2. School of Mechanical & Automotive Engineering, Qilu University of Technology (Shandong Academy of Sciences), Ji'nan 250300, China

In 2004, Yeh et al.[1] introduced the concept of "high entropy alloy(HEA)", which has recently gained significant attention in the materials field and sparked extensive discussions among researchers. In contrast to normal alloys, HEAs belong to a unique class of alloys that contain five or more elements. The composition of each element is carefully balanced, with no component exceeding 35%[2]. The notable characteristics of HEA include the high entropy effect[3] and slow diffusion effect[4], which contributes to a reduction in Gibbs free energy. The reduced Gibbs free energy prevents intermetallic compounds from developing, which causes a stable solid solution to form inside the alloy. The amalgamation of multiple principal components not only allows for the utilization of each element's individual properties but also highlights the intricate interplay and synergy among these elements, known as the cocktail effect[5]. Additionally, the size disparities among the atoms of each element induce lattice distortion effects within the alloy system[6]. These four effects intricately interact with one another, ultimately influencing the mechanical properties of HEA[7].Extensive investigations have demonstrated that HEA holds tremendous potential in various engineering fields, including aerospace, nuclear power, energy, chemical, automotive, and biomedical applications. In comparison to conventional alloys, HEA exhibits exceptional properties such as high hardness[8], improved yield strength[9], high radiation resistance[10], excellent high-temperature wear resistance[11], good corrosion resistance[12], and oxidation resistance[13-17]. Consequently, HEA presents a wide range of prospects in material surface modification endeavors.

Due to its remarkable mechanical characteristics, a lot of research has been done on the CoCrFeNi HEA in the metallurgical materials field. However, this alloy exhibits low wear resistance and hardness. As research has progressed, AlCoCrFeNi has emerged as the most representative HEA system. CoCrFeNi is substantially harder and more resistant to wear after being combined with aluminum. In recent years, a large number of researchers have explored HEA with improved performance by modifying the preparation methods and alloy compositions.

Liu et al.[18] synthesized TiC precipitates at the micro-nano scale in the coating by introducing titanium, resulting in a notable improvement in hardness and wear resistance. Zeng et al.[19]demonstrated that the laser cladding of an AlCoCrFeNiTi0.5 HEA coating onto a Ti6Al4V substrate was shown to effectively enhance the substrate's resistance to high-temperature oxidation. Wang et al.[20] noticed that when exposed to an acidic solution, CoCrFeMnNi HEA formed a passivation coating on its surface. This passivation film exhibits specific thermal stability at both room and high temperatures. Duan et al.[21] established that the friction and wear properties of AlCoCrFeNiCu HEA are significantly improved by employing a lubricant and lubricating oil equivalent to a 90% hydrogen peroxide solution. Zhu et al.[22] examined the compressive characteristics and microstructure of AlCoCrFeNiMox (x=0, 0.1, 0.1, 0.2, 0.3, 0.4, and 0.5). The results demonstrate a notable increase in yield strength with increasing Mo content. Lin et al.[23] fabricated an AlCoCrFeNiNbx high-entropy alloy (HEA) coating. The addition of niobium is shown to be an effective stabilizer for the face-centered cubic (FCC) phase, the optimal hardness and wear resistance performance are achieved when x = 0.5. Liu et al.[24] successfully produced an AlCoCrFeNiSix HEA coating on the AlSi304 substrate. The findings revealed that an enhancement in hardness was observed as the silicon content increased, both the friction coefficient and wear rate will be significantly reduced concurrently.

Laser cladding technology provides several advantages, including a high solidification rate and low substrate dilution rate, which promote strong bonding between the coating and substrate and ensure a defect-free coating surface[25]. By optimizing laser process parameters, it is possible to reduce the dilution rate[26]. This study primarily investigated the microstructure and mechanical properties of a laser-cladded coating composed of an AlCoCrFeNiTi HEA on the surface of 21-4N.

