2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

The energy shortage and environment pollution has become the biggest difficulties in the world. The most effective method to reduce the energy consumption is to cut down the weight of the aircraft, therefore, can solve the energy and pollution problems. Light weight design of the aircraft can be realized in the following two aspects: to adopt more light alloys and to increase the thin-walled castings. Nowadays, the castings design is to reduce the casting weight by improving the mechanical properties of the alloy, or use the reasonable structure with far smaller wall-thickness[1-2].

Titanium alloys have been widely used in the aeronautic and aerospace engineering due to the excellent combination of low density, high specific strength and outstanding elevated temperature properties, etc[3-5]. The TC4 alloy is one of the duplex phases (α+ β) titanium alloys, which has superior plasticity and toughness. And it has been considered as the most preferred material in the field of aeronautic and aerospace engineering[6-7]. At present, the vertical centrifugal precision casting technology is the most cost-effective and extensively used near-net shaping technology for the TC4 alloy castings[8-10]. However, the titanium alloys show very high chemical activity at high temperature, and thus the solubility of gases in molten titanium alloys is pretty high[11-14]. When the titanium alloy melts solidify, the temperature decrease makes the solubility of gas in the liquid titanium alloy melt drop. Thus the gases escape from the liquid melt and take shape into bubbles in the alloys. Then some bubbles precipitate on the surface of the casting mould or other solids and eventually form surface or subsurface porosity, while other bubbles are remained in the casting and finally form inner pores[15-16]. Therefore, the gas voids and porosity in the TC4 castings are caused by the entrapment and evolution of gases during the solidification of TC4 alloy melt in vertical centrifugal casting process.

However, the bubble evolution in the liquid TC4 alloy melt during vertical centrifugal casting process is still unclear. Thus, the bubble migration in liquid titanium alloy melt during vertical centrifugal casting process will be predicted by numerical simulation in the present paper. The aim of the present work is to study the bubble migration, and effects of initial bubble location and mould rotation direction on the bubble migration in the liquid TC4 alloy melt during vertical centrifugal casting process.

2 Numerical Model and Settings 2.1 Governing EquationsIn order to simplify the simulation of the bubble migration in liquid titanium alloy melt during vertical centrifugal casting process, the following assumptions were introduced in the numerical modeling.

(a) The titanium alloy melt is incompressible viscous fluid and the gas bubble migration can be solved as the incompressible gas-liquid two-phase flow problem.

(b) The gas and liquid has the same pressure inside each grid cell. And there is no mass transportation between the gas and liquid.

(c) Furthermore, the heat transfer capability between the melt and the gas bubbles is infinite. Consequently, the temperature of the gas and the titanium alloy melt are same. Therefore, there is no expansion in the bubbles due to temperature variation and then the energy equation does not need anymore.

With the previously mentioned assumptions, the governing equations for the bubble-melt two-phase flow can be expressed as follows:

The mass conservation equation:

| $ \frac{\partial }{{\partial t}}\left( {{\rho _k}{\alpha _k}} \right) + \nabla \cdot \left( {{\alpha _h}{\rho _k}{U_{ki}}} \right) = 0 $ | (1) |

in which, the index k = L represents the liquid titanium alloy melt and k = G represents the gas bubble. ρk and αk are the density and volume fraction of phase k, respectively. And Uki is the velocity component in direction i of phase k.

The bubble-melt two-phase flows are described with an Eulerian-Eulerian two fluid model. The liquid titanium alloy melt and the gas bubble are considered as two different continua, and are assumed to share space in proportion to their volume such that their volume fractions sums to unity in the cells domain:

| $ {\alpha _L} + {\alpha _G} = 1.0 $ | (2) |

The momentum conservation equation:

| $ \begin{array}{l} \frac{\partial }{{\partial t}}\left( {{\rho _k}{\alpha _k}{U_{ki}}} \right) + \nabla \cdot \left( {{\alpha _k}{\rho _k}{U_{ki}}{U_{ki}}} \right) = - {\alpha _k}\nabla p + \\ \;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\nabla \cdot {\overline{\overline \tau } _{effk}} + {\alpha _k}{\rho _k}{a_{ki}} + {R_{ki}} \end{array} $ | (3) |

where, p is the pressure of the flow, Rki is the momentum exchange between the gas and liquid melt in direction i, and aki is the acceleration in direction i of phase k. In the present paper, the coriolis and centrifugal force during vertical centrifugal casting process have been considered, thus the acceleration aki can be decompose into three different components akx, aky and akz, and can be expressed as follows:

| $ {a_{kx}} = x{\omega ^2} + 2\omega {U_x}, {a_{ky}} = y{\omega ^2} - 2\omega {U_y}, {a_{kz}} = g $ | (4) |

in which, Ux and Uy are the velocity component at direction x and direction y, respectively, ω is the rotational speed of the casting mould (rad/s), and g is the gravity acceleration.

