Cement asphalt composite binder (CACB) is composed of cement, asphalt, water, and various additives through curing[1-3]. Possessing both cement and asphalt characteristics, it exhibits a certain degree of strength as well as significant flexibility and deformability[4-6]. It is thus widely used in transportation infrastructure construction.

As a semi-flexible binder, CACB can be used as binder for semi-flexible bases and sub-bases in highways to prevent reflection cracks[7-8] or as a sealant in pavement maintenance[9-10]. To serve the purposes of a binder, it demands a certain degree of flexibility and deformability. As a type of viscoelastic material, the deformability of CACB is closely related to creep properties. Furthermore, as typical viscoelastic material, the viscoelastic properties of asphalt change with asphalt aging[11-13], so do the creep properties of the CACB.

Asphalt aging and its effects on the properties of asphalt mixture have been extensively studied[14-16]. However, studies on the effects of asphalt aging on CACB creep properties are relatively scarce. Therefore, further research on asphalt aging and CACB creep properties is highly necessary.

2 Materials and Test Schemes 2.1 Raw Materials and Mix ProportionsOrdinary Portland cement with a strength grade of 42.5 and cationic emulsified asphalt with a solid content of 60% were used. The admixture consisted of polyurethane thickening agent, lignin water reducer, and organosilicon defoamer. The mass ratios of emulsified asphalt and cement (A/C) were 1.0, 1.2, and 1.4, while the water and cement ratio was 0.8. The technical properties of the cement and emulsified asphalt are listed in Tables 1-2, while the raw material mix proportions (where cement mass was used as the unit) are displayed in Table 3.

| Table 1 Technical properties of emulsified asphalt |

| Table 2 Technical properties of cement |

| Table 3 Mix proportions of CACB |

2.2 Test Methods 2.2.1 Heat aging test

An accelerated heat aging test was conducted. After a curing period of 28 d, specimens were placed in the oven for heating, and the test temperature was 150±2 ℃, while the aging times were 4, 8, 12, 18, and 24 h.

2.2.2 Creep testA dynamic shear rheometer was used for the CACB creep test. Both the original specimens and those after aging were tested. The test temperature was 25±0.2 ℃ and the duration of each test was 1 200 s.

2.3 Mechanical Model and Creep EquationTaking the effects of aging on the viscoelastic properties of CACB into consideration, the Burgers model revised by fractional derivative was used to describe the mechanical behavior of the CACB. The viscoelastic mechanical model (Fig. 1) is composed of Maxwell unit and revised Kelvin unit, in which an Abel dashpot replaces the Newton dashpot and five material parameters E1, E2, η1, η2, and r are used. The model differs from the Burgers model mainly in terms of the introduction of the Abel dashpot containing a fractional derivative, thus it is referred to as the Burgers model revised by fractional derivative. The constitutive relation of the Abel dashpot is as follows:

|

Fig.1 Burgers model revised by fractional derivative |

| $ σ_{2}=η_{2}ε^{(r)} $ | (1) |

The value of fractional derivative r is within the range of 0 to 1. The material becomes completely elastic-like when r approaches 0 and completely viscous-like when r approaches 1. The change in r during the aging process can characterize the change in the elastic-viscous component ratio in the CACB, and the effects of aging on the CACB viscoelastic properties can be analyzed thoroughly using r.

The model creep compliance consists of three parts, namely, compliance of the independent spring, independent dashpot, and revised Kelvin unit. The creep compliances J1(t), J2(t), and J3(t) characterize the instant elastic deformation, viscous flow deformation, and delayed elastic deformation of the viscoelastic deformation, respectively. The instant elastic and viscous flow deformation are a result of the elastic and viscous components in the material respectively, while the delayed elastic deformation is due to the interaction between the two components. As typical viscoelastic material, the aging of asphalt influences its viscoelastic properties and composite binder creep properties. By analysis of the material creep compliance through aging, the effects of asphalt aging on the CACB creep properties can be further studied.

