2. University of Chinese Academy of Sciences, Beijing 100049, China

As the representative of high temperature superconducting (HTS), REBa2Cu3O7-x (REBCO) has been intensively investigated, due to its high critical current density (Jc), high critical transition temperature (Tc), high irreversible field (Hirr), and low AC loss. The most conventional products of REBCO are coated conductors, which mainly come from two processes: ion-beam-assisted deposition (IBAD) and rolling-assisted biaxially textured substrate (RABiTs). There are already multiple excellent reports on the fabrication of REBCO coated conductors[1-12].

Research on REBCO is not restricted to the lab. In the past decades, a huge number of large scale electrical applications using REBCO have been reported, including motors[13-15], generators[16-17], cables[18-21], SMES[22-23], current limiters[24-26], transformers[27-28], and current leads[29]. The most outstanding application of the REBCO is to use it as an insert coil in a high magnetic field facility. The world record d.c. magnetic field value is 45.5 T with a 14.38 T REBCO insert in a 31.08 T resistive magnet[30]. Multiple whole superconductor high magnetic field instruments have been fabricated, such as 30.5 T in RIKEN[31], 26.4 T in SuNAM[32], and 32 T in National High Magnetic Field Laboratory (Maglab)[33]. In 2019, our group in the Institute of Electrical Engineering, Chinese Academy of Sciences (IEE CAS) successfully reached 32.35 T by using REBCO as an insert coil, which is the world-record magnetic field among all superconductor magnets[34].

All the REBCOs mentioned above have a coated conductor structure with a complicate structure, because REBCO needs biaxial texture to carry high supercurrent. However, the coated conductor is not the only choice. Single domain REBCO bulks also have high Jc, which meet the application criterion. Up to now, several single domain preparation processes have been developed, such as melt-texture growth (MTG)[35], liquid-phase process[36], powder melting process (PMP)[37], melt powder melt growth (MPMG)[38], infiltration and top seed growth (ITSG)[39], infiltration and growth (IG)[40], and top-seeded melt-growth (TSMG)[41-42] process. Among these synthesis methods, TMSG, ITSG, and IG have the most outstanding superconducting properties. Their Jc values can meet the application criterion even in a large diameter bulk (over 40 mm).

Such single domain bulks can easily trap high magnetic field after field cooling (FC) under an external field. The world record of the trapped field reached 17.6 T at 26 K in the middle of two REBCO bulks[43]. The trapped field of more than 10 T is potentially applicable to multiple scenarios. As the bulks are kept at low temperatures by cryocooler, it can be easily moved to any desired place. Such a bulk magnet has emerged in multiple engineering applications, including flywheel[44-45], motors[46-47], generator[48], and magnetic sheilding[49]. There is an excellent review on SUST in 2018 about these applications[50].

In this review, the focus is on some unpopular but fascinating application scenarios of the REBCO bulk magnets, which can provide a broader vision to readers. A brief introduction is given to the research progress of magnet lens, compact NMR, magnetron sputtering system, drug magnetic targeting system, magnetic separation, and magnetic mirror in the subsequent section.

2 Magnet LensAs mentioned above, the REBCO bulk magnet can trap a high magnetic field after the FC process, which is due to excitation supercurrent in the REBCO bulk during the FC process. By suppressing the current circuit along the circumference of the REBCO hollow cone bulk, a magnetic field concentration around the narrow end of the cone can be expected, as shown in Figs. 1(a) and 1(b)[52]. With such a prototype of a magnet lens, the magnetic field in the lens (Bcenter) reached 5.65 T at 4.2 K when the applied field (Bexternal) was only 2.00 T. It indicates that the magnet lens can amplify the magnetic field in about 3 times. By optimizing the geometry parameters of the magnet lens, the amplifier factor reached near 4, as shown in Fig. 1(c).

|

Fig.1 (a) Photograph of the two sets of machined Gd-Ba-Cu-O bulk superconductors[51] (Reprinted with permission from Ref. [51], Copyright 2009 IEEE) (b) Schematic illustration of the magnetic flux concentrator[51] (Reprinted with permission from Ref.[51], Copyright 2009 IEEE) (c) A geometry effect of HTS bulk amplifier on the multiplication factor[52] (Reprinted with permission from Ref. [52], Copyright 2009 AIP) |

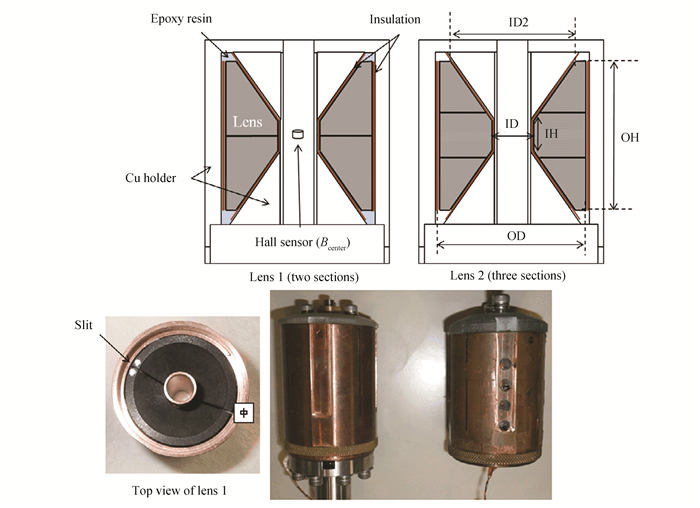

Further development on the shape of the magnet lens allowed consequent improvement on the amplified function. However, along with the increase of Bexternal, the flux jump phenomenon became a severe problem, which can cause a macro crack or even break[53-54], as shown in Fig. 2. After reinforcing the magnet lens with resin, the mechanical properties can be dramatically improved. At 20 K, the Bcenter exceeded 13 T without any flux jump when the Bexternal was only 7 T. This shows that it can easily get a magnetic field of more than 10 T by using a magnet lens[54].

|

Fig.2 Schematic illustration and photograph of the further developed GdBCO lenses 1 and 2[53] (Reprinted with permission from Ref. [53], Copyright 2012 IOP) |

After proof on the amplified function of the magnet lens, the magnet lens were used in the real 7 T superconducting magnet and 28 T hybrid magnet, as shown in Fig. 3(a) and 3(b)[55-56]. In both scenarios, flux jump still occurred, which hinted the amplified factor reached the maximum value. The flux jump caused the quench of the external 7 T superconducting magnet, which restrained the maximum of Bexternal to be at only 5.68 T. The final Bcenter reached 10.7 T under such conditions[55]. When the 28.3 T external field was applied to the magnet lens by the hybrid magnet, the final Bcenter exceeded 30 T. However, the Bcenter should be over 32 T without the flux jump.

|

Fig.3 (a) Schematic illustration of compact conduction-cooled superconducting magnet lens magnet system[55] (Reprinted with permission from Ref. [55], Copyright 2013 IOP) (b) Schematic illustration of the magnetic flux concentrator[56] (Reprinted with permission from Ref. [56], Copyright 2012 AIP) |

Although the magnet lens can significantly increase the magnetic field, it still needs a large volume external magnet, which is not portable. In 2018, Takahashi et al.[57] put forward a new concept of hybrid trapped field magnet lens by using a GdBCO lens and an MgB2 cylinder trapped field magnet, as shown in Fig. 4, and it was experimentally tested in 2019[58]. After completely removing the external filed, the new hybrid magnet lens can trap the high field for a long time. It can maintain 3.55 T with Bexternal of 2 T at 20 K. The main disadvantage of such a new magnet lens is that the MgB2 cannot trap a very high field. If this disadvantage is overcome, it is more efficient than only using a cylinder REBCO bulk magnet, which still needs further investigation.

|

Fig.4 Model of the MgB2 cylinder, GdBaCuO magnetic lens, and solenoid magnetizing coil[57] (Reprinted with permission from Ref. [57], Copyright 2018 IOP) |

3 Compact NMR

The nuclear magnetic resonance (NMR) can help researchers analyze the fine molecular structure, which is widely used in biology, macromolecule study, drug, food, chemistry, buttery, and so on. The resolution of NMR is proportional to the magnetic field strength. The 400 MHz NMR (9.4 T) is the most conventional one. Up to now, 1.02 GHz NMR (23.5 T) has been successfully reached by using NbTi, Nb3Sn, and REBCO tapes[59]. The NMR with a high magnetic field typically has a vast size and weight, which makes this NMR very expensive and hard to move. However, not every research needs an extremely high resolution on NMR. In some industrial application scenarios, low resolution is also acceptable. What needed is a cheap, small-size, even portable NMR instead of the large and expensive commercial one. So there is a market demand for compact NMR with a medium magnetic field, smaller size, and lower cost. In 2005, Iwasa et al.[60] proposed the concept and design of the compact NMR by using REBCO. Currently, there are mainly three research groups who focus on the development of compact NMR: Iwasa's group at MIT, Kim's group at Okayama University, and Nakamura's group at RIKEN. Due to the length limitation, this review only focuses on the results from the Nakamura's group. The detailed results of the other two groups can be found in Refs. [61-70].

