2. Tata Steel, 1970 CA Ijmuiden, Netherlands

To reduce fuel consumption and exhaust-gas emissions of lighter weight vehicles, the application of aluminum alloys in the automotive fabrication industry has drawn much attention. 6xxx series alloys have been widely studied and utilized due to their excellent formability, age hardening ability, and recyclability. However, compared with steels, the strengths and formability of 6xxx series alloys still need to be largely enhanced[1-5].

As is known to all, Si is an essential element in the precipitation of 6xxx series alloys during aging treatment. It is normally accepted that the lattice parameters of different precipitate precursors or the precipitation sequence basically cannot be changed with the change of Si content, while the composition, distribution, and number density of precipitates can be greatly changed. Additionally, increasing Si content can enhance the tensile ductility and stretch formability of 6xxx series alloys, which mainly results from the increase of the work hardening and strain hardening capabilities[6-9]. In order to improve the age hardening response, effects of Cu and Zn additions on the age hardening behaviors of 6xxx series alloys have been widely studied in recent years[10-20]. It has been found that the normally observed β″ (Mg5Si6) phases in the Al-Mg-Si alloys could be replaced by some Cu-containing phases, such as Q′ (Al3Cu2Mg9Si7), QP (a=b=0.393, c=0.405), and QC (a=b=0.670, c=0.405), in Cu-containing Al-Mg-Si alloys[10-12]. The improved age hardening capability in peak aged alloys also contribute to the formation of coexisted Q′, β″, and their precursors. Therefore, Cu addition is of great importance for improving the strengths and age hardening ability[13-15] and has a significant impact on plasticity and formability[16]. Zn addition has also been applied to improve the age hardening response of Al-Mg-Si alloys[17-20]. Although it has been found that the age hardening response and strengths of Al-Mg-Si-(Cu) alloys can be both increased after adding Zn, the deep drawability of the Zn-containing alloys could be reduced in a certain level[21-22]. Thus, it is necessary to find a way to greatly increase the ductility and deep drawability of Zn-containing Al-Mg-Si-Cu alloys in order to meet the demanding requirements.

Additionally, it is well known that iron elements would be inevitably introduced in aluminum alloys during melting, which are often identified as impurity elements because of the formation of iron-rich phases and the low solubility in Al alloy matrices. For example, if Fe, Mn, and Si coexist in Al alloys, many coarse intermetallic particles (Al(FeMn)Si) could be observed in 6xxx series Al alloys. The existence of Al(FeMn)Si phases is often believed to have a negative effect on formability due to some micro-cracks distributed in the coarse particles after thermomechanical processes[23-25]. However, many researchers recently found that the transformation of plate-like β-AlFeSi phases to α-Al(FeMn)Si could occur during high temperature homogenization treatments, which could greatly reduce the negative impact of iron-rich phases on the formability and ductility of Al alloys[26-29]. The transformation rate is largely dependent on compositions (such as, Fe, Mn and Si contents, and Fe/Mn ratio[26]), homogenization temperature and time, as-cast microstructure, and so on. Compared with other elements, Si contents should not be paid less attention on the improvements in mechanical properties and formability due to their strong interactions with Fe, Mn, Mg, and Si elements, and significant influence on the formation, composition, size, morphology, and distribution of iron-rich phases in 6xxx series alloys.

Therefore, in order to improve the age hardening response and formability of Zn-containing Al-Mg-Si-Cu alloys, it is necessary to conduct a systematic study on the influence of Si contents on Zn-containing Al-Mg-Si-Cu alloys, whose results would hopefully provide guidance on the design, processing, and application of Zn-containing Al-Mg-Si-Cu alloys.