2.2 Numerical SettingsIn the paper, the research is done for the TC4 alloy melt during its vertical centrifugal casting process. The solidus and liquidus temperature of the alloy is TS=1 678 ℃ and TL=1 703 ℃, respectively. The density of the TC4 alloy melt is 4 430 kg/m3, and its viscosity is set to be 1.28×10-3 Pa·s. The density of the gas bubble is 1.25 kg/m3, and its viscosity is set to be 1.8 Pa·s. The initial temperature of the TC4 alloy melt is 1 750 ℃. The surface tension between the TC4 melt and the gas bubble is set to be σL=1.65 N/m and the initial diameter of the gas bubble is 2 mm. The bubble is stationary relative to the rotational casting mould before it released from the generation chamber.

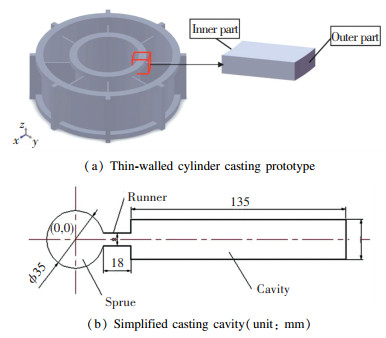

The migrations of the bubbles in the TC4 alloy melt are predicted by the computational fluid dynamics software FLUENT 6.3 incorporated with the Multiple Reference Frames (MRF) method and the two-phase fluid model. The mould cavity is selected from the thin-walled cylinder shape casting (the prototype is shown in Fig. 1(a)). The casting mould is a part of which shown in the rectangle. For the casting wall thickness is very small (about 3-5 mm), the bubble migration at its height can be ignored. And the selected zone is therefore simplified to a two-dimensional cavity shown in Fig. 1(b). The filling process of the TC4 alloy melt is under the vacuum circumstance, and the gas porosity cannot form at this stage. The gas bubbles are formed because of the reaction between the liquid melt with the outer part of the casting mould. Thus different initial locations, such as (160, 0), (160, 10) and (160, -10) are set to investigate the bubble migration process. And the bubble migration process under diverse mould rotational speed of 160 r/min, 300 r/min and 500 r/min are also simulated. When calculating the bubble evolution process, the boundary condition of casting mould wall is set to be the nonslip boundary condition.

|

Fig.1 Geometry structure of the casting mould |

3 Numerical Results and Experimental Verification 3.1 Numerical Results

Fig. 2 shows the bubble migration contrail in the titanium alloy melt during vertical centrifugal casting process when the casting mould rotates clockwise at 300 r/min and the bubble diameter is 3 mm. Results show that the gas bubbles begin to move forward the rotation axis after it releases from the chamber under the synthetic influence of buoyancy force (formed by the pressure difference during vertical centrifugal casting process), centrifugal force and coriolis force. However, the bubble migration contrail deviates from the line between the bubble initial position and the rotation axis of the casting mould. And the deviate direction is opposite to the rotation direction of the casting mould.

|

Fig.2 Numerical simulation of bubble migration contrail at 300 r/min |

As has been stated above, it can be concluded that the bubble migration in the titanium alloy melt during vertical centrifugal casting process can be divided into the movement to the rotation axis of the casting mould and the movement to the opposite direction of the rotational casting mould. The gas bubble finally migrates like a straight line which is near the mould wall located at the same direction of the rotational casting mould.

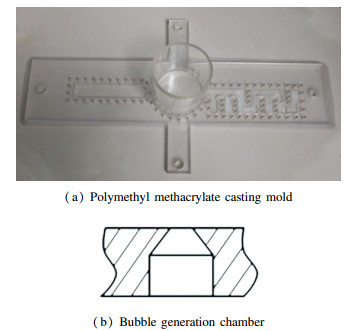

3.2 Hydraulic Experimental VerificationThe bubble migration in the titanium alloy melt during vertical centrifugal casting process is an invisible process due to its high temperature. Therefore, the hydraulic simulation experiments have been done to verify the bubble migration process by numerical simulation with the FLUENT software. The polymethyl methacrylate casting mold for physical simulation is shown Fig. 3(a), and the geometry of the bubble generation chamber is shown in Fig. 3(b). The simulated liquid in the experiment is water with certain amount of tackifier. The bubble migration process in the simulated liquid was taken by high speed digital camera, and the photographing frequency set as 1 000 frames per second.