The first compact NMR using REBCO bulk was fabricated in 2006 and reported in 2007[71]. Two SmBCO bulks with an outer diameter of 36 mm and a hole with a diameter of 7 mm were used to constitute the main part of the compact NMR. After being energized at 60 K at 3 T, the SmBCO bulk magnet was stable at 2.89 T, which is equal to 123 MHz. The first 1H NMR spectrum was also successfully obtained, and the best resolution value was 228 kHz. Although the resolution is really low, this result is the milestone in the history of compact NMR.

After the proof of the concept on the compact NMR using the REBCO bulk magnet, Nakamura's group set the first set of parameters of compact NMR to be achieved, which included a magnetic strength of 4.7 T (400 MHz), a magnetic field stability of 0.235 μT/h, and a magnetic field homogeneity of 1 ppm in a space with a diameter of 3 mm and a length of 5 mm. At the first stage, it was found that the relative magnetic permeability is essential to the magnetic field homogeneity in compact NMR. After a systematical investigation, it was found that the EuBCO material has the best balance on the low relative magnetic permeability, high Jc value, and feasibility to fabricate large bulk[72]. The new compact NMR used four EuBCO bulks with an outer diameter of 60 mm, an inner diameter of 16 mm, and a height of 20 mm[73]. The total height of the compact NMR is 742 mm, and the outer diameter of the vacuum chamber is 88 mm, which is much smaller than conventional NbTi NMR. The EuBCO bulk magnet successfully trapped a 4.7 T magnetic field at 50 K. It was also proved that the EuBCO bulk can produce a more homogenous magnetic field than SmBCO, and the best resolution reached 0.4 ppm by testing the toluene. After measuring the magnetic field for 10 days, the magnetic field stability was confirmed to be 0.018 μT/h, which can meet the goal (less than 0.0235 μT/h).

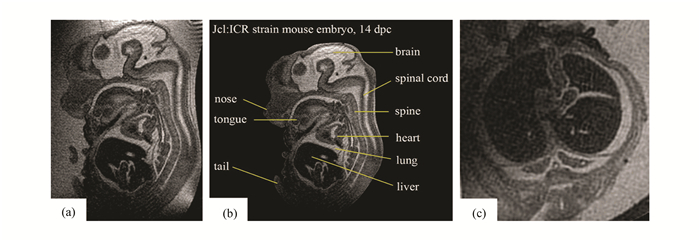

In 2011, Nakamura et al.[74] fabricated the first magnetic resonance microscope using the REBCO bulk magnet. The magnetic resonance microscope is a magnetic resonance imaging (MRI) system that archives a spatial resolution of less than 100 μm for small animals and intake specimens[75]. This system contained six EuBCO bulks with an outer diameter of 60 mm, an inner diameter of 28 mm, and a height of 20 mm. The magnet was also energized to 4.7 T at 50 K. Spatial distribution and a histogram of the magnetic field were measured and generated at cylindrical region with a diameter of 6.2 mm and a length of 9.1 mm. Peak-to-peak and root mean square values of the inhomogeneity were 37 ppm and 3.1 ppm, respectively. Fig. 5 shows midsagittal and horizontal cross-sections of the mouse embryo selected from a 3D image data set, in which the internal structures of the embryo are visualized clearly. It is proved that temporal stability and spatial homogeneity of the magnetic field produced by the bulk magnet are sufficient for MR microscopy of small samples.

|

Fig.5 The midsagittal (a), horizontal (b), and cross-sections (c) of mouse embryo chemically fixed at 14-day postconception measured by MR microscope. The voxel size is 50 μm3 [74] (Reprinted with permission from Ref. [74], Copyright 2011 AIP) |

In conventional NMR and MRI, the shim coil is commonly used to compensate for the field to get a more homogenous magnetic field. In 2015, Nakamura et al.[76] tried to introduce the shim coil to the NMR and MRI by using the EuBCO bulk magnet. Both single-layer shim coil and multi-channel shim coil were tested. The multi-channel shim coil included the 0th- and 1st-order z coil and other 2nd-order shim coils, as shown in Fig. 6(a). The EuBCO bulk magnet also trapped 4.74 T at 50 K. After using the single-layer shim coil, the magnetic field inhomogeneity improved from 42.9 to 6.9 ppm peak-to-peak for the central cylindrical region with a diameter of 6.2 mm and a length of 9.1 mm, as shown in Figs. 6(b) and 6(c). By using multi-channel shim coil current, the NMR spectra of ethanol were measured. The resolution reached 21 Hz (0.1 ppm) in the best condition.

|

Fig.6 (a) Multi-channel shim coil system developed for NMR spectrum acquisition (b) Magnetic field distribution measured when the current of the single-layer shim coil is (b) 0 mA and (c) 600 mA. The left- and right-hand figures show magnetic field distributions in the central YZ and XY planes, respectively[76] (Reprinted with permission from Ref. [76], Copyright 2015 ELSEVIER) |

4 Magnetron Sputtering System

In conventional magnetron sputtering system, a permanent magnet located below the target plate enhances the density of plasma in the region immediately above it. The electrons in the plasma are susceptible to being trapped due to the Lorentz force in the presence of looped magnetic fluxes[77]. Due to the low magnetization on the NdFeB, the magnetic field parallel to the target is only 0.05 T in the conventional magnetron sputtering system. Such a low magnetic field is not good enough for multiple application scenarios. Increasing the magnetic field allows the user to deposit the film under much lower pressure or much faster under the same pressure, which is beneficial in film deposition. By using the GdBCO bulk magnet with a diameter of 60 mm, the maximum magnetic field reached 6.4 T at the surface of GdBCO bulk, and the magnetic field parallel to the target exceeded 1 T at 40 K, which is more than 20 times higher than the permanent magnet, as shown in Fig. 7[78-79]. By using such a high magnetic field, the inert gas pressure could be decreased to 10-3 Pa at the lowest, when the conventional system only allows 10-1 Pa, which brings smaller discharge current[80]. More importantly, the ultra-high magnetic field makes the deposition of Fe and Ni possible by magnetron sputtering[81].

|

Fig.7 (a) Schematic illustration of the magnetron cathode[78] (Reprinted with permission from Ref.[78], Copyright 2003 IOP) (b) Intensity map of the magnetic field generated by the bulk superconductor used in the present ultra-strong-field sputtering system[79] (Reprinted with permission from Ref.[79], Copyright 2009 ELSEVIER) |

There are already two successful application scenarios created by using the magnetron sputtering system with the GdBCO bulk magnet. The satisfying results are briefly introduced below.

