Composite materials reinforced with naturally available resources are gaining importance globally in recent years owing to their wide potential application in several engineering fields. Now days, this increasing interest in the area of natural fiber composites (NFC) is mainly due to their advantages in terms of renewability, less cost, recyclability and environmentally friendly[1-3]. Among all the naturally available reinforcing materials, kenaf fiber tends to be a promising material because of its low cost and ease of availability[4-5]. These advantages make the natural fibers ideal for the entire or partial replacement of the synthetic fibers in large-scale for industrial applications. However, in spite of the several attractiveness of natural fiber, the less thermal stability, low moisture resistance, poor interfacial adhesion with matrix and lower mechanical properties are the major drawbacks[6-7]. However, the hybrid composites are designed to provide a tailored balanced property by keeping the benefits of all reinforcement with suppressing the limitations. Hybridization of natural fibers can be made with stronger engineered fibers such as glass, carbon, aramid, etc. Among them, glass fiber is very suitable due to its well industrial applicability and excellent properties like lightweight, strength and robustness [8-9]. It also helps in overcoming the hydrophilic character of composites that contributed by natural fiber. Thus, hybrid composites are quickly gaining popularity than the composite made with single type of fiber. Again, this addition of natural fiber in hybridization has also boost its wide potential applicability options in several manufacturing sectors [10-11].

Several researches have already been carried out to describe hybrid reinforcement into a common matrix to fabricate composite such as natural-natural, natural-synthetic and synthetic-synthetic combinations. Selver et al. [12] had explored the outcome of stacking order on physical properties of jute/glass and flax/glass composites. It was noticed that hybrid composite laminates density was reduced from 1.81g/cm3 to 1.48g/cm3 and 1.61g/cm3 for jute/glass and flax/glass epoxy composites respectively on altering of stacking order. The study of Sreenivas et al. [13] was based on the consequences of hybridization on composite's strengths, mainly on polyester resin with kenaf and kevlar fibers. It was found that the hybridization reflected an improvement in the flexural strength by 34%, impact strength by 46%, tensile strength by 24% and hardness by 14%. In another work, Singh et al. [14] considered the piling order as vital factor in determining the mechanical performances of kenaf(K)/jute(J) hybrid laminates. By altering the piling order, KKK, JJJ, KJK, and JKJ hybrid laminates were fabricated with a high-density polyethylene. Their findings reflected that the JKJ laminates possessed a maximum flexural strength of 55.64 MPa, while the KJK laminate exhibited a peak flexural modulus of 3.65 GPa. However, the laminate with pilling order KKK reflected a peak tensile strength of 60 MPa and impact strength of 31.8 kJ/m2 with Shore-D hardness values of 58.8 HV.

The erosion wear (EW) nature of composites is one of the major tribological issues confronted by several industrial sectors. Wear happens when solid particles in the air become entrapped and strike the samples at varying impinging angles. Afterward, the material from the surface of composite will be removed which considered to be the most common failures in the material industry. According to research, EW behavior is influenced by the size, quality, and mass flow rate of the erodent material, as well as the air velocity and impact angle[15-16]. Some machines used in a variety of applications, including aero-plane wings, wind turbine blades, water pipelines, and pump impellers, are vulnerable to erosion wear. Therefore, evaluation of erosion wear behavior is essential since it modifies both the component's characteristics and the specimen's surface. Many researches are explored their literature on EW characterization of plant-based fiber polymer composites. The behavior of EW differs depending on whether the material is brittle, semi-brittle, or ductile[17-18]. The EW of a composite specimen is influenced by several parameters, including filler size, filler material, erodent velocity, impact angle and standoff distance. Pradhan and Acharya studied erosive performances of Eulaliopsis Binate fiber epoxy composite [19]. Lowest erosive wear was seen in the composite with a 30 wt% of fiber inclusion. Again, a shifting of erosive wear characteristic from semi ductility to semi brittleness was also observed with the rise of particle velocity which found to be aligned with the magnitude of erosion efficiency. Prakash et al. [20] studied tribological characteristics of Syngonanthus nitens (SN) natural fiber composite with different weight fractions (10%, 20%, 30% and 40%). The erosion characteristics of composites were investigated using an air jet erosion test equipment with distinct impact angles (30°, 45°, 60°, and 90°) and particle velocities (48 m/s, 70 m/s, 82 m/s and 109 m/s). The composite shows a highest wear rate at a 45° and 60° impact angle with respect to lower particle velocity (48 m/s and 70 m/s) and higher particle velocity (82 m/s and 108 m/s) respectively. This reflected the semi-ductile character of the test samples. Recently, Naik et al. [21] had also reported similar facts that, a peak erosion occurs between 45° and 60° impingement angles which again indicate a semi-ductile behavior of composite structure. In Another work, Bagci et al.[22] had explored the data of erosion tests of unidirectional and multidirectional carbon/glass epoxy composite with various fiber orientations. The specimens were tested at three distinct impact angles of 30°, 60°, and 90° at a speed of 34 m/s. They found a reduction in rate of erosion while the impact angle shifted from 60° to 90° and peak erosion rate was noticed at 30° impact angle. Sachin Tejyan[23] fabricated and investigated mechanical and erosive performances of epoxy composites reinforced with cotton fiber (5, 10, and 15 wt.%) and filled with 4 wt.% of wooden dust. A sharp rise in tensile strength, impact strength and hardness were noticed with rise of cotton fiber loading from 5 wt.% to 15 wt.%. An increase in density and decrease in void content was also found with rise of cotton fiber loading. While analyzing the erosion data, a peak erosion rate was found at 60° impingement angle, which prove the semi-ductility nature. Similar studies on erosive wear performance of glass-flax-sisal hybrid laminates were investigated by Kalagi et al.[24] and the rate of erosion was found to be uppermost at an impact angle of 90°. In an identical research, Nayak and Satapathy[25] explored the erosive response of marble dust filled kenaf polymer composites. The results reflected that the filler content and particle velocity were major parameters in influencing the wear rate. Similarly, Latha and Rao[26] prepared glass-bamboo polymer composites where, the weight percentages of ZrO2 filler varied from 3% to 9%. The laminate with piling order GBBG laminate and 6% ZrO2 filler exhibited a minimal wear in respect to all other laminates.