The creep compliance of the dependent spring of the Maxwell unit is as follows:

| $ J_{1}(t)= \frac{{ 1 }}{{E_{1}}} $ | (2) |

The creep compliance of the dependent dashpot of the Maxwell unit is as follows:

| $ J_{2}(t)= \frac{{t}}{{ η_{1} }} $ | (3) |

The constitutive equation of the revised Kelvin unit with the Abel dashpot is as follows:

| $ σ=Eε_{2}+ηε^{(r)}_{2} $ | (4) |

Eq.(4) was transformed from Laplace into the equation below:

| $ \bar σ _{2}(S)=(E_{2}+η_{2}S^{r})\bar ε _{2}(S) $ | (5) |

The Laplace transformation equation of the revised Kelvin unit with the Abel dashpot is as follows:

| $ \bar J _{3}(S)= \frac{{1}}{{ S(E_{2}+η_{2}S^{r})}} $ | (6) |

Eq.(6) was calculated by infinite series expansion and then inverse Laplace transformation, and the result is as follows:

| $ J_{3}(t)= \frac{{1}}{{ E_{2}}} \sum\limits^∞_{1} \frac{{ (-1)^{n}(E_{2}/η_{2})^{n+1}t^{(n+1)r}}}{{\varGamma [(n+1)r+1]}} $ | (7) |

The item n= -1 was added to the infinite series and subtracted out of it at the same time, and the result is as follows:

| $ J_{3}(t)= \frac{{1}}{{ E_{2} }}\sum\limits^∞_1 \frac{{ (-t^{r}E_{2}/η_{2})^{n}}}{{ \varGamma (nr+1) }} $ | (8) |

The composite binder creep process is related to load duration. Consequently, Eq.(8) was approximated by assigning r in the Gamma function as 1 and retaining the parameter r as the load duration index. Finally, Γ(n+1)=n! was put into the equation, and the result is as follows:

| $ J_{3}(t)= \frac{{1}}{{ E_{2}}} \sum\limits^∞_1 \frac{{ (-t^{r}E_{2}/η_{2})^{n}}}{{ n!}} $ | (9) |

According to the equation below:

| $ { e}^{x}=1+x+ \frac{{x^{2}}}{{ 2}} +…+ \frac{{x^{n}}}{{ n!}} $ | (10) |

where x in the above equation was assigned as:

| $ x=- \frac{{E_{2}t^{r}}}{{ η_{2}}} $ | (11) |

Eq.(11) was then put into Eq.(10) and combined with Eq.(9). The creep compliance of the revised Kelvin unit with the Abel dashpot was established as follows:

| $ J_{3}(t)= \frac{{ 1}}{{ E_{2} }}(1-{ e}^{- \frac{{E_{2}}}{{ η_{2}}} t^r}) $ | (12) |

According to the superposition principle, the creep compliance of the Burgers model revised by fractional derivative is as follows:

| $ J(t)=J_{1}(t)+J_{2}(t)+J_{3}(t) $ | (13) |

The creep compliance of the Burgers model revised by fractional derivative was established as follows:

| $ J(t)= \frac{{ 1}}{{ E_{1}}} + \frac{{t}}{{ η_{1}}} + \frac{{1}}{{ E_{2}}} (1-{ e}^{- \frac{{E_{2}}}{{ η_{2} }}·t^r}) $ | (14) |

where E1 represents elastic modulus of the spring in the Maxwell unit, η1 represents viscous coefficient of the dashpot in the Maxwell unit, E2 represents elastic modulus of the spring in the revised Kelvin unit, and η2 and r represent viscous coefficient and fractional derivative of the dashpot in the revised Kelvin unit, respectively.

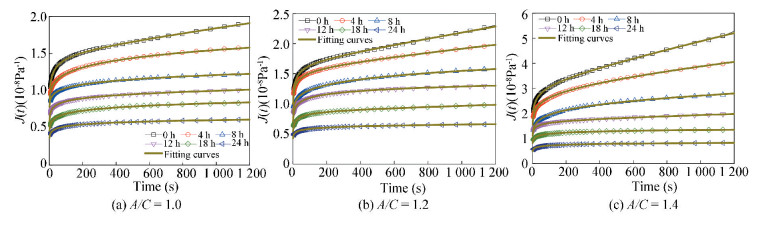

3 Test Results and FittingThe CACB creep compliance curves were obtained from the creep test on specimens with various aging times. The curves were fitted using Eq.(14). The fitting results are illustrated in Fig. 2 and the fitting parameters are displayed in Table 4.

|

Fig.2 Fitting of creep curves |

| Table 4 Major fitting parameters of Burgers model revised by fractional derivative |

The fitting results demonstrate that Eq.(14) exhibited high fitting precision, and the Burgers model revised by fractional derivative effectively described the mechanical properties of the CACB after aging.