1 Experimental Procedure 1.1 Substrate and Coating MaterialsIn this study, the selected substrate material was 21-4N, with a dimensional size of 100 mm×50 mm×10 mm. Table 1 provides the detailed elemental composition of the 21-4N substrate. AlCoCrFeNiTi powder was used for the overlaying process, characterized by particle dimensions ranging from 45 to 105 μm with a purity exceeding 99.9 wt%. The fundamental properties of the six constituent elements are presented in Table 2. Prior to laser cladding, the AlCoCrFeNiTi powder underwent comprehensive mixing. Subsequently, the powder was subjected to drying at 60 ℃ for 24 h in a drying oven. Simultaneously, the substrate was preheated at 60 ℃ for a duration of 30 min.

| Table 1 Elemental composition of 21-4N[27] |

| Table 2 Basic properties of elements in AlCoCrFeNiTi powder[28] |

1.2 Coating Preparation

The cladding experiment was conducted using an LYHS ultra-high-speed laser cladding machine, with argon gas serving as the shielding gas during the experiment. After careful parameter optimization, the optimal process parameters were identified as: a laser power of 1.5 kW, a scan speed of 15 mm/s, a laser spot size of 6 mm, and a powder feeding speed of 16 g/min.

1.3 Microstructure Characterization of CoatingThe raw material was prepared as 10 mm×10 mm× 10 mm samples, which were subsequently subjected to grinding using various metallographic sandpapers and polished using a polishing machine. A chemical attack was performed on the samples using diluted aqua regia solution for the duration of 24 s, followed by rinsing with anhydrous ethanol and drying. The surfaces of the tested samples underwent a comprehensive examination using an optical microscope for analysis and evaluation. The microstructure and corroded surface morphology were observed using a Phenom Pro X scanning electron microscope(Helios G4 CX). An energy spectrum analyzer(X-Max80) was employed to investigate the element distribution in different regions of the coating. Furthermore, performing phase analysis on the coating surface using X-ray diffractometry (Smart Lab).

1.4 Performance TestingThe samples' hardness was evaluated using an HXD-1000TMC micro-Vickers hardness tester, applying a load force of 1.96 N for a duration of 15 s. Hardness measurements were taken at regular intervals of 25 μm across the sample's cross-sectional area. To assess the coating surface's wear resistance, a UMT-5 surface fatigue wear tester was utilized. Experimental parameters were configured as follows: temperatures were set at room temperature, 400 ℃, 600 ℃, and 800 ℃; a 6 mm diameter Si3N4 ceramic ball was employed; a load force of 10 N was applied; the friction frequency was set to 3 Hz; and the friction time was 60 min. The worn surface morphology of the AlCoCrFeNiTi HEA coating under different temperatures was observed using a Helios G4 CX scanning electron microscope. The morphology of the worn surface of the alloy was examined using a Contour Gt-K white light interference three-dimensional profile measuring instrument.

2 Results and Discussion 2.1 Phase AnalysisIn Fig. 1(a), the XRD pattern of the AlCoCrFeNiTi HEA coating is displayed. The diffraction pattern reveals the presence of BCC and FCC structures as the primary phase structures in the HEA coating. The analysis reveals that the BCC phase corresponds to Fe-Cr, whereas the FCC phase corresponds to (Ti/Al)-Ni.

|

Fig.1 AlCoCrFeNiTi HEA coating cross section (a) XRD pattern; (b) cross section after attack; (c) magnification of the bonding area |

2.2 Microstructure Characterization

Fig. 1(b) shows the cross-sectional appearance of the AlCoCrFeNiTi HEA coating, displaying a well-formed cladding layer with a compact structure. No visible pores, cracks, or defects are observed. The cross-section can be divided into three distinct regions upon chemical attack: the cladding zone(CZ), bonding zone(BZ), and heat-affected zone(HAZ). Notably, Fig. 1(c) emphasizes a bright and luminous region representing the bonding zone (BZ) at the interface junction. This phenomenon demonstrates the excellent bonding between the coating and the substrate, without any noticeable defects.

Fig. 2 displays the SEM images depicting the AlCoCrFeNiTi HEA coating. Specifically, Fig. 2(a) presents the bonding zone between the cladding layer and the substrate, while Fig. 2(b) focuses on the internal region of the cladding layer. In Fig. 2(a), a distinct interface between the cladding layer and the substrate is observed, characterized by the absence of cracks and pores in close proximity to the interface. This observation signifies a robust and well-adhered connection between the junction of the two entities.Fig. 2(b) illustrates the overall structure of the cladding layer, which exhibits a distinctive dendritic pattern. The dendritic structure is a prominent characteristic observed throughout the entirety of the cladding layer.