From the above literature review, it is observed that very few works have been explored on hybrid kenaf/glass reinforced polyester laminate. In the current study, kenaf/glass hybrid polyester laminate samples with several piling orders are made by hand-lay-up method to examine the influence of piling order on density, micro-hardness and erosive characteristics. Wear test was conducted at three distinct velocities and four different impingement angles. The rate of erosion and efficiency were determined. To evident the mechanism of erosion, the morphological examination of eroded surfaces was carried-out with the help of SEM.

1 Experimental Procedure 1.1 MaterialsThe major reinforcements in the current hybrid laminates are bidirectional woven types PPLSF and E-glass fiber mats. The mat thickness of both kenaf and glass are 0.5 mm and 0.25 mm respectively. The fiber orientations in the mats were in 0°/90° pattern. For preparation of laminates, polyester resin was used as matrix with methyl-ethyl-ketone-peroxides (MEKP) hardener. Cobalt-naphthenate was used as accelerator to promote the reaction. All the fiber mats and resins were procured locally. Properties of reinforcing materials and polyester matrix are presented in Table 1.

1.2 Fabrication of Composites

In the current work, hand layup method was adopted to fabricate the laminates. A metallic mould of dimension 160 mm×120 mm×5 mm was used for the fabrication process. Initially silicone gel was employed on the mould surface to facilitate the removal of castings without sticking. Thin Perspex sheets were provided at both top and bottom surface to get a good surface finish. A polyester mix was prepared by mixing unsaturated polyester with catalyst MEKP in 10 ̄1 ratio with 2% accelerator. Both the kenaf and glass fabrics were cut to the size of mould and soaked in the polyester mix for a period of 10 min. After adequate absorption of polyester, the mats were ready for making laminates. Small amount of polyester mix was put into the mould and spread uniformly with the help of brush. Laminates with desire pilling sequences were casted by placing the soaked mats of kenaf and glass in accordance with stacking order. The stacking order of laminates is explained in Table 2. A thin layer of polyester mix was deployed at each interface of stacking. Each layer of soaked mats was press rolled by means of roller to remove any air entrapment during placing of mats. After placing the final layer again small amount of polyester mix was applied. Finally, putting the Perspex sheets at top, the cover plate mould was placed. A load around 30 kg was applied on the cover plate to remove excess amount of polyester and air bubbles that present in the castings. Then it was kept isolated for 48 h to cure. After curing, the casted laminate was taken-away from the mould and cut to the dimension for conduction different tests. Again, the details of stacking order, thickness and weight percentage of fiber are presented in Table 2.

| Table 2 Laminate stacking order |

1.3 Characterization and Experimental Testing

After the fabrication, the test samples were cut to the size and tested as per the respective ASTM standards. For each concluding result, five samples of of each category were tested and the mean value of the readings was recorded. Morphological analysis was performed to examine the mode failure of test specimens.

1.3.1 Density and void contentThe density of the laminates was determined by following immersion approach, which was in accordance with the Archimedes principle. Again, the theoretical density (ρct) was evaluated by using the rule of mixture (ROM), which was represented by Eq. (1).

| $ \frac{1}{\rho_{c t}}=\frac{w_g}{\rho_g}+\frac{w_k}{\rho_k}+\frac{w_m}{\rho_m} $ | (1) |

where wg, wk, wm, ρg, ρk and ρm represent the weight fractions and densities for glass, kenaf and polyester matrix respectively. The voids content of the laminates was evaluated by the following Eq. (2).

| $ \text { Void content }(\%)=\left(\frac{\rho_{c t}-\rho_{c e}}{\rho_{c t}}\right) \times 100 $ | (2) |

The Micro-hardness was determined by performing hardness test on Vickers micro-hardness tester (Make: Leco, model: LM248AT) with a pyramidal diamond indenter. The laminate specimens were cut and tested in accordance to the ASTM E384 standard. The experiment was held under a load of 5 gf and dwell time of 10 s.

1.3.3 Tensile and three-point bend testBoth tensile and three-point bend tests were carried out by using universal testing machine (UTM: model INSTRON 3382, USA) as per ASTM D638-03 and ASTM D790 standards respectively. In both the tests, a cross head speed of 2 mm/min was maintained. Three samples of each laminate were tested at 25℃ room temperature with 50% humidity and an average value of that was recorded.

