2. School of Electro-Mechanical Engineering, Harbin Institute of Technology, Harbin 150001, China

The winter time in northern China is long, where snow and ice often occur on roads, especially on expressways and living areas, seriously affecting the normal production and daily activities of people.

Snow melting agent as an efficient solution has become a key component of deicing and snow removal, which is mainly divided into manual throwing and institutional throwing [1-6]. Manual throwing is labor intensive and harmful to clothing and skin because of the chemical action of the snow melting agent [7-12]. Moreover, the poor dynamic performance of the existing throwing mechanisms results in unstable performance and uneven throwing, due to the lack of appropriate research methods and means for mechanism motion characteristics. Thus the corresponding motion parameters cannot be adjusted timely according to the road conditions to improve the throwing efficiency [13-17]. Therefore, it is necessary to develop an effective throwing mechanism and a research method of motion performance to improve the throwing efficiency and dynamic performance while reducing the amount of throwing and the environmental pollution.

Nowadays, snow melting agents are evenly distributed on pavement at home and abroad. However, practice has proved that there is no relationship between uniform distribution and snow melting efficiency, and the distribution density of snow melting agent is the main factor that affects snow melting efficiency. The non-uniform distribution of snow melting agent by pulse method is proved to be better than the uniform distribution method through experiments [18]. Variable crank length cam-linkage rod combination mechanism can accurately meet any given trajectory requirements, reduce the overall size of the mechanism, and improve the dynamic performance of the machine [19-21].

To address the above problems, a snow melting agent throwing mechanism with variable crank length is designed in this paper. By analyzing its motion characteristics and combining the Visual Basic (VB) programming, a parametric model of key parts of the mechanism with human-computer interaction function based on knowledge engineering and computer aided three-dimensional interactive application (CATIA) secondary development technology is established, which improves the throwing efficiency and the realization of snow melting agent, as well as provides an effective mechanism and method for rapid modeling of complex mechanisms.

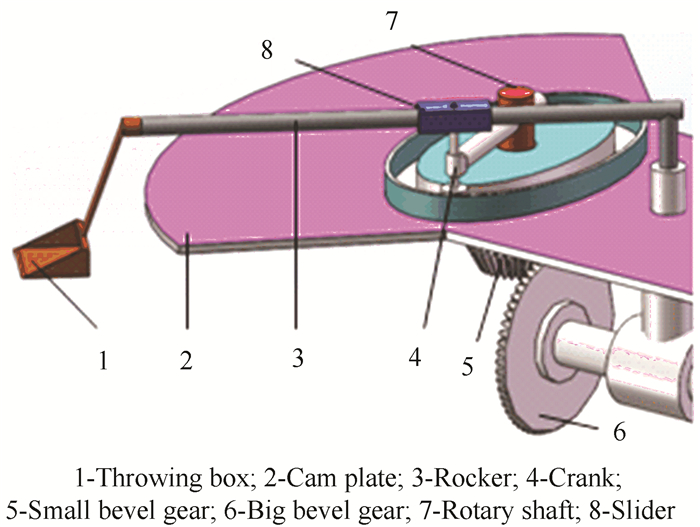

1 Overall Structures and Working PrincipleThe variable crank length snow melting agent throwing mechanism is mainly composed of a transmission part, an execution part, and a trajectory control part. The transmission part consists of a large bevel gear and a small bevel gear. The executive part consists of a rotary shaft, a crank, a rocker, a slider, and a throwing frame. The trajectory control part consists of a cam plate. The dispersal device of the snow melting agent and the overall structure throwing mechanism are shown in Figs. 1-2. The working principle of the mechanism is that the big bevel gear transfers power to the small bevel gear, which then drives the rotary shaft fixed to the small bevel gear, and lastly the rotary shaft drives the T-type crank to rotate. Because of the shape locking, the roller at one end of the T-type crank transverse rod moves in the cam groove of the cam plate, and the slider at the other end drives the rocker to swing back and forth to complete the snow melting process.

