2. State Key Laboratory of Development and Application Technology of Automotive Steels (Baosteel Group), Shanghai 201900, China

Low carbon bainitic steel possesses excellent mechanical properties [1-3]. As a major micro-alloying element, niobium (Nb) can improve the microstructure and properties of steels by precipitation strengthening and grain refinement during hot deformation [4-5]. One of the important alloying elements of bainitic steel, molybdenum (Mo) can effectively reduce the bainite starting temperature (Bs), broaden the range of cooling rate of bainite transformation and improve the toughness and strength of steels [6].

Many studies have been conducted on the strengthening mechanism of Nb, most of which focus on high-temperature phase transformation and dynamic recrystallization of austenite during hot rolling process. Nie et al. [7] and Sun et al. [8] investigated the effect of Nb on recrystallization of hot deformed austenite. Chen et al. [9] characterized carbide precipitation in hot rolled Ti-Nb-Mo steel, confirming that the precipitation strengthening of Ti-Nb-Mo steel was better than Ti-Nb steel. Wu et al. [10] found that with the addition of Nb, the final martensite microstructure was refined and the distribution of (Nb, Ti)C in Nb-rich steel led to precipitation strengthening. Moreover, there are some studies about the effects of Nb on recrystallization behavior of cold rolled sheets during annealing. Zhang et al. [11] studied the effect of annealing temperature on the recrystallization behavior of Nb-Ti microalloyed cold rolled sheet. The studies revealed that dispersed nano-sized (Nb, Ti)C particles would delay recrystallization process and increase recrystallization temperature. Ogawa et al. [12] investigated the effects of Nb on recrystallization temperature during annealing in cold rolled low-carbon steels.

However, only a few studies show the effect of Nb on the microstructure and properties of cold rolled and annealed high strength steels. Especially, the impact of Nb on the microstructure and mechanical properties of cold rolled and annealed Mo bearing low carbon bainitic steel has not been reported yet. In the present study, two kinds of Mo bearing low carbon bainitic steels, Nb-free Mo bearing and Nb + Mo addition steels, are cold rolled and annealed to investigate the effect of Nb on the microstructure and properties of Mo bearing cold rolled steels.

2 ExperimentalTwo types of steels (Nb-free and Nb addition) were refined in a 50 kg laboratory vacuum induction furnace and were hot rolled to plates with a thickness of 12 mm in five passes on the laboratory mill at a finishing temperature of 870 ℃. Steel A was microalloyed with Mo (Nb-free) and Steel B was microalloyed with Nb and Mo (Nb addition). Their chemical compositions are shown in Table 1.

| Table 1 Chemical composition of experimental steels(wt%) |

The specimens were cold rolled from 3 mm to 1.35 mm by three passes on four-high cold mill and annealed at temperatures of 500, 550, 600, 650 ℃ and annealing time of 15, 30, 45, 60 min respectively. After annealing, the microstructure was observed by Nova 400 Nano scanning electron microscope (SEM). Mechanical properties were measured by tensile tests on UTM-5305 electronic universal testing machine. The precipitate morphology of carbon extraction replica specimens was observed by a JEM-2100F field emission transmission electron microscope (TEM) operated at 120 kV, and the composition of precipitated phases was analyzed with INCA spectrometer.

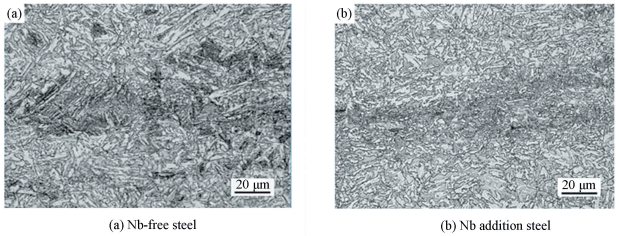

3 Results and Discussion 3.1 MicrostructureFig. 1 shows the optical microscope (OM) micrographs of hot rolled specimens. It shows that the microstructures of both steels consist of bainite, ferrite and small amount of martensite. The grain size of the steel with Nb addition is finer than that without Nb.

