2. State Key Laboratory of Safety and Health for In-Service Long Span Bridges, JSTI Group, Nanjing 210019, China;

3. BRE Centre for Innovative Construction Materials, University of Bath, Bath BA2 7AY, UK

Nowadays, microbiologically-induced calcite-precipitation (MICP) in geotechnical treatment and structural repair has become significant and is emerging intensively[1-4]. With suitable environments, various types of bacteria can induce calcium carbonate, which is mainly in the form of calcite[5]. MICP can be brought by one of the following three routes: 1) enzymatic hydrolysis of urea, 2) aerobic metabolic conversion of calcium salts, and 3) dissimilation of nitrates[6-7]. In the first pathway, urea hydrolyses under the catalyst effect of urease from physiological activities of bacteria. The sequences involved in the precipitation of calcite was demonstrated by Siddique and Chahal[8] as follows:

| $ {\rm{CO(N}}{{\rm{H}}_{\rm{2}}}{{\rm{)}}_{\rm{2}}}{\rm{ + }}{{\rm{H}}_{\rm{2}}}{\rm{O}} \to {\rm{N}}{{\rm{H}}_{\rm{2}}}{\rm{COOH + N}}{{\rm{H}}_{\rm{3}}} $ | (1) |

| $ {\rm{N}}{{\rm{H}}_{\rm{2}}}{\rm{COOH + }}{{\rm{H}}_{\rm{2}}}{\rm{O}} \to {\rm{N}}{{\rm{H}}_{\rm{3}}}{\rm{ + }}{{\rm{H}}_{\rm{2}}}{\rm{C}}{{\rm{O}}_{\rm{3}}} $ | (2) |

| $ {{\rm{H}}_{\rm{2}}}{\rm{C}}{{\rm{O}}_{\rm{3}}} \to {\rm{HC}}{{\rm{O}}_{\rm{3}}}^{\rm{ - }}{\rm{ + }}{{\rm{H}}^{\rm{ + }}} $ | (3) |

| $ {\rm{2N}}{{\rm{H}}_{\rm{3}}}{\rm{ + 2}}{{\rm{H}}_{\rm{2}}}{\rm{O}} \to {\rm{2N}}{{\rm{H}}_{\rm{4}}}^{\rm{ + }}{\rm{ + 2O}}{{\rm{H}}^{\rm{ - }}}{\rm{(pH}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\rm{increase)}} $ | (4) |

| $ {\rm{HC}}{{\rm{O}}_{\rm{3}}}^{\rm{ - }}{\rm{ + }}{{\rm{H}}^{\rm{ + }}}{\rm{ + 2O}}{{\rm{H}}^{\rm{ - }}} \to {\rm{C}}{{\rm{O}}_{\rm{3}}}^{{\rm{2 - }}}{\rm{ + 2}}{{\rm{H}}_{\rm{2}}}{\rm{O}} $ | (5) |

| $ {\rm{C}}{{\rm{O}}_{\rm{3}}}^{{\rm{2 - }}}{\rm{ + C}}{{\rm{a}}^{{\rm{2 + }}}} \to {\rm{CaC}}{{\rm{O}}_{\rm{3}}}{\rm{(calcite}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\rm{precipitation)}} $ | (6) |

| $ \begin{array}{l} {\rm{CO (N}}{{\rm{H}}_{\rm{2}}}{{\rm{)}}_{\rm{2}}}{\rm{ + 2}}{{\rm{H}}_{\rm{2}}}{\rm{O + C}}{{\rm{a}}^{{\rm{2 + }}}} \to {\rm{2N}}{{\rm{H}}^{{\rm{4 + }}}}{\rm{ + }}\\ {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\rm{CaC}}{{\rm{O}}_{\rm{3}}}{\rm{(overall}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\rm{reaction) }} \end{array} $ | (7) |

Chahal et al.[9] found out the most suitable temperature for this process is from 22 to 32 ℃.

The first attempt of urea-hydrolyzing bacteria-based structural repair was utilized to protect stones in 1990[10-11], which was later suggested to be applied in the repair of concrete structures. In 2001, Ramachandran et al.[12] investigated the potential of combining sporosarcina pasteurii, nutrients, and sand as filling materials to repair concrete. They found that the strength and stiffness of samples treated by bacteria-based materials are obviously higher than those without any treatment. Day et al.[13] employed a microbiological method with various filling materials to seal cracks and examined the effects of the applied filling materials on the efficiency of crack repairing. Their results showed that the bacteria with polyurethane perform better in improving the stiffness of beam compared with other filling materials such as silica, fly ash, lime, and sand. Furthermore, De Belie and De Muynck[14] considered the use of B. sphaericus with ceramic as filling material instead of adding bacteria alone to seal the cracks of concrete, where bacteria are immobilised in a solution of silica so that it can survive from a higher pH of concrete. Their observations clearly demonstrated that the samples repaired by B. sphaericus with ceramic are similar to those repaired by epoxy injection. Richardson et al.[15-16]studied the ability of bacteria and medium (nutrients and precursor) on the surface treatment to repair concrete cracks. The capability of S. pasteurii to seal micro-cracks with depths of up to 20 mm was noted in their study. Similar studies have found out the improvement in the compressive strength of concrete by microbiological processes[17-20]. Moreover, microbiological treatment can improve the durability of concrete owing to enhanced impermeability of the surface[15-16].