|

Fig.1 Dispersal device of snow melting agent |

|

Fig.2 Overall structure diagram of throwing mechanism |

2 Kinematics Modeling and Simulation of Variable Crank Length Mechanism

As shown in Fig. 3, the kinematics equation of the mechanism was established based on analytic method. The length lOB of the crank OB varies with the change of the cam diameter, and the angle between it and the x-axis is θ1. The length lAC of the rocker AC is fixed, and the angle between it and the x-axis is θ2. Assuming that the cam is elliptic-like structure, the long half-axis of the ellipse is On and the short half-axis is Om. When the ratio of the length between the long and the short half-axes changes, the profile of the cam will change, and the distance from slider to swing center lAB will change accordingly. Taking θ1 as a variable, the top of the rocker is represented by the point C, and its coordinate equation is established as follows:

| $ \left\{ {\begin{array}{*{20}{c}} {{x_C} = {l_{AC}}{\rm{cos}}{\theta _2}}\\ {{y_C} = {l_{AC}}{\rm{sin}}{\theta _2}} \end{array}} \right. $ | (1) |

|

Fig.3 Motion analysis diagram of throwing mechanism |

where

| $ \begin{array}{l} {\rm{cos}}{\theta _2} = \frac{{{l_{OB}}}}{{\sqrt {{l_{OA}}^2 + {l_{OB}}^2 + 2{l_{OA}}{l_{OB}}{\rm{sin}}{\theta _1}} }}{\rm{cos}}{\theta _1}\\ {\rm{sin}}{\theta _2} = \frac{{{l_{OB}}{\rm{sin}}{\theta _1} + {l_{OA}}}}{{\sqrt {{l_{OA}}^2 + {l_{OB}}^2 + 2{l_{OA}}{l_{OB}}{\rm{sin}}{\theta _1}} }}\\ {l_{OB}} = \sqrt {O{n^2}{\rm{cos}}{\theta _1}^2 + O{m^2}{\rm{sin}}{\theta _1}^2} \end{array} $ |

where θ1=ωt, ω is the angular velocity of the crank, and t represents the time.

In order to verify the correctness of Eq. (1), the lengths of each component in the mechanism were defined as follows: lOm equals 40 mm, lOn equals 60 mm, lOA equals 80 mm, lAC equals 155 mm, ω equals 60 rad/s, and the forward speed of mechanism v0 equals 18 m/s. By introducing the above values of structural parameters and motion parameters into Eq. (1), the coordinates of point C which varies with time can be obtained, from which the trajectory of the snow melting agent can be obtained. The model of the variable crank length snow melting agent throwing mechanism was established by using CATIA software. The kinematics simulation of the throwing mechanism was carried out by Digital Mockup (DMU) module. The comparison between the theoretical trajectory derived by Eq. (1) and the simulation trajectory obtained by CATIA software is presented in Fig. 4.

|

Fig.4 Trajectory contrast diagram of throwing mechanism |

From Fig. 4, it can be seen that the simulation trajectory and the theoretical trajectory basically coincided with each other, and the error was very small. Moreover, it was found that the theoretical deduction results in this paper are accurate and reliable.

In order to study the influence of different parameters on the trajectory of throwing, the parametric analysis method was used to investigate the effects of cam structural parameters, rotary shaft angular velocity, and the overall forward velocity of the throwing mechanism on the trajectory and the acceleration of throwing. The results are shown in Figs. 5-7.

|

Fig.5 Diagrams of effects of structural parameters |

|

Fig.6 Diagrams of effects of angular velocity |

|

Fig.7 Diagrams of effects of forward velocity |

It can be observed in Fig. 5 that when a/b (i.e., the ratio of the lengths of the cam's long and short half-axes) increases gradually, the throwing trajectory of the snow melting agent presents pulsation characteristics, the peak value becomes larger, the wave peak becomes sharper, the spreading width increases, the spacing changes insignificantly, and the acceleration curve of the snow melting agent throwing gradually becomes gentle. When the ratio exceeds 2.5, the acceleration curve exhibits sharp points, which indicates that the motion becomes unstable.

According to Fig. 6, when the angular velocity of the rotary shaft increases, the spreading width remains unchanged, the spraying interval increases, and the amplitude of the throwing acceleration increases gradually, while the increase is not large and the period of speed and acceleration decrease.

From Fig. 7, it can be found that under the same conditions, with the change of the overall forward speed of the mechanism, the peak value of the throwing trajectory changes obviously. With the increase of the forward velocity, the spreading width remains unchanged, the spacing becomes larger, and the throwing acceleration does not change significantly.