|

Fig.3 Polymethyl methacrylate casting mold for physical simulation of bubble migration |

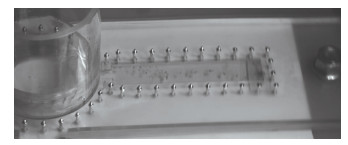

Fig. 4 shows the bubble migration contrail by the hydraulic experiments when the casting mould rotates clockwise at 300 r/min and the initial location of the gas bubble is (160, 0). Comparison between the hydraulic and the numerical simulation result shows that the bubble migration contrail obtained by numerical simulation is consistent with that of the hydraulic experiment, and the numerical simulations are reliable. Therefore, we will discuss the effects of different parameters on the bubble migration trajectories by the numerical simulation in the following sections.

|

Fig.4 Hydraulic experiment result of bubble migration contrail |

4 Discussions 4.1 Effect of Bubble Initial Location and Mould Rotation Direction on the Migration Contrail

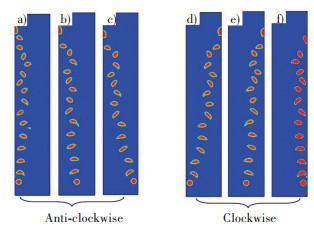

In this part, the effects of bubble initial location and mould rotational direction on bubble migration contrail in the TC4 alloy melt during vertical centrifugal casting process are studied. Fig. 5(a)-Fig. 5(f) are the bubble migration trajectories with different initial location when the casting mould rotates at 300 r/min. Fig. 5(a)-Fig. 5(c) are the bubble migration trajectories when the casting mould rotates anti-clockwise while Fig. 5(d)-Fig. 5(f) are the migration trajectories when the casting mould rotate clockwise.

|

Fig.5 Motion contrail of bubble with different initial location((a)(f) near the wall relative to the rotating direction; (b)(e) at the central line; (c)(d) near the wall the same as the rotating direction) |

The gas bubble located at (160, -10) (i.e. the bubble located at the position near the mould wall opposite to the mould rotational direction) migrates in a linear way to the rotation axis, and its migration contrail can be regarded as a straight line when the casting mould rotates anti-clockwise (as shown in Fig. 5(a)). When the gas bubble located at (160, 0) (i.e. the bubble located at center line of the two mould wall) and at (160, 10) (i.e. the bubble located at the position near the mould wall close to the mould rotational direction), the bubble migrations contain the radial movement forward to the casting rotation axis and the circular movement to the opposite direction of the rotational casting mould. And the gas bubble finally migrates like a line near the casting mould wall in the opposite direction to the rotation of the mould (as shown in Fig. 5(b) and Fig. 5(c) respectively) because of the impeditive effect of the casting mould wall on the circular movement.

When the casting mould rotates clockwise, the gas bubble located at (160, 10) (i.e. the bubble located at the position near the mould wall opposite to the mould rotational direction) migrates like a straight line to the rotation axis (as shown in Fig. 5(f)). While the gas bubble located at (160, 0) (i.e. the bubble located at center line of the two mould wall) and at (160, -10) (i.e. the bubble located at the position near the mould wall close to the mould rotational direction), the bubble migrations contain the radial movement forward to the casting rotation axis and the circular movement to the opposite direction of the rotational casting mould. And they finally migrate like a line near the casting mould wall (as shown in Fig. 5(d) and Fig. 5(e) respectively).

To summarize, the bubble located at the position near the mould wall opposite to the mould rotational direction migrates in a near linear way to the rotation axis, and its migration contrail can be regarded as a straight line whether the mould rotates clockwise or anti-clockwise. While the bubble located at center line of the two mould walls and at the position near the mould wall close to the mould rotational direction all finally migrate like a line near the casting mould wall in the opposite to the mould rotational direction. In addition, the moving speed of the bubble located at the position near the wall close to the mould rotational direction is lower, that of the bubble located at center line of the two mould walls is intermediate, and that of the bubble located at the position near the mould wall opposite to the rotational direction of the casting mould rotational direction is much faster. The results are irrelevant to the mould rotational direction whether the mould rotates clockwise or anti-clockwise.

Therefore, the bubble initial position has a significant influence on the bubble migration process in the TC4 alloy melt during vertical centrifugal casting process. And the bubble moving direction is greatly affected by the rotational direction of the casting mould. Accordingly, the bubbles at the position near the mould wall located at the opposite direction of the rotational casting mould are much easier to migrate in a straight line.

