum(44.67%) after test. In contrast, the woven fabric is intertwined with polypropylene chip, the surface of which is flat and smooth. Soil particles which are hardly to be affixed on the surface of fabric prevent the siltation. The external characteristic of machine-woven fabric is between the woven and non-woven fabric, so the effect of mud-water separation is neither good nor bad.

3.4.3 Influence of vacuum degree for geotextilesDuring the trial, geotextiles on the surface of the filter tubes are directly under the vacuum negative pressure. When the ventilation rate remains unchanged, mud-water separation effect presents the peak-value change progress with the increase of the vacuum pressure, which indicates the vacuum degree should be controlled in a restricted range (less than 50 kPa). As the vacuum degree increases, soil particles would be stuck on the subtle channel of the filter material, which reduces the rate of drainage. As the vacuum degree decreases, soil particles would drop or shift to make water-vapor porous channels, which present a better penetration capacity[21]. The vacuum negative pressure is equivalent to the same positive pressure on the surface of the geotextiles[22]. Because of compact fibrous structure, internal forms of woven and machine-woven fabric will not change significantly under the negative pressure. According to the research achievements by Chou[23], the structure of non-woven fabric is quite loose and when suffered by the superficial pressure, thickness and pore size and porosity turn to smaller, fibers get compacted, permeability becomes worse. Therefore, it is more likely to be blocked up and the effect of mud-water separation is not good enough compared with woven and non-woven fabric.

4 Conclusions1) Based on the lab model test of aeration vacuum rapid mud-water separating (AVMWS) technique, evaluated by the cumulative weight of pumping water, the decrease of moisture content and the stable pumping speed, the results show that: different types of geotextiles have different effects of mud-water separation; woven fabric is the best anti-clogging aeration vacuum material which separates mud with water best, followed by machine-woven, fabric and non-woven fabric is the worst.

2) The reasons why different types of geotextiles have different effects of mud-water separation are presented that: small thickness, linear pore forms and smooth surface of woven and machine-woven fabric reduce the possibility of clogging, however, larger thickness, unordered fibers, nonlinear pore forms and rough surface of non-woven fabric lead it more easily to be silt up; the structure of non-woven fabric get compacted, internal pore size get smaller and permeability becomes worse under the vacuum negative pressure which has little influence on woven fabric and machine-woven fabric. Therefore, non-woven fabric has worse effect of mud-water separation than woven fabric and machine-woven fabric.

| [1] |

Lu Jinyou, Huang Yue. Comparison of sedimentation in three gorges reservoir between calculated prediction and prototype measurement.

Journal of Yangtze River Scientific Research Institute, 2013 , 30 (12) : 1-6.

( 0) 0)

|

| [2] |

Lai Y, Tan G, Wang J. Study on transmitting and spreading rules of dredging sediment of Shenzhen Western Port channel.

Engineering Journal of Wuhan University, 2006 , 39 (3) : 41-45.

( 0) 0)

|

| [3] |

Zhang Guoan, Yu Zhiying. Environmental effect of dredging engineering in Lianyungang.

Yellow Sea and Bohai Sea, 2001 , 19 (2) : 46-56.

( 0) 0)

|

| [4] |

Miles of Shimizu Corporation in Zhejiang Province of the 11th Five-year Plan.Water Resources Department in Zhejiang Province, 2006.(in Chinese)

( 0) 0)

|

| [5] |

Zhu Wei, Zhang Chunlei, Gao Yufeng. The current situation of the processing technology of renewable resources of dredging.

Environmental Sciences and Technology, 2002 , 25 (4) : 39-41.

( 0) 0)

|

| [6] |

Deng Dongsheng. Comparison of remolded shear strength with intrinsic strength line for dredged deposits.

China Ocean Engineering, 2007 , 21 (2) : 363-369.

( 0) 0)

|

| [7] |

Chen Ping, Zhang Zhenying, Li Xiaoshan, et al. Solidification technology of dredged sediment for reuse as civil engineering materials..

Zhejiang Hydrotechnies, 2006 , 148 (6) : 1-3.

( 0) 0)

|

| [8] |

Tang Yixin, Miyazaki Y, Tsuchida T. Practices of reused dredging by cement.

Soils and Foundations, 2001 , 41 (5) : 129-143.