3 Parameter Optimization and Human-Computer Interaction Design of Throwing MechanismIn order to facilitate designers to modify the structural parameters of the throwing mechanism according to the road conditions and adjust the matching relationship between dynamic parameters in real-time, a human-computer interaction simulation system for the variable crank length throwing mechanism was established by using VB6.0 software as shown in Fig. 8, in which the left side is the input box of structural parameters and dynamic parameters, and the middle is the trajectory display area.

|

Fig.8 Human-computer interaction simulation system for throwing mechanism |

According to the provisional provisions of the national urban planning quota indicators, the maximum width of the main road is 60 m, and the number of two-way motor lanes is 4. If the width of the middle isolation zone is removed, 2 L2, which is the spreading width of the snow melting agent, should reach 3.5 m. Considering the abilities of different snow melting agents, the spreading interval of L1 should not be greater than 1.5 m. Therefore, according to the requirements of snow melting agent distribution, three-level and four-factor orthogonal experiments were adopted to design the spraying width and spacing of the snow melting agent, respectively. The results are presented in Tables 1-2.

| Table 1 Orthogonal test of throwing width |

| Table 2 Orthogonal test of throwing spacing |

In the tables, A, B, C, and D represent the factors of orthogonal test, respectively. The subscript in A3, B2, C2, and D1 indicate the level of the specific factor. v represent the travel speed of the throwing mechanism. yj and zj represent the width and spacing that can be achieved under each combination. The subscripts in yj1, yj2, and yj3 indicate the sum of each lever for width. The subscripts in zj1, zj2, and zj3 indicate the sum of each lever for spacing.

The rules and checking attributes to meet the requirements of specific throwing trajectory were determined based on the principle of knowledge engineering. When the parameters fail to meet the requirements, the interactive system prompts the parameters to make mistakes, which provides guidance for the subsequent improvement design.

According to the orthogonal test design of throwing width and spacing, the optimum parameters for winter snow melting agent throwing in Harbin are as follows: the length of cam long half-axis is 2000 mm, the length of cam short half-axis is 1200 mm, the forward speed of the whole machine is 20 m/s, and the angular speed of the rotating axis is 60 rad/s.

4 ConclusionsIn this paper, a snow melting agent throwing mechanism is designed, and its trajectory, velocity, and acceleration are deduced by theoretical analysis. The correctness of the theoretical results was verified by CATIA motion simulation. The effects of different structural parameters and motion parameters on the trajectory and motion characteristics of the throwing mechanism were compared using parametric method. The human-computer interaction simulative system of the throwing mechanism was established by VB programming. Based on knowledge engineering and combined with the parameters of main roads in Harbin, a three-level and four-factor orthogonal test table was constructed. The human-computer interaction simulation system was used to obtain the optimum structure and working parameter combination of the throwing mechanism suitable for Harbin, which lays a theoretical foundation for the use of variable crank length snow melting agent throwing mechanism. The specific conclusions are drawn as follows:

1) With the increase of the length ratio of the long half shaft and the short half shaft of the cam, the spreading width increased, and the spreading interval did not change significantly. When the ratio exceeded 2.5, the acceleration curve presented a sharp point, and the spreading motion became uneven and stable;

2) When the rotary angular velocity increased, the spreading width remained the same, the spreading interval increased, and the amplitude of the spreading acceleration increased;

3) With the increase of the overall forward speed of the throwing mechanism, the spreading width remained the same, the spreading interval became larger, and the spreading acceleration did not change significantly, which means the movement was stable.

| [1] |

Liu S, Zheng N X, Yang J, et al. Ice melting performance of deicers and their effect on stripping resistance of asphalt mixture. Journal of Southeast University (English Edition), 2016, 32(3): 327-332. DOI:10.3969/j.issn.1003-7985.2016.03.012 (  0) 0) |

| [2] |

Zdaniuk G J, Chamra L M, Mago P J. Experimental determination of heat transfer and friction in helically-finned tubes. Experimental Thermal and Fluid Science, 2008, 32(3): 761-775. DOI:10.1016/j.expthermflusci.2007.09.006 (  0) 0) |

| [3] |

Huneault M, Langheit C, Caron J. Combined models for glaze ice accretion and de-icing of current-carrying electrical conductors. IEEE Transactions on Power Delivery, 2005, 20(2): 1611-1616. DOI:10.1109/tpwrd.2004.838466 (  0) 0) |

| [4] |

Wang J, Liu H T. Snow removal resource location and allocation optimization for urban road network recovery: a resilience perspective. Journal of Ambient Intelligence and Humanized Computing, 2019, 10(1): 395-408. DOI:10.1007/s12652-018-0717-3 (  0) 0) |

| [5] |

Siu M F F, Liu C, Wales R, et al. Operation effort optimization for planning performance-based snow-removal projects. Journal of Computing in Civil Engineering, 2017, 31(6): 04017060. DOI:10.1061/(ASCE)CP.1943-5487.0000709 (  0) 0) |