Along with the development of a small and speedy device, narrow wiring of the device is demanded, and an interconnected resistance-capacitance (RC) delay can no longer be ignored. Therefore, Cu has been considered to be a better candidate of wiring material, because it can reduce the RC delay due to its lower electrical resistivity, while Al cannot, which is currently used. In the current fabrication process, the electrochemical deposition (ECD) has been adopted for Cu deposition on a barrier layer with the precondition of uniform Cu seed layer commonly being deposited by the magnetron sputtering[82]. However, it was complicated to make a uniform Cu seed layer on the surface, which have a high aspect ratio hole with a diameter of 200 nm, by conventional magnetron sputtering. The best solution to this problem is to use large throw distance Dst during sputtering, which can be reached by increasing the magnetic field under low pressure. By using the GdBCO bulk magnet with a magnetic field of 4.2 T, the maximum Dst could reach 500 mm at 2.66 × 10-2 Pa. It can be found in Figs. 8(a) and 8(b). The longer Dst (500 mm) caused higher and more homogenous bottom coverage than the shorter one (150 mm). Moreover, it is possible to deposit the Cu seed layer in a high aspect ratio hole, such as one with a diameter of 200 nm and a depth of 1.15 mm, as shown in Fig. 8(c). Fig. 8(d) shows the relationship of bottom coverage ratio vs. the aspect ratio of holes under different Dst. It can be clearly seen that sputtering with Dst = 500 mm allows us to uniformly deposit a Cu thin film at the bottom of a deep hole patterned on the substrate with a diameter of at least 120 mm. It is further noted that the present data are entirely free of any overhang at the mouth of the via in contrast to the difficulty encountered when conventional magnetron sputtering is employed[83]. This is due to the slow deposition rate and the minimization of damage from radiant heat produced by the plasma in comparison with those of conventional magnetron.

|

Fig.8 Micrograph of the Cu film deposited into circular vias with a diameter of 300 nm and a depth of 1.15 mm under Ar gas pressure of 2.66×10-2 Pa with (a) Dst = 500 mm and (b) Dst = 150 mm (c) Sputtering result of the circular vias with a diameter of 200 nm and a depth of 1.15 mm under 2.66×10-2 Pa with Dst = 500 mm. (d) Aspect ratio dependence of bottom coverage under 2.66×10-2 Pa with different Dst values. The solid lines represent the results obtained above the target center and the dotted lines represent those above the erosion ring[82] (Reprinted with permission from Ref. [82], Copyright 2004 IOP) |

Another application example is the fabrication of Mo/Si multilayer structures. The reflection-type Mo/Si multilayer film is the best substitution of the ordinary optical lens in extreme ultraviolet (EUV) lithography, which has received great attention because it can fabricate patterns at technology nodes that are less than 32 nm[84]. Although the theoretical reflectivity of the Mo/Si multilayer is around 75%, the most measured value is limited to less than 70%. One of the most important reason is the evitable interlayer interference. It is reported that lowering the Xe gas pressure down to 0.08 Pa in the magnetron sputtering apparatus could enhance the reflectivity of the Mo/Si multilayer film to 71.3% at a wavelength of 13.0 nm[85].

Since the magnetron sputtering with the GdBCO bulk magnet can further decrease the pressure, Yamaguchi et al.[86] tried to deposit Mo/Si multilayer by suing the GdBCO magnet. The schematic illustration of the system is shown in Fig. 9. There are two GdBCO bulk magnets with the maximum trapped field of 6.2-6.4 T, and the magnetic field parallel to target reached more than 1 T. The inert gas pressure is as low as 2 × 10-2 Pa, and the Dst is around 450 mm.

|

Fig.9 Schematic illustration of the two-cathode superconducting magnetron sputtering apparatus[86] (Reprinted with permission from Ref. [86], Copyright 2004 ELSEVIER) |

After deposition of 50 layers of Mo/Si film using the superconducting magnetron sputtering apparatus, the interlayer inter-diffusion layer was detected as 1.5 nm (Mo-on-Si) and 0.5 nm (Si-on-Mo)[87-88], as shown in Fig. 10. The inter-diffusion layer is significantly suppressed by smaller pressure and longer Dst[86]. The rms of surface roughness reached only 0.02 nm. However, although the inter-diffusion layer is suppressed, the EUV reflectivity is only 67%, which is 3% lower than the calculated value. After analysis, it is deduced that the small amount of Xe remaining in the film may be the key to the deterioration of the EUV reflectivity[87].

|

Fig.10 Cross-sectional TEM image of a Mo/Si multilayer film[87-88] (Reprinted with permission from Refs. [87-88], Copyright 2008 ELSEVIER) |

5 Drug Magnetic Targeting System

In 2015, there were 4.29 million new cancer cases and 2.81 million cancer deaths in China[89]. The most conventional treatment of cancer is chemotherapy. However, due to the inaccurate location of chemotherapy drugs on the cancer tissue, the efficiency is quite low, and the side effect is inevitable. In the past decades, enormous efforts have been devoted to exploiting targeted drug carriers, which are able to attack specific tumor tissue or cells. With the advance of nanotechnology, novel nano-size drug carriers, which can automatically accumulate in the tumor tissue, were widely investigated. Among all kinds of drug carriers, the magnetic nanoparticles drug carrier has its unique advantages, which is considered as one of the most potential candidates for new combination therapy[90-94]. Combining the magnetic drug carriers with a magnetic field, magnetic nanoparticles drug carriers have three extra functions compared with other nanocarriers:

1) Magnetic targeting: the magnetic nanoparticles drug carrier can be targeted by an external magnetic field;

2) Theranostic: the magnetic nanoparticles drug carrier can also act as the contrast of MRI, which allows the characteristic of the drug accumulation in vivo;

3) Hyperthermia: the magnetic nanoparticles drug carrier can generate heat under an AC magnetic field, which supports another treatment on the tumor tissue at the same time with chemotherapy drugs.

The magnetic targeting is the most outstanding advantage of the magnetic drug carrier, which can significantly improve the accumulation of the drugs in the tumor. There are multiple magnetic targeting methods, including electronic solenoid coil assay and commercial MRI. Such results are already summarized in another review[95]. Although the targeting methods mentioned above are ingenious, they are still too complicated for application now. The simplest targeting method is to put a single but strong enough magnet on the position of the tumor tissue to pull the magnetic nanoparticles drug carrier to the general direction instead of precise positioning. Due to the weak magnetic moment of the magnetic nanoparticles drug carrier and the thickness of the subcutaneous fat of human body, it needs a tesla-level magnetic field to finish the magnetic targeting. The REBCO bulk magnet is the best or even the only candidate to act in this role.

In 2007, Takeda et al.[96] tried to fabricate a prototype magnetic targeting system, which contained two GBCO bulk (SmBCO and GdBCO) magnets with more than 1 T trapped field at 77 K, as shown in Fig. 11 (a). During the test, a Y-shaped glass tube with a branching point was placed over the superconducting magnet at a distance of 20 mm, which corresponds to the distance between a rat's vena cava and its body surface. Magnetic particles with a diameter of 100 nm flowed in real pig blood from the left to the right side at a flow velocity of 100 mm/s, and the drag force and the magnetic force are measured, as shown in Fig. 11(b)[96]. Affected by the REBCO bulk magnet at a distance of 20 mm, more than 90% of magnet nanoparticles were pulled by the magnetic field, which verified the magnetic targeting effect by using REBCO bulk magnet. During the magnetic targeting, the magnetic gradient is the key to the targeting effect. As shown in Fig. 11(c), the magnetic gradient is 75 times higher than the conventional permanent magnet at 20 mm. The high magnetic gradient means the REBCO bulk magnet can affect deeper tissue or smaller nanoparticles, which is critical to real application in human body.

|

Fig.11 (a) Schematic illustration of the REBCO bulk superconductors, (b) Photograph of the experimental model system, (c) Comparison of the magnetic field gradients generated by a permanent and superconducting magnet as a function of distance from the magnetic surface[96] (Reprinted with permission from Ref. [96], Copyright 2007 ELSEVIER) |

In 2009, Saho et al.[97] successfully fabricated the first magnetic target system, which fitted the application criterion for humans. The system included six GdBCO bulks with a diameter of 45 mm and a thickness of 15 mm, as shown in Fig. 12(a). The GdBCO magnet was cooled to 38 K by cryocooler. The total length of the primary part of the system is less than 800 mm and around 15 kg, which is portable, as shown in Fig. 12(b). After being energized at 6 T on the GdBCO bulk magnet, the total magnetic flux density at the surface of the vacuum chamber reached 5.07 T, and the magnetic field gradient was as high as 430 T/m. Even at a distance of 50 mm, the field strength was 0.22 T. In particular, the magnetic field gradient was still 9.5 T/m, which is also much higher than that of the permanent magnet. Fig. 12(c) shows a photograph of the trial portable HTS bulk magnet system set up in an operating room for the magnetic targeting experiment on a pig. The HTS bulk magnet was installed on the head of a nonmagnetic material-made balancing stand. It is found that the HTS bulk magnet can be easily moved to any position and held in place at any angle, which is very convenient in the following clinical research.

|

Fig.12 (a) Structure of the trial portable HTS bulk magnet (b) Photograph of the trial portable HTS bulk magnet with six bulk superconductors (c) Photograph of our trial HTS bulk magnet system[97] (Reprinted with permission from Ref. [97], Copyright 2009 ELSEVIER) |

6 Magnetic Separation

In the drug magnetic targeting, the magnetic nanoparticles drug carrier is controlled at an external position, which can also be used in industrial application scenario. By using a high magnetic field, the magnetic substance can be trapped in a specific position, which is separated from the original system, namely magnetic separation. In industrial application scenario, the pipeline of the fluid is usually much thicker than human blood vessel, and the flow speed can also be faster. So it also needs a very high magnetic field to obtain better separation results. The small volume of the REBCO bulk magnet makes it one of the best candidates. Two representative examples of magnetic separation using the REBCO bulk magnet are briefly introduced below.