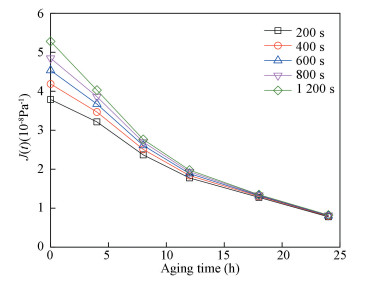

4 Analysis of Test and Fitting Results 4.1 Effects of Aging on DeformabilityThe physical significance of the creep compliance J(t) is represented by the material strain under a unit load at an action time of a certain load t, and can characterize the material deformability. For the CACB with an A/C of 1.4, the creep compliance at 200, 400, 600, 800, and 1200 s are illustrated in Fig. 3, which shows that the material deformability decreased sharply as aging time increased. By reference to the creep compliance curve characteristic of an increasing function of load duration, it is found that the creep compliance increased with increasing load duration for the material that underwent the same aging time. Fig. 3 further indicates that as the aging time increased, the material creep compliance gap at different load durations narrowed and the compliance values tended to be close, demonstrating that the material deformability decreased through the aging process.

|

Fig.3 Effects of aging on creep compliance |

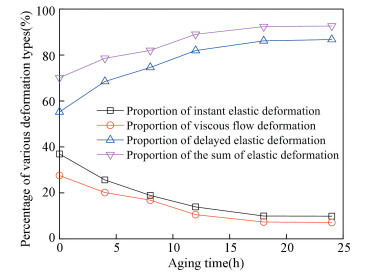

According to the fitting result of Eq.(14), the percentages of the instant elastic, viscous flow, and delayed elastic deformations in the viscoelastic deformation can be analyzed. For the CACB with an A/C of 1.4, the effects of aging time on the relative proportions of the three deformation types at a load duration of t=1 200 s are shown in Fig. 4.

|

Fig.4 Effects of aging on deforming properties |

Fig. 4 illustrates that with increasing aging time, the proportions of the instant elastic and viscous flow deformations were reduced, but that of the delayed elastic deformation increased. Furthermore, both the instant and delayed elastic deformation are essentially recoverable elastic deformation, thus their sum characterizes the material elastic component. The proportion of the elastic deformation sum increased obviously with aging time, which indicates that as asphalt aging deepened, the CACB deformability tended to be elastic-like.

According to Figs. 3-4, the curves develop fully in two stages according to the aging time. When the aging time was within 12 h, the creep compliance and various deformation components varied sharply as aging time increased. When the aging time was more than 12 h, the variation trend of the curves slowed down. During the initial aging stage, a severe oxidation reaction occurred in the asphalt and a large amount of saturates and aromatics were converted into resins and asphaltenes, causing an obvious change in material properties. As the aging process continued, the light components in the asphalt reduced sharply and the oxidation reaction degree weakened, which made the material viscoelastic properties stable.

As asphalt aging progressed, the mechanical properties of the asphalt in the CACB changed from viscoelastic to elastic, which contributed to CACB stiffening. Furthermore, as asphalt aging deepened, the CACB deformability decreased and its mechanical properties tended to be elastic-like.