In recent years, MICP has been further studied in structural repair to deliver self-healing capacity[21]. In these studies, bacteria and their growth components were mixed either directly or in the form of capsules in fresh concrete[22-25]. Urea hydrolysis was the first applied delivery strategy both in the repair of cracks and in self-healing concrete[26-28]. However, ammonium ions, the products of urea hydrolysis, may damage the environment by excessive loading of nitrogen[29]. Besides, urea cannot remain stable in a strong alkaline environment. Therefore, enzymatic urea hydrolysis has been suggested as the best externally applied repair treatment rather than a self-healing technique[30]. Nowadays, MICP based repair and self-healing are still in laboratory stage. Although repairing through external application is less innovative compared with self-healing technique, it is still worthy of further examination in order to remove the technical barriers in commercialisation.

With high fluidity and low viscosity, bio-based repair agents (RAs) can permeate easily into narrow cracks in concrete structures than traditional repair materials. Some researchers prefer to premix bacteria with a solution of urea to maximise carbonate ion content[31]. This is to ensure the presence of enough carbonate ions to contact calcium ion once the repair starts so as to effectively accelerate precipitation. It is expected that the repair would not take long time, but the premixing may arouse a concern that calcite may precipitate superficially and prevent deeper permeation.

To better investigate bacteria-based remediation of concrete cracks through externally applied repair strategy, this study analysed the remediation of cracks with two strategies: premixing bacteria with urea and without any premixing. Tracking observation, computed tomography (CT), water absorption, chloride penetration, and flexural strength tests were carried out to characterise bacteria-based remediation of concrete cracks, which clearly showed differences in the effectiveness between the two strategies. Analyses were separately conducted under two humidity environments (90% RH and 60% RH) to study the influence of humidity in combination with the two strategies. An in-site repair of an in-service bridge was also considered to illustrate the visual coordination of bio-calcite with concrete.

2 Materials and Methods 2.1 Bacteria StrainSporosarcina pasteurii DSM33 was used in this study. Living cells were routinely cultured in a medium containing 20 g/L yeast extract, 12.5 g/L (NH4)2SO4, 10 mg/L MnSO4·H2O, and 1.2 mg/L NiCl·6H2O. NaOH was added to adjust the pH to 8.5. Cell suspensions were prepared in the medium and incubated at 30 ℃ on an orbital shaker spinning at 200 r/m for 24 h till achieving an OD600 of 1.2 to 1.3. Cell suspensions were applied within 7 h after preparation to make different batches display a similar level of activity.

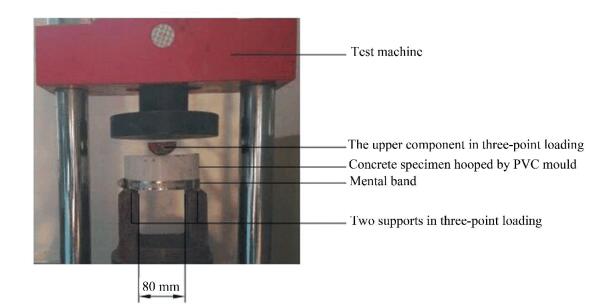

2.2 Concrete Specimens and Artificial CracksC40 concrete was casted into Φ100 mm×500 mm PVC pipes and cured for 28 days before cutting into 50 mm-thick specimens. The mix proportion of the concrete is shown in Table 1. Specimens with PVC pipes were then hooped with metal bands at the bottom (Fig. 1).

|

Fig.1 Artificial cracks making installation |

| Table 1 Mix proportion of C40 concrete in the study |

Artificial cracks on the specimens were produced by three-point loading at the speed of 0.01 kN/s. The span between two supports was 80 mm (Fig. 1). Test machine was turned off when the load either stopped increasing or started decreasing. Specimens were hooped with PVC moulds throughout the process. The moulds had to be patched after unloading as they were inevitability cracked during loading.