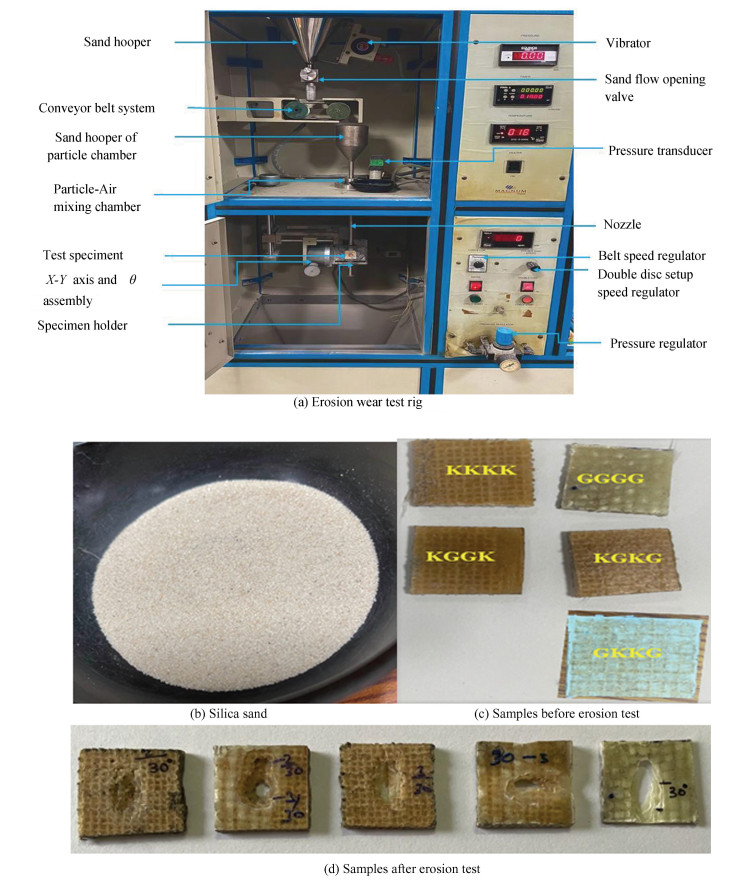

1.3.4 Erosion wear testIn accordance to the ASTM G76 standard, the test was performed on erosion wear test rig as represented in Fig. 1. The setup was consisting of hopper for loading the erodent, conveyor belt system for feeding particle to mixing and accelerating chamber and air compressor. The silica sand should be perfectly dried before loading to the hopper. A vibrator was installed at the hopper to assure the free and continuous flow of erodent during the experiment. Dry silica sand was selected as erodent for conducting the test. The mass flow of erodent was controlled by regulating the speed of the belt. The impact velocity is controlled by regulating the supply pressure of air from compressor and its value was determined by double-disc apparatus [30]. High velocity air mixed silica sand from mixing chamber came out from a converging nozzle of 5 mm diameter. The distance from the nozzle tip to specimen distance is termed as stand-off distance. The stand-off distance is adjusted by rotating the lead screw which moves the swivel table vertically up and down. For this test, a 10 mm stand-off distance was fixed. The test sample was clamped to the table and different impingement angles were set by rotating the swivel table. For conducting the test, the laminates were cut to 25 mm×25 mm dimension. Finally, the test was conducted at three distinct impact velocity and four different impingement angles. The various input parameters, such as particle velocity, impact angles, stand-off distance, temperature, etc. for conducting test are reflected in Table 3. The erosion rate was calculated by weight loss method. The weight loss of tested specimens was evaluated after proper cleaning of the test sample by the help of brush and acetone-soaked cotton plug. Erosion rate was then evaluated through the following equation:

| $ E_r=\frac{\Delta w}{w_e} $ | (3) |

|

Fig.1 Erosion wear test rig, silica sand, samples before and after erosion test |

| Table 3 Test parameters for hybrid kenaf/glass polyester composites |

where △w denotes the weight loss of sample in gm and we represents the weight of erodent (i.e. testing time×particle feed rate).

1.3.5 Surface morphologyThe morphological study of eroded surface was carried out on SEM (Make: - CARL ZEISS SMT, GERMANY, Model: - EVO MA 15). Gold coating was provided to the eroded surface to increase the conductivity before scanning. Images were taken at different magnification to study the mode of failure/fragmentation of fiber and matrix.

2 Results and Discussion 2.1 Void ContentThe experimental and theoretical densities of all composite laminate samples are presented in Table 4. The percentages of variations are calculated by taking the difference in theoretical and experimental densities of each laminate. The presence of voids in the samples resulted a reduction in physical and mechanical strength[31]. From the listed data it is clearly seen that, the laminate KKKK exhibited a higher void content (3.821%) in comparison to other laminates. It is about 44.85% higher than GGGG laminate. Again, the inclusion of glass mats with replacement of kenaf, reduces the voids content. This signifies the inadequate wetting of kenaf fiber by the polyester mix which leads to voids and air pockets generation during casting process. Thus, the hybridization of kenaf with E-glass leads to minimize the void content. Similarly, the variation of void content is also noticed due to alternation of stacking order, while comparing the data of KGKG, KGGK and GKKG laminates.

| Table 4 Actual and theoretical densities of composite laminates |

2.2 Mechanical Properties

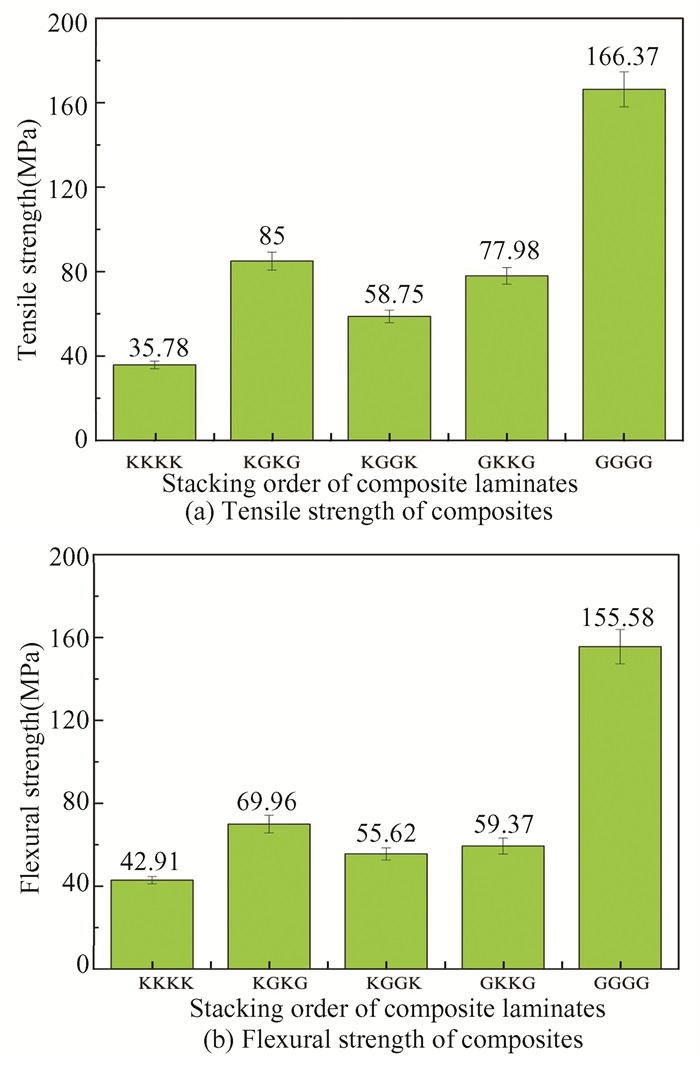

The average values of tensile and flexural strength of fabricated laminates are shown in Fig. 2. The tensile strength of hybrid laminates such as KKKK, KGKG, KGGK, GKKG and GGGG are found to be 35.78, 85, 58.75, 77.98 and 166.38 MPa, respectively. However, the flexural strength as per above sequence are found to be 42.91, 69.96, 55.62, 59.37 and 155.58 MPa respectively. The tensile strength of hybrid laminates is found to be significantly enhanced due to successive addition of glass mat by replacing the kenaf mat. This is due to the higher strength and stiffness of glass fiber in comparison to kenaf fiber. Similar observation is also marked, while comparing the flexural strength data. This increase in flexural strength due to addition of glass ply in hybrid laminates may be due to larger bending stiffness of glass fiber than kenaf fiber and load transfer capability of glass laminates[32]. While comparing the data of two layers of glass and two layers of kenaf, the position of glass ply also has a greater impact on flexural strength.

