2. Shanghai Spaceflight Precision Machinery Institute, Shanghai 201600, China

Aerospace products, as a representative of high-precision parts, are characterized by complex structures, long production cycles, and high precision requirements[1]. The transition of aerospace products from design to manufacturing is not smooth. Designers cannot fully consider the structural craftsmanship of the product and the limitations of the actual manufacturing resources of the enterprise, which makes it difficult for the design to directly guide the production process. Therefore, it is necessary to carry out manufacturability assessment in the intermediate link between design and process design to identify design defects early and evaluate the manufacturability of the product. This allows the product design to meet the requirements of the manufacturing process, reducing the amount of repeated work and the number of program changes. The manufacturability of a product refers to the possibility that the designed product can be manufactured under the existing manufacturing resources[2]. Manufacturability assessment is the timely detection of defects in the design and assessment of the manufacturability of a product by analyzing the main factors affecting the manufacturing process of the product (machining economy, structural craftsmanship, resource satisfaction, etc.) at the product design stage with the help of a set of software tools and a related knowledge base[3]. The assessment report is then fed back to the designer for updates ensuring the product design meets the requirements of the manufacturing process. The manufacturability assessment can enhance the manufacturing efficiency, reduce costs, and improve the manufacturability of the product.

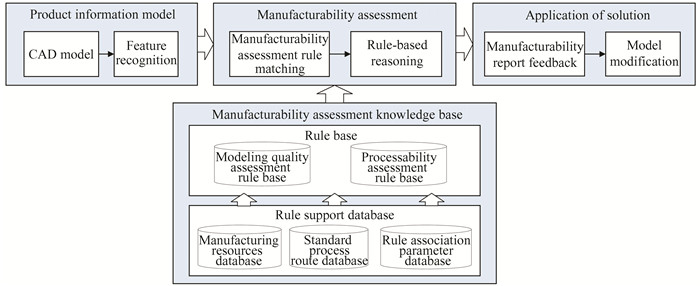

The automated manufacturability assessment process of aerospace product is shown in Fig. 1, which mainly includes important links, such as product information model extraction, manufacturability assessment rule matching, rule-based assessment, report generation and application. Among them, the assessment rule matching link needs to match the applicable assessment rules based on the extracted product manufacturing feature information and knowledge base. The accuracy of the assessment rule matching in this link directly determines the result of the assessment. At present, due to the constraints of poor structure, low reusability, and incomplete semantics of product manufacturing feature information and assessment knowledge, only the fuzzy matching method based on natural language can be used in the matching method, and the matching performance is suboptimal. Therefore, how to establish structured manufacturing feature model and knowledge model to improve the precision and recall of rule matching is a key issue in manufacturability assessment.

|

Fig.1 Automated aerospace product manufacturability assessment process |

Knowledge graph is a structured knowledge representation that uses graph structures to model and store knowledge[4-5]. In recent years, knowledge graphs have been widely used in various fields due to the advantages of having a directed data structure, strong retrieval capabilities and support for intelligent knowledge reasoning[6-8]. There has been a lot of work on knowledge graphs in CAD (Computer Aided Design)[9], CAM (Computer Aided Manufacturing)[10], CAPP (Computer Aided Process Planning)[11], and fault diagnosis[12-13]. Li et al.[14] proposed a structured heterogeneous CAM model based on process knowledge graph, which achieves conceptual/semantic matching between the ontology model and the process knowledge graph through multi-strategy ontology mapping. Ma et al.[15] proposed a knowledge-based process planning approach that utilizes ontologies to build a knowledge base in which taxonomies, attributes, and causal relationships between core concepts such as machining features, machining operations, cutting tools, and machine tools are formally defined. Hu et al.[16] constructed a multi-modal process knowledge graph for wind turbines and proposed a wind turbine assembly process question answering system, which combines a multimodal knowledge graph and a large-scale language model to achieve effective utilization of historical assembly process knowledge. Shen et al.[17] proposed a dynamic knowledge modeling fusion method based on knowledge graph for the production process of customized clothing. Liu et al.[18] proposed a knowledge graph-based method for wind turbine assembly sequence recommendation, which designed an assembly information representation model and knowledge extraction method for different modal data.