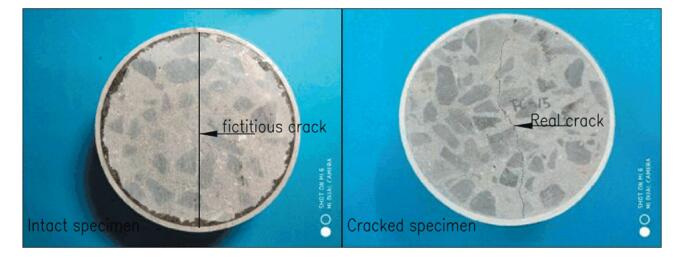

All V-shaped artificial cracks showed good consistency: 0.3-0.4 mm width on the cracked surfaces and 32±2 mm depth into cracked surfaces (never penetrated the specimens). A typical artificial crack is shown in Fig. 2. Compared with pre-embedding thin slice[31] and splitting loading[32], cracks made by bending were closer to real cracks in the tension zone of reinforced concrete components.

|

Fig.2 Overhead(a) and elevation views(b) of cracked specimens |

2.3 RAs and Environmental Humidity

In the study, all repair works were conducted by injecting RAs into cracks. The RAs consisting of RA1 and RA2 were properly mixed for a few minutes before use. Each cracked specimen was injected for 12 times and 3 times per day.

To investigate the effects of RAs on the remediation of concrete cracks, four different repair conditions were considered, i.e., repair combination (two strategies) and environmental humidity (two RH values). The details of grouping are provided in Table 2.

| Table 2 Details of grouping |

For groups BU 90 and BU 60, RA1 was prepared for 60 min before use to ensure the presence of abundant carbonate ions in the RAs when the repair started and the reaction could continue in an accelerated rate. However, an accelerated reaction rate might lead to a quick sealing in shallow spaces of cracks, which could impede the repair in deeper spaces. For groups CU 90 and CU 60, carbonate ions were at a much lower concentration before injection, so the reaction would not be accelerated.

In laboratory investigations, it is easy to provide an environment with high RH for ionic reaction. However, a high RH is not always achievable on a construction site. In this study, 90% RH was selected to simulate an ideal humidity, and a setup with 60% RH was also presented to simulate the normal conditions.

2.4 Physical Remediation of CracksThe surfaces of the cracks were recorded by using a camera after completing every injection. Moreover, Phoenix v|tome|x s microfocus industrial CT was used to assess the efficiency of internal healing of concrete cracks during repair. The applied scanning voltage, scanning current, and integration time were 180 kV, 100 μA, and 1000 ms, respectively.

2.5 Water Absorption TestSpecimens with PVC pipes were dried in an oven at 60±5 ℃ for 48 h, and then cooled down to room temperature. For a comprehensive comparison, intact specimens, cracked specimens, and repaired specimens were considered in the test. For intact specimen, a fictitious "crack" was assumed to coincide with any diameter of either side of the cylinder (Fig. 3).

|

Fig.3 Fictitious crack in intact specimen and real crack in cracked specimen |

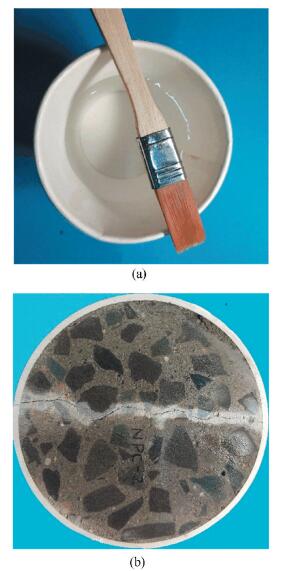

The whole surface, except where it was less than 5 mm from the crack, was covered with organosilicon polymer (Fig. 4).

|

Fig.4 Cracked surface coated with organosilicon polymer |

The coating on un-cracked area in cracked surface was to expand the differences among test results and make the differences have stronger relationship with the state of cracks, thus eliminating effects of the un-cracked area. After coating, the specimens were weighed. Then, the cracked surfaces were soaked into a 20 mm-deep thermostatic water tank and kept at 20 ℃ to conduct water absorption test. In the test, the soaking time and water absorption curves were recorded.

Tests for repaired specimens were the same as those for cracked specimens. Before testing for the repaired specimens, the cracked specimens to be repaired were injected with RAs for 12 times. Repaired specimens were cured for seven days at 20±2 ℃ under 60±5% RH before repeating the procedures. Specimens were hooped with PVC pipes in the whole process.

2.6 Electric Flux TestTo study the level of chloride-penetration resistance, electric flux test was conducted. The tests of resistance to chloride penetration were conducted in accordance with GB/T 50082-2009 Standard for test methods of long-term performance and durability of ordinary concrete, which is similar to ASTM C 1202. However, all fictitious (Fig. 3), repaired and un-repaired cracked surfaces, were coated as described in Section 2.5 before tests. For device installation, the cracked surfaces of specimens had to contact the cathode.