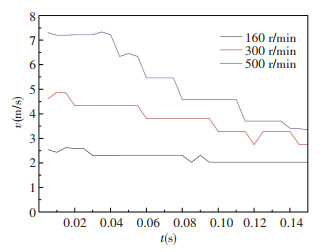

4.2 Bubble Instantaneous Velocity in TC4 MeltFig. 6 show instantaneous velocity of the gas bubble in TC4 alloy melt at different time under different mould rotational speed. The figures show that the instantaneous velocities of the gas bubble in vertical centrifugal field increases slightly at the primary stage and then decrease gradually in a ladder-like shape. On the other aspect, the velocity at different time increases with the increment of the casting mould rotational speed. This can be explained by the force analysis in the bubble migration process during the vertical centrifugal casting process.

|

Fig.6 Bubble instantaneous velocity in TC4 melt under different rotational speed |

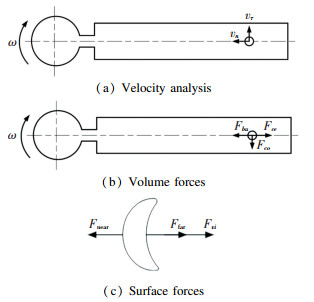

The rotational casting mould is selected as the reference frame when analyzing the force of the gas bubble in the titanium alloy melt. Fig. 7 shows the speed and force analysis during the migration of the bubble in liquid TC4 alloy melt during vertical centrifugal casting process.

|

Fig.7 Schematic of force analysis during migration of the bubble |

During vertical centrifugal casting process, the moving speed of the bubble migration in liquid TC4 alloy melt can be divided into the tangential velocity vτ and normal velocity vn (as shown in Fig. 7(a)). And the migration of gas bubble is influenced by the synthetic effect of the following volume forces (as shown in Fig. 7(b)), which are buoyancy force, centrifugal force and coriolis force (the gravity force is neglected in two-dimensional condition). In which, the centrifugal force Fce=mrω2 and the coriolis force Fco=2mvrω. The acceleration speed in vertical centrifugal casting process is g/rω2 times of that in the gravity casting process. Thus, the buoyancy force of bubble in liquid TC4 alloy melt is formed by the pressure difference in vertical centrifugal casting process, so the buoyancy force of bubble is as follows:

| $ {F_{bu}} = {\rho _m}r{\omega ^2}V $ | (5) |

In which, V is the volume of the gas bubble, and ρm is the density of the TC4 alloy melt.

Besides these volume forces, the migration of the gas bubble is still influenced by the surface forces, which are the viscous force and the surface tension between the liquid melt and the gas bubble (as shown in Fig. 7(c)). The bubble surface presents a hemisphere convex shape, and its radius is R. Thus, the surface tension between the bubble and the melt is

| $ F = \sigma \cdot 2{\rm{\pi}} R $ | (6) |

The surface tension of bubble near and far from the rotation axis are set as Ffar and Fnear. Quite evidently that the Fnear is almost equal to Ffar.

The viscous force of the bubble follow the Newton's Law of Viscosity, that is

| $ {F_{vi}} = \mu A\frac{{{\rm{d}}u}}{{{\rm{d}}x}} $ | (7) |

Therefore, the viscous force of the gas bubble continues changing during the whole migration process. It is proportional to the velocity gradient

Accordingly, the centrifugal force and the buoyancy force of the gas bubble are getting smaller during the bubble migration process to the rotation axis. While the viscous force and the surface tension between the liquid melt and the gas bubble remain constant during the whole migration progress. The resultant force of bubble at the axial direction is forward to the rotating shaft. Therefore, the bubbles under different mould rotational speed are in deceleration state, so the moving speeds of the gas bubbles are getting smaller and smaller.

In another aspect, the direciton of velocity vτ is opposite to that of the coriolis force. Thus, the casting mould wall has an impeditive effect on the circular movement of the bubble during its migration process. And the bubble finally migrates like a straight line near the mould wall in the opposite direction of the rotational casting mould. This also explained the phenomenon obtained in the front parts.

5 Conclusions(1) The bubble migration in the TC4 alloy melt under vertical centrifugal casting process can be divided into the radial movement to the mould rotation axis and the circular movement to the opposite direction of the rotational casting mould.

(2) The bubble finally migrates like a straight line. The bubbles at the position near the mould wall located at the opposite direction of the rotational casting mould are much easier to migrate in a straight line.