2 ExperimentsDetailed chemical compositions of the experimental Al alloys with different Si contents are listed in Table 1.

| Table 1 Composition of the three experimental Al alloys |

The raw materials (i.e., Al, Mg, Zn, Ni, Al-20wt.% Si, Al-50wt.% Cu, Al-20wt.% Fe, and Al-10wt.% Mn alloys) were melted in an electrical resistance furnace and then cast into a steel mould to obtain corresponding ingots. The cast ingots were homogenized at 545 ℃ for 24 h with a heat rate of 30 ℃ per hour and hot rolled into sheets (the thickness: 6 mm) at 545 ℃. Subsequently, the hot rolled sheets were cold rolled into 3 mm sheets followed by intermediate annealing (400 ℃ for 1 h), and then they were further cold rolled into sheets (the thickness: 1 mm). The final cold rolled alloy sheets were solid solution treated at 555 ℃ for 2 min in a salt bath furnace and immediately quenched into water at room temperature. Finally, they were pre-aged by cooling from 80 ℃ to 40 ℃ within 12 h.

The tensile properties, including ultimate strength (UTS), yield strength (YS), and elongation of the pre-aged Al-Mg-Si-Cu-Zn alloy sheets, were measured by using an MTS 810 electro-hydraulic servo universal performance machine. The microstructure evolution of the alloy sheets was analyzed by using a Carl Zeiss Axio Imager A2m optical microscope (OM). The analyzed samples were prepared by the standard metallographic techniques and the Keller's reagent (1.5vol% HCl + 95vol% H2O + 2.5vol% HNO3 + 1vol% HF). Additionally, the size, type, morphology, and distribution of different particles in the alloy sheets were analyzed by an SUPRA 55 field emission scanning electron microscope (SEM), whose samples were also prepared based on the standard metallographic techniques. The composition of the typically shaped phases was identified by X-ray energy dispersive spectrometers (EDS). The recrystallization texture of the sample after the solid solution treatment was analyzed by electron back scatter diffraction (EBSD) technique.

3 Results 3.1 Mechanical Property AnalysisThe deep drawability of Al alloys mainly depends on the strain hardening coefficient n and plasticity strain ratio r values. It indicates that r and n values are positively correlated with the deep drawability of many Al alloys, but the n values have little impact on the formability[30]. Hence, the average r and △r values are often used to display the deep drawability of 6xxx series alloys as follows[30]:

| $ \bar r = \left( {{r_0} + 2{r_{45}} + {r_{90}}} \right)/4 $ | (1) |

| $ r = \left( {{r_0} + {r_{\infty 0}} - 2{r_{45}}} \right)/2 $ | (2) |

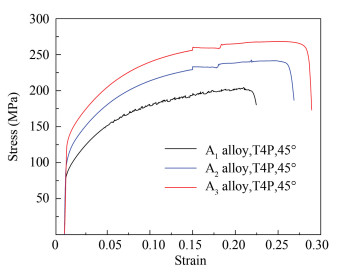

where r0, r45, r90 are the r values in 0°, 45°, and 90° directions with respect to the longitudinal direction (i.e., the rolling direction). It shows that the r45 value has a great influence on the average r and △r values. The detailed tensile properties of the pre-aged alloys in the 45° direction are presented in Table 2 and the tensile curves of the pre-aged alloy are shown in Fig. 1. It can be observed that the yield strength, ultimate tensile strength, and elongation of the pre-aged alloys were all increased with increasing Si content, which is essential for the forming of Al alloys used in automotive fields. It suggests that higher Si content could improve strengths and formability. Therefore, in order to clarify the reason behind this, the microstructure evolution of the alloys with different Si contents needs to be discussed in detail.