2.7 Flexural Strength TestBefore flexural strength testing, PVC pipes were removed from the specimens. The tests were then conducted by three-point loading at the speed of 0.01 kN/s. The upper component of the rig was in contact with the crack. The span between other two components (two supports) was 80 mm. Repaired specimens were cured at 20±2 ℃ and under 60±5 % RH for seven days before subjected to this test.

2.8 In-site RepairIn this study, a vertical crack on the side of Ramp Bridge H of Zhennan Interchange, the starting point of No.338 Provincial Highway, was chosen for an in-site repair evaluation. At the beginning, a solution of bacteria and urea were mixed (RA1) for 60 min before use, while Ca(NO3)2 solution (RA2) was prepared as described in Section 2.3. RA1 and RA2 were mixed and injected into the crack using injectors until the crack was filled with solution. Such injection was repeated as described in Section 2.3. During repair, the site temperature was at 23-30 ℃, and the site humidity was at 49%-90% RH.

3 Results and Discussion 3.1 Photographing of Traces of External SealingPhysical remediation includes external sealing and internal healing. External sealing is the most intuitionistic indicator for the repair of specimens or structures, and the easiest to control. It is the first barrier to prevent harmful substances from entraining into concrete matrix. Although external sealing can always be achieved by extending the operation time of repair or increasing repetitions of repair works as long as the methodology of the repair is correct, the operation period is very important for the commercialisation of a new repair technology.

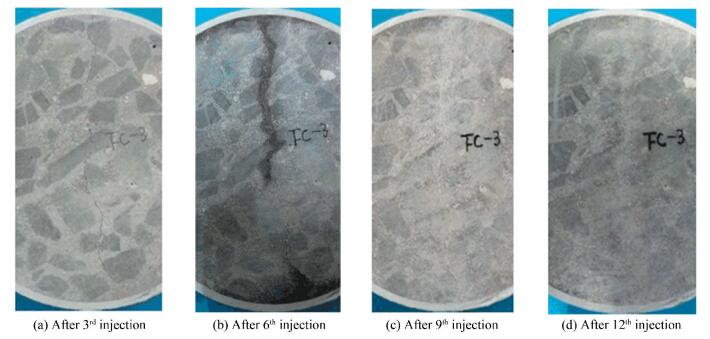

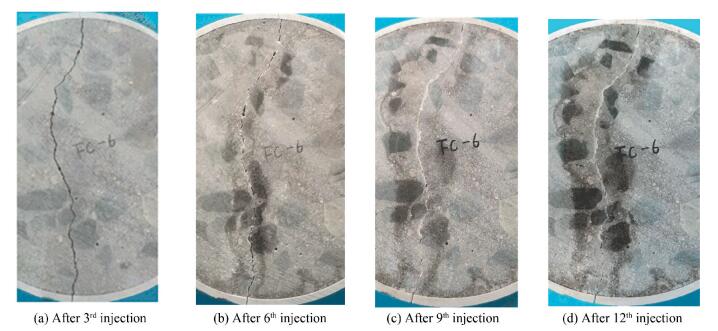

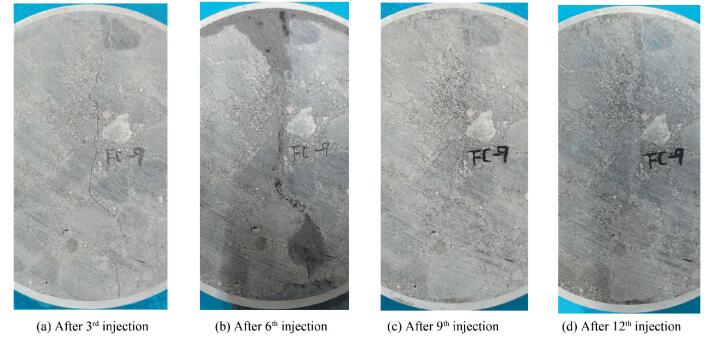

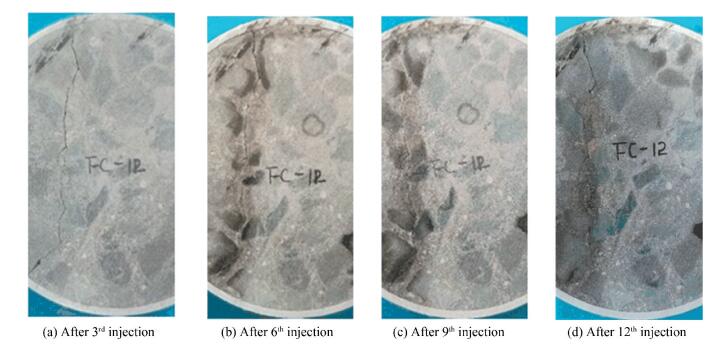

Traces of the whole process of sealing typical cracks are shown in Figs. 5-8, where the speed of the crack remediation can be clearly observed. Precipitates could not be observed until the RAs were injected for more than six times. After the 6th injection, the surfaces of the cracks gradually began to be sealed. After the 12th injection, calcite precipitates perfectly sealed the crack surfaces.