In terms of manufacturability analysis, knowledge graphs are widely used in the field of additive manufacturing[19-20]. Ranjan et al.[21] used a graph-based system approach to implement manufacturability analysis in additive manufacturing. These design rules will help designers to come up with efficient part designs that can be manufactured with minimal error. Ko et al.[22] proposed a new approach for building design rules for additive manufacturing based on machine learning and knowledge graphs, using ontologies with knowledge graphs as a knowledge base for storing a priori and newly discovered knowledge about additive manufacturing. Mayerhofer et al.[23] proposed a knowledge-driven framework that automatically checks the geometric properties of parts and compares them with additive manufacturing guidelines.

However, knowledge graphs are currently less studied for matching and assessment knowledge for manufacturability assessment rules for 3D models of aerospace products. This is due to the following two difficulties in constructing the knowledge graph for manufacturability assessment of aerospace products:

1) The first is domain complexity. Manufacturing processes are inherently complex, involving multiple disciplines such as engineering, materials science, and production planning. Capturing and representing this multidisciplinary knowledge in a comprehensive knowledge graph requires a deep understanding of the domain-specific concepts, relationships, and ontologies. In addition, parts of aerospace products are often highly complex, and this complexity makes the assessment of their manufacturability more challenging than simple products.

2) The second is the knowledge representation challenges. Representing manufacturability assessment knowledge in a knowledge graph involves modeling various aspects, including features, tools, machines, process parameters, model labeling, and constraints. Defining appropriate ontologies, relationships, and mappings between different knowledge domains is a non-trivial task. The lack of standardized representations and ontologies for manufacturing further complicates the development of a manufacturability assessment knowledge graph. Therefore, how to build ontology models and data storage models for knowledge graph to structurally represent and store the manufacturability assessment knowledge in the aerospace product domain is a critical issue.

In summary, knowledge graph-related technology can accurately describe the intrinsic association of knowledge, effectively make up for the deficiencies of existing methods in the characterization and management of knowledge for manufacturability assessment, and provide a new approach for the expression, storage, retrieval, reasoning, and reuse of aerospace product manufacturability assessment knowledge. Therefore, a knowledge graph construction and rule matching method is proposed in this paper for aerospace product manufacturability assessment, taking into account the advantages that knowledge graphs exhibit in the field of knowledge engineering. Based on the semantic information and association information expressed by the knowledge graph, a rule matching method based on subgraph matching is innovatively proposed. The method solves the current issue of low efficiency of rule matching in manufacturability assessment, and can significantly improve the precision and recall of assessment rule matching, while reducing the dependence on experts and effectively lowering the labor cost.

1 Ontology Modeling for Manufacturability AssessmentEnterprises have accumulated a large amount of manufacturability assessment knowledge in guiding the actual production process. The knowledge is mostly stored in the form of semi-structured and unstructured text, which are characterized by a wide range of assessment knowledge, many elements involved, and non-standardized descriptions, which make the knowledge difficult to store and increase the difficulty of access. Therefore, it is necessary to study the standardized manufacturability assessment knowledge representation method and knowledge graph construction method for aerospace products.

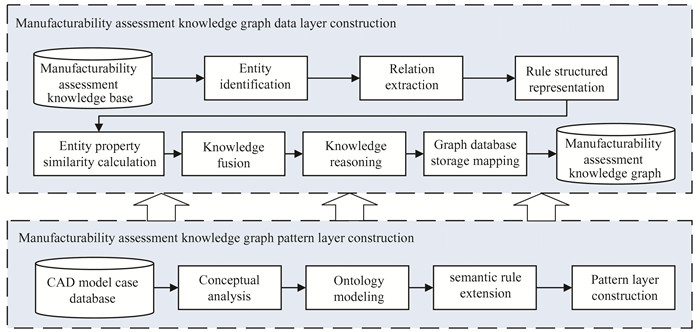

The overall process of knowledge graph construction is shown in Fig. 2, which mainly includes two parts: pattern layer construction and data layer construction. The pattern layer construction mainly utilizes the CAD model case base, as well as the historical cases of manufacturability assessment to establish the upper-level conceptual model of the domain. The ontology models of single concept and inter-multiple concepts are established respectively. Then SWRL (Semantic Web Rule Language) rules are established by parsing the accumulated natural language-based assessment rules to improve the semantic expression ability of the ontology. The knowledge graph data layer first performs entity identification and relation extraction from the enterprise's accumulated knowledge base of manufacturability assessment. Then knowledge fusion is performed based on the semantic similarity of entities to remove duplicates. Finally, the construction of the knowledge graph data layer is completed by knowledge reasoning and storage mapping of the graph database. The domain complexity of part structures, machining processes, and process constraints of aerospace products poses challenges for the construction of the manufacturability assessment knowledge graph. These challenges are primarily related to ontology construction, structured representation, and storage mapping of the data layer.Therefore, these aspects will be explored in detail in this paper.