| Table 2 Tensile properties of the three pre-aged alloy sheets |

|

Fig.1 Tensile curves of the three pre-aged alloy sheets |

3.2 Microstructure Evolution

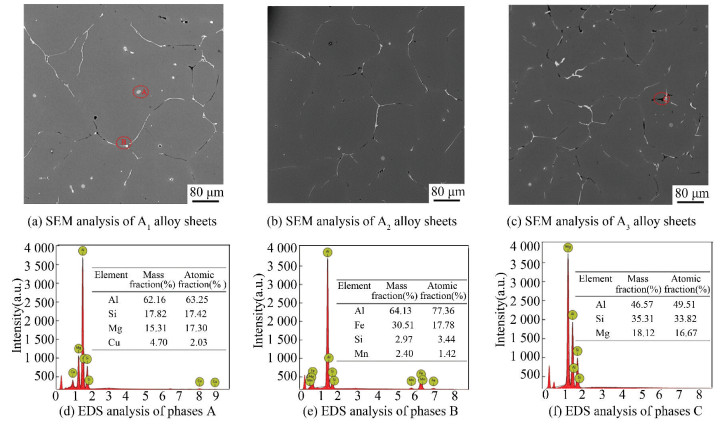

The SEM and EDS analyses of the experimental alloys in the as-cast condition are shown in Fig. 2, where four types of phases can be seen in the matrix. Based on the EDS analysis, the needle-like and spherical black particles were identified as Mg2Si and the spherical gray particles were identified as Q. Accordingly, a large number of plate-like white phases were identified as iron-rich phases (i.e., Al(FeMn)Si), which exhibits high density but small size in the matrix of alloys with high Si content. Additionally, the grain size was gradually reduced with increasing Si content. Therefore, it can be concluded that excess Si addition cannot only refine the size of as-cast grains but also the size of iron-rich phases.

|

Fig.2 SEM and EDS analyses of the alloys in the as-cast condition |

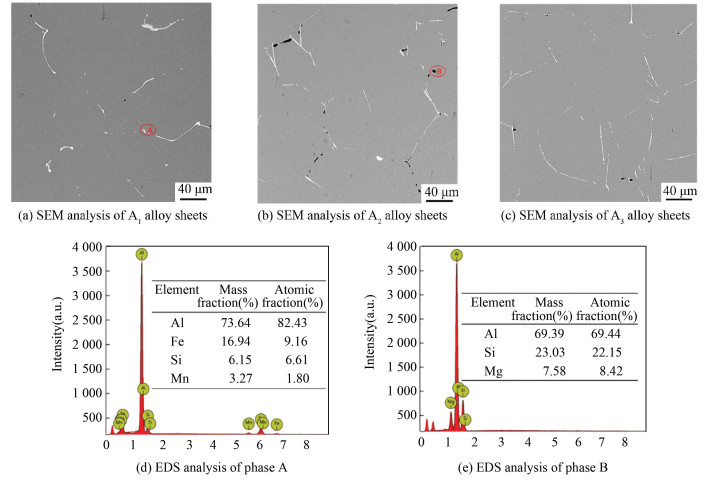

Compared with other treatments or processes, the homogenization process is a very important process, which has a great influence on the secondary phases of 6xxx series alloys and can improve formability and microstructure of the materials[28]. Fig. 3 shows the SEM and ESD analyses of the homogenized alloy sheets. It is clear that the needle-shaped Mg2Si almost all transformed to Mg2Si with a globular morphology and the Q phase particles basically dissolved back into the matrix. In addition, some plate-like iron-rich phases transformed to spherical iron-rich phases. Consistent with related studies, plate-like iron-rich phases (i.e., β-AlFeSi phases) always transform to multiple rounded iron-rich phases (i.e., α-AlFeMnSi phases) during homogenization[29, 31]. Even if some coarse needle-shaped iron-rich phases cannot transform to spherical iron-rich phases, they could be broken up into some smaller needle-like or lamellar iron-rich phases and the average size of the iron-rich phases is smaller with a higher Si content. Therefore, excess Si addition can promote the formation of some fine and spherical iron-rich phases during homogenization treatment, leading to a good rolling formability.