|

Fig.5 Images of traces of cracks healing of BU 90 |

|

Fig.6 Images of traces of cracks healing of BU 60 |

|

Fig.7 Images of traces of cracks healing of CU 90 |

|

Fig.8 Images of traces of cracks healing of CU 60 |

Tracking observations of the traces confirmed that a high RH is good for the sealing of cracks. This may be due to the reaction type of enzymatic urea hydrolysis, which is a series of ionic reactions where sufficient water is necessary. At 90% RH, repair either with premixing bacteria with urea in solution or without premixing showed effective external sealing, and the rate of which was obviously higher than those under 60% RH.

However, in the case of 60% RH, it was found that the premixing showed an acceleration effect compared with that without premixing, as expected. The cause might be the presence of abundant carbonate ions which were well distributed in the solution by premixing and a higher concentration of reactants which accelerated the reactions.

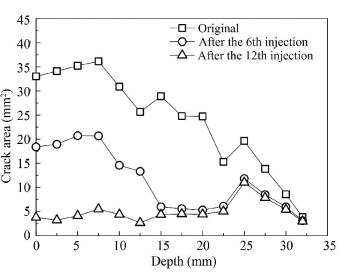

3.2 CT Visualisation of Internal HealingInternal healing is essential to guarantee further remediation of cracked concrete. Only when the cracks are filled with repair materials, its ability to resist harmful substances can be rejuvenated. Unlike photographing of traces, CT can scan the internal spaces of concrete cracks and reflect their geometric characteristics. The calculated crack areas obtained from CT scan results are provided in Figs. 9-10.

|

Fig.9 Crack area of BU 90 during injections |

|

Fig.10 Crack area of CU 90 during injections |

From these figures it can be noted that the effective depth of repair from bacteria-based delivery reached more than 25 mm. With first 6 times of injections, the precipitates filled more than 40% crack spaces from 0 to 15 mm deep and most crack spaces from 15 to 25 mm deep. The rest of the crack spaces from 0 to 15 mm deep was nearly filled when it was injected for more than 6 times, but such injections made limited contribution to the healing of crack spaces that were more than 15 mm deep. By comparing Fig. 9 and Fig. 10, it can be found that BU 90 performed slightly better than CU 90 in deep healing, especially when it was deeper than 15 mm from the surface, although both of them revealed effective healing of shallower spaces of cracks.

The results cleared up the doubts that accelerated precipitation by premixing bacteria with urea in solution might prevent deeper permeation. On the contrary, groups without premixing did not show the predicted superiority, which might be because of the heterogeneity of components in the RAs. Also, the rate of enzymatic hydrolysis of urea might be negatively affected by water evaporation and the increase in alkalinity. However, in shallow spaces, the possible negative effect should be compensated by the continuous supply of carbon dioxide from air.

3.3 Rejuvenation of Resistance to Water AbsorptionPermeability is a key factor for concrete durability, which positively correlates to water absorption. It is unlikely to expect that the resistance to water absorption of cracked concrete can be completely rejuvenated after repair because calcite has a higher permeability than C-S-H gel of concrete matrix. However, the calcite precipitates can protect the internal capillary system of concrete from direct exposure to water and hence reduce water absorption.

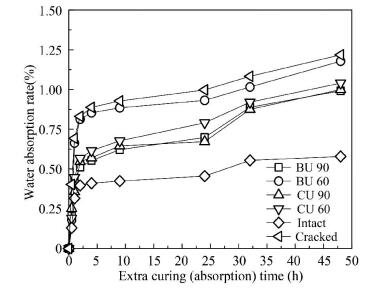

The test results of constant water absorption are shown in Fig. 11. That the curves of BU 90 and CU 90 were almost coincident with each other indicates a significant rejuvenation of water absorption resistance of cracked concrete, though they were still lower than those of intact specimens. A high resemblance in water absorption of BU 90 and CU 90 confirmed the similarity of both external sealing and internal healing as described in Sections 3.1 and 3.2.

|

Fig.11 Water absorption of concrete crack repaired in different conditions |

The water absorption rate of CU 60 was slightly higher than those of BU 90 and CU 90, whilst in the case of BU 60, the reduction in water absorption was limited compared with cracked specimens. These differences were also consistent with those in physical remediation in Sections 3.1 and 3.2.