The first example is to treat polluted water after washing the drum cans. The drum cans are used in various kinds of factories, such as in chemical, petroleum, and pharmaceutical factories. The used cans are gathered for reuse by the drum washing factories. Consequently, the wash water of the used cans inevitably becomes a mixture of various kinds of oil constituents and chemicals, which could not be directly reused or even be discharged into sewerage. The chemical oxygen demand (COD) must be reduced to 100 ppm or even lower to meet the criterion. One of the methods is to use magnetic separation.

Since the polluted water is either paramagnetic or diamagnetic, the first step is to improve the magnetic properties by adding magnetic particles. During the addition, some other regents need to be added simultaneously to help the magnetic particles bond with the pollution in the water. Afterwards, the pollution become floc with strong magnetic properties, which can be separated by magnetic field. As shown in Fig. 13(a), the GdBCO bulk magnet with a magnetic field of 2.1 T was set as 10 mm under the pipeline[98]. The field strength near the pipe reached 1.2 T. With a flow speed of 200 mm/s, the magnetic floc could be successfully captured at the bottom of the pipe, as shown in Fig. 13(a). The COD of the water was decreased from 180 ppm to the only 74 ppm, which indicates that magnetic separation in the flow field can be realized using an HTS bulk magnet. The system in large scale application is shown in Fig. 13(b). In the system, the large-size floc was caught by permanent magnets, while small-size floc, which cannot be caught by the permanent magnet, was filtrated with the HTS bulk magnet. The combination of permanent magnets and HTS bulk magnet can reduce the load of the magnetic filtration device and enables long-time operation.

|

Fig.13 (a) Magnetic filtration experiment using the HTS bulk magnet (b) The system design of the filtration equipment and the connectional diagram of magnetic seeding tank, magnetically assisted separating device, and magnetic filtration device with HTS bulk magnet[98] (Reprinted with permission from Ref. [98], Copyright 2009 IEEE) |

Another example of magnetic separation is more attractive to common users. After the accident of the Fukushima Daiichi Nuclear Plant, many kinds of radioactive substances have been spread around the power plant. Cs-137 with half-life of more than 30 years is the most dangerous. Most of the cesium is adsorbed in the soil, especially clay minerals, which have the smallest particle size[99]. Usually, there are primarily two kinds of clay consisting of different ratios of tetrahedral and octahedral sheets, one at the ratio of 2:1 and the other at 1:1. It is known that some of 2:1 type clay minerals strongly adsorb ions such as cesium in the interlayer space. On the other hand, 1:1 type clay minerals have weak sorption sites on their surface where cations such as cesium ion can be easily eliminated by ion-exchange[100]. Thus, if the 2:1 type clay minerals can be classified, the most amount of cesium can be separated.

The 2:1 type clay minerals such as vermiculite are paramagnetic substances, whereas 1:1 type clay minerals such as kaolinite are diamagnetic substances. According to the different magnetic properties, the two types of minerals can be classified. However, the magnetic susceptibility of both materials is quite low compared with magnetic particles such as Fe3O4 which are added to the polluted water in the previous example. It needs a powerful magnetic field to affect them. This is the reason why the REBCO bulk magnet can act in this role.

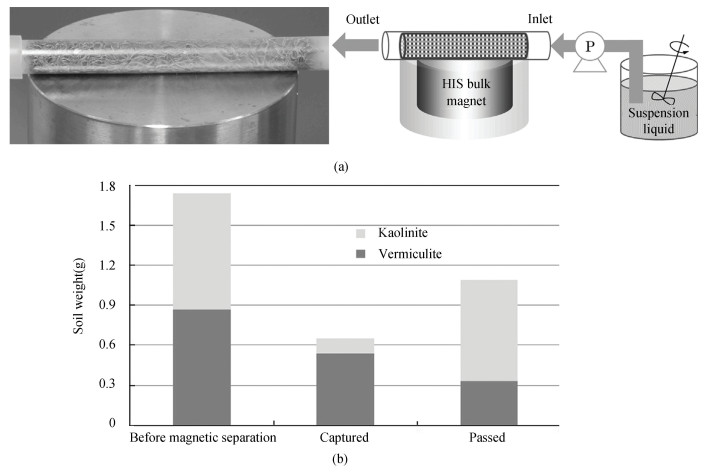

As shown in Fig. 14(a), the magnetic separation system has a GdBCO bulk magnet (diameter:60 mm; height:20 mm; maximum surface magnetic flux density: 3.5 T). The ferromagnetic stainless steel mesh(SUS430) with a saturation magnetization of 1.6 T was used as a magnetic filter. The mean wire diameter of the mesh fiber was 0.15 mm, and 3.0 g of the mesh was packed into 8 cm of the section of the flow path. The volume packing factor was 2.5%. The magnetic flux density at the central bottom of the path was 3.0 T[101]. The Kaolinite and Vermiculite represent the 1:1 and 2:1 type clay minerals, respectively. After flowing the mixture of Kaolinite and Vermiculite at a speed of 10 mm/s though the magnetic separation system, the ratio between the two types of clay minerals showed significant change, which is illustrated in Fig. 14(b). From the above result, the possibility of the volume reduction of the radioactive cesium polluted soil is shown by separating the 2:1 type clay minerals such as vermiculite, which selectively adsorb more radioactive cesium.

|

Fig.14 (a) Photograph and outline of the high gradient magnetic separation device (b) Soil weight of the clay mineral before magnetic separation, the captured soil weight and the passed soil weight of the clay material[101](Reprinted with permission from Ref. [101], Copyright 2009 ELSEVIER) |

7 Magnetic Mirror

Just like the magnetic particle can be trapped or targeted by the external magnetic field, the charged particle beam such as plasma can also be affected, when a bulk magnet has a magnetic throat (maximum field) near the axial midpoint of the hole. Such a diverging field is popular in the field of plasma science and technology and is called a magnetic mirror because the magnetic field of this configuration reflects charged particles[102]. The principle of the mirrors is as follows[102-103]. Suppose that electrons drift toward a magnetic throat with a velocity parallel to the magnetic field lines, accompanied by gyromotion around the field lines. Hence, the drift velocity gradually decreases until it becomes zero at a point near the throat, due to the deceleration of the magnetic field. The spiral pitch of the gyromotion decreases successively. At the same time, velocity perpendicular to the field lines increases because the magnetic moment of the electrons is conserved. On arriving at the turning point, the electrons begin to drift back into the previous weaker-field region under the influence of the decelerating or the now accelerating force. Macroscopically, the electrons bounce back and forth between the throats as if the electrons were reflected from glass mirrors. Consequently, a pair of magnetic mirrors effectively confines higher-density plasmas with increasing throat fields.