|

Fig.2 Manufacturability assessment knowledge graph construction process |

Ontologies, as shared formal specification descriptions, are abstract models that describe concepts of the objective world[24]. An ontology model of a complex domain can be viewed as consisting of multiple relationships within and between multiple single concepts[25]. Therefore, based on the characteristics of the domain model for aerospace product manufacturability assessment, the ontology model adopts a construction mode from concept to realization and from part to whole.

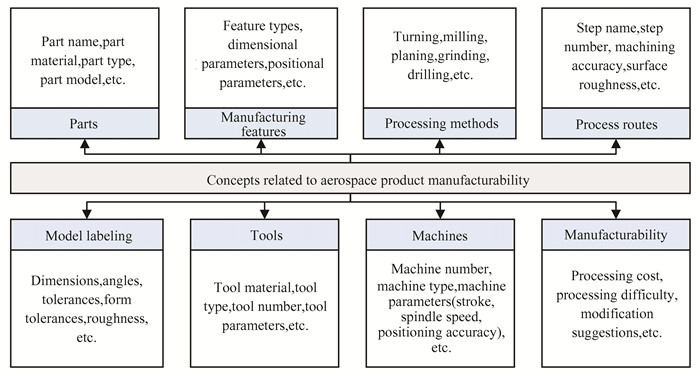

First, parsing the knowledge structure in the information model, the ontology model of manufacturability knowledge graph can be decomposed into multiple sub-conceptual models. Then, the multi-source information in the manufacturability assessment process is gradually integrated into these concepts to provide the property and relationship basis for the ontology model construction of the knowledge graph. Fig. 3 shows the generalized obtained concepts related to manufacturability assessment, including parts, machining features, machining methods, process routes, model annotation, machining machines, machining tools, and manufacturability.

|

Fig.3 Concepts related to aerospace product manufacturability |

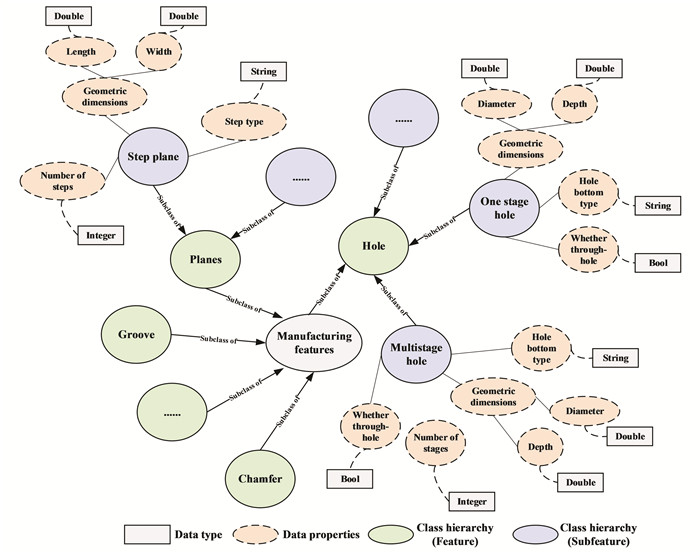

The ontological model of a single concept is a description and expression of factual knowledge. In order to ensure the rationality of concept description, after completing the classification of concept set, each concept should be refined gradually. By analyzing the concept property types and hierarchical relationships to establish a mesh knowledge structure model that can clearly express the information between the concepts' associated properties, and gradually complete the ontology construction of each concept in this way. The specific construction contents are as follows. First, the basic class of concepts is established based on the sub-concepts related to manufacturability assessment. Then, the internal properties of the basic classes are described in detail to complete the construction of the ontology for a single concept. Taking manufacturing features as an example, the class and subclass concept hierarchy in the OWL (Ontology Web Language) is used. Utilize data types and data properties to complete the description of concept properties. The description of intra-conceptual relations is completed by object properties. Finally, an ontology model with rich semantic relationships and clear hierarchical structure is constructed. Fig. 4 shows part of the ontology model constructed with the manufacturing feature concept as an example.