|

Figure 1 OM micrographs of hot-rolled steels |

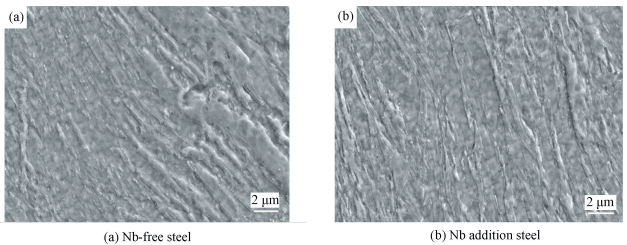

Fig. 2 shows the SEM microstructure of cold rolled specimens. The cold rolled bainitic ferrite grains are flattened and elongated along the direction of rolling, showing many small broken grains.

|

Figure 2 SEM micrographs of cold-rolled steels |

3.1.1 Microstructure of Nb-free steel after annealing

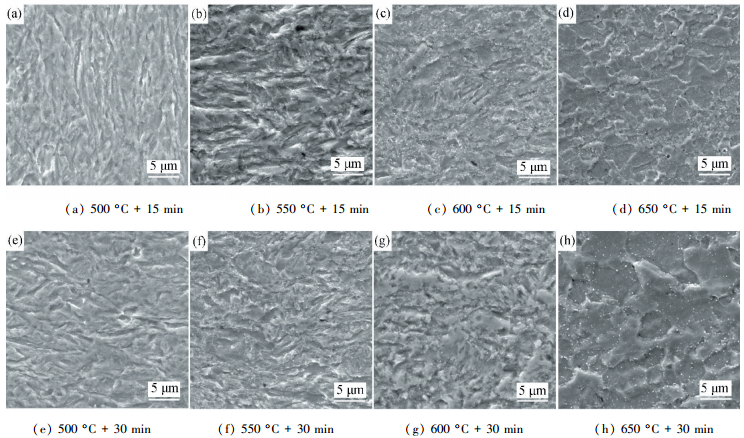

Fig. 3 shows SEM microstructure of Nb-free steel under different annealing procedures. There is no significant change in the microstructure with annealing time at 500 ℃ and the grains are elongated along the rolling direction. At this stage recovery occurs and point defects and dislocation density decrease, while grain morphology shows no obvious change [13-14]. At 550 ℃, the grain orientation presents disordered characterization, fiber textures gradually disappear and equiaxed grains begin to appear, which indicates occurrence of partial recrystallization at 550 ℃. A small amount of cementite is also observed in grain boundaries. Full recrystallization accompanied with a large number of carbide precipitates occurs when specimens are annealed at 600 ℃. At 650 ℃, recrystallized grains grow to equiaxed grains and cementite mainly appears on the grain boundaries. Recrystallized grains and precipitates begin to grow with annealing time.

|

Figure 3 SEM micrographs of Nb-free steel under different annealing procedures |

3.1.2 Microstructure of Nb addition steel after annealing

Fig. 4 shows the SEM micrographs of Nb addition steel annealed for 30 min at different annealing temperatures. The recrystallization process is similar to that of Nb-free steel. Therefore, the recrystallization temperature of these two kinds of Mo bearing low-carbon bainitic steels ranges from 550 to 600 ℃, and the recrystallization process is accompanied with carbide precipitation. Only recovery occurs at temperatures lower than 550 ℃ and the microstructure shows no obvious change with annealing time. On the other hand, obvious grain growth takes place at temperatures higher than 650 ℃. The comparison between Figs. 4(a)-4(c) and Fig. 3(f)-3(h) shows that there is no obvious difference in the grain size of Nb addition steel and Nb-free steel.

|

Figure 4 SEM micrographs of Nb addition steel at different annealing temperatures for 30 min |