In the magnetic mirror, a strong field in a compact volume is essential on the restrain effect on the plasma. So neither weak field NdFeB permanent magnet or large volume solenoid coils can compete with the REBCO bulk magnet. Itou et al.[104] showed a magnetic mirror structure by using two GdBCO bulk magnets, as shown in Fig. 15(d). The E1 and E2 are GdBCO bulk magnets with a magnetic field of 1.25 T and 0.75 T at 77 K, respectively. The 6 mm electrodes were inserted into both of the magnets. Fig. 15(a)-(c) shows the spatial distribution of fluorescence at 0.2 Torr. It can be clearly seen that the plasma became more restrained along with the increasing of the GdBCO bulk magnet. The discharge current is only 1mA in this experiment.

|

Fig.15 Photographs of neon fluorescence for (a) two-magnet, (b) single-magnet, and (c) no-magnet operations at 0.2 Torr neon and dc 1 mA. The cathode E1(-) was set at the top and the anode E2(+) at the bottom. (d) Experimental setup. M1 and M2 indicate the bulk magnets, and E1 and E2 the discharge electrodes[104](Reprinted with permission from Ref. [104], Copyright 2005 ELSEVIER) |

8 Conclusions and Outlook

In this review, multiple application scenarios of the REBCO bulk magnet are briefly introduced, including magnet lens, compact NMR, the magnetron sputtering system, the drug magnetic targeting system, magnetic separation, and magnetic mirror. The properties of all kinds of systems are significantly improved by using the REBCO bulk magnet. Compared with the conventional NdFeB permanent magnet, the REBCO bulk magnet can generate one-order-higher magnetic field. Although the REBCO bulk magnet needs a cooling system, it is believed that the cooling cost can be fully covered when the required magnetic field is higher than 5 T at the surface of the magnet. Compared with the more popular REBCO tape, the REBCO bulk is more brittle without the metal substrate, so it could not be used to fabricate extremely large field magnet (over 15 T). However, it is tough to wind the REBCO tape in a small radius, which means the REBCO tape cannot be used in some scenarios with strict requirements on the magnet size. Moreover, the REBCO bulk does not need expensive reel-to-reel fabrication instruments under a high vacuum. Thus, the cost of the bulk is significantly lower than the REBCO tape. The REBCO film can be deposited on the substrate with a large area by stacking the multiple films together. It can also trap the tesla-level field. This is a very promising technical route to fabricate trapped field magnet. However, the large area REBCO films are typically deposited on the single crystal substrate, which makes it more brittle than bulk. If it can be successfully fabricated on the metal substrate, it will be the biggest competition to the bulk magnet. Based on the analysis above, it can be easily concluded that the REBCO bulk magnet has its own application potential, which should be paid more attention to.

| [1] |

Chu J Y, Zhao Y, Khan M Z, et al. Insight into the interfacial nucleation and competitive growth of YBa2Cu3O7-delta films as high-performance coated conductors by a fluorine-free metal-organic decomposition route. Crystal Growth & Design, 2019, 19(11): 6752-6762. DOI:10.1021/acs.cgd.9b01120 (  0) 0) |

| [2] |

Foltyn S R, Civale L, Macmanus-Driscoll J L, et al. Materials science challenges for high-temperature superconducting wire. Nature Materials, 2007, 6: 631-642. DOI:10.1038/nmat1989 (  0) 0) |

| [3] |

Zhao Y, Zhu J M, Jiang G Y, et al. Progress of second generation high temperature superconducting tape fabrication at Shanghai superconductor technology. Superconductor Science and Technology, 2019, 32: 044004. DOI:10.1088/1361-6668/aafea5 (  0) 0) |

| [4] |

Chu J Y, Zhao Y, Liu L F, et al. Topography evolution of rough-surface metallic substrates by solution deposition planarization method. Applied Surface Science, 2018, 427: 237-242. DOI:10.1016/j.apsusc.2017.08.161 (  0) 0) |

| [5] |

MacManus-Driscoll J L, Bianchetti M, Kursumovic A, et al. Strong pinning in very fast grown reactive co-evaporated GdBa2Cu3O7 coated conductors. APL Materials, 2014, 2: 086103. DOI:10.1063/1.4893339 (  0) 0) |

| [6] |

Xu A, Delgado L, Khatri N, et al. Strongly enhanced vortex pinning from 4 to 77 K in magnetic fields up to 31 T in 15 mol.% Zr-added (Gd, Y)-Ba-Cu-O superconducting tapes. APL Materials, 2014, 2: 046111. DOI:10.1063/1.4872060 (  0) 0) |

| [7] |

Feighan J P F, Kursumovic A, MacManus-Driscoll J L. Materials design for artificial pinning centres in superconductor PLD coated conductors. Superconductor Science and Technology, 2017, 30: 123001. DOI:10.1088/1361-6668/aa90d1 (  0) 0) |

| [8] |

Yoshida Y, Ichino Y, Xu Q, et al. Improvement in Jc performance below liquid nitrogen temperature for SmBa2Cu3Oy superconducting films with BaHfO3 nano-rods controlled by low-temperature growth. APL Materials, 2016, 4(1): 016102-1-016102-8. DOI:10.1063/1.4939182 (  0) 0) |

| [9] |

Ercolano G, Harrington S A, Wang H, et al. Enhanced flux pinning in YBa2Cu3O7-delta thin films using Nb-based double perovskite additions. Superconductor Science and Technology, 2010, 23(2): 022003. DOI:10.1088/0953-2048/23/2/022003 (  0) 0) |

| [10] |

Rizzo F, Augieri A, Armenio A A, et al. Enhanced 77 K vortex-pinning in YBa2Cu3O7-x films with Ba2YTaO6 and mixed Ba2YTaO6 + Ba2YNbO6 nano-columnar inclusions with irreversibility field to 11 T. APL Materials, 2016, 4: 061101. DOI:10.1063/1.4953436 (  0) 0) |

| [11] |

Opherden L, Sieger M, Pahlke P, et al. Large pinning forces and matching effects in YBa2Cu3O7-delta thin films with Ba2Y(Nb/Ta)O-6 nano-precipitates. Scientific Reports, 2016, 6: 21188. DOI:10.1038/srep21188 (  0) 0) |

| [12] |

Llordes A, Palau A, Gazquez J, et al. Nanoscale strain-induced pair suppression as a vortex-pinning mechanism in high-temperature superconductors. Nature Materials, 2012, 11: 329-336. DOI:10.1038/NMAT3247 (  0) 0) |

| [13] |

Chen X, Zheng S J, Li J, et al. A linear induction motor with a coated conductor superconducting secondary. Physica C: Superconductivity and its Applications, 2018, 550: 82-84. DOI:10.1016/j.physc.2018.04.002 (  0) 0) |

| [14] |

Ma G T, Gong T Y, Zhang H, et al. Experiment and simulation of REBCO conductor coils for an HTS linear synchronous motor. IEEE Transactions on Applied Superconductivity, 2017, 27(4): 5201805. DOI:10.1109/TASC.2017.2662601 (  0) 0) |

| [15] |

Tamura K, Iwakuma M, Ueno T, et al. Study on the optimum arrangement of the field winding for a 20-kW fully superconducting motor. IEEE Transactions on Applied Superconductivity, 2016, 26(4): 5206905. DOI:10.1109/TASC.2016.2544351 (  0) 0) |

| [16] |

Bergen A, Andersen R, Bauer M, et al. Design and in-field testing of the world's first ReBCO rotor for a 3.6 MW wind generator. Superconductor Science and Technology, 2019, 32(12): 125006. DOI:10.1088/1361-6668/ab48d6 (  0) 0) |

| [17] |

Komiya M, Aikawa T, Sasa H, et al. Design study of 10 MW REBCO fully superconducting synchronous generator for electric aircraft. IEEE Transactions on Applied Superconductivity, 2019, 29(5): 5204306. DOI:10.1109/TASC.2019.2906655 (  0) 0) |

| [18] |

Obana T, Terazaki Y, Yanagi N, et al. Self-field measurements of an HTS twisted stacked-tape cable conductor. Cryogenics, 2020, 105: 103012. DOI:10.1016/j.cryogenics.2019.103012 (  0) 0) |

| [19] |

Gao P, Dhalle M, van Nugteren B, et al. Inter-strand resistance and AC loss in resin-filler impregnated REBCO Roebel cables. Superconductor Science and Technology, 2019, 32(12): 125002. DOI:10.1088/1361-6668/ab4665 (  0) 0) |

| [20] |

Wang Y W, Zheng J X, Zhu Z X, et al. Quench behavior of high-temperature superconductor (RE)Ba2Cu3Ox CORC cable. Journal of Physics D: Applied Physics, 2019, 52(34): 345303. DOI:10.1088/1361-6463/ab1e2c (  0) 0) |

| [21] |

Celentano G, Vannozzi A, de Marzi G, et al. Bending behavior of HTS stacked tapes in a cable-in-conduit conductor with twisted Al-slotted core. IEEE Transactions on Applied Superconductivity, 2019, 29(5): 4801205. DOI:10.1109/TASC.2019.2899248 (  0) 0) |