| [6] |

Quirion-Blais O, Langevin A, Trépanier M. A case study of combined winter road snow plowing and de-icer spreading. Canadian Journal of Civil Engineering, 2017, 44(12): 1005-1013. DOI:10.1139/cjce-2017-0185 (  0) 0) |

| [7] |

Min Z H, Xia Y Y, Li X C, et al. Performances evaluation of epoxy asphalt mixture containing snow-melting agent. Construction and Building Materials, 2017, 155: 762-769. DOI:10.1016/j.conbuildmat.2017.08.009 (  0) 0) |

| [8] |

Klein-Paste A, Sinha N K. Comparison between rubber-ice and sand-ice friction and effect of loose snow contamination. Tribology International, 2010, 43(5-6): 1145-1150. DOI:10.1016/j.triboint.2009.12.037 (  0) 0) |

| [9] |

Wu Y H. Development of a new non-chloride snow-melting agent. Applied Mechanics and Materials, 2013, 368-370: 716-719. DOI:10.4028/www.scientific.net/AMM.368-370.716 (  0) 0) |

| [10] |

Wu Y H. Study on environmentally-friendly snow-melting agents application. Advanced Materials Research, 2013, 709: 923-927. DOI:10.4028/www.scientific.net/AMR.709.923 (  0) 0) |

| [11] |

Fan X H, Wu Y H, Liu J Y. Impacts of highway snow-melting agents on greening vegetation. Advanced Materials Research, 2014, 831: 272-275. DOI:10.4028/www.scientific.net/AMR.831.272 (  0) 0) |

| [12] |

Wang Z J, Zhang T, Shao M Y, et al. Investigation on snow-melting performance of asphalt mixtures incorporating with salt-storage aggregates. Construction and Building Materials, 2017, 142: 187-198. DOI:10.1016/j.conbuildmat.2017.03.070 (  0) 0) |

| [13] |

Vo H V, Park D W, Dessouky S. Simulation of snow melting pavement performance using measured thermal properties of graphite-modified asphalt mixture. Road Materials and Pavement Design, 2015, 16(3): 696-706. DOI:10.1080/14680629.2015.1020847 (  0) 0) |

| [14] |

Jin Y, Liu L X, Xiao P F. Study on influence of snowmelt agent to performances of asphalt. Advanced Materials Research, 2014, 960-961: 78-81. DOI:10.4028/www.scientific.net/AMR.960-961.78 (  0) 0) |

| [15] |

Tao S C, Yao J L, Chen C Y, et al. The impact of expressway snowmelt agent usage on the environment in an extreme freezing snow and sleet condition. IOP Conference Series: Earth and Environmental Science, 2018, 191(1): 2-9. DOI:10.1088/1755-1315/191/1/012073 (  0) 0) |

| [16] |

Wang Z J, Li F P, Ma R, et al. Experiment on road performance on asphalt mixture with automatic long-term snowmelt agent. International Journal of Pavement Research and Technology, 2013, 6(4): 372-378. DOI:10.6135/ijprt.org.tw/2013.6(4).372 (  0) 0) |

| [17] |

Fu L P, Sooklall R, Perchanok M S. Effectiveness of alternative chemicals for snow removal on highways. Transportation Research Record, 2006, 1948: 125-134. DOI:10.3141/1948-14 (  0) 0) |

| [18] |

Liu J Q, Zhang C, Wang Y X, et al. Kineto-elastodynamics analysis of a linkage with a variable length crank. Chinese Journal of Mechanical Engineering, 2000, 36(4): 41-44. (in Chinese) DOI:10.3901/JME.2000.04.041 (  0) 0) |

| [19] |

Yao Y S, Yan Q Q, Wang R L, et al. Spraying quality control of vehicle-mounted sprayer for liquid deicing and snow-melting agent. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(1): 120-125. (in Chinese) DOI:10.13229/j.cnki.jdxbgxb201601018 (  0) 0) |

| [20] |

Li Y Q, Wu W F, Wang J F, et al. Study on parameter optimization of concave disc copying icebreaking snow sweeper. International Journal of Smart Home, 2014, 8(3): 197-206. DOI:10.14257/ijsh.2014.8.3.19 (  0) 0) |

| [21] |

Gao J S, Zou Y Q. Fuzzy-PID control in electro-hydraulic proportional valve control system of snow-melting agent spreading truck. Advanced Materials Research, 2012, 490-495: 277-282. DOI:10.4028/www.scientific.net/AMR.490-495.277 (  0) 0) |

2021, Vol. 28

2021, Vol. 28