|

Fig.2 Tensile and flexural strength of composites |

2.3 Micro-hardness

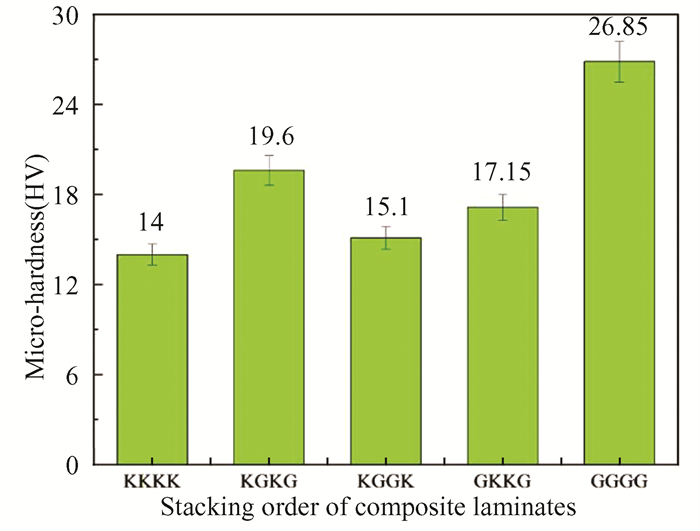

Fig. 3 illustrates the micro-hardness of composite laminates. The hardness value of 14 HV and 26.85 HV are reported for KKKK and GGGG laminates respectively. The result revealed that, the GGGG laminate possess 91.78% higher hardness value due to better polyester/E-glass interfacial adhesion in compare to KKKK laminate. Again, the hardness value followed by 19.6 HV, 15.1 HV and 17.15 HV for KGKG, KGGK and GKKG laminates respectively. An increase of hardness due to incorporation of glass pile and variation of hardness with alternation of piling order is also marked. The hardness of GKKG laminate is found to be 13.57% higher than that of KGGK laminate. It may so happen due to the existence of glass mat at outer layers. Further, these types of findings can be related to similar observation made by Sanjay et al. [33] and James et al. [34] in their research.

|

Fig.3 Micro-hardness of composite laminates |

2.4 Erosion Characteristics of Kenaf/Glass Hybrid Composites

The erosion characteristics of kenaf/glass hybrid composites on the basis of erosion rate and erosion efficiency are investigated. The variations of erosion rate with respect to particle velocity and impact angle are scrupulously studied.