|

Fig.2 SEM images of AlCoCrFeNiTi HEA coating (a) joint; (b) cladding layer |

Fig. 3 displays the scanning electron microscope (SEM) images of the AlCoCrFeNiTi HEA coating. In Fig. 3(a), the cladding layer exhibits a distinct dendritic and inter-dendritic structure. Notably, Fig. 3(b) reveals the presence of grey dendrites (DR), dark grey inter-dendritic regions (ID), and irregular black precipitates. Furthermore, Fig. 3(c) illustrates the elemental distribution within the cladding layer. It is worth noting that due to the specific dilution rate associated with laser cladding of HEA coatings, a slight distribution of elements onto the substrate can also be observed.

|

Fig.3 AlCoCrFeNiTi alloy coating scanning electron microscope (a) interface of the overlaying layer; (b) the cladding layer; (c) elements distribution map(Ti, Co, Cr, Fe, Ni, Al) |

Fig. 4(a) provides a magnified view of a specific region in Fig. 3(b). Additionally, Fig. 4(b) presents the elemental distribution in this region. The observation results indicate that the distribution of elements within the coating during the entire solidification process of the alloy powder is non-uniform. Specifically, Fe and Cr are the first elements to solidify and form, primarily concentrating in the white dendritic area. On the other hand, the inter-dendritic regions exhibit a higher content of Co, Al, Ni, and Ti elements. Table 3 presents the mixing enthalpy values between different elements. In accordance with thermodynamics, if the mixing enthalpy between two elements is positive, they tend to repel each other. Conversely, if the mixing enthalpy is negative, components are more likely to attract one another and form stable phases. Notably, Table 3 indicates a mixing enthalpy of -22 kJ/mol between Al and Ni. Consequently, Al and Ni have a greater tendency to combine and accumulate at grain boundaries. Meanwhile, Cr and Fe elements are segregated within the inter-dendritic regions due to their higher electronegativity compared to other elements, making them more active within the dendritic structures.

|

Fig.4 SEM images and elemental analysis mapping (a) SEM images of cladding layer; (b) elements distribution maps(Cr, Ni, Ti, Co, Al, Fe) |

| Table 3 Enthalpy of mixing between elements of AlCoCrFeNiTi[29] |

2.3 Hardness

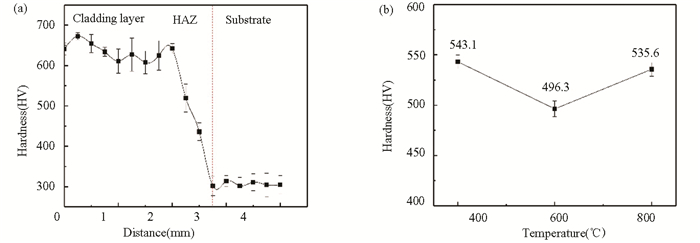

Fig. 5(a) depicts the micro-hardness distribution across the cross-sectional area of the coating. The hardness values at the coating's edge and joint exhibit a slightly higher value, approximately 650 HV, while the hardness in the middle of the cladding layer is comparatively lower, around 610 HV. Additionally, the figure reveals the existence of HAZ situated between the cladding layer and the substrate, with an average hardness measured at 480.3 HV. The overall hardness of the cladding layer demonstrates minimal variations. Observing the atomic radii provided in Table 1, it can be noted that the elements Al and Ti possess larger atomic radii of 1.43 and 1.45, respectively, compared to the other elements.This leads to lattice distortion within the solid solution, thereby increasing the resistance of dislocation movement and achieving the effect of solution strengthening. Consequently, the average hardness of the entire cladding layer reaches 620 HV. Additionally, the rapid melting and solidification process associated with laser cladding technology contribute to grain refinement, which is another significant factor contributing to the hardness enhancement[30].

|

Fig.5 Hardness of AlCoCrFeNiTi HEA (a) cross-section hardness; (b) average hardness of coating area |

Fig. 5(b) presents the variation in hardness of the cladding layer at different temperatures. The curve initially decreases and then increases. It is worth noting that the average hardness of the HEA coating at high temperatures is 526.1 HV.