|

Fig.3 SEM and EDS analyses of the homogenized alloy sheets |

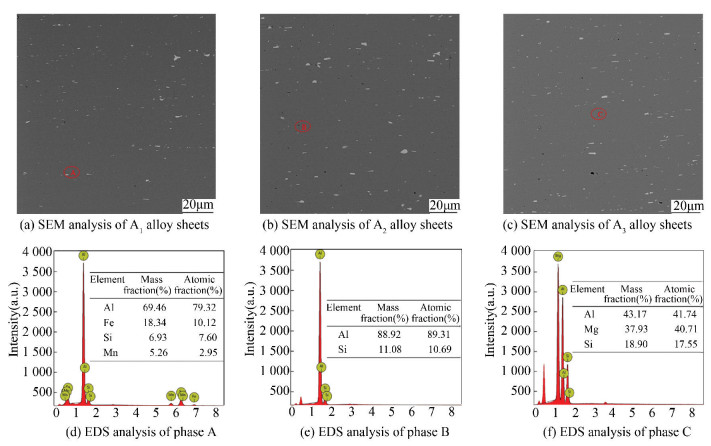

After the final cold rolling, all secondary phases tended to distribute along the direction of hot or cold rolling (as shown in Fig. 4) with two main kinds of phases distributed in the matrix. The EDS analysis shows that the white particles should be iron-rich phases (i.e., Al(FeMn)Si) and the black particles should be Mg2Si or Si phases. However, there was almost no Mg2Si or Si in the alloy sheet with the lowest Si content. The distribution of secondary phases was more homogeneous in the alloys after increasing the content of Si, but the number density of black particles gradually increased in high Si alloys. It suggests that excess Si addition has a positive influence on the distribution of iron-rich phases, while some Si phases could be precipitated in the matrix if the Si content (such as A3 alloy) increases greatly.

|

Fig.4 SEM and EDS analyses of the alloys in the final cold rolling condition |

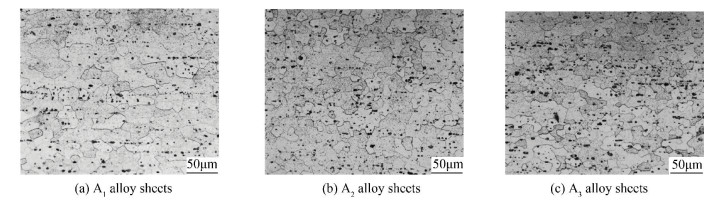

After solid solution treatment, the distribution and morphology of the secondary phases in the alloys basically remained unchanged compared with the final cold rolling state, as shown in Fig. 5. However, the black spherical particles basically disappeared, mainly due to the dissolution of Mg2Si or Si particles in the alloy matrix. Fig. 6 shows the recrystallized microstructures of the solution treated alloy sheets. It can be found that the microstructure characteristic was mainly composed of the equiaxed grains in the three alloys and the recrystallized grain size apparently decreased with the increase of the Si content. It can also be observed that the distribution and density of iron-rich phases (the black particles in Fig. 6) were consistent with that of metallographic observation, as shown in Fig. 4 and Fig. 5. The EBSD microstructures of the three alloys are shown in Fig. 7, where the grains with different colors show different ideal orientations. It can be concluded that grains with relatively low Si content are in anomalous growth in alloys. The average recrystallization grain sizes of A1, A2, and A3 alloy sheets were 23.9 μm, 20.7 μm, and 15.7 μm, respectively, which were the same as the optical microstructure (Fig. 6), and the grain orientation was more ideal with increasing Si content. In consequence, excess Si addition can refine the recrystallization microstructure and has a great influence on the recrystallization texture.

|

Fig.5 SEM analysis of the alloys in the solution condition |

|

Fig.6 Recrystallization microstructures of the alloys in the solution condition |

|

Fig.7 EBSD analysis maps of grain orientation in the three alloys in the solution condition |

4 Discussion 4.1 Effect of Si on Morphology and Distribution of Secondary Phases

The experiment shows that Si contents have a significant influence on the density and distribution of iron-rich phases in different processes. During die-casting, with the addition of excess Si, the formulation of plate-like β-AlFeSi intermetallic phases gradually increases along the grain boundary, resulting in grain size refinement (Fig. 2). In turn, the refined as-cast grain size leads to the refinement of the size of plate-like β-AlFeSi intermetallic phases.