|

Fig.4 Partial ontological modeling of manufacturing features |

2 Aerospace Product Manufacturability Assessment Knowledge Representation and Knowledge Graph Construction 2.1 Ontology-Based Representation of Assessment Knowledge

The knowledge graph ontology model achieves an abstract description and structured representation of fact-based knowledge in the domain of manufacturability assessment, but fails to represent well the more semantically strong inference-based rule knowledge in the domain. SWRL is a rule markup language based on the OWL, which is used to improve the insufficient representation and constraint ability of the OWL[26]. Therefore, in order to extend the knowledge graph pattern layer and improve the expressive ability of the knowledge graph, SWRL semantic rules are constructed and integrated into the ontology model. The specific steps of the method are as follows. 1) Design the rule expression structure according to different types of rules. 2) Analyze and extract the experts' experience knowledge and decompose it according to the rule expression structure using natural language processing methods. 3) Express the extracted rule knowledge using if-then conditional statements, and then transform it into SWRL rules. 4) Verify the constructed SWRL rules, and store them after verifying that there are no errors into the knowledge base. The SWRL rule representation is illustrated below using rule r1 as an example.

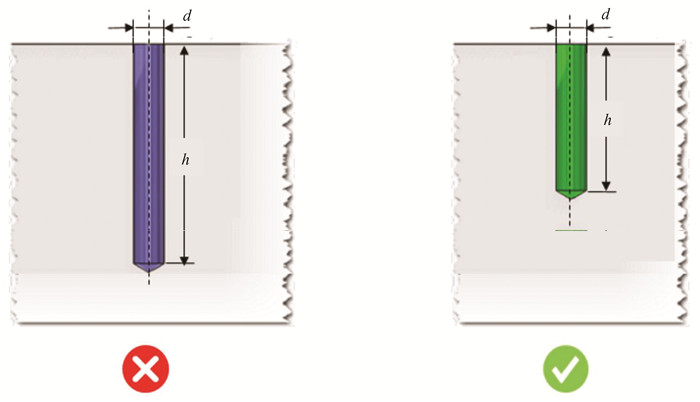

Rule r1: Deep hole machining capability rule. Deep and long holes are difficult to machine, and holes with too large a depth-to-diameter ratio should be avoided. The hole depth-to-diameter ratio should be no greater than the maximum machining capability of the tool for this ratio. A schematic of the rule is shown in Fig. 5.

|

Fig.5 Schematic diagram of deep hole machining capability rules |

The rule r1 can be represented using SWRL as:

Hole (?h)^HasFeature(?h, ?f)∧Feature(?f)^UseTool(?f, ?t)^HasDepthDiaCap(?t, ?ddc)∧Feature(?f)^HasDepth(?f, ?depth)∧Feature(?f)^HasDiameter(?f, ?diameter)^swrlb: greaterthan(?depth/?diameter, ?ddc) ->Feature(?f)^Manufacturability(?f, ?m)^HasSuggestion(?m, The depth-to-diameter ratio of the hole is too large for the tool capacity)

2.2 Knowledge Graph Construction Based on Graph DatabasesDue to the non-standardization and non-uniformity of terminology expression in product design, process, and manufacturing, it is possible that words with the same semantics in the knowledge graph may point to different entities. Therefore, this paper firstly adopts the method based on the similarity calculation of entity properties to discriminate ambiguous entities, and merges the entities that point to the same object, so as to realize the fusion of knowledge. When the sum of the similarity of two entity properties is greater than a set threshold, it is recognized that the two entities are the same, otherwise they are considered different entities. After entity fusion, the quality of the knowledge graph is effectively improved. However, there are still some implicit semantic relationships to be further mined. The knowledge reasoning method based on ontology and SWRL rules can effectively acquire the implicit knowledge in the knowledge graph, thus further expanding the scale of the knowledge graph.

In terms of storage of knowledge graphs, traditional relational databases realize the storage of ternary data only by using the method of association table. However, with the increase of data volume, the association table becomes more and more complex, resulting in low query efficiency and difficult data maintenance. RDF (Resource Description Framework) is a description framework proposed by W3C for standardized description and storage of semantic knowledge. In order to realize the transformation of structured data into knowledge graph, the knowledge extraction process from relational database to RDF is realized by applying the R2RML (RDB to RDF Mapping Language) mapping method driven by knowledge graph pattern layer.