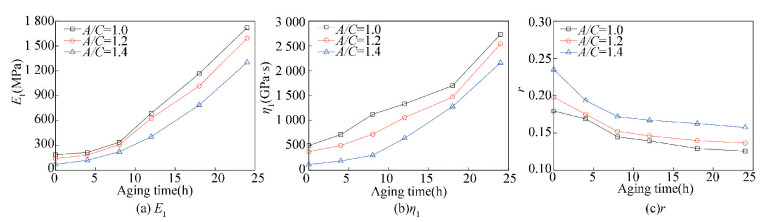

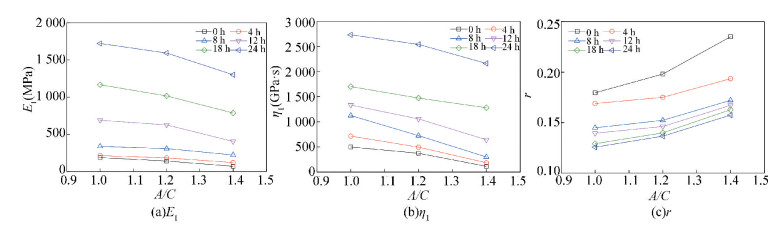

4.2 Effects of Aging on ParametersAccording to the creep compliance fitting results of creep compliance, three major material parameters of the CACB with different mix proportions under various aging times were obtained, namely E1, η1, and r, and their changes with increasing aging time are illustrated in Fig. 5, which demonstrates that as aging time increased, E1 and η1 of the CACB increased, indicating that as asphalt aging deepened, the ability of the material to resist instant elastic and viscous flow deformation was enhanced and its deformability weakened. Moreover, r of the CACB decreased with increasing aging time, which shows that the elastic component proportion in the material increased and that of the viscous component was reduced, and the CACB properties tended to be elastic-like.

|

Fig.5 Effect of aging time on material parameters |

Heat aging caused both the elastic and viscous deformability of the material to decrease, but the viscous deformability declined more sharply, thus the CACB tended to be elastic-like. For example, for the CACB with an A/C of 1.2, E1, η1, and r were 309.41 MPa, 725.14 GPa·s, and 0.152 3 at an aging time of 8 h, respectively, while these values were 1 593.8 MPa, 2 541.1 GPa·s, and 0.136 6 at an aging time of 24 h, respectively. Therefore, aging had a significant influence on the viscoelastic mechanical parameters of the CACB.

Fig. 5 also indicates that the parameter variation trends developed fully in two stages according to the aging time, with the dividing point being an aging time of 12 h. This rule is in agreement with the above conclusion.

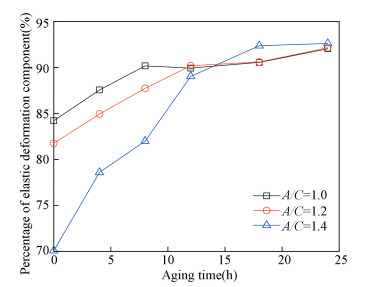

4.3 Effects of Asphalt Content on DeformabilityChanges in elastic deformation in the sum deformation of the composite binder with various asphalt contents at a load duration of t=1 200 s are shown in Fig. 6.

|

Fig.6 Effects of asphalt application on material deforming properties |

Fig. 6 illustrates that when the aging time was within 12 h, the elastic deformation proportion in the sum creep deformation reduced with increasing asphalt content, while the viscous deformation proportion increased. The figure shows that within a certain aging time range, increasing asphalt content improved CACB deformability, which subsequently improved anti-aging ability. Thus, the CACB may still exhibit effective deformability after aging.

When the aging time was over 12 h, the elastic deformation proportion in the sum creep deformation of the CACB with different asphalt contents was basically the same, which demonstrates that with a long aging time, asphalt content had less influence on the material deformability. Furthermore, increasing the asphalt content in this condition was not effective in improving the CACB deformability. When aging lasted for a long time, the CACB tended to become elastic-like due to the deep aging of the asphalt, thus asphalt content had less influence on the material deformability.

4.4 Effects of Asphalt Content on ParametersThe material parameters of the CACB with various asphalt contents after the same aging times are illustrated in Fig. 7, which shows that after the same aging time, E1 and η1 of the CACB decreased with increasing asphalt content, the ability of the material to resist instant and shear deformation weakened, and the material deformability was enhanced. After the same aging time, r of the CACB increased with increasing asphalt content, and the viscous component proportion in the material also increased. For example, after 18 h of aging, r of the CACB with an A/C of 1.0, 1.2, and 1.4 was 0.129 2, 0.139 9, and 0.162 8, respectively, E1 was 1 167.1, 1 017.1, and 787.96 MPa, respectively, and η1 was 1 701.3, 1 472.6, and 1 280.5 GPa·s, respectively. Taking aging into consideration, the material could be more viscoelastic, and its deformability could be maintained at a high level by increasing the asphalt content appropriately.

|

Fig.7 Effects of asphalt application on material parameters |

4.5 Aging Characterization and Its Evolution Model

The fractional derivative r reflects the effect nature of aging on viscoelastic properties of the CACB to a large extent, which is the most representative parameter. Thus, an aging influence factor of CACB was established based on parameter r, which is defined as

| $ D_{t}=1- \frac{{r_{t}}}{{ r_{0}}} $ | (15) |

where Dt represents aging influence factor of CACB after t time of aging, rt represents fractional derivative of t of CACB after t time of aging, and r0 represents fractional derivative of t of CACB without aging.