| [22] |

Zhu J H, Chen P P, Qiu M, et al. Experimental investigation of a gigh temperature superconducting pancake consisted of the REBCO composite cable for superconducting magnetic energy storage system. IEEE Transactions on Applied Superconductivity, 2019, 29(5): 5700704. DOI:10.1109/TASC.2019.2897574 (  0) 0) |

| [23] |

Ciceron J, Badel A, Tixador P, et al. Test in strong background field of a modular element of a REBCO 1 MJ high energy density SMES. IEEE Transactions on Applied Superconductivity, 2018, 28(4): 5701005. DOI:10.1109/TASC.2018.2820906 (  0) 0) |

| [24] |

Buran M, Vojenciak M, Mosat M, et al. Impact of a REBCO coated conductor stabilization layer on the fault current limiting functionality. Superconductor Science and Technology, 2019, 32(9): 095008. DOI:10.1088/1361-6668/ab2c8e (  0) 0) |

| [25] |

Kudymow A, Bauer A, Elschner S, et al. Smartcoil-design, assembly and test of a 10 MVA superconducting air coil fault current limiter. Superconductor Science and Technology, 2019, 32: 065002. DOI:10.1088/1361-6668/ab099a (  0) 0) |

| [26] |

Hellmann S, Abplanalp M, Elschner S, et al. Current limitation experiments on a 1 MVA-class superconducting current limiting transformer. IEEE Transactions on Applied Superconductivity, 2019, 29(5): 5501706. DOI:10.1109/TASC.2019.2906804 (  0) 0) |

| [27] |

Li M Y, Chen X Y, Gou H Y, et al. Conceptual design and characteristic analysis of a sliding-type superconducting wireless power transfer system using REBCO primary at 50 Hz. IEEE Transactions on Applied Superconductivity, 2019, 29(2): 5501304. DOI:10.1109/TASC.2019.2894444 (  0) 0) |

| [28] |

Nakamura F, Iwakuma M, Miura S, et al. Numerical analysis of current-limiting cooperation of a 20 MVA superconducting transformer and cable. IEEE Transactions on Applied Superconductivity, 2019, 29(5): 5502105. DOI:10.1109/TASC.2019.2909236 (  0) 0) |

| [29] |

Zappatore A, Heller R, Savoldi L, et al. Assessment of the performance of a 20 kA REBCO current lead. Cryogenics, 2018, 95: 95-101. DOI:10.1016/j.cryogenics.2018.09.003 (  0) 0) |

| [30] |

Hahn S, Kim K, Kim K, et al. Larbalestier. Nature, 2019, 570(7762): 496. DOI:10.1038/s41586-019-1293-1 (  0) 0) |

| [31] |

Suetomi Yu, Yoshida Taisuke, Takamashi Shunji, et al. Fri-Mo-Or27-02: 30 T generation using an intra-layer no-insulation (LNI) REBCO coil in a 17 T LTS magnet. Proceedings of the International Conference on Magnet Technology. Vancouver, 2019.Contribution ID: 1308.

(  0) 0) |

| [32] |

Yoon S, Kim J, Cheon K, et al. 26-T 35-mm all-REBCO multi-width no-insulation superconducting magnet. Superconductor Science and Technology, 2016, 29(4): 04LT04. DOI:10.1088/0953-2048/29/4/04LT04 (  0) 0) |

| [33] |

Roberts K, Weijers H, New World-record Magnet Fulfills Superconducting Promise. https://nationalmaglab.org/news-events/news/new-world-record-magnet-fulfills-superconducting-promise, 2020-04-06.

(  0) 0) |

| [34] |

Liu J H, Wang Q L, Qin L, et al. World record 32.35tesla direct-current magnetic field generated with an all-superconducting magnet. Superconductor Science and Technology, 2020, 33(3): 03LT01. DOI:10.1088/1361-6668/ab714e (  0) 0) |

| [35] |

Jin S, Tiefel T H, Sherwood R C, et al. Melt-textured growth of polycrystalline YBa2Cu3O7-δ with high transport Jc at 77 K. Physical Review B, 1988, 37(13): 7850-7853. DOI:10.1103/PhysRevB.37.7850 (  0) 0) |

| [36] |

Murakami M, Morita M, Doi K, et al. A new process with the promise of high Jc in oxide superconductors. Japanese Journal of Applied Physics, 1989, 28(7): 1189-1194. DOI:10.1143/JJAP.28.1189 (  0) 0) |

| [37] |

Feng Y, Pradhan A K, Zhao Y, et al. Influence of Ho substitution for Y on flux pinning in melt-processed YBCO superconductors. Physica C: Superconductivity, 2001, 357-360: 799802. DOI:10.1016/S0921-4534(01)00368-9 (  0) 0) |

| [38] |

Murakami M, Oyama T, Fujimoto H, et al. Melt processing of bulk high Tc superconductors and their application. IEEE Transactions on Magnetics, 1991, 27(2): 1479-1486. DOI:10.1109/20.133464 (  0) 0) |

| [39] |

Noudem J G, Meslin S, Horvath D, et al. Fabrication of textured YBCO bulks with artificial holes. Physica C: Superconductivity and its Applications, 2007, 463465: 301307. DOI:10.1016/j.physc.2007.03.503 (  0) 0) |

| [40] |

Namburi D K, Durrell J H, Jaroszynski J, et al. A trapped field of 14.3 T in Y-Ba-Cu-O bulk superconductors fabricated by buffer-assisted seeded infiltration and growth. Superconductor Science and Technology, 2018, 31: 125004. DOI:10.1088/1361-6668/aae2cf (  0) 0) |

| [41] |

Gruss S, Fuchs G, Krabbes G, et al. Superconducting bulk magnets: very high trapped fields and cracking. Applied Physics Letters, 2001, 79(19): 3131-3133. DOI:10.1063/1.1413502 (  0) 0) |

| [42] |

Cardwell D A. Processing and properties of large grain (RE)BCO. Materials Science and Engineering: B, 1998, 53(1-2): 1-10. DOI:10.1016/S0921-5107(97)00293-6 (  0) 0) |

| [43] |

Durrell J H, Dennis A R, Jaroszynski J, et al. A trapped field of 17.6 T in melt-processed, bulk Gd-Ba-Cu-O reinforced with shrink-fit steel. Superconductor Science and Technology, 2014, 27: 082001. DOI:10.1088/0953-2048/27/8/082001 (  0) 0) |

| [44] |

Matsunaga K, Tomita M, Yamachi N, et al. YBCO bulk for the superconducting bearing for a 10 kWh flywheel. Superconductor Science and Technology, 2002, 15(5): 842-845. DOI:10.1088/0953-2048/15/5/341 (  0) 0) |

| [45] |

Strasik M, Hull J R, Mittleider J A, et al. An overview of Boeing flywheel energy storage systems with high-temperature superconducting bearings. Superconductor Science and Technology, 2010, 23(3): 034021. DOI:10.1088/0953-2048/23/3/034021 (  0) 0) |

| [46] |

Kovalev L K, Ilushin KV, Penkin V T, et al. High output power reluctance electric motors with bulk high-temperature superconductor elements. Superconductor Science and Technology, 2002, 15: 817-822. DOI:10.1088/0953-2048/15/5/335 (  0) 0) |

| [47] |

Itoh Y, Yanagi Y, Yoshikawa M, et al. High-temperature superconducting motor using Y-Ba-Cu-O bulk magnets. Japanese Journal of Applied Physics, 1995, 34(10): 5574-5578. DOI:10.1143/JJAP.34.5574 (  0) 0) |

| [48] |

Oka T, Yokoyama K, Itoh Y, et al. A 3 T magnetic field generator using melt-processed bulk superconductors as trapped field magnets and its applications. Physica C: Superconductivity, 2003, 392-396: 709-712. DOI:10.1016/S0921-4534(03)01017-7 (  0) 0) |

| [49] |

Wera L, Fagnard J F, Namburi D K, et al. Magnetic shielding above 1 T at 20 K with bulk, large grain YBCO tubes made by buffer-aided top seeded melt growth. IEEE Transactions on Applied Superconductivity, 2017, 27(4): 6800305. DOI:10.1109/tasc.2016.2633301 (  0) 0) |