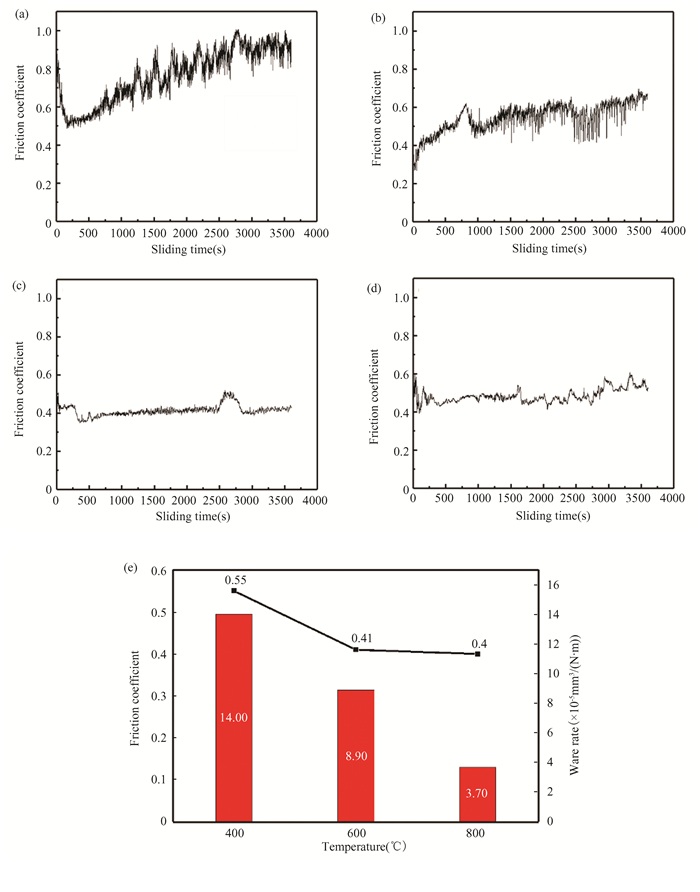

2.4 Wear ResistanceIn Fig. 6, the friction coefficient curve of the AlCoCrFeNiTi HEA coating is shown at various temperatures. Subdivided into two phases, Figs. 6(a)-(d) illustrates the entire experimental process, including the friction running-in period and the steady friction period. The duration of the steady friction period increases with temperature, while the running-in period becomes shorter. Furthermore, Fig. 6(e) demonstrates that both the friction coefficient and wear rate decrease as the temperature increases. Importantly, the morphology and dispersion of precipitates in the AlCoCrFeNiTi HEA exhibit no significant changes under varying temperature conditions[31]. Moreover, the precipitated phase contributes to diffusion strengthening at elevated temperatures, causing the HEAs toughness and plasticity decrease while its hardness and strength are significantly increased. This is further supported by the sustained high hardness observed at 600 ℃ and 800 ℃.

|

Fig.6 The friction coefficient (μ) and sliding friction time of the AlCoCrFeNiTi HEA coating were measured at different temperatures (a) room temperature; (b) 400℃; (c) 600℃; (d) 800℃; (e) average friction coefficient and wear rate |

In Fig. 7, the wear width of the AlCoCrFeNiTi HEA coating is shown as it varies during the friction and wear test at different temperatures. The results indicate a gradual reduction in the wear width as the temperature rises. In Fig. 7(a) and Fig. 7(b), the coating surface exhibits a flat morphology with plough-like grooves, which can also be observed in Fig. 7(c) and Fig. 7(d). These features are primarily attributed to the high hardness of the Si3N4 ceramic balls and the reciprocating friction between the balls and the coating surface during the experiments, leading to shear forces at the interface. At room temperature, the primary wear mechanism observed for the AlCoCrFeNiTi HEA coating is abrasive wear. However, when comparing Fig. 7(a), Fig. 7(b), Fig. 7(c), and Fig. 7(d), it can be observed that the coating surface becomes rougher and the bottom of the wear marks exhibit non-uniform features as the temperature increases. This is due to the plasticity enhancement of HEA coatings at high temperatures, resulting in adhesion and mutual compression between the coating and the Si3N4 ceramic balls during frictional contact. Consequently, tear holes are formed each time the balls move, contributing to the observed surface roughness.

|

Fig.7 Wear morphology of AlCoCrFeNiTi HEA coatings at different temperatures (a) room temperature; (b) 400 ℃; (c) 600 ℃; (d) 800 ℃ |