As a result, the fine plate-like β-AlFeSi intermetallic phases in the alloy with a higher Si content can easily transform to a spherical α-Al(FeMn)Si phase during the homogenization (Fig. 3), which is beneficial to hot rolling formability. The distribution of iron-rich phases in the alloys is more homogeneous after the final cold rolling, as shown in Fig. 4. Moreover, with the addition of excess Si, some black spherical particles are identified as Mg2Si or Si particles distributed in the matrix, even though these phases will be dissolved back into the matrix after the solid solution treatment (Fig. 5 and Fig. 6). In addition, the morphology and distribution of the iron-rich phases in the alloys after the solid solution treatment remain basically unchanged but the recrystallization grain size apparently decreases with the increase of the Si content and the change of the ideal orientation of the grain. It indicates that the distribution of iron-rich phases has significant impact on the recrystallization of Al-Mg-Si-Cu-Zn alloys.

Hence, it can be concluded that Si contents can promote the transformation of plate-like β-AlFeSi phases into the spherical α-Al(FeMn)Si phases. The number density and homogeneous distribution level of precipitates in the final cold rolled alloys both increase with increasing Si content. The recrystallization grain can be refined with the addition of excess Si due to the influence of secondary particles after the final cold rolling, i.e., the simulated nucleation effect of coarse particle (Al(FeMn)Si particles) and the retarding effect of fine particles (Mg2Si or Si particles) on the recrystallization grains during high temperature heat treatment[32].

4.2 Effect of Si Contents on Mechanical PropertiesThe tensile properties of alloy sheets are mainly determined by the final microstructure. As mentioned above, with the addition of excess Si, the recrystallization grain size can be refined and the grain refinement is found beneficial to the strengths and formability. The yield strength is related to the grain size by Hall-Petch relationship[33], σYS=σ0+k/

Furthermore, the number density and homogeneous distribution level of precipitates in the final cold rolled alloys increase with the increase of the Si content. Although the number density and distribution of iron-rich phases remain unchanged during the solid solution treatment, some black spherical particles (Mg2Si or Si particles) are dissolved back into the alloy matrix and the grain orientation is more ideal with increasing Si content. It has been found in previous studies that the distribution of bimodal grain size could improve the plasticity of nanostructured alloys, which normally possesses a high strength but a low ductility[5, 34-35]. In our previous study[2], we found that the formability of Al-Mg-Si-Cu alloys can be improved by introducing reasonable iron-rich phases due to the formation of bimodal grain sized microstructure and the weakened textures in the T4P state alloys. The elongations of the pre-aged alloys in the direction of 45° are also increased with the increase of the Si content (Table 2). That is because the distribution of precipitates in the final cold rolling induces large particles to promote recrystallization (PSN) and fine particles to retard the movement of grain boundaries to prevent grain coarsening, which can lead to weak recrystallization textures (Fig. 7). Additionally, Ancote and Evans[36] mentioned that pure Si particles can be formed at grain boundaries with addition of excess Si content in the Al alloys, which will lead to intergranular fracture and the reduction of the formability. Therefore, the excess Si particles are also detrimental to the formability of A1 alloys. It can be found that the elongation of A3 alloy is slightly higher than A2 alloy (Table 2), which indicates that the addition of 1.0 wt% Si is still favorable to the tensile properties of Al-Mg-Si-Cu-Zn alloys, resulting from the positive effect on the distribution and number density of iron-rich phases. If the Si content is increased continually, the addition of excess Si should also have a negative effect on the improvement in the tensile properties and formability of Al-Mg-Si-Cu-Zn alloys.