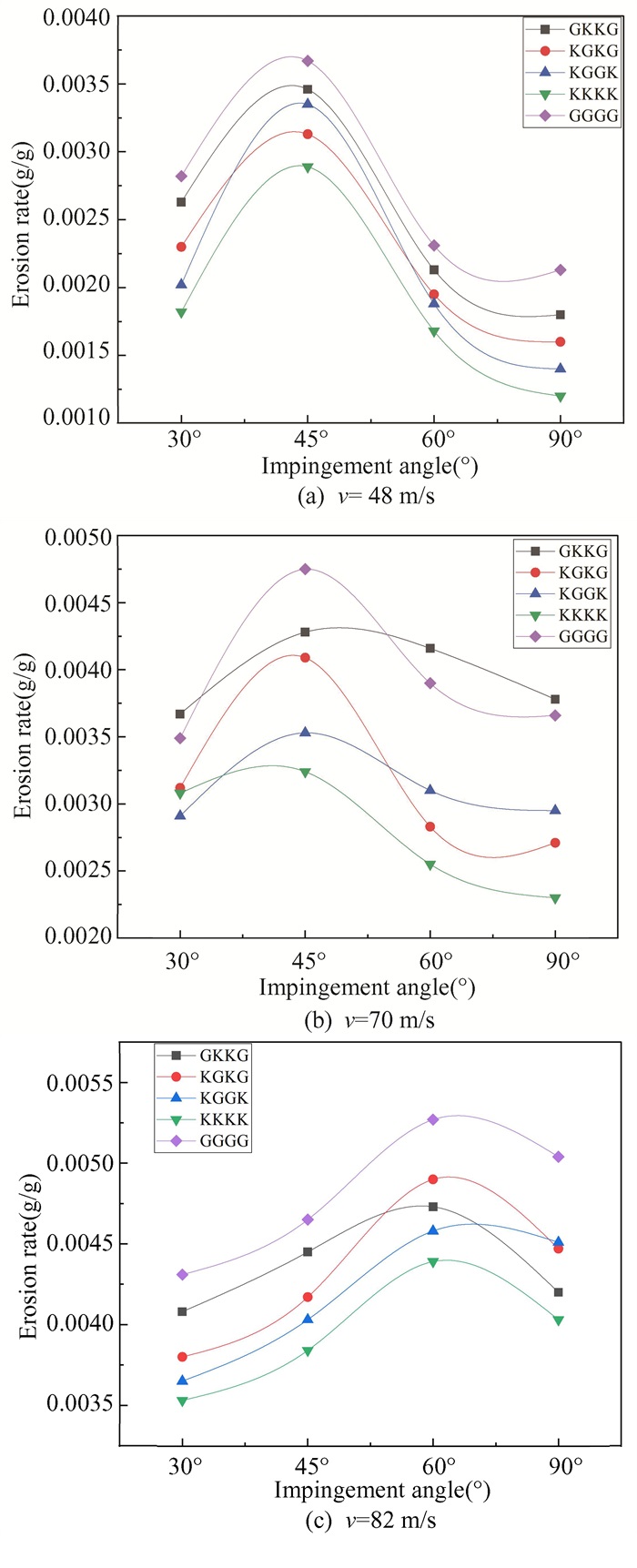

2.4.1 Effect of impingement angle on erosion rate at constant velocityThe variations of erosion rate with respect to impact angles under three distinct particle velocities are presented in Fig. 4(a) to (c). Irrespective of particle velocity, the significant influence of impingement angle on erosion rate can be easily point-out from the plots. Figs. 4 (a)-(b) indicate that, irrespective of pilling order, all laminates exhibited a peak value of erosion at 45° impact angle under lower velocities (48 m/s and 70 m/s). When the particle velocity increases to 82 m/s, a peak value of erosion occurs at 60° impact angle (Fig. 4(c)). Hence, the increase of velocity has resulted in the peak erosion rate with shifting of impact angle from 45° to 60°. The ductile behavior of material is characterized when the peak rate of erosion takes place at less impact angle (30° <θ<45°), whereas it behaves brittle when the peak erosion happens at normal impact angle (θ= 90°). Research clarifies that the materials are characterized for their ductility or brittleness, based on the correlation between the rate of erosion and impact angle[35-36]. However, this categorization is not absolute because the compositions of the target materials and the experimental settings have a significant impact on erosion performance. In the current study, the peak rate of erosion is observed within the range of impact angles 45° to 60°, which specify that these composites behave neither as fully brittle nor as purely ductile in nature. Furthermore, all fabricated laminates also change their behavior from semi-ductile to semi-brittle with the increase in velocity. This fact can also be evidenced with the findings explored by Deo et al.[37] and Prakash et al.[20] during working with Lantana Camara and Rubberwood polymer composites respectively. Compared to other laminates, laminate KKKK exhibits a lower erosion rate and laminate GGGG possess high rate of erosion under all distinct particle velocities and impact angles. Also the rate of erosion subsequently decreases with addition of kenaf fiber mats. This demonstrate the brittle character of glass fiber which plays an important role in increasing the erosion rate because of the removal of glass fiber due to unsupported fiber bending. The resistance to bending mostly depends upon the fiber-matrix adhesion. Since, the glass fiber possess less interfacial bonding compared to kenaf fiber, the unsupported fiber bending occurs due to the removal of matrix from the surrounding. Again, the inclusion of kenaf ply by replacing the glass one also increases the erosion resistance properties. Further, the erosion resistance of hybrid laminate GKKG is found less with respect to other hybrid laminates (KGKG and KGGK) due to inclusion of kenaf fiber at the outmost layer.

|

Fig.4 Distribution of erosion rate versus impact angle at velocities(v) of 48 m/s, 70 m/s and 82 m/s |

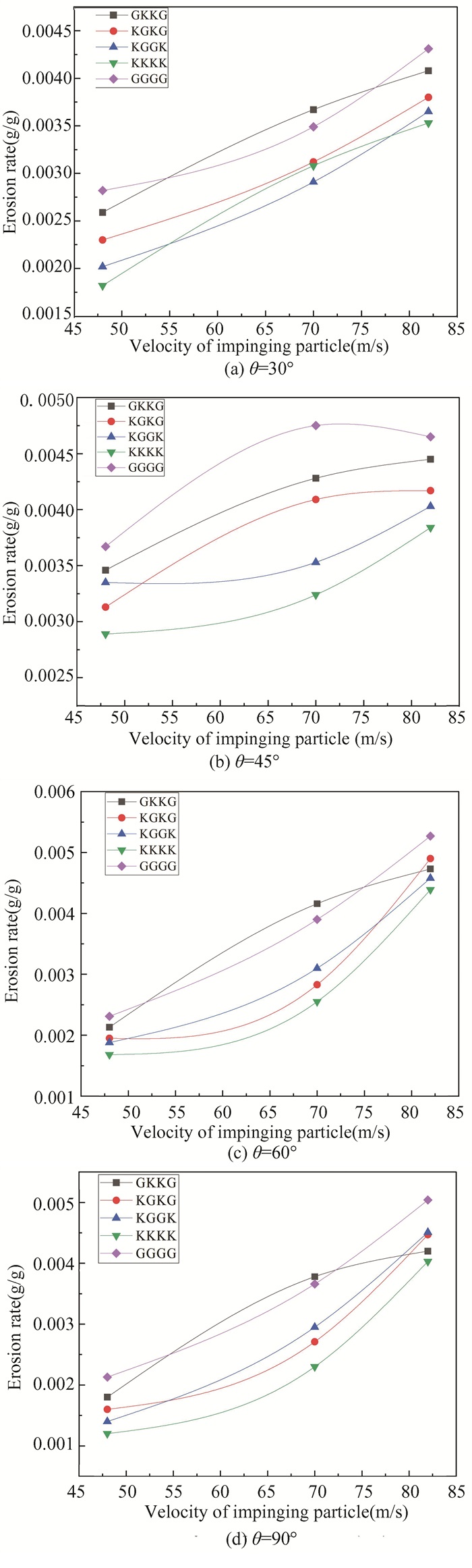

2.4.2 Effect of velocity of impinging particle on erosion rate at constant impinging angle

The results of erosion testing at three distinct particle velocities under four different impact angles are illustrated in Figs. 5(a)-(d). The plots clearly indicate a sharp increase of wear rate with increase in particle velocity at all sets of impingement angle. Thus, the striking velocity has a significant impact on the erosion characteristic. If the impact velocity is relatively small, the stresses at impact are inadequate to cause plastic deformation; subsequently wear occurs through surface fatigue. With increase in velocity of the erodent particles, the eroded material may show plastic deformation. The GGGG laminate which consists of glass layers only exhibited a higher value of erosion rate. Again, a makeable enhancement of erosion resistance is found with addition of kenaf layer on replacing the glass mat. Further the position of kenaf fiber at the outer layer also increases the wear resistance property. This shows the ductile nature of kenaf fiber which lead to kinetic energy absorbing capability.

|

Fig.5 Distributions of erosion rate with velocity at impact angle(θ) of 30°, 45°, 60° and 90° |