3.2 Grain Size

Fig. 5 shows the column graph of grain size distribution for the two experimental steels under different annealing procedures. The grain size was measured by the linear intercept method on SEM micrographs using software Image-Pro Plus 6.0. Several lines drawn on each micrograph intercepted different grains to improve measurement accuracy. The average grain diameter was then determined. The grains show a gradual growth with the increase in annealing temperature. The grain size of Nb addition steel is almost the same as that of Nb-free steel under the same annealing procedure.

|

Figure 5 The average grain size for Nb-free and Nb addition steels at different annealing procedures |

3.3 Precipitates

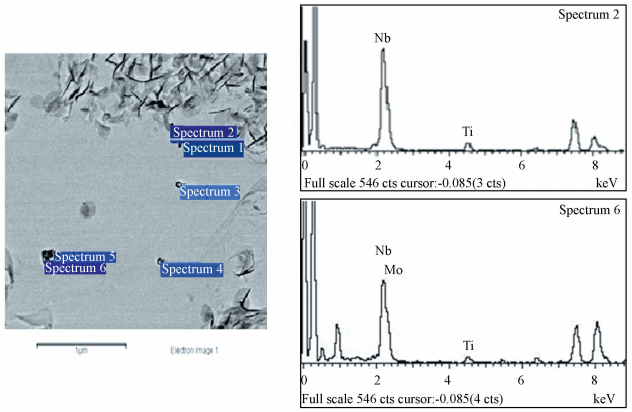

Carbon extraction replica samples were preparedin order to analyze the effect of Nb on the precipitation of Mo bearing steel. The composition of precipitate phases was analyzed with INCA energy-dispersive spectrometry (EDS). The precipitates of Mo cannot be observed in Nb-free steel, whereas the precipitates of Nb(C, N) and (Nb, Mo)(C, N) were observed in Nb addition steel (Fig. 6 and Table 2).

|

Figure 6 Precipitation morphology and energy spectrum of Nb addition steel |

| Table 2 Composition of precipitate phase |

3.4 Mechanical Properties

Based on the microstructure, partial samples were selected for tensile test.The results as shown in Table 3 indicate no significant difference in the strength of the two cold rolled steels. After annealing treatment, the tensile strength of Nb addition steel is higher than that of Nb-free steel. Under the same annealing conditions, the tensile strength of Nb addition steel increased by 10% to 20% compared to Nb free steel, but elongation shows no obvious decrease.The significant change of strength of the two steels can be observed at 550 ℃ and 650 ℃, which is consistent with the microstructure, i.e., recrystallization begins at 550 ℃ and growth of these recrystallized grains occurs at 650 ℃.

| Table 3 Mechanical properties of two as-cold rolled and annealed steels |

3.5 Discussion

After cold rolling, grains are either elongated or get damaged and a large number of crystal defects exist in the microstructure, resulting in the increase of internal free energy in steels. Below the recrystallization temperature, the increase of annealing temperature and annealing time can only reduce or eliminate point defects and dislocation density, but the crystal structure does not change. The recrystallization temperatures of the two steels range from 550 to 600 ℃. Fine and uniform equiaxed grains are formed through nucleation and growth of recrystallized grains. The fiber texture gradually disappears during recrystallization.

Comparing the mechanical properties of the two steels (Table 3), it is apparent that the yield strength and tensile strength of Nb addition steel increase. According to the precipitate morphology and energy spectrum, Nb addition steel contains Nb(C, N) and composite precipitates of (Nb, Mo)(C, N). As the element Mo is difficult to combine with C and N, the precipitation of Mo(C, N) cannot form even if more Mo element added. However, when Nb is added, Mo is enriched on the precipitates of Nb(C, N). The precipitate of Nb addition steel is fine and in large quantity, resulting in better precipitation strengthening.