Fig. 8 presents SEM images illustrating the wear morphology of the AlCoCrFeNiTi HEA coating under various temperature conditions. At room temperature, the coating surface exhibits wear debris and grooves. Fig. 8 (c) and Fig. 8 (d) demonstrate an increased occurrence of grooves and minor pits on the worn surface. Upon reaching a temperature of 400 ℃, the coating demonstrates enhanced plasticity, resulting in the adhesion of ceramic balls to the coating surface and the construction of tearing pits. Furthermore, an oxide film is observed in Figs. 8 (e)-(h), indicating the development of an oxide layer on the worn surface. The presence of this oxide film significantly contributes to the improved wear resistance of HEA coatings. This observation additionally corroborates the trend of decreasing friction coefficient and wear rate with increasing temperature. At 800 ℃, the worn surface continues to exhibit plowed grooves generated by the relative motion between the ceramic ball and the coating surface. Moreover, the presence of debris from material bulges, pile-ups, and plastic deformations is evident. In summary, the dominant wear mechanism of AlCoCrFeNiTi HEA coatings at room temperature is characterized by abrasive wear. At elevated temperatures, the wear process involves a combination of abrasive wear, adhesive wear and, to a lesser extent, plastic deformation.

|

Fig.8 SEM topography and local magnification of wear morphology of AlCoCrFeNiTi HEA coating at various temperatures (a) (b) room temperature; (c) (d) 400 ℃; (e) (f) 600 ℃; (g) (h) 800 ℃ |

3 Conclusions

Within the confines of this investigation, the laser cladding technique was utilized to produce an AlCoCrFeNiTi HEA coating on a 21-4N substrate. This study comprehensively investigated the phase composition, microstructure, hardness and wear resistance of the coating. A summary of the findings is given below:

(1) The AlCoCrFeNiTi HEA coating showcased a discernible phase composition characterized by the coexistence of BCC and FCC phases. Microstructural examination of the coating revealed a dendritic morphology, with dendritic growth occurring perpendicular to the interface between the coating and the substrate. EDS analysis substantiated the prevalent distribution of Fe and Cr elements within the white dendritic regions, while the interdendritic regions exhibited elevated concentrations of Co, Al, Ni, and Ti elements.

(2) The characterization of hardness demonstrated that the AlCoCrFeNiTi HEA coating displayed an average hardness of 620 HV at room temperature. Nevertheless, at elevated temperatures, the average hardness decreases significantly to 526.1 HV.

(3) The AlCoCrFeNiTi HEA coating showcased its peak wear resistance at 800 ℃, as evidenced by an average friction coefficient of 0.4μ and a wear rate of 3.7 × 10-5 mm3/(N·m). The enhanced wear resistance can be attributed to the formation of an oxide film on the coating surface, which occurs under elevated temperature conditions. The wear mechanism of the coating involves abrasive wear at room temperature, while at elevated temperatures it encompasses a combination of abrasive, adhesive, and mild plastic deformations.

Therefore, the utilization of laser cladding technology for the fabrication of HEA coatings on valve surfaces represents a promising strategy for augmenting their wear and corrosion resistance, thereby extending the operational lifetime of valves while simultaneously reducing production costs. The amalgamation of laser cladding techniques with HEA has broadened the range of potential applications in diverse domains, thereby contributing to the advancement of material surface modification techniques.

| [1] |

Huang P K, Yeh J W, Shun T T, et al. Multi-principal-element alloys with improved oxidation and wear resistance for thermal spray coating. Advanced Engineering Materials, 2004, 6(1-2): 74-78. DOI:10.1002/adem.200300507 (  0) 0) |

| [2] |

Arif Z U, Khalid M Y, ur Rehman E, et al. A review on laser cladding of high-entropy alloys, their recent trends and potential applications. Journal of Manufacturing Processes, 2021, 68((Part B): 225-273. DOI:10.1016/j.jmapro.2021.06.041 (  0) 0) |

| [3] |

Huang E W, Yu D, Yeh J W, et al. A study of lattice elasticity from low entropy metals to medium and high entropy alloys. Scripta Materialia, 2015, 101: 32-35. DOI:10.1016/j.scriptamat.2015.01.011 (  0) 0) |

| [4] |

Chen J, Zhou X, Wang W, et al. A review on fundamental of high entropy alloys with promising high-temperature properties. Journal of Alloys and Compounds, 2018, 760: 15-30. DOI:10.1016/j.jallcom.2018.05.067 (  0) 0) |