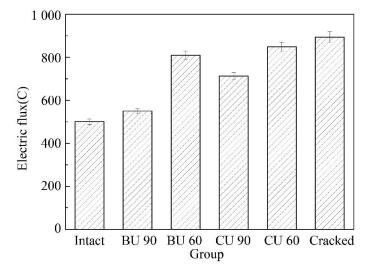

3.4 Rejuvenation of Resistance to Chloride PenetrationElectric flux is often used as an index to assess the resistance to chloride penetration of concrete materials. The test results of electric flux are shown in Fig. 12. The repair works were confirmed to rejuvenate the resistance to chloride penetration of cracked concrete, however, the rejuvenation effects varied among the tested groups. In the tests, the premixing of bacteria with urea brought more effective rejuvenation compared with the increase of humidity, although both of which had positive effects on the rejuvenation. Compared with CU 90, better performance of BU 90 in chloride penetration resistance confirmed the better internal healing as illustrated in Figs. 9-10. It is very encouraging to note that BU 90 successfully eliminated most of the detrimental effect on resistance to chloride penetration caused by cracking, indicating that MICP is good in protecting reinforced concrete structures under favorable repair conditions. The reason of the rejuvenation in chloride penetration resistance is that the calcite precipitates prevent internal capillary system of concrete from exposing to environments with abundant chloride presence.

|

Fig.12 Electric flux of concrete crack repaired in different conditions |

3.5 Rejuvenation of Flexural Strength

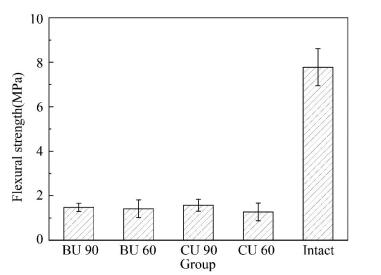

Although it is known that the mechanical properties of calcite are inferior to hydrated calcium silicate, the product of cement hydration, it is still expected that the precipitates can more or less contribute to the tensile or flexural strength so as to potentially adjust further expansion of the repaired cracks in addition to filling the crack.

Test results of flexural strength are shown in Fig. 13, which indicate that a flexural strength of 16%-20% could be rejuvenated by repair works. Indeed, such level of rejuvenation is better to be considered as a good bonding between calcite and concrete instead of a rejuvenation of flexural loading capacity followed in routine engineering practice. Humidity is essential for rejuvenation in flexural strength and CU 90 had the highest flexural strength after repair. However, the results of all groups, except for the intact group, showed significant deviations, especially those repaired in low humidity. Additionally, the cracked specimens without repair showed no flexural strength.

|

Fig.13 Flexural strength of concrete repaired in different conditions |

On the basis of a good bonding between calcite and concrete combined with the well-known superiority of calcite in deformability compared with concrete, it can be deduced that MICP has good adjustability to potential expansion of repaired cracks. Moreover, the mechanical contribution brought by precipitates in deep spaces of cracks would ameliorate crack-tip stress field to restrain further cracking.

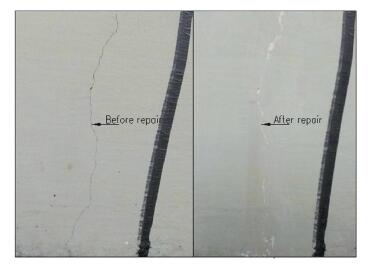

3.6 Visual Coordination of In-site Bridge RepairVisual coordination with original concrete is always considered in repair materials selection. A couple of in-site concrete repair photographs are displayed in Fig. 14, exhibiting the exterior of a 0.3 mm-wide crack on a bridge before and after repair works by bacteria-based agents. It showed that MICP successfully sealed the cracks. The precipitated calcite presented a good visual coordination as it blended in well with bridge concrete.

|

Fig.14 Bacteria-based crack remediation on concrete bridge |

4 Conclusions

Physical and impermeable rejuvenation of concrete cracks repaired by MICP in enzymatic urea hydrolysis pathway were investigated. The physical rejuvenation was characterised by photographing of traces of external sealing and CT visualisation of internal healing. While impermeable rejuvenation was characterised by resistance to water absorption and chloride penetration. The bonding strength of bio-calcite precipitates with concrete matrix was assessed by flexural strength rejuvenation. Visual coordination of precipitates with concrete structures was also discussed in the study. Results show that bacteria-based repair delivered good rejuvenation in physical and impermeable properties. The repair depth could reach more than 25 mm, the precipitates had good bonding with concrete matrix, and the visual quality of the repaired structure was good.