According to the earlier studies, the austenite grain growth can be retarded by the solute drag effect induced by Nb in solid solution during the heating process before hot rolling, and is further impeded by the pinning force exerted by Nb(C, N) precipitates during subsequent dynamic recrystallization or static recrystallization in the thermomechanical process[15-16]. Due to the addition of Nb, dispersive second-phase particles slow down the driving force of recrystallization by influencing nucleation and growth of recrystallization grains [17]. Small precipitates have significant pinning effect on grain boundary and suppress recrystallization during hot rolling process, thereby refining the recrystallized grains [18]. However, in the present study, the grains broke after cold rolling and the precipitates of Nb(C, N) distributed randomly within the grains. During annealing no new Nb(C, N) precipitates were formed because of low temperature, resulting in little hindrance of precipitates on grain growth. Thus, the grain size of Nb addition steel is almost the same as that of Nb-free steel under the same annealing conditions.

The strengthening mechanisms of microalloyed steels include solution strengthening, precipitation strengthening, grain refinement strengthening and dislocation strengthening. The yield strength for Nb microalloyed steels is given by Eq. (1) [19].

| ${\sigma _y} = {\sigma _{{\text{base}}}} + {\sigma _{{\text{disl}}}} + {\sigma _{{\text{ppt}}}} + {\sigma _{{\text{transf}}}}$ | (1) |

where σdisl is dislocation strengthening; σtransf is phase transformation strengthening; σppt is precipitation strengthening and σbase represents base yield strength in terms of chemical composition and grain size. It can be calculated by empirical formulas (2a)-(2c).

| ${\sigma _y} = {\sigma _{{\text{base}}}} + {\sigma _{{\text{disl}}}} + {\sigma _{{\text{ppt}}}} + {\sigma _{{\text{transf}}}}$ | (2a) |

where σ0 is base strength and is related to chemical compositions of steel, and σgf is grain refinement strengthening and is related to grain size[19].

| ${\sigma _0} = 63 + 23{\text{Mn}} + 53{\text{Si}} + 700{\text{P}}$ | (2b) |

| ${\sigma _{gf}} = \left[{15.4 - 30{\text{C + }}\frac{{6.09}}{{0.8 + {\text{Mn}}}}} \right]{d^{ - 1/2}}$ | (2c) |

Precipitation strengthening can be calculated by Eq. (3) [20],

| $\begin{gathered} {\sigma _p} = \frac{{538Gbf_v^{1/2}}}{X}\ln \left( {\frac{X}{{2b}}} \right) \hfill \\ {\sigma _p} = \frac{{538Gbf_v^{1/2}}}{X}\ln \left( {\frac{X}{{2b}}} \right) \hfill \\ \end{gathered} $ | (3) |

where Δσp is increment of yield strength (MPa); G is shear modulus (MPa) (the shear modulus of Fe is 81 600 MPa); B is Burgers vector (nm) (the Burgers vector of ferrite is 0.248 nm); fv is the volume fraction of precipitate and X is precipitate size (nm). X is Dmean in Eq. (4).

fv can be calculated by Eq. (4) [21].

| ${f_v} = \frac{{1.4\pi }}{6}\left( {\frac{{ND_{{\text{mean}}}^2}}{A}} \right)$ | (4) |

where Dmean is average size of precipitates (nm); N is amount of grains and A is observation area (mm2). In the selected observation area A, the amount N of grains is counted and the diameter of each precipitate is measured. Dmean is calculated by the measurement of precipitates.

The processing technology is the same for the two steels. The main reasons for the difference in their mechanical properties are precipitation strengthening and grain refinement strengthening. The amount of precipitation strengthening and grain refinement strengthening of the two steels can be separately calculated by Eqs. (1)-(4) and is given in Table 4.

| Table 4 Precipitation strengthening and grain refinement strengthening amount of two steels |

It is obvious that the grain size of Nb addition steel is finer than that of Nb-free steel after hot rolling (Fig. 1). Nb addition can refine grains in hot rolling process resulting in significant grain refinement strengthening. Although the grain size of the two steels is distinctly different after hot rolling, the grain size of the two steels after cold rolling and annealing shows no significant difference, indicating that the influence of Nb on the grain size is eliminated after cold rolling and annealing.