| [50] |

Durrell J H, Ainslie M D, Zhou D, et al. Bulk superconductors: a roadmap to applications. Superconductor Science and Technology, 2018, 31(10): 103501. DOI:10.1088/1361-6668/aad7ce (  0) 0) |

| [51] |

Kiyoshi T, Choi S, Matsumoto S, et al. Magnetic flux concentrator using Gd-Ba-Cu-O bulk superconductors. IEEE Transactions on Applied Superconductivity, 2009, 19(3): 2174-2177. DOI:10.1109/TASC.2009.2018440 (  0) 0) |

| [52] |

Choi S, Kiyoshi T, Matsumoto S. Magnetic field amplifier employing high-Tc bulk superconductor. Journal of Applied Physics, 2009, 105: 833-835. DOI:10.1063/1.3068645 (  0) 0) |

| [53] |

Zhang Z Y, Matsumoto S, Teranishi1 R, et al. Improving the properties of GdBCO magnetic lenses by adopting a new design and resin impregnation. Superconductor Science and Technology, 2013, 26: 045001. DOI:10.1088/0953-2048/26/4/045001 (  0) 0) |

| [54] |

Zhang Z Y, Matsumoto S, Teranishi R, et al. Magnetic field, temperature and mechanical crack performance of a GdBCO magnetic lens. Superconductor Science and Technology, 2012, 25(11): 115012. DOI:10.1088/0953-2048/25/11/115012 (  0) 0) |

| [55] |

Zhang Z Y, Matsumoto S, Teranishi R, et al. Development of a compact superconducting magnet with a GdBCO magnetic lens. Superconductor Science and Technology, 2013, 26(10): 105011. DOI:10.1088/0953-2048/26/10/105011 (  0) 0) |

| [56] |

Choi S, Yoon J H, Lee B S, et al. Magnetic lens effect using Gd-Ba-Cu-O bulk superconductor in very high magnetic field. Journal of Applied Physics, 2012, 111: 07E728-1-07E728-3. DOI:10.1063/1.3678301 (  0) 0) |

| [57] |

Takahashi K, Fujishiro H, Ainslie M D. A new concept of a hybrid trapped field magnet lens. Superconductor Science and Technology, 2018, 31(4): 044005. DOI:10.1088/1361-6668/aaae94 (  0) 0) |

| [58] |

Namba S, Fujishiro H, Naito T, et al. Experimental realization of a hybrid trapped field magnet lens using a GdBaCuO magnetic lens and MgB2 bulk cylinder. Superconductor Science and Technology, 2019, 32: 12LT03. DOI:10.1088/1361-6668/ab5048 (  0) 0) |

| [59] |

Maeda H, Shimoyama J, Yanagisawa Y, et al. The MIRAI program and the new super-high field NMR initiative and its relevance to the development of superconducting joints in Japan. IEEE Transactions on Applied Superconductivity, 2019, 29(5): 4602409. DOI:10.1109/TASC.2019.2905360 (  0) 0) |

| [60] |

Iwasa Y, Hahn S, Tomita M, et al. A "persistent-mode" magnet comprised of YBCO annuli. IEEE Transactions on Applied Superconductivity, 2005, 15(2): 2352-2355. DOI:10.1109/TASC.2005.849664 (  0) 0) |

| [61] |

Hahn S, Kim Y, Song Y, et al. Operation of a 130-MHz/9-mm compact HTS annulus magnet with a Micro-NMR probe. IEEE Transactions on Applied Superconductivity, 2015, 25(3): 4300905. DOI:10.1109/TASC.2014.2367658 (  0) 0) |

| [62] |

Hahn S, Kim Y, Voccio J P, et al. Temporal enhancement of trapped field in a compact NMR magnet comprising YBCO annuli. IEEE Transactions on Applied Superconductivity, 2014, 24(3): 4300805. DOI:10.1109/TASC.2013.2283226 (  0) 0) |

| [63] |

Hahn S, Kim Y, Voccio J, et al. Bulk and plate annulus stacks for compact NMR magnets: trapped field characteristics and active shimming performance. IEEE Transactions on Applied Superconductivity, 2013, 23(3): 4300504. DOI:10.1109/TASC.2013.2240752 (  0) 0) |

| [64] |

Gagnon B, Hahn S, Park D K, et al. Field performance of a prototype compact YBCO "annulus" magnet for micro-NMR spectroscopy. Physica C: Superconductivity, 2013, 486: 26-31. DOI:10.1016/j.physc.2012.12.013 (  0) 0) |

| [65] |

Hahn S, Voccio J, Park D K, et al. A stack of YBCO annuli, thin plate and bulk, for Micro-NMR spectroscopy. IEEE Transactions on Applied Superconductivity, 2012, 22(3): 4302204. DOI:10.1109/TASC.2011.2178969 (  0) 0) |

| [66] |

Miyazawa D, Kim S B, Kitamura H, et al. Numerical study to obtain the improved field homogeneity and enlarged inner diameter of HTS bulk magnet for compact NMR. Physics Procedia, 2015, 65: 245-248. DOI:10.1016/j.phpro.2015.05.135 (  0) 0) |

| [67] |

Kim S B, Hayashi N, Kitamura H, et al. Study on the remagnetization process to improve the field homogeneity of the stacked HTS bulk magnets. IEEE Transactions on Applied Superconductivity, 2014, 24(3): 4301405. DOI:10.1109/TASC.2013.2290591 (  0) 0) |

| [68] |

Kim S B, Kitamura H, Ishizuka D, et al. The study to improve the field homogeneity of the NMR relaxometry magnets using the packaged HTS bulks with various iron rings. IEEE Transactions on Applied Superconductivity, 2015, 25(3): 4602204. DOI:10.1109/TASC.2014.2372896 (  0) 0) |

| [69] |

Kim S B, Ishizuka D, Kitamura H, et al. Study on the shape optimization of the HTS bulk magnets with active compensation for compact NMR relaxometry magnets. IEEE Transactions on Applied Superconductivity, 2015, 25(3): 117-122. DOI:10.1109/TASC.2014.2374337 (  0) 0) |

| [70] |

Kim S B, Saito R, Takahashi M, et al. Shape optimization of the stacked HTS double pancake coils for compact NMR relaxometry operated in persistent current mode. IEEE Transactions on Applied Superconductivity, 2016, 26(4): 4301704. DOI:10.1109/TASC.2016.2518487 (  0) 0) |

| [71] |

Nakamura T, Itoh Y, Yoshikawa M, et al. Development of a superconducting magnet for nuclear magnetic resonance using bulk high-temperature superconducting materials. Concepts in Magnetic Resonance Part B, 2007, 31B(2): 65-70. DOI:10.1002/cmr.b.20083 (  0) 0) |

| [72] |

Sakai N, Nariki S, Hirabayashi I, et al. Development of single-domain annular REBCO bulk superconductors for compact Cyogen-free NMR. Teion Kogaku (Journal of Cryogenics and Superconductivity Society of Japan), 2011, 46(3): 131-138. DOI:10.2221/JCSJ.46.131.(inJapanese) (  0) 0) |

| [73] |

Nakamura T, Itoh Y, Masaaki Y, et al. Application of a compact cryogen-free superconducting bulk magnet to NMR-evaluation of a superconducting bulk magnet using NMR signal. Teion Kogaku (Journal of Cryogenics and Superconductivity Society of Japan), 2011, 46(3): 139-148. DOI:10.2221/jcsj.46.139.(inJapanese) (  0) 0) |

| [74] |

Ogawa K, Nakamura T, Terada Y, et al. Development of a magnetic resonance microscope using a high Tc bulk superconducting magnet. Applied Physics Letters, 2011, 98: 234101. DOI:10.1063/1.3598440 (  0) 0) |

| [75] |

Glover P, Mansfield P. Limits to magnetic resonance microscopy. Reports on Progress in Physics, 2002, 65(10): 1489-1511. DOI:10.1088/0034-4885/65/10/203 (  0) 0) |

| [76] |

Nakamura T, Tamada D, Yanagi Y, et al. Development of a superconducting bulk magnet for NMR and MRI. Journal of Magnetic Resonance, 2015, 259: 68-75. DOI:10.1016/j.jmr.2015.07.012 (  0) 0) |