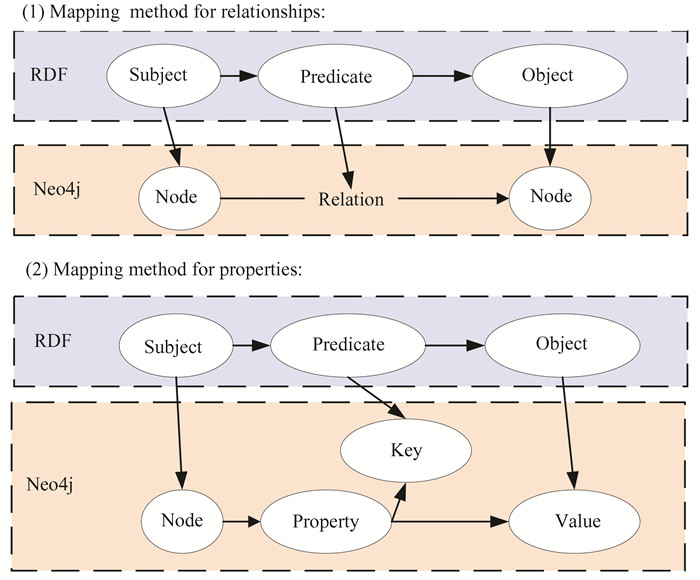

Since graph databases have the advantages of efficient retrieval, rich and powerful interfaces, and excellent visualization, Neo4j graph database is chosen as the storage tool for knowledge graphs in this paper. Although the description form of RDF triples generated by the R2RML mapping protocol is very similar to the graph structure (Node, Relation, Node, Property) in the Neo4j graph database, there are actually some differences that make it impossible to store the mapping directly. Therefore, we use the RDF-based Neo4j graph database mapping rules as shown in Fig. 6. In which, when the ternary of RDF represents inter-entity relationships, the data of Subject node of RDF is mapped to Node, Predicate relationship node is mapped to Relation, and Object is mapped to Node. When the triad of RDF represents entity properties, the Predicate relationship node is mapped to the key of Property, and Object is mapped to the value of Property.

|

Fig.6 Mapping methods for RDF and Neo4j |

3 Knowledge Graph-Based Rule Matching Method

In the process of aerospace product manufacturability assessment, it is necessary to match the applicable assessment rules in the knowledge base based on the extracted information of product manufacturing features in the assessment rule matching session. The accuracy of the assessment rule matching in this link directly determines the result. In order to improve the rule matching effect, this paper utilizes the rich semantic information and intrinsic association information in the knowledge graph for matching. First, a subgraph of part feature parameters is formed based on the ontology model. Then the knowledge graph is utilized for graph search to match the subgraphs of the feature parameter model with the subgraphs of the assessment rules, which finally results in a list of successfully matched rules.