In addition, it can be seen from Table 4 that Nb addition has no significant effect on grain refinement during cold rolling and annealing procedure. Therefore, the grain refinement strengthening for the two steels is basically the same. Compared to dynamic recrystallization process during hot processing, Nb has less influence on grain refinement in static recrystallization. Recrystallization occurs at 500 ℃ for the two steels and grains have no obvious growth. Therefore, the grain size has no significant difference for the two steels. At 650 ℃, the grains in the two steels show obvious growth, but the grain size for the two steels is basically the same because the grain refinement caused by pinning and dragging effect of Nb in static recrystallization is not as evident as in dynamic recrystallization during hot processing. On the other hand, the increment of precipitation strengthening for the two steels is significantly different. It can be concluded that the main reason for the higher strength of Nb addition steel is precipitation strengthening and not grain refinement strengthening. Thus, the addition of small amount of Nb can improve the strength of Mo bearing low carbon bainitic steel by precipitation strengthening in cold rolling and annealing.

4 ConclusionsThe effect of Nb on the microstructure and properties of Mo microalloyed low carbon high strength bainitic steel produced by cold rolling and annealing procedure was investigated. Microstructure observation, precipitation analysis and tensile tests were conducted. The results showed that under the same annealing procedures the grain size of Nb addition steel is almost the same as that of Nb-free steel. No precipitates were observed in Nb-free steel, whereas two types of precipitates, i.e., single Nb(C, N) and composite (Nb, Mo)(C, N) precipitates, were observed in the Nb + Mo microalloyed steel, resulting in precipitation strengthening. Unlike the obvious grain refinement and precipitation strengthening observed in hot rolling, the increase in yield strength of Nb addition steels in cold rolling and annealing mainly results from precipitation strengthening, while the effect of grain refinement strengthening can be almost ignored.

| [1] |

Zhang Songshu.

Toughening Mechanism and Technical Approach of Steel. Beijing: Weapon Industry Press, 1995 : 5 -20.

( 0) 0)

|

| [2] |

Erest J. Development and certification of HSLA-100 steel for naval ship construction.

Naval Engineers Journal, 1990 , 5 : 50-54.

( 0) 0)

|

| [3] |

Wang S C, Kao P W. The effect of alloying elements on the structure and mechanical properties of ultra low carbon bainitic steels.

Journal of Materials Science, 1993 , 28 : 5169-5175.

DOI:10.1007/BF00570058 ( 0) 0)

|

| [4] |

Chen Yan, Zhang Dantian, Liu Yongchang, et al. Effect of dissolution and precipitation of Nb on the formation of acicular ferrite/bainite ferrite in low-carbon HSLA steels.

Materials Characterization, 2013 , 84 : 232-239.

DOI:10.1016/j.matchar.2013.08.005 ( 0) 0)

|

| [5] |

Hausmann K, Krizan D, Spiradek-Hahn K, et al. The influence of Nb on transformation behavior and mechanical properties of TRIP-assisted bainitic-ferritic sheet steels.

Materials Science & Engineering A, 2013 , 588 : 142-150.

DOI:10.1016/j.msea.2013.08.023 ( 0) 0)

|

| [6] |

Chen Xiaowei, Qiao Guiying, Han Xiulin, et al. Effects of Mo, Cr and Nb on microstructure and mechanical properties of heat affected zone for Nb-bearing X80 pipeline steels.

Materials and Design, 2014 , 53 : 888-901.

DOI:10.1016/j.matdes.2013.07.037 ( 0) 0)

|

| [7] |

Nie Wenjin, Shang Chengjia, Wu Shengjie, et al. Effects of Nb on recovery of hot-deformed austenite.

Acta Metallurgica Sinica, 2012 , 48 : 775-781.

( 0) 0)

|

| [8] |

Sun Xiaojun, Liu Yazheng, Xiao Jinfu, et al. Effect of niobium on dynamic recrystallization of spring steel 60Si2MnA.