2.4.3 Erosion efficiency

To distinguish among the ductile and brittle characteristic of polymeric composite, Sundararajan et al. [38] suggested an equation to evaluate the erosion efficiency (η) as follow:

| $ \eta(\%)=\frac{2 E_r H}{\rho_{c e} V^2} \times 100 $ | (4) |

where Er denotes the rate of erosion wear (gm/gm), the target material hardness is represented by H (N/m2), ρce indicates the material density (kg/m3) and V represents the impact velocity (m/s). Again, the nature and mode of erosion wear can be characterized by the value of erosion efficiency (η)[38]. When only ideal ploughing is involved without any surface fracture for material removal, the erosion efficiency will be zero otherwise the value of η, equal to 1 or 100%, reflects the case of ideal micro-cutting. However, 0 <η<1 or 0% <η<100% indicates the formation of a lip and its subsequent fracture during erosion and η>100% represent the spalling along with removal of large chunks of material by interlinking of lateral or radial cracks during erosion. Moreover, Patnaik et al. [39] had suggested the range of η value for different erosion response of the material such as:η>100% for brittle, 10% <η<100% for semi-ductile and η<10% for ductile. The erosion efficiency of composite laminates with varying stacking sequence under different impact velocities and impinging angles are calculated and presented in Table 5. The data presented in Table 5 reflected that, the efficiency of kenaf-glass hybrid polyester composites varies from 12.98% to 62.27% and 11.83% to 39.20% with changing of impact angles from 45° to 60° respectively. Similarly the efficiency of kenaf-glass hybrid polyester composites varies from 14.18% to 40.76% and 12.66% to 21.87% with changing of impact velocity from 48 m/s to 82 m/s respectively. In contrast, regardless of impact velocity and impingement angles, all fabricated kenaf/glass hybrid composites exhibited below 100% erosion efficiency. Similar observation was also illustrated by Pradhan et al.[19], Prakash et al.[20] and Naik et al.[21] while studying the solid particle erosion behavior of Eulaliopsis binata fiber, Syngonanthus nitens fiber and orange peels particulate reinforced polymer composite respectively.

| Table 5 Erosion efficiency of hybrid kenaf/glass composite |

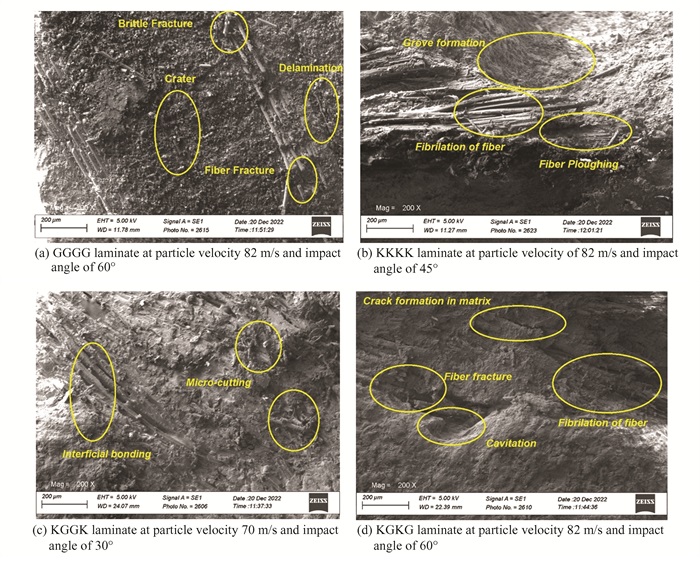

2.4.4 Surface morphology of eroded surface

The morphological analysis of eroded surface was done through examining the images of SEM Figs. 6 (a)-(d). Fig. 6 (a) illustrates the eroded surface micrograph of GGGG laminate at velocity of 82 m/s and impact angle of 60°. Delamination, crater formation and brittle fracture of fiber are clearly noticed, which leads to maximum removal of material due to severe plastic deformation. Further, the micrograph of eroded surface of KKKK laminate at impact velocity of 82 m/s and 45° impact angle is displayed in Fig. 6 (b). Due to high velocity of impacted particle, the kenaf fiber gets fibrillated and undergoes ploughing. Grove formation in polyester matrix is also marked due to high progressive removal of material by whirling motion of particle which confined the progression of particle movement. Fig. 6 (c) shows the eroded surface of KGGK laminate at velocity of impact of 70 m/s at 30° of impact angle. Only micro-cutting of fiber with a good interfacial bonding of kenaf and polyester matrix is observed. This may lead to a minimum erosion rate due to solid particle bombardments. Fiber fracture, fiber fibrillation and cavity formation with crack propagation in matrix due to abrupt is clearly noticed while examining the micrograph of sample KGKG at impact velocity of 82 m/s and impact angle of 60°(Fig. 6 (d)). These mechanisms of failure may promote the higher value of erosion rate. Thus, the erosion of materials at high velocity of impact is presumed with the failure mechanism such as fiber fracture, cavitations, crack formation and fiber fibrillations. However, at low velocity, only micro-cutting predominates but prohibited with fiber chipping.

|

Fig.6 SEM images of Eroded surface of GGGG laminate at particle velocity 82 m/s and impact angle of 60°, KKKK laminate at particle velocity of 82 m/s and impact angle of 45°, KGGK laminate at particle velocity 70 m/s and impact angle of 30° and KGKG laminate at particle velocity 82 m/s and impact angle of 60° |

3 Conclusions

The consequence of stacking sequence of kenaf and glass fibers on polyester resin composite was studied. Based on the experimental findings, the subsequent conclusions are drawn:

1)On successive inclusion of glass mats into kenaf structure, fabrication of a novel hybrid composite laminate is possible by adopting hand-lay-up method. The successive replacement of kenaf layer by glass mat not only reduces the void formation in the laminates, but also enhances the tensile, flexural and hardness values. By replacement of two layers of kenaf with two layers glass mats substantially reduces the voids content by 36.38% and enhances the hardness, tensile strength, flexural strength by 40%, 137.56% and 63.03% respectively. Again, the erosion wear rate also significantly increases with subsequent incorporation of glass mats in place of kenaf.

2)However, both particle velocity and angle of impingement are the important parameter to decide the erosive response of the material but in the current work, the particle velocity plays a vital role. Because, with changing of velocity from low to high, the maximum rate of erosion occurs with shifting of impact angles from 45° to 60°. Again, a semi-ductile behavior of material is characterized for this kenaf/glass hybrid laminate, as a peak rate of erosion take place in between impact angles of 45° and 60° under all impact velocities. Moreover, to evident this semi-ductile response, the erosion efficiency of hybrid laminate was also evaluated and the efficiency values is found to be in the range of 10.67% to 62.28%.