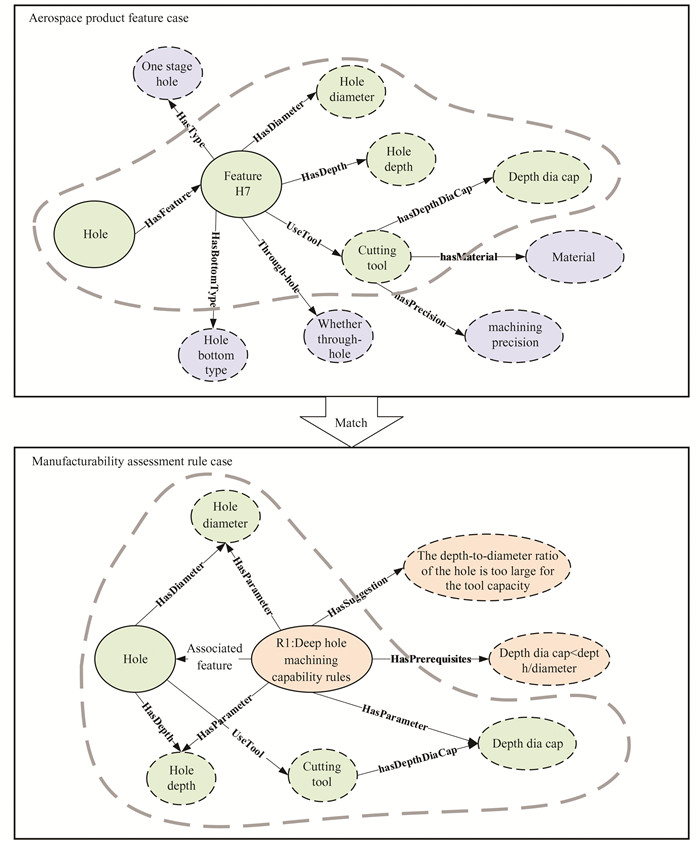

An example of knowledge graph-based rule matching is shown in Fig. 7. The manufacturability assessment requirements for a manufacturing feature can be viewed as a subgraph consisting of properties and relationships of the feature. For example, the upper part of Fig. 7 represents the parameter model of a hole feature instance H7 extracted from an aerospace product part, which is represented by a subgraph consisting of the hole feature H7 and its related properties. The rule matching method needs to match the corresponding set of rules from the knowledge graph based on this subgraph. The lower part of Fig. 7 then represents the relevant entities and properties of the matched rule r1 (deep hole machining capability rule) in the knowledge graph.

|

Fig.7 A case for knowledge graph-based manufacturability rule matching |

In the matching process, let the set of entities and properties contained in the input feature parameter model f be Xf={e1, e2, p1, p2, p3, p4}. Let the set of entities and properties contained in rule r in the rule base be Yr={e′1, p′1, p′2, p′3, m′1, m′2}, where e′i∈E and p′1, p′2, p′3∈P denote the entities and properties associated with the feature, and m′1, m′2∈M denote the entities and properties associated only with the assessment rule entities and not with the manufacturing feature entities. Corresponding to the rule subgraph of Fig. 7, the green nodes represent the nodes associated with hole features in the subgraph of this rule, while the orange nodes indicate the properties that only have a relationship with the rule nodes, including the judgment premise and conclusion of the rule.

If the parts belonging to E and P in the subgraphs of rule r can be completely covered by the subgraphs of feature parameter model f, which means that it satisfies (Yr∩(E∪P))⊆Xf, it can be regarded as a successful match between rule r and feature f. And if the feature parameter model f fails to cover any rule successfully, it can be considered as an incomplete feature model with missing elements, which needs to be complemented and then matched. In summary, the algorithm flow of matching feature f with rule r is shown in Fig. 8.