In the characterisation of bacteria-based crack rejuvenation by externally applied repair, the effectiveness of two strategies including premixing of bacteria with urea in solution before repair and without any premixing were analysed under two RHs (i.e., 90% RH and 60% RH). The obtained results confirmed that humidity is very important to the bacteria-based repair process. Moreover, the premixing of bacteria with urea in solution showed not only a slightly better healing in deep spaces but also significant superiority in resistance to chloride penetration. The outcome from this investigation is very important because the potentially negative effects caused by the accelerated reactions can be avoided and the efficiency of repair can be significantly improved. However, further tests are needed to ensure that the premixing does not impede bacterial activity.

AcknowledgementsThe authors would like to acknowledge Zhenjiang Highway Management Office and Dr. Yixuan Han for providing in-site study opportunities. Dr. Ang Li is thanked for his guidance in works about microbiology in the study. We thank technical staff in the School of Transportation Science and Engineering and the School of Environment at Harbin Institute of Technology for key support.

| [1] |

Weiner S, Dove P M. An overview of biomineralization processes and the problem of the vital effect. Reviews in Mineralogy and Geochemistry, 2003, 54(1): 1-29. DOI:10.2113/0540001 (  0) 0) |

| [2] |

Dick J, De Windt W, De Graef B, et al. Bio-deposition of a calcium carbonate layer on degraded limestone by Bacillus species. Biodegradation, 2006, 17(4): 357-367. DOI:10.1007/s10532-005-9006-x (  0) 0) |

| [3] |

De Muynck W, De Belie N, Verstraete W. Microbial carbonate precipitation in construction materials: A Review. Ecological Engineering, 2010, 36(2): 118-136. DOI:10.1016/j.ecoleng.2009.02.006 (  0) 0) |

| [4] |

Okumura T, Takashima C, Kano A. Textures and processes of laminated travertines formed by unicellular cyanobacteria in Myoken hot spring, southwestern Japan. Island Arc, 2013, 22(3): 410-426. DOI:10.1111/iar.12034 (  0) 0) |

| [5] |

Boquet E, Boronat A, Ramos-Cormenzana A. Production of calcite (calcium-carbonate) crystals by soil bacteria is a general phenomenon. Nature, 1973, 246: 527-529. DOI:10.1038/246527a0 (  0) 0) |

| [6] |

Morse J W. The kinetics of calcium carbonate dissolution and precipitation. Reviews in Mineralogy and Geochemistry, 1983, 11(1): 227-264. (  0) 0) |

| [7] |

Frankel R B, Bazylinski D A. Biologically induced mineralization by bacteria. Reviews in Mineralogy and Geochemistry, 2003, 54(1): 95-114. DOI:10.2113/0540095 (  0) 0) |

| [8] |

Siddique R, Chahal N K. Effect of ureolytic bacteria on concrete properties. Construction and Building Materials, 2011, 25(10): 3791-3801. DOI:10.1016/j.conbuildmat.2011.04.010 (  0) 0) |

| [9] |

Chahal N, Siddique R, Rajor A. Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of fly ash concrete. Construction and Building Materials, 2012, 28(1): 351-356. DOI:10.1016/j.conbuildmat.2011.07.042 (  0) 0) |

| [10] |

Adolphe J P, Loubiere J F, Paradas J, et al. Procédé de traitement biologique d'une surface artificielle. European Patent. 90400G97.0. 1990.

(  0) 0) |

| [11] |

Richardson A, Coventry K A, Forster A M, et al. Surface consolidation of natural stone materials using microbial induced calcite precipitation. Structural Survey, 2014, 32(3): 265-278. DOI:10.1108/SS-07-2013-0028 (  0) 0) |

| [12] |

Ramachandran S K, Ramakrishnan V, Bang S S. Remediation of concrete using microorganisms. Aci Materials Journal, 2001, 98: 3-9. DOI:10.14359/10154 (  0) 0) |

| [13] |

Day J, Ramakrishnan V, Bang S S. Microbiologically induced sealant for concrete crack remediation. Proceedings of the 16th Engineering Mechanics Conference. Seattle, 2003. 1-8. https://www.researchgate.net/publication/237213296_MICROBIOLOGICALLY_INDUCED_SEALANT_FOR_CONCRETE_CRACK_REMEDIATION.

(  0) 0) |

| [14] |

De Belie N, De Muynck W. Crack repair in concrete using biodeposition. Proceedings of the 2nd International Conference on Concrete Repair, Rehabilitation and Retrofitting.London: CRC Press, 2008.291-292.

(  0) 0) |

| [15] |

Richardson A, Coventry K, Pasley J. Micro-induced calcite precipitation: Crack sealing application. http://nrl.northumbria.ac.uk/id/eprint/27235, 2019-03-19.