5 ConclusionsThe microstructure evolution and tensile properties of Al-Mg-Si-Cu-Zn alloys with different Si contents were systematically investigated. It can be concluded that:

1) Si contents have a significant impact on the tensile properties of the Al-Mg-Si-Cu-Zn alloy sheets. The YS, UTS, and elongation of the pre-aged alloys in the direction of 45° were all increased with the increase of the Si content. Both the increased YS and UTS values resulted from the decrease of the recrystallization grain size. The number density and homogeneous distribution level of precipitates in the final cold rolled alloys increased with the increase of the Si content. As a result, the elongation value also increased with increasing Si content. However, with the addition of excess Si content, some Si particles precipitated in the matrix which is detrimental to the formability of Al-Mg-Si-Cu-Zn alloys, so the comprehensive effect of Si particles and iron-rich phases on formability remains for further study.

2) It can be found that Si contents have a significant impact on the density and distribution of iron-rich phases. Firstly, the as-cast grain size was gradually refined with increasing Si content due to the formation of many iron-rich phases and precipitates during the casting process. Then, the plate-like β-AlFeSi phase in the matrix with a higher Si content easily transformed to a spherical α-Al(FeMn)Si phase which is favorable for improving formability during homogenization treatment. Finally, the distribution of the iron-rich phases was more homogeneous in the final cold rolled alloys with increasing Si content, which further gave a positive effect on the formation of fine recrystallization grains during the subsequent solution treatment.

| [1] |

Hirsch J. Recent development in aluminium for automotive applications. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 1995-2002. DOI:10.1016/S1003-6326(14)63305-7 (  0) 0) |

| [2] |

Guo M X, Zhu J, Zhang Y, et al. The formation of bimodal grain size distribution in Al-Mg-Si-Cu alloy and its effect on the formability. Materials Characterization, 2017, 132: 248-259. DOI:10.1016/j.matchar.2017.08.013 (  0) 0) |

| [3] |

Remøe M S, Marthinsen K, Westermann I, et al. The effect of alloying elements on the ductility of Al-Mg-Si alloys. Materials Science and Engineering: A, 2017, 693: 60-72. DOI:10.1016/j.msea.2017.03.078 (  0) 0) |

| [4] |

Zhong H, Rometsch P, Estrin Y. Effect of alloy composition and heat treatment on mechanical performance of 6xxx aluminum alloys. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2174-2178. DOI:10.1016/S1003-6326(14)63329-X (  0) 0) |

| [5] |

Shakoori Oskooie M S, Asgharzadeh H, Kim H S. Microstructure, plastic deformation and strengthening mechanisms of an Al-Mg-Si alloy with a bimodal grain structure. Journal of Alloys and Compounds, 2015, 632: 540-548. DOI:10.1016/j.jallcom.2015.01.229 (  0) 0) |

| [6] |

Marioara C D, Andersen S J, Zandbergen H W, et al. The influence of alloy composition on precipitates of the Al-Mg-Si system. Metallurgical and Materials Transactions A, 2005, 36(3): 691-702. DOI:10.1007/s11661-005-0185-1 (  0) 0) |

| [7] |

Xu X, Yang Z, Ye Y, et al. Effects of various Mg/Si ratios on microstructure and performance property of Al-Mg-Si alloy cables. Materials Characterization, 2016, 119: 114-119. DOI:10.1016/j.matchar.2016.07.011 (  0) 0) |

| [8] |

Afify N, Gaber A, Mostafa M S, et al. Influence of Si concentration on the precipitation in Al-1at.% Mg alloy. Journal of Alloys and Compounds, 2008, 462(1-2): 80-87. DOI:10.1016/j.jallcom.2007.08.043 (  0) 0) |

| [9] |

Hirth S M, Marshall G J, Court S A, et al. Effects of Si on the aging behaviour and formability of aluminium alloys based on AA6016. Materials Science and Engineering: A, 2001, 319-321: 452-456. DOI:10.1016/S0921-5093(01)00969-8 (  0) 0) |

| [10] |

Saito T, Marioara C D, Andersen S J, et al. Aberration-corrected HAADF-STEM investigations of precipitate structures in Al-Mg-Si alloys with low Cu additions. Philosophical Magazine, 2013, 94(5): 520-531. DOI:10.1080/14786435.2013.857051 (  0) 0) |