| [5] |

Feng X, Fan S, Meng F, et al. Effect of Zr addition on microstructure and mechanical properties of CoCrFeNiZrx high-entropy alloy thin films. Applied Nanoscience, 2019, 11: 771-776. DOI:10.1007/s13204-019-01057-7 (  0) 0) |

| [6] |

Yeh J W. Alloy design strategies and future trends in high-entropy alloys. JOM, 2013, 65: 1759-1771. DOI:10.1007/s11837-013-0761-6 (  0) 0) |

| [7] |

Soto A O, Salgado A S, Niño E B. Thermodynamic analysis of high entropy alloys and their mechanical behavior in high and low-temperature conditions with a microstructural approach - A review. Intermetallics, 2020, 124: 106850. DOI:10.1016/j.intermet.2020.106850 (  0) 0) |

| [8] |

Xin S W, Shen X, Du C C, et al. Bulk nanocrystalline boron-doped VNbMoTaW high entropy alloys with ultrahigh strength, hardness, and resistivity. Journal of Alloys and Compounds, 2021, 853: 155995. DOI:10.1016/j.jallcom.2020.155995 (  0) 0) |

| [9] |

Xiong F, Fu R D, Li Y J, et al. Effects of nitrogen alloying and friction stir processing on the microstructures and mechanical properties of CoCrFeMnNi high-entropy alloys. Journal of Alloys and Compounds, 2020, 822: 153512. DOI:10.1016/j.jallcom.2019.153512 (  0) 0) |

| [10] |

Lu Y, Huang H, Gao X, et al. A promising new class of irradiation tolerant materials: Ti2ZrHfV0.5Mo0.2 high-entropy alloy. Journal of Materials Science & Technology, 2019, 35(3): 369-373. DOI:10.1016/j.jmst.2018.09.034 (  0) 0) |

| [11] |

Cheng H, Fang Y, Xu J, et al. Tribological properties of nano/ultrafine-grained FeCoCrNiMnAlx high-entropy alloys over a wide range of temperatures. Journal of Alloys and Compounds, 2020, 817: 153305. DOI:10.1016/j.jallcom.2019.153305 (  0) 0) |

| [12] |

Wang W, Wang J, Sun Z, et al. Effect of Mo and aging temperature on corrosion behavior of (CoCrFeNi)100-xMox high-entropy alloys. Journal of Alloys and Compounds, 2020, 812: 152139. DOI:10.1016/j.jallcom.2019.152139 (  0) 0) |

| [13] |

Fang Y, Chen N, Du G, et al. High-temperature oxidation resistance, mechanical and wear resistance properties of Ti(C, N)-based cermets with Al0.3CoCrFeNi high-entropy alloy as a metal binder. Journal of Alloys and Compounds, 2020, 815: 152486. DOI:10.1016/j.jallcom.2019.152486 (  0) 0) |

| [14] |

Li T, Jiao W, Miao J, et al. A novel ZrNbMoTaW refractory high-entropy alloy with in-situ forming heterogeneous structure. Materials Science and Engineering: A, 2021, 827: 142061. DOI:10.1016/j.msea.2021.142061 (  0) 0) |

| [15] |

Li T, Wang S, Fan W, et al. CALPHAD-aided design for superior thermal stability and mechanical behavior in a TiZrHfNb refractory high-entropy alloy. Acta Materialia, 2023, 246: 118728. DOI:10.1016/j.actamat.2023.118728 (  0) 0) |

| [16] |

Li T, Lu Y, Li Z, et al. Hot deformation behavior and microstructure evolution of non-equimolar Ti2ZrHfV0.5Ta0.2 refractory high-entropy alloy. Intermetallics, 2022, 146: 107586. DOI:10.1016/j.intermet.2022.107586 (  0) 0) |

| [17] |

Li T, Miao J, Lu Y, et al. Effect of Zr on the as-cast microstructure and mechanical properties of lightweight Ti2VNbMoZrx refractory high-entropy alloys. International Journal of Refractory Metals and Hard Materials, 2022, 103: 105762. DOI:10.1016/j.ijrmhm.2021.105762 (  0) 0) |

| [18] |

Liu H, Liu J, Chen P, et al. Microstructure and high temperature wear behaviour of in-situ TiC reinforced AlCoCrFeNi-based high-entropy alloy composite coatings fabricated by laser cladding. Optics & Laser Technology, 2019, 118: 140-150. DOI:10.1016/j.optlastec.2019.05.006 (  0) 0) |