Journal of Wuhan University of Science and Technology, 2009 , 32 (6) : 596-599.

( 0) 0)

|

| [9] |

Chen Chihyuan, Chen Chienchon, Yang Jerren. Microstructure characterization of nanometer carbides heterogeneous precipitation in Ti-Nb and Ti-Nb-Mo steel.

Materials Characterization, 2014 , 88 : 69-79.

DOI:10.1016/j.matchar.2013.11.016 ( 0) 0)

|

| [10] |

Wu Huibin, Ju Biao, Tang Di, et al. Effect of Nb addition on the microstructure and mechanical properties of an 1800 MPa ultrahigh strength steel.

Materials Science & Engineering A, 2015 , 622 : 61-66.

DOI:10.1016/j.msea.2014.11.005 ( 0) 0)

|

| [11] |

Zhang Ke, Sun Xinjun, Yong Qilong, et al. Effect of annealing temperature on recrystallization behavior of Nb-Ti microalloyed cold rolled steel sheet.

Heat Treatreatment of Metals, 2013 , 38 (12) : 49-53.

( 0) 0)

|

| [12] |

Ogawa T, Sugiura N, Maruyama N, et al. Influence of state of Nb on recrystallization temperature during annealing in cold-rolled low-carbon steels.

Materials Science & Engineering A, 2013 , 564 : 42-45.

DOI:10.1016/j.msea.2012.11.083 ( 0) 0)

|

| [13] |

Humphreys F J, Hatherly M.

Recrystallization and Related Aannealing Phenomena. Oxford: Pergamon Press, 1996 : 127 .

( 0) 0)

|

| [14] |

Martinez-de-Guerenu A, Arizti F, Gutierrez I. Recovery during annealing in a cold rolled low carbon steel. Part II: Modelling the kinetics.

Acta Materiali, 2004 , 52 (12) : 3665-3670.

DOI:10.1016/j.actamat.2004.04.020 ( 0) 0)

|

| [15] |

Hutchinson C R, Zurob H S, Sinclair C W, et al. The comparative effectiveness of Nb solute and NbC precipitates at impeding grain-boundary motion in Nb steels.

Scripta Materialia, 2008 , 59 (6) : 635-637.

DOI:10.1016/j.scriptamat.2008.05.036 ( 0) 0)

|

| [16] |

Cao Yabin, Xiao Furen, Qiao Guiying, et al. Strain-induced precipitation and softening behaviors of high Nb microalloyed steels.

Materials Science & Engineering A, 2012 , 552 : 502-513.

DOI:10.1016/j.msea.2012.05.078 ( 0) 0)

|

| [17] |

Belyakov A, Kimura Y, Tsuzaki K. Recovery and recrystallization in ferritic stainless steel after large stain deformation.

Materials Science & Engineering A, 2005 , 403 (1) : 249-259.

( 0) 0)

|

| [18] |

Belyakov A, Kimura Y, Tsuzaki K. Microstructure evolution in dual phase stainless steel during serve deformation.

Acta Materialia, 2006 , 54 : 2521-2532.

DOI:10.1016/j.actamat.2006.01.035 ( 0) 0)

|

| [19] |

Misra R D K, Nathani H, Hartmann J E, et al. Microstructural evolution in a new 770 MPa hot rolled Nb-Ti microalloyed steel.

Materials Science & Engineering A, 2005 , 394 : 339-352.

( 0) 0)

|

| [20] |

Gladman T. Precipitation hardening in metals.

Materials Science and Technology, 1999 , 15 : 30-36.

DOI:10.1179/026708399773002782 ( 0) 0)

|

| [21] |

Ma Hongxu, Li Youguo. Measurement of size distribution and volume fraction of precipitates in silicon steel.

Materials Science & Engineering, 2002 , 3 : 328-330.

( 0) 0)

|

2016, Vol. 23

2016, Vol. 23