| [11] |

Ding L, Jia Z, Nie J F, et al. The structural and compositional evolution of precipitates in Al-Mg-Si-Cu alloy. Acta Materialia, 2018, 145: 437-450. DOI:10.1016/j.actamat.2017.12.036 (  0) 0) |

| [12] |

Xiao Q, Liu H, Yi D, et al. Effect of Cu content on precipitation and age-hardening behavior in Al-Mg-Si-xCu alloys. Journal of Alloys and Compounds, 2017, 695: 1005-1013. DOI:10.1016/j.jallcom.2016.10.221 (  0) 0) |

| [13] |

Torsæter M, Lefebvre W, Marioara C D, et al. Study of intergrown L and Q' precipitates in Al-Mg-Si-Cu alloys. Scripta Materialia, 2011, 64(9): 817-820. DOI:10.1016/j.scriptamat.2011.01.008 (  0) 0) |

| [14] |

Svenningsen G, Larsen M H, Walmsley J C, et al. Effect of artificial aging on intergranular corrosion of extruded AlMgSi alloy with small Cu content. Corrosion Science, 2006, 48(6): 1528-1543. DOI:10.1016/j.corsci.2005.05.045 (  0) 0) |

| [15] |

Liu C H, Zhang X M, Tang J G, et al. Effect of copper on precipitation and baking hardening behavior of Al-Mg-Si alloys. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2289-2294. DOI:10.1016/S1003-6326(14)63346-X (  0) 0) |

| [16] |

Zhong H, Rometsch P A, Cao L, et al. The influence of Mg/Si ratio and Cu content on the stretch formability of 6xxx aluminium alloys. Materials Science and Engineering: A, 2016, 651: 688-697. DOI:10.1016/j.msea.2015.11.016 (  0) 0) |

| [17] |

Saito T, Ehlers F J H, Lefebvre W, et al. HAADF-STEM and DFT investigations of the Zn-containing β″ phase in Al-Mg-Si alloys. Acta Materialia, 2014, 78: 245-253. DOI:10.1016/j.actamat.2014.06.055 (  0) 0) |

| [18] |

Guo M X, Sha G, Cao L Y, et al. Enhanced bake-hardening response of an Al-Mg-Si-Cu alloy with Zn addition. Materials Chemistry and Physics, 2015, 162: 15-19. DOI:10.1016/j.matchemphys.2015.07.033 (  0) 0) |

| [19] |

Guo M X, Zhang Y, Zhang X K, et al. Non-isothermal precipitation behaviors of Al-Mg-Si-Cu alloys with different Zn contents. Materials Science and Engineering: A, 2016, 669: 20-32. DOI:10.1016/j.msea.2016.05.060 (  0) 0) |

| [20] |

Yan L, Zhang Y, Li X, et al. Effect of Zn addition on microstructure and mechanical properties of an Al-Mg-Si alloy. Progress in Natural Science: Materials International, 2014, 24(2): 97-100. DOI:10.1016/j.pnsc.2014.03.003 (  0) 0) |

| [21] |

Wang X, Guo M, Zhang J, et al. Effect of Zn addition on the microstructure, texture evolution and mechanical properties of Al-Mg-Si-Cu alloys. Materials Science and Engineering: A, 2016, 677: 522-533. DOI:10.1016/j.msea.2016.09.084 (  0) 0) |

| [22] |

Wang X, Guo M, Luo J, et al. Effect of Zn on microstructure, texture and mechanical properties of Al-Mg-Si-Cu alloys with a medium number of Fe-rich phase particles. Materials Characterization, 2017, 134: 123-133. DOI:10.1016/j.matchar.2017.10.012 (  0) 0) |

| [23] |

Ji S, Yang W, Gao F, et al. Effect of iron on the microstructure and mechanical property of Al-Mg-Si-Mn and Al-Mg-Si diecast alloys. Materials Science and Engineering: A, 2013, 564: 130-139. DOI:10.1016/j.msea.2012.11.095 (  0) 0) |