(  0) 0) |

| [16] |

Richardson A, Coventry K, Pasley J. Bacterial crack sealing and surface finish application to concrete. http://www.claisse.info/2016%20papers/M100.pdf, 2019-03-19.

(  0) 0) |

| [17] |

Bang S S, Lippert J J, Yerra U, et al. Microbial calcite, a bio-based smart nanomaterial in concrete remediation. International Journal of Smart and Nano Materials, 2010, 1(1): 28-39. DOI:10.1080/19475411003593451 (  0) 0) |

| [18] |

Ramakrishnan V. Performance characteristic of bacterial concrete-a smart biomaterial. Proceedings of 1st International Conference on Recent Advances in Concrete Technology. Lancaster: DEStech Publications, 2007, 67-68. (  0) 0) |

| [19] |

De Muynck W, Debrouwer D, De Belie N, et al. Bacterial carbonate precipitation improves the durability of cementitious materials. Cement and Concrete Research, 2008, 38(7): 1005-1014. DOI:10.1016/j.cemconres.2008.03.005 (  0) 0) |

| [20] |

Achal V, Mukherjee A, Reddy M S. Effect of calcifying bacteria on permeation properties of concrete structures. Journal of Industrial Microbiology & Biotechnology, 2011, 38(9): 1229-1234. DOI:10.1007/s10295-010-0901-8 (  0) 0) |

| [21] |

Li W T, Dong B Q, Yang Z X, et al. Recent advances in intrinsic self-healing cementitious materials. Advanced Materials, 2018, 30(17): 1705679. DOI:10.1002/adma.201705679 (  0) 0) |

| [22] |

Alazhari M, Sharma T, Heath A, et al. Application of expanded perlite encapsulated bacteria and growth media for self-healing concrete. Construction and Building Materials, 2018, 160: 610-619. (  0) 0) |

| [23] |

Wiktor V, Jonkers H M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cement and Concrete Composites, 2011, 33(7): 763-770. DOI:10.1016/j.cemconcomp.2011.03.012 (  0) 0) |

| [24] |

Erşan Yç, Hernandez-Sanabria E, Boon N, et al. Enhanced crack closure performance of microbial mortar through nitrate reduction. Cement and Concrete Composites, 2016, 70: 159-170. DOI:10.1016/j.cemconcomp.2016.04.001 (  0) 0) |

| [25] |

Alazhari M, Sharma T, Cooper R, et al. Effect of bacterial self-healing agents on the early-age properties of cementitious materials. https://www.researchgate.net/publication/299742248_Effect_of_bacterial_self-healing_agents_on_the_early-age_properties_of_cementitious_materials, 2019-03-19.

(  0) 0) |

| [26] |

Bang S S, Galinat J K, Ramakrishnan V. Calcite precipitation induced by polyurethane-immobilized Bacillus pasteurii. Enzyme and Microbial Technology, 2001, 28(4-5): 404-409. DOI:10.1016/S0141-0229(00)00348-3 (  0) 0) |

| [27] |

De Muynck W, Verbeken K, De Belie N, et al. Influence of temperature on the effectiveness of a biogenic carbonate surface treatment for limestone conservation. Applied Microbiology and Biotechnology, 2013, 97(3): 1335-1347. DOI:10.1007/s00253-012-3997-0 (  0) 0) |

| [28] |

Hasan H A H. Ureolytic microorganisms and soil fertility: A review. Communications in Soil Science and Plant Analysis, 2000, 31(15-16): 2565-2589. DOI:10.1080/00103620009370609 (  0) 0) |

| [29] |

Jonkers H M, Thijssen A, Muyzer G, et al. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecological Engineering, 2010, 36(2): 230-235. DOI:10.1016/j.ecoleng.2008.12.036 (  0) 0) |

| [30] |

Achal V, Mukerjee A, Reddy M S. Biogenic treatment improves the durability and remediates the cracks of concrete structures. Construction and Building Materials, 2013, 48: 1-5. DOI:10.1016/j.conbuildmat.2013.06.061 (  0) 0) |

| [31] |

Jia Q, Zhao C C, Sun Z B. Bearing pressure experimental research of the concrete cracks after bioremedying. Journal of Basic Science and Engineering, 2017, 25(1): 141-148. (in Chinese) DOI:10.16058/j.issn.1005-0930.2017.01.013.(inChinese) (  0) 0) |

| [32] |

Alazhari M, Sharma T, Heath A, et al. Application of expanded perlite encapsulated bacteria and growth media for self-healing concrete. Construction and Building Materials, 2018, 160: 610-619. DOI:10.1016/j.conbuildmat.2017.11.086 (  0) 0) |

2020, Vol. 27

2020, Vol. 27