| [19] |

Zeng X, Liu Z, Wu G, et al. Microstructure and high-temperature properties of laser cladded AlCoCrFeNiTi0.5 high-entropy coating on Ti 6Al-4V alloy. Surface and Coatings Technology, 2021, 418: 127243. DOI:10.1016/j.surfcoat.2021.127243 (  0) 0) |

| [20] |

Wang L, Seyeux A, Perriere L, et al. Insight on passivity of high entropy alloys: Thermal stability and ion transport mechanisms in the passive oxide film on CoCrFeMnNi surfaces. Corrosion Science, 2021, 188: 109540. DOI:10.1016/j.corsci.2021.109540 (  0) 0) |

| [21] |

Duan H, Wu Y, Hua M, et al. Tribological properties of AlCoCrFeNiCu high-entropy alloy in hydrogen peroxide solution and in oil lubricant. Wear, 2013, 297: 1045-1051. DOI:10.1016/j.wear.2012.11.014 (  0) 0) |

| [22] |

Zhu J M, Fu H M, Zhang H F, et al. Microstructures and compressive properties of multicomponent AlCoCrFeNiMox alloys. Materials Science and Engineering: A, 2010, 527: 6975-6979. DOI:10.1016/j.msea.2010.07.028 (  0) 0) |

| [23] |

Lin D, Zhang N, He B, et al. Structural evolution and performance changes in FeCoCrNiAlNbx high-entropy alloy coatings cladded by laser. Journal of Thermal Spray Technology, 2017, 26: 2005-2012. DOI:10.1007/S11666-017-0634-6 (  0) 0) |

| [24] |

Liu H, Sun S, Zhang T, et al. Effect of Si addition on microstructure and wear behavior of AlCoCrFeNi high-entropy alloy coatings prepared by laser cladding. Surface and Coatings Technology, 2021, 405: 126522. DOI:10.1016/j.surfcoat.2020.126522 (  0) 0) |

| [25] |

Alizadeh-Sh M, Marashi S P H, Ranjbarnodeh E, et al. Laser cladding of Inconel 718 powder on a non-weldable substrate: Clad bead geometry-solidification cracking relationship. Journal of Manufacturing Processes, 2020, 56: 54-62. DOI:10.1016/j.jmapro.2020.04.045 (  0) 0) |

| [26] |

Fogagnolo J B, Rodrigues A V, Sallica-Leva E, et al. Surface stiffness gradient in Ti parts obtained by laser surface alloying with Cu and Nb. Surface and Coatings Technology, 2016, 297: 34-42. DOI:10.1016/j.surfcoat.2016.04.025 (  0) 0) |

| [27] |

Yin L M, Qu S K, Lai F Q, et al. High temperature properties of 21-4N valve steel. Journal of Materials Science and Engineering, 2020, 38(3): 409-413, 517. DOI:10.14136/j.cnki.issn1673-2812.2020.03.011 (  0) 0) |

| [28] |

Zhou J L, Cheng Y H, Chen Y X, et al. Composition design and preparation process of refractory high-entropy alloys: A review. International Journal of Refractory Metals and Hard Materials, 2022, 105: 105836. DOI:10.1016/j.ijrmhm.2022.105836 (  0) 0) |

| [29] |

Takeuchi A, Wada T, Nagase T, et al. Ultra-high mixing entropy alloys with single bcc, hcp, or fcc structure in Co-Cr-V-Fe-X (X=Al, Ru, or Ni) systems designed with structure-dependent mixing entropy and mixing enthalpy of constituent binary equiatomic alloys. Materials Transactions, 2022, 63: 835-844. DOI:10.2320/matertrans.mt-m2022004 (  0) 0) |

| [30] |

Pang M, Ding Q F. Microstructure and properties of FeCoNiCrAl high entropy alloy by laser cladding. Transactions of Materials and Heat Treatment, 2020, 41: 108-113. DOI:10.13289/j.issn.1009-6264.2020-0085 (  0) 0) |

| [31] |

Zhang A, Han J, Su B, et al. Tribological properties of AlCoCrFeNi high entropy alloy at elevated temperature. Tribology, 2017, 37: 776-783. (  0) 0) |

2024, Vol. 31

2024, Vol. 31