| [24] |

Zhao Q, Qian Z, Cui X, et al. Influences of Fe, Si and homogenization on electrical conductivity and mechanical properties of dilute Al-Mg-Si alloy. Journal of Alloys and Compounds, 2016, 666: 50-57. DOI:10.1016/j.jallcom.2016.01.110 (  0) 0) |

| [25] |

Shivkumar S, Wang L, Apelian D. Molten metal processing of advanced cast aluminum alloys. JOM, 1991, 43(1): 26-32. DOI:10.1007/BF03220114 (  0) 0) |

| [26] |

Kuijpers N C W, Vermolen F J, Vuik C, et al. The dependence of the β-AlFeSi to α-Al(FeMn)Si transformation kinetics in Al-Mg-Si alloys on the alloying elements. Materials Science and Engineering: A, 2005, 394(1-2): 9-19. DOI:10.1016/j.msea.2004.09.073 (  0) 0) |

| [27] |

Sweet L, Zhu S M, Gao S X, et al. The effect of iron content on the iron-containing intermetallic phases in a cast 6060 aluminum alloy. Metallurgical and Materials Transactions A, 2011, 42(7): 1737-1749. DOI:10.1007/s11661-010-0595-6 (  0) 0) |

| [28] |

Johannes Albert Österreicher, Kumar M, Schiffl A, et al. Secondary precipitation during homogenization of Al-Mg-Si alloys: Influence on high temperature flow stress. Materials Science & Engineering A, 2017, 687: 175-180. DOI:10.1016/j.msea.2017.01.074 (  0) 0) |

| [29] |

Bayat N, Carlberg T, Cieslar M. In-situ study of phase transformations during homogenization of 6005 and 6082 Al alloys. Journal of Alloys & Compounds, 2017, 725: 504-509. DOI:10.1016/j.jallcom.2017.07.149 (  0) 0) |

| [30] |

Leu D K. Prediction of the limiting drawing ratio and the maximum drawing load in cup-drawing. International Journal of Machine Tools & Manufacture, 1997, 37(2): 201-213. DOI:10.1016/0890-6955(95)00107-7 (  0) 0) |

| [31] |

Kuijpers N C W, Kool W H, Koenis P T G, et al. Assessment of different techniques for quantification of α-Al(FeMn)Si and β-AlFeSi intermetallics in AA 6xxx alloys. Materials Characterization, 2002, 49(5): 409-420. DOI:10.1016/S1044-5803(03)00036-6 (  0) 0) |

| [32] |

Sidor J, Petrov R H, Kestens L A I. Deformation, recrystallization and plastic anisotropy of asymmetrically rolled aluminum sheets. Materials Science and Engineering: A, 2010, 528(1): 413-424. DOI:10.1016/j.msea.2010.09.023 (  0) 0) |

| [33] |

Hansen N. Hall-Petch relation and boundary strengthening. Scripta Materialia, 2004, 51(8): 801-806. DOI:10.1016/j.scriptamat.2004.06.002 (  0) 0) |

| [34] |

Han B O, Lavernia E J, Lee Z, et al. Deformation behavior of bimodal nanostructured 5083 Al alloys. Metallurgical and Materials Transactions A, 2005, 36(4): 957-965. DOI:10.1007/s11661-005-0289-7 (  0) 0) |

| [35] |

Witkin D, Lee Z, Rodriguez R, et al. Al-Mg alloy engineered with bimodal grain size for high strength and increased ductility. Scripta Materialia, 2003, 49(4): 297-302. DOI:10.1016/S1359-6462(03)00283-5 (  0) 0) |

| [36] |

Aucote J, Evans D W. Effects of excess silicon addition on ductility of Al-0.95%Mg2Si alloy. Metal Science, 1978, 12(2): 57-63. DOI:10.1179/msc.1978.12.2.57 (  0) 0) |

2020, Vol. 27

2020, Vol. 27