DOI:10.3208/sandf.41.5_129 ( 0) 0)

|

| [9] |

Horpibulsuk S, Miura N, Nagaraj T S.. Assessment of strength development in cement admixed high water content clays with Abram's law as a basis..

Geotechnique, 2003 , 53 (4) : 439-444.

DOI:10.1680/geot.2003.53.4.439 ( 0) 0)

|

| [10] |

Dong Z, Li W, Zhang G. Experimental study on treatment of soft soil in intertidal zone with vacuum preloading. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(Supp. 2):3490-3494.(in Chinese)

https://www.researchgate.net/publication/289604051_Experimental_study_on_treatment_of_soft_soil_in_intertidal_zone_with_vacuum_preloading ( 0) 0)

|

| [11] |

Yu Y, Zhang Y. Test study on engineering properties of dredging soil of West Lake in Hangzhou. Rock and Soil Mechanics, 2004, 25(4):579-582.(in Chinese)

https://www.researchgate.net/publication/298511858_Test_study_on_engineering_properties_of_dredging_soil_of_West_Lake_in_Hangzhou ( 0) 0)

|

| [12] |

Deng D, Hong Z, Liu C, et al. Large-scale model tests on dewater of dredged clay by use of ventilating vacuum method. Chinese Journal of Geotechnical Engineering, 2009, 31(2): 250-253.(in Chinese)

https://www.researchgate.net/publication/295627730_Large-scale_model_tests_on_dewater_of_dredged_clay_by_use_of_ventilating_vacuum_method ( 0) 0)

|

| [13] |

Liu Chuanjun. Study on Dredged Silt Breathable Vacuum Rapid Muddy Water Separation in the White Horse Lake. Nanjing: Hohai University, 2007.

( 0) 0)

|

| [14] |

Deng Dongsheng, Hong Zhenshun, Zhu Wei, et al. The yard breathable vacuum rapid muddy water separation of dredged silt with high water content:China, CN101219297, 2007.

( 0) 0)

|

| [15] |

Yee T W, Lawson C R, Wang Z Y, et al. Geotextile tube dewatering of contaminated sediments, Tianjin Eco-city, China.

Geotextiles and Geomembranes, 2012 , 31 : 39-51.

DOI:10.1016/j.geotexmem.2011.07.005 ( 0) 0)

|

| [16] |

Xu Riqing, Wang Jingchun.

Geosynthetics Applications Technology. Beijing: Chemical Industry Press, 2005 .

( 0) 0)

|

| [17] |

Wang Liang, Cao Linglong, Li Lei, et al. Vane shear tests on thixotropy of Taihu Lake and Baimuahu Lake dredged slurries.

Journal of Engineering Geology, 2015 , 23 (3) : 548-553.

( 0) 0)

|

| [18] |

Zhou Yuan, Liu Chuanjun, Ji Feng, et al. Lab simulation of rapid vacuum consolidated draining of aerated sludge.

Chinese Journal of Vacuum Science and Technology, 2010 , 30 (2) : 215-220.

( 0) 0)

|

| [19] |

Gao Yufeng, Zhou Yuan, Deng Dongsheng, et al. Breathable antisludge composite filter tube structure and binding method: China, CN200910028430.3, 2009.

( 0) 0)

|

| [20] |

Jiang Hong, Lei Guohui, Yang Mingchang. Research progress of vertical infiltration characteristics of geotextiles.

Advances in Science and Technology of Water Resources, 2014 , 34 (3) : 89-94.

( 0) 0)

|

| [21] |

Gao Yufeng, Zhou Yuan. Effect of vacuum degree and aeration rate on sludge dewatering behavior with the aeration-vacuum method.

Journal of Zhejiang University Science, 2010 , 11 (9) : 638-655.

DOI:10.1631/jzus.A0900651 ( 0) 0)

|

| [22] |

Zhou Yuan, Gao Yufeng, Tao Hui, et al. Drainage-promotion effect of aeration vacuum rapid mud-water separation technique on dredge sludge.

Chinese Journal of Rock Mechanics and Engineering, 2010 , 29 (A01) : 3064-3070.

( 0) 0)

|

| [23] |

Chou Rong, Zhang Hongdi. Evaluation and engineering significance on penetrating quality of geotextile.

Textile Research Journal, 2000 , 21 (3) : 180-183.

( 0) 0)

|

2016, Vol. 23

2016, Vol. 23