3)Furthermore, the stacking order in this hybrid laminate has a greater impact on erosive characteristics. Laminate positioned with kenaf layer at the outer show higher erosive resistance properties than that of glass layers because of higher kinetic energy absorbing capability of kenaf fiber due to its ductility nature.

4)During morphological study of eroded surface, severe plastic deformation, fibrillation of fiber, crater formation due to crack and development of cavity due to abrupt removal of matrix are detected as major failure mechanism at high velocity of impact. However, micro-cutting of fiber and ploughing actions are the major insights of failure mechanism at low particle velocity.

AcknowledgementsThe authors are thankful to the authorities of the Department of Mechanical Engineering, VSSUT Burla, for providing the research facilities.

| [1] |

Gokul K, Ram Prabhu T, Rajasekaran T. Processing and evaluation of mechanical properties of sugarcane fiber reinforced natural composites. Transactions of the Indian Institute of Metals, 2017, 70: 2537-2546. DOI:10.1007/s12666-017-1116-8 (  0) 0) |

| [2] |

Ramesh M, Deepa C, Aswin U S, et al. Effect of alkalization on mechanical and moisture absorption properties of azadirachta indica (Neem Tree) fiber reinforced green composites. Transactions of the Indian Institute of Metals, 2017, 70: 187-199. DOI:10.1007/s12666-016-0874-z (  0) 0) |

| [3] |

Pantaloni D, Rudolph A L, Shah D U, et al. Interfacial and mechanical characterisation of biodegradable polymer-flax fiber composites. Composites Science and Technology, 2021, 201: 108529. DOI:10.1016/j.compscitech.2020.108529 (  0) 0) |

| [4] |

Rogovina S Z, Prut E V, Berlin A A. Composite materials based on synthetic polymers reinforced with natural fibers. Polymer Science, Seres A, 2019, 61: 417-438. DOI:10.1134/S0965545X19040084 (  0) 0) |

| [5] |

Kumar Sathees S, Mugesh Raja V. Processing and determination of mechanical properties of Prosopis juliflora bark, banana and coconut fiber reinforced hybrid bio composites for an engineering field. Composites Science and Technology, 2021, 208: 108695. DOI:10.1016/j.compscitech.2021.108695 (  0) 0) |

| [6] |

Tamrakar S, Kiziltas A, Mielewski D, et al. Characterization of kenaf and glass fiber reinforced hybrid composites for underbody shield applications. Composites Part B: Engineering, 2021, 216: 108805. DOI:10.1016/j.compositesb.2021.108805 (  0) 0) |

| [7] |

Rout L N, Mishra D, Swain P T R. Influence of Silicon Carbide (SiC) reinforcement on sliding and erosive wear characteristics of glass fiber/epoxy hybrid composites. Transactions of the Indian Institute of Metals, 2023, 76: 1113-1121. DOI:10.1007/s12666-022-02828-7 (  0) 0) |

| [8] |

Saroj S, Nayak R K. Improvement of mechanical and wear resistance of natural fiber reinforced polymer composites through synthetic fiber (Glass/Carbon) hybridization. Transactions of the Indian Institute of Metals, 2021, 74: 2651-2658. DOI:10.1007/s12666-021-02347-x (  0) 0) |

| [9] |

Nayak S, Nayak R K, Panigrahi I. Improvement of low-velocity impact and abrasive wear resistance of Carbon/Glass fiber-reinforced polymer hybrid composites. Transactions of the Indian Institute Metals, 2021, 74: 2245-2254. DOI:10.1007/s12666-021-02318-2 (  0) 0) |

| [10] |

Ramesh M, Palanikumar K, Hemachandra Reddy K. Evaluation of mechanical and interfacial properties of Sisal/Jute/Glass hybrid fiber reinforced polymer composites. Transactions of the Indian Institute of Metals, 2016, 69: 1851-1859. DOI:10.1007/s12666-016-0844-5 (  0) 0) |

| [11] |

Sathyaseelan P, Sellamuthu P, Palanimuthu L. Influence of stacking sequence on mechanical properties of areca-kenaf fiber-reinforced polymer hybrid composite. Journal of Natural Fibers, 2022, 19: 369-381. DOI:10.1080/15440478.2020.1745118 (  0) 0) |

| [12] |

Selver E, Ucar N, Gulmez T. Effect of stacking sequence on tensile, flexural and thermomechanical properties of hybrid flax/glass and jute/glass thermoset composites. Journal of Industrial Textiles, 2018, 48: 494-520. DOI:10.1177/1528083717736102 (  0) 0) |

| [13] |

Sreenivas H T, Krishnamurthy N, Murali M S, et al. Influence of stacking sequence and orientation of the fabric on mechanical properties of twill Kenaf/Kevlar reinforced unsaturated polyester hybrid composites. Journal of Industrial Textiles, 2021, 1-22. DOI:10.1177/15280837211019 (  0) 0) |

| [14] |

Singh M K, Zafar S. Effect of layering sequence on mechanical properties of woven kenaf/jute fabric hybrid laminated microwave-processed composites. Journal of Industrial Textiles, 2020, 1-22. DOI:10.1177/1528083720911 (  0) 0) |

| [15] |

Suresh S, Vinod B, Reddy S S K, et al. Investigation of Tribo-Mechanical properties of polyamide 6 Nano-Biocomposite: Novel approach prediction of fiber orientation with OMMT. Transactions of the Indian Institute of Metals, 2022, 75: 1481-1492. DOI:10.1007/s12666-021-02504-2 (  0) 0) |

| [16] |

Miyazaki N. Solid particle erosion of composite materials: A critical review. Journal of Composite Materials, 2016, 50: 3175-3217. DOI:10.1177/002199831561781 (  0) 0) |

| [17] |

Patnaik A, Satapathy A, Chand N, et al. Solid particle erosion wear characteristics of fiber and particulate filled polymer composites: A review. Wear, 2010, 268(1-2): 249-263. DOI:10.1016/j.wear.2009.07.021 (  0) 0) |