Because r reduced with increasing aging time, the range of Dt was [0, 1] according to its definition formula, and Dt monotonically increased with increasing aging time. A larger Dt indicates that after aging, the viscous component of CACB and deformability reduced more, and aging affected the material properties more seriously.

The Dt of CACB after different aging times were calculated by their r, which are listed in Table 5.

| Table 5 Aging influence factor of CACB |

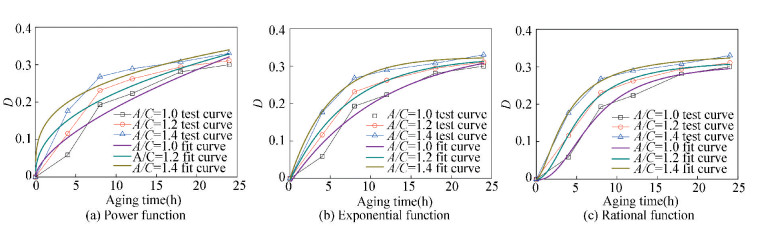

The evolution models of CACB aging characterization were established by the fitting of the aging influence factor curves. Three functions used in fitting are as below:

a) Power function:

| $ y=ax^{b} $ | (16) |

b) Exponential function:

| $ y=c_{1}(1-{ e}^{-x/d_{1}})+c_{2}(1-{ e}^{-x/d_{2}}) $ | (17) |

c) Rational function:

| $ y=f(1- \frac{{1}}{{ 1+(x/g)^{h}}} ) $ | (18) |

where a, b, c1, c2, d1, d2, f, g, h are undetermined parameters.

The fit curves of the CACB aging influence factor are illustrated in Fig. 8, and the fitting parameters of power function, exponential function, and rational function are listed in Tables 6-8.

|

Fig.8 The fit curves of the CACB aging influence factor |

| Table 6 Power function fit curves of aging influence factor |

| Table 7 Exponential function fit curves of aging influence factor |

| Table 8 Rational function fit curves of aging influence factor |

According to Tables 6-8, rational function fitted the CACB aging influence factor curve best, which is appropriate for the evolution model of CACB aging characterization. Fitting accuracy of three functions all increased with increasing asphalt content, which is in agreement with the conclusion proposed in the fitting part of the constitutive model.

In summary, the aging influence factor D can characterize the effects of aging time and asphalt content well, which is applicable for the CACB aging characterization. The rational function fitted the CACB aging influence factor curve well, which is appropriate for the evolution model of CACB aging characterization.

5 Conclusions1) As aging time increased, the creep compliance of the CACB decreased and its deformability weakened. As asphalt aging deepened, the instant elastic and viscous flow deformation proportions decreased, while as the delayed elastic deformation proportion increased, and the CACB deforming properties tended to be elastic-like.

2) As aging time increased, E1 and η1 of the CACB increased, while r decreased. As asphalt aging deepened, the ability of the material to resist instant elastic and viscous flow deformation was enhanced, the elastic component proportion in the material increased while the viscous component reduced, and the material deformability weakened.

3) The effects of asphalt aging on the CACB properties were related to aging time and developed into two stages. During the initial stage (aging time within 12 h), the aging time significantly influenced the viscoelastic mechanical properties of the material. During the latter stage (aging time over 12 h), aging time had less influence on the viscoelastic mechanical properties of the material.

4) During the initial aging stage, increasing asphalt content appropriately improved the CACB deformability. During the latter aging stage, the CACB deformability with various asphalt contents was basically the same.