(3) The instantaneous velocity of bubble increases with the increase of the mould rotational speed. And it increases slightly at the primary stage, and then gradually decreases like ladder form regardless of the mould rotational speed is high or low.

| [1] |

Moiseyev V N. Application of Titanium Alloy in Russian Aircraft and Aerospace. Dong Baoming, Zhang Sheng, Guo Delun. Beijing: Aviation Industrial Publishing Press, 2008. (in Chinese)

(  0) 0) |

| [2] |

Jin Hexi, Wei Kexiang, Li Jianming, et al. Research development of titanium alloy in aerospace industry. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 280-292. (in Chinese) (  0) 0) |

| [3] |

Williams J C, Jr Starke E A. Progress in structural materials for aerospace systems. Acta Materialia, 2003, 51(19): 5775-5799. DOI:10.1016/j.actamat.2003.08.023 (  0) 0) |

| [4] |

Li X X, Zhang Q Y, Zhou Y, et al. Mild andsevere wear of Titanium alloys. Tribology Letters, 2016, 61(2): 14. DOI:10.1007/s11249-015-0637-8 (  0) 0) |

| [5] |

Kothari K, Radhakrishnan R, Wereley N M. Advances in gamma titanium aluminides and their manufacturing techniques. Progress in Aerospace Sciences, 2012, 55: 1-16. DOI:10.1016/j.paerosci.2012.04.001 (  0) 0) |

| [6] |

Siwiec G. Thekinetics of aluminium evaporation from the Ti-6Al-4V alloy. Archives of Metallurgy & Materials, 2013, 58(4): 1155-1160. DOI:10.2478/amm-2013-0141 (  0) 0) |

| [7] |

Zhou Y, Shen M X, Cai Z B, et al. Study on dual rotary fretting wear behavior of Ti6Al4V titanium alloy. Wear, 2017, 376-377. DOI:10.1016/j.wear.2016.10.027 (  0) 0) |

| [8] |

Wu Shi-ping, Xu Qin, Zhang Jun. Solidified structure of thin-walled titanium parts by vertical centrifugal casting. China Foundry, 2011, 18(2): 218-222. (  0) 0) |

| [9] |

Léopold G, Nadot Y, Billaudeau T, et al. Influence of artificial and casting defects on fatigue strength of moulded components in Ti-6Al-4V alloy. Fatigue & Fracture of Engineering Materials & Structures, 2015, 38(9): 1026-1041. DOI:10.1111/ffe.12326 (  0) 0) |

| [10] |

Li Yi. Research on investment precision casting process of large thin wall complex Ti-6Al-4V alloy. Titanium Industry Progress, 2012, 29(3): 22-25. (in Chinese) DOI:10.3969/j.issn.1009-9964.2012.03.006.(inChinese) (  0) 0) |

| [11] |

Sui Yanwei, Li Bangsheng, Liu Aihui, et al. Gas bubble nucleation in centrifugal casting liquid metal filling and flow process. Chinese Journal of Materials Research, 2008, 22(6): 580-584. (in Chinese) DOI:10.3321/j.issn:1005-3093.2008.06.004.(inChinese) (  0) 0) |

| [12] |

NetoR L, Duarte T P, Alves J L, et al. The influence of face coat material on reactivity and fluidity of the Ti6Al4V and TiAl alloys during investment casting. Proceedings of the Institution of Mechanical Engineers, Part L Journal of Materials: Design & Applications, 2017, 231(1-2): 38-48. DOI:10.1177/1464420716681824 (  0) 0) |

| [13] |

Shao Heng, Li Yan, Nan Hai, et al. Research on the interfacial heat transfer coefficient between casting and ceramic shell in investment casting process of Ti6Al4V alloy. Acta Metallurgica Sinica, 2015, 51(8): 976-984. DOI:10.11900/0412.1961.2015.00037 (  0) 0) |

| [14] |

Ermachenko A G, Lutfullin R Y, Mulyukov R R. Advanced Technologies of Processing Titanium Alloys and Their Applications. Reviews on Advanced Materials Science, 2011, 29(1): 68-82. (  0) 0) |

| [15] |

Plessis A D, Rossouw P. Investigation ofporosity changes in cast Ti6Al4V rods after hot isostatic pressing. Journal of Materials Engineering & Performance, 2015, 24(8): 3137-3141. DOI:10.1007/s11665-015-1580-4 (  0) 0) |

| [16] |

Zhou Yanbang. Titanium Alloy. Beijing: Aviation Industry Press, 2000. (in Chinese)

(  0) 0) |

2019, Vol. 26

2019, Vol. 26