| [18] |

Patel B C, Acharya S K, Mishra D M. Effect of stacking sequence on the erosive wear behavior of jute and juteglass fabric reinforced epoxy composite. International Journal of Engineering Science and Technology, 2011, 3: 213-219. DOI:10.4314/ijest.v3i1.67648 (  0) 0) |

| [19] |

Pradhan S, Acharya S K. Solid particle erosive wear behaviour of Eulaliopsis binata fiber reinforced epoxy composite. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2021, 235(4): 830-841. DOI:10.1177/1350650120931 (  0) 0) |

| [20] |

Prakash V, Pradhan S, Acharya SK. Tribological behavior of Syngonanthus nitens natural fiber reinforced epoxy composite. Transactions of the Indian Institute of Metals, 2021, 74: 1741-1750. DOI:10.1007/s12666-021-02268-9 (  0) 0) |

| [21] |

Naik P, Sahoo P, Acharya S K, et al. Erosive wear behavior of bio-waste particulate-reinforced epoxy composites for low cost applications. Journal of the Indian Academy of Wood Science, 2021, 18: 1-13. DOI:10.1007/s13196-020-00272-y (  0) 0) |

| [22] |

Bagci M. Influence of fiber orientation on solid particle erosion of uni/multidirectional carbon fiber/glass fiber reinforced epoxy composites. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2017, 231: 594-603. DOI:10.1177/1350650116666739 (  0) 0) |

| [23] |

Tejyan S. Effect of erosive parameters on solid particle erosion of cotton fiber-based nonwoven mat/wooden dust reinforced hybrid polymer composites. Journal of Industrial Textiles, 2022, 51: 2514S-2532S. DOI:10.1177/152808372110642 (  0) 0) |

| [24] |

Kalagi G, Buradi A, Kaladgi A R, et al. Erosion wear behavior of glass fiber hybridized flax and sisal fabric hybrid composites with taguchi experimental design. Materialstoday: Proceedings, 2021, 47: 5901-5906. DOI:10.1016/j.matpr.2021.04.430 (  0) 0) |

| [25] |

Nayak S K, Satapathy A. Erosion response analysis of waste marble dust reinforced kenaf-polyester composites. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2022, 44: 1-15. DOI:10.1007/s40430-022-03699-1 (  0) 0) |

| [26] |

Sneha Latha P, Venkateswara Rao M. Investigation into effect of ceramic fillers on mechanical and tribological properties of bamboo-glass hybrid fiber reinforced polymer composites. Silicon, 2018, 10: 1543-1550. DOI:10.1007/s12633-017-9637-7 (  0) 0) |

| [27] |

Koc U, Aykut Y, Eren R. Natural fibers woven fabric reinforced hydrogel composites for enhanced mechanical properties. Journal of Industrial Textiles, 2020, 1-18. DOI:10.1177/1528083720944485 (  0) 0) |

| [28] |

Ku H, Wang H, Pattarachaiyakoop N, et al. A review on the tensile properties of natural fiber reinforced polymer composites. Composites Part B: Engineering, 2011, 42(2): 856-873. DOI:10.1016/j.compositesb.2011.01.010 (  0) 0) |

| [29] |

Mahjoub R, Yatim J M, Mohd Sam A R, et al. Tensile properties of kenaf fiber due to various conditions of chemical fiber surface modifications. Construction and Building Materials, 2014, 55: 103-113. DOI:10.1016/j.conbuildmat.2014.01.036 (  0) 0) |

| [30] |

Dalbehera S, Acharya S K. Impact of stacking sequence on tribological wear performance of woven Jute-glass hybrid epoxy composites. Tribology - Materials Surfaces & Interfaces, 2015, 9(4): 196-201. DOI:10.1080/17515831.2015.1121343 (  0) 0) |

| [31] |

Chaudhary V, Bajpai P K, Maheshwari S. Studies on mechanical and morphological characterization of developed jute/hemp/flax reinforced hybrid composites for structural applications. Journal of Natural Fibers, 2018, 15: 80-97. DOI:10.1080/15440478.2017.1320260 (  0) 0) |

| [32] |

Mohapatra D K, Deo Chitta C, Mishra P, et al. Mechanical characterization of kenaf/glass fiber hybrid composite laminates: An experimental and numerical approach. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2022, 1-19. DOI:10.1177/0954408922113681 (  0) 0) |

| [33] |

Sanjay M R, Yogesha B. Studies on hybridization effect of jute/kenaf/E-glass woven fabric epoxy composites for potential applications: Effect of laminate stacking sequences. Journal of Industrial Textiles, 2018, 47: 1830-1848. DOI:10.1177/15280837177107 (  0) 0) |

| [34] |

James D J D, Manoharan S, Saikrishnan G, et al. Influence of bagasse/sisal fiber stacking sequence on the mechanical characteristics of hybrid-epoxy composites. Journal of Natural Fibers, 2020, 17(10): 1497-1507. DOI:10.1080/15440478.2019.1581119 (  0) 0) |

| [35] |

Tewari U S, Harsha A P, H└ger A M, et al. Solid particle erosion of carbon fiber-and glass fiber-epoxy composites. Composities Science and Technology, 2003, 63(3-4): 549-557. DOI:10.1016/S0266-3538(02)00210-5 (  0) 0) |

| [36] |

Mishra P, Acharya S K. Solid particle erosion of Bagasse fiber reinforced epoxy composite. Internaltional Journal of Physical Sciences, 2010, 5: 109-115. (  0) 0) |

| [37] |

Deo C, Acharya S K. Solid particle erosion of lantana camara fiber-reinforced polymer matrix composite. Polymer-Plastics Technology and Engineering, 2009, 48: 1084-1087. DOI:10.1080/03602550903094340 (  0) 0) |

| [38] |

Sundararajan G, Roy M, Venkataraman B. Erosion efficiency-a new parameter to characterize the dominant erosion micromechanism. Wear, 1990, 140(2): 369-381. DOI:10.1016/0043-1648(90)90096-S (  0) 0) |

| [39] |

Patnaik A, Satapathy A, Mahapatra S S, et al. Modeling and prediction of erosion response of glass reinforced polyester-flyash composites. Journal of Reinforced Plastics and Composites, 2009, 28: 513-536. DOI:10.1177/073168440708564 (  0) 0) |

2024, Vol. 31

2024, Vol. 31