| [77] |

Kelly P J, Arnell R D. Magnetron sputtering: a review of recent developments and applications. Vacuum, 2000, 56(3): 159-172. DOI:10.1016/S0042-207X(99)00189-X (  0) 0) |

| [78] |

Mizutani U, Hazama H, Matsuda T, et al. Performance of the magnetron sputtering apparatus equipped with 60 mmφ superconducting bulk magnet. Superconductor Science and Technology, 2003, 16(10): 1207-1211. DOI:10.1088/0953-2048/16/10/314 (  0) 0) |

| [79] |

Ikuta H, Yokouchi K, Ohta I, et al. Development of a magnetron sputtering system with an extraordinary strong magnetic field near the target. Vacuum, 2009, 83(3): 475-478. DOI:10.1016/j.vacuum.2008.04.006 (  0) 0) |

| [80] |

Mizutani U, Hazama H, Matsuda T, et al. Magnetron sputtering activated by a 60 mm diameter superconducting bulk magnet. Superconductor Science and Technology, 2005, 18(2): S30-S33. DOI:10.1088/0953-2048/18/2/007 (  0) 0) |

| [81] |

Matsuda T, Kashimoto S, Imai A, et al. Application of 60 mm/ superconducting bulk magnet to magnetron sputtering. Physica C: Superconductivity, 2003, 392-396: 696-703. DOI:10.1016/S0921-4534(03)01021-9 (  0) 0) |

| [82] |

Hazama H, Matsuda T, Mizutani U, et al. Bottom coverage of Cu deposit for 200-nm-class circular vias with high aspect ratios investigated by magnetron sputtering activated using superconducting bulk magnet. Japanese Journal of Applied Physics, 2004, 43(9A): 6026-6031. DOI:10.1143/JJAP.43.6026 (  0) 0) |

| [83] |

Ichiki T, Kikuchi T, Sano A, et al. Gap-filling of Cu employing sustained self-sputtering with inductively coupled plasma ionization. Japanese Journal of Applied Physics, 1997, 36(3B): 1469-1472. DOI:10.1143/JJAP.36.1469 (  0) 0) |

| [84] |

Watanabe T, Tatsumura K, Ohdomari I. International technology roadmap for semiconductors 2005 edition. Physical Review Letters, 96(19): 196102. DOI:10.1103/PhysRevLett.96.196102 (  0) 0) |

| [85] |

Shiraishi M, Kandaka N, Murakami K. Mo/Si multilayers deposited by low-pressure rotary magnet cathode sputtering for extreme ultraviolet lithography. SPIE Proceedings, Emerging Lithographic Technologies Ⅶ, 2003, 5037: 249-256. DOI:10.1117/12.484436 (  0) 0) |

| [86] |

Yamaguchi T, Ikuta H, Yanagi Y, et al. Development of a magnetron sputtering apparatus equipped with superconducting bulk magnets for the preparation of optical multilayer films. Physica C: Superconductivity and its Applications, 2007, 463-465: 1342-1345. DOI:10.1016/j.physc.2007.04.310 (  0) 0) |

| [87] |

Mizutani U, Yamaguchi T, Ikuta H, et al. Fabrication of Mo/Si multilayer mirrors for extreme ultraviolet lithography by means of superconducting bulk magnet magnetron sputtering. Physica C: Superconductivity, 2008, 468(15-20): 1456-1460. DOI:10.1016/j.physc.2008.05.239 (  0) 0) |

| [88] |

Yamaguchi T, Ikuta H, Tomofuji T, et al. Reflective properties of Mo/Si multilayer for EUV lithography deposited by the magnetron sputtering device with superconducting bulk magnets. Physica C: Superconductivity, 2008, 468: 2170-2173. DOI:10.1016/j.physc.2008.05.149 (  0) 0) |

| [89] |

Chen W Q, Zheng R S, Baade P D, et al. Cancer statistics in China 2015. CA: A Cancer Journal for Clinicians, 2016, 66(2): 115-132. DOI:10.3322/caac.21338 (  0) 0) |

| [90] |

Hu S H, Liao B J, Chiang C S, et al. Core-shell nanocapsules stabilized by single-component polymer and nanoparticles for magneto-chemotherapy/hyperthermia with multiple drugs. Advanced Materials, 2012, 24: 3627-3632. DOI:10.1002/adma.201201251 (  0) 0) |

| [91] |

Tian Y, Jiang X J, Chen X, et al. Doxorubicin-loaded magnetic silk fibroin nanoparticles for targeted therapy of multidrug-resistant cancer. Advanced Materials, 2014, 26(43): 7393-7398. DOI:10.1002/adma.201403562 (  0) 0) |

| [92] |

Wang C, Xu H, Liang C, et al. Iron oxide @ polypyrrole nanoparticles as a multifunctional drug carrier for remotely controlled cancer therapy with synergistic antitumor effect. ASC Nano, 2013, 7(8): 6782-6795. DOI:10.1021/nn4017179 (  0) 0) |

| [93] |

Chiang C S, Tseng Y H, Liao B J, et al. Magnetically targeted nanocapsules for PAA-cisplatin-conjugated cores in VA/SPIO shells via surfactant-free emulsion for reduced nephrotoxicity and enhanced lung cancer therapy. Advanced Healthcare Materials, 2015, 4(7): 1066-1075. DOI:10.1002/adhm.201400794 (  0) 0) |

| [94] |

Lee J H, Chen K J, Noh S H, et al. On-demand drug release system for in vivo cancer treatment through self-assembled magnetic nanoparticles. Angewandte Chemie International Edition, 2013, 52(16): 4384-4388. DOI:10.1002/anie.201207721 (  0) 0) |

| [95] |

Zhang Z L, He P, Zhang J Y, et al. Recent advances in magnetic targeting based on high magnetic field and magnetic particles. High Voltage, 2017, 2(4): 220-232. DOI:10.1049/hve.2017.0082 (  0) 0) |

| [96] |

Takeda S, Mishima F, Fujimoto S, et al. Development of magnetically targeted drug delivery system using superconducting magnet. Journal of Magnetism and Magnetic Materials, 2007, 311(1): 367-371. DOI:10.1016/j.jmmm.2006.10.1195 (  0) 0) |

| [97] |

Saho N, Nishijima N, Tanaka H, et al. Development of portable superconducting bulk magnet system. Physica C: Superconductivity, 2009, 469(15-20): 1286-1289. DOI:10.1016/j.physc.2009.05.134 (  0) 0) |

| [98] |

Mishima F., Terada T., Ohnishi T., et al. High-Speed Magnetic Filtration System Using HTS Bulk Magnet for Used Wash Water of Drum. IEEE Transactions on Applied Superconductivity, 2009, 19(3): 2165-2168. DOI:10.1109/TASC.2009.2018040 (  0) 0) |

| [99] |

Vejsada J, Hradil D, Randa Z, et al. Adsorption of cesium on Czech smectite-rich clays-a comparative study. Applied Clay Science, 2005, 30(1): 53-66. DOI:10.1016/j.clay.2005.03.003 (  0) 0) |

| [100] |

Bergaya F, Theng B K G, Lagaly G. Handbook of Clay Science. Amsterdam: Elsevier Science, 2006. (  0) 0) |

| [101] |

Igarashi S, Nomura S, Mishima F, et al. Study on magnetic separation for decontamination of cesium contaminated soil by using superconducting magnet. Physica C: Superconductivity and its Applications, 2014, 504: 144-147. DOI:10.1016/j.physc.2014.02.015 (  0) 0) |

| [102] |

Chen F F. Introduction to Plasma Physics and Controlled Fusion. 2nd ed. New York: Plenum, 1984.

(  0) 0) |

| [103] |

Roth J R. Industrial Plasma Engineering, Volume 1, Principles. Bristol: Institute of Physics Publishing, 1995.

(  0) 0) |

| [104] |

Itou K, Honda Y, Ohishi Y, et al. Compact, high-field magnetic mirrors formed by a pair of high-temperature superconducting bulk magnets applicable to plasma/charged particle beam devices. Physica C: Superconductivity, 2005, 433(1-2): 75-82. DOI:10.1016/j.physc.2005.04.039 (  0) 0) |

2020, Vol. 27

2020, Vol. 27