5) The aging influence factor D can characterize the effects of aging time and asphalt content well, the rational function fitted the CACB aging influence factor curve well, which is appropriate for the evolution model of CACB aging characterization. References

| [1] |

Tan Y Q, Ouyang J, Lv J F, et al. Effect of emulsifier on cement hydration in cement asphalt mortar. Construction and Building Materials, 2013, 47: 159-164. DOI:10.1016/j.conbuildmat.2013.04.044 (  0) 0) |

| [2] |

Wang Y, Yuan Q, Deng D H, et al. Measuring the pore structure of cement asphalt mortar by nuclear magnetic resonance. Construction and Building Materials, 2017, 137: 450-458. DOI:10.1016/j.conbuildmat.2017.01.109 (  0) 0) |

| [3] |

Jiang J Y, She W, Li W, et al. Effect of functional chemical admixtures on the performance of cement asphalt mortar used in ballastless track. Journal Wuhan University of Technology (Materials Science Edition), 2015, 30(5): 995-1000. DOI:10.1007/s11595-015-1263-x (  0) 0) |

| [4] |

Qiu K C, Chen H S, Ye H P, et al. Thermo-mechanical coupling effect on fatigue behavior of cement asphalt mortar. International Journal of Fatigue, 2013, 51: 116-120. DOI:10.1016/j.ijfatigue.2013.01.001 (  0) 0) |

| [5] |

Fu Q, Xie Y J, Long G C, et al. Dynamic mechanical thermo-analysis of cement and asphalt mortar. Powder Technology, 2017, 313: 36-43. DOI:10.1016/j.powtec.2017.02.058 (  0) 0) |

| [6] |

Xi S Z. Advance of emulsified asphalt cement mortar. World of Construction Materials, 2012, 33(3): 49-52. (in Chinese) DOI:10.3963/j.issn.1674-6066.2012.03.0140 (  0) 0) |

| [7] |

Sun D G, Wang B, Zhu X S, et al. Performances and application of cement and emulsified asphalt stabilized macadam. Journal of Highway and Transportation Research and Development, 2007, 24(8): 27-31. (in Chinese) (  0) 0) |

| [8] |

Geng J G, Chen Z D, Li L, et al. Mixing design of cement emulsified asphalt cold recycled mixture (CEACRM). Journal of Chang'an University (Natural Science Edition), 2009, 29(1): 10-14. (in Chinese) DOI:10.19721/j.cnki.1671-8879.2009.01.003 (  0) 0) |

| [9] |

Zhang W, Liang M, Fan W Y, et al. Recent advances in asphalt pavement crack filling materials. Petroleum Asphalt, 2015, 29(2): 6-12. (in Chinese) (  0) 0) |

| [10] |

Li J S, Xu G D, Chen Y Z, et al. Multiple scaling investigation of magnesium phosphate cement modified by emulsified asphalt for rapid repair of asphalt mixture pavement. Construction and Building Materials, 2014, 69: 346-350. DOI:10.1016/j.conbuildmat.2014.07.079 (  0) 0) |

| [11] |

He L, Ling T Q, Ma Y, et al. Research on asphalt rubber aging performance and characteristics. Journal of Building Materials, 2015, 18(4): 565-571. (in Chinese) DOI:10.3969/j.issn.1007-9629.2015.04.006 (  0) 0) |

| [12] |

Li N L, Zhao X P, Sun J S, et al. Effect of aging on the high-temperature rheological properties of rubber-modified asphalt. Highway, 2015, 2: 165-168. (in Chinese) (  0) 0) |

| [13] |

Zhang J P, Liu G Q, Du H, et al. Rheological properties of warm mix asphalt binder by DSR test at medium temperature. Journal of Southeast University (English Edition), 2015, 31(3): 384-388. DOI:10.3969/j.issn.1003-7985.2015.03.015 (  0) 0) |

| [14] |

Zhu H Z, Zhang X Y. Effect of asphalt aging on pavement performance of asphalt mixture. Journal of Liaoning Technical University (Natural Science), 2016, 35(10): 1144-1148. (in Chinese) DOI:10.11956/j.issn.1008-0562.2016.10.025 (  0) 0) |

| [15] |

Ma L X. Research on the Viscoelastic Properties of Asphalt and Asphalt Mixture in the Process of Aging. Wuhan: Wuhan University of Technology, 2012, 1-15. (  0) 0) |

| [16] |

Yang S, Braham A, Wang L F, et al. Influence of aging and moisture on laboratory performance of asphalt concrete. Construction and Building Materials, 2016, 115: 527-535. DOI:10.1016/j.conbuildmat.2016.04.063 (  0) 0) |

2020, Vol. 27

2020, Vol. 27