|

Fig.8 Knowledge graph-based rule matching algorithm flowchart |

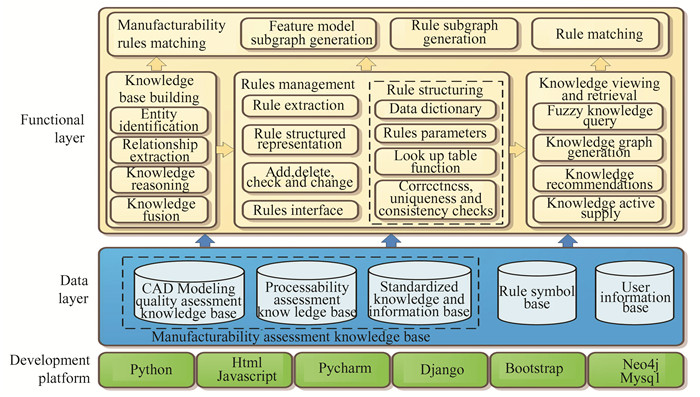

4 Application Validation 4.1 Application of Knowledge Graph Construction Methods

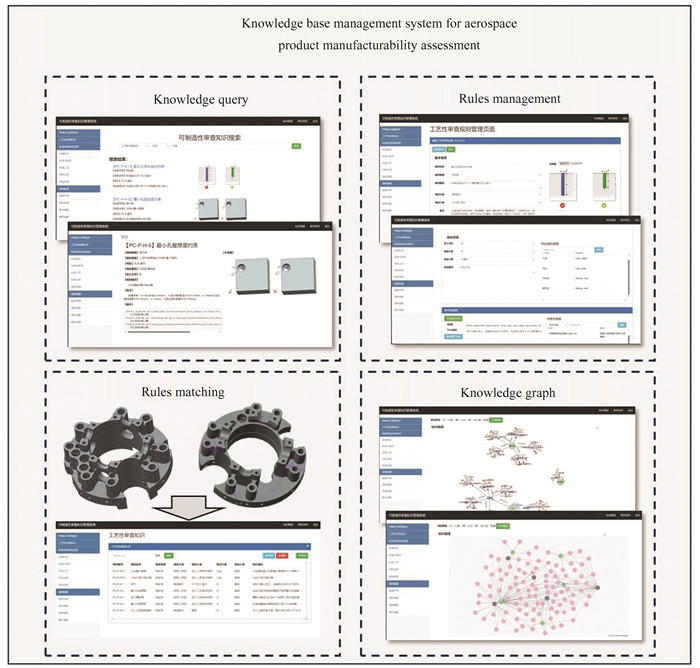

In order to verify the effectiveness of the proposed aerospace product manufacturability assessment knowledge graph construction method, this paper designs and develops a knowledge base management system for aerospace product manufacturability assessment, utilizing the proposed methed for application verification. The overall architecture of the system is shown in Fig. 9. The system is based on Python language and Django framework as the back-end, and uses HTML and JavaScript as the front-end. The main application interface of the system is shown in Fig. 10. The software platform realizes several functional modules including management of rules, rule query, and rule matching, which verifies the feasibility and effectiveness of the method.

|

Fig.9 General architecture of the software system |

|

Fig.10 Main application interface of the software system |

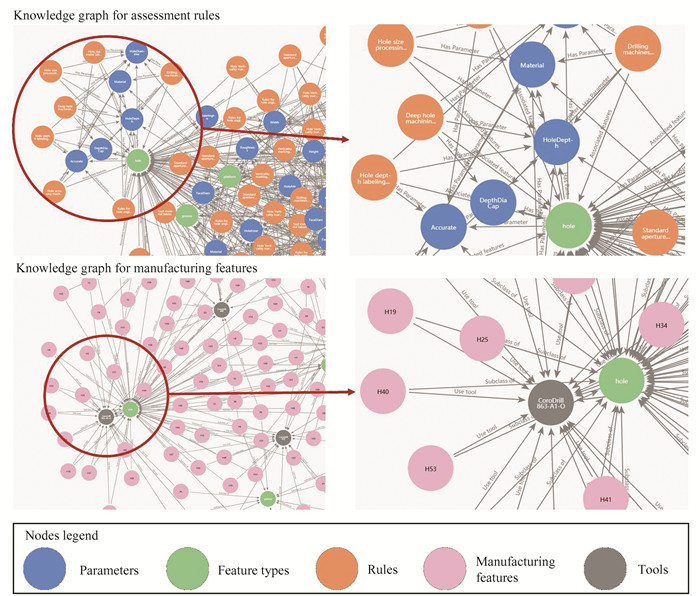

For the knowledge graph construction, the ontology model is built using Protégé and SWRL rules are constructed using the SWRLTab plug-in. Neo4j graph database is chosen as the storage tool for knowledge graphs. The visualization of entity relationship construction for knowledge graph is shown in Fig. 11. After the steps of knowledge fusion, knowledge inference, and storage mapping, a total of 178 rules including assessment rules for modeling quality, manufacturing resource capability, spatial location, and structural manufacturability are covered in the rule knowledge graph. The number of each type of nodes and relationships in the rule knowledge graph is shown in Table 1.

|

Fig.11 The visualization of entity relationship construction for knowledge graph |

| Table 1 Number of nodes and relationships in the knowledge graph for assessment rules |

4.2 Performance Validation of Rule Matching Approach

In this paper, the method of rule matching is validated based on product feature data and knowledge of manufacturability assessment accumulated during the application of knowledge management system. Precision rate and recall rate are selected as two indicators for performance comparison. The formula for precision rate Precision is as follows:

| $ \text { Precision }=\mathrm{TP} /(\mathrm{TP}+\mathrm{FP}) $ | (1) |

where TP is the number of correctly matched rules among all matched rules; FP is the number of incorrectly matched rules among all matched rules.

Recall rate represents the proportion of correctly matched rules to the total number of actually correctly matched rules, which can visualize whether there are missing rules. The formula for recall rate is as follows:

| $ \text { Recall }=\mathrm{TP} /(\mathrm{TP}+\mathrm{FN}) $ | (2) |

where FN is the number of rules in the rule base that should be matched but have not been matched.

At present, the rule matching method commonly used in actual production is the manual search method. The engineer searches the corresponding rule from the rule base according to the keywords and manually judges whether it matches or not. We simulate this manual search matching method with algorithms based on natural language processing. To validate the performance of the rule matching method, the knowledge graph-based rule matching method proposed in this paper is compared with two natural language processing methods: LDA (Latent Dirichlet Allocation)[27] and Word2vec+TextRank[28], which are two commonly used subject keyword extraction methods. First, the subject keywords of natural language description rules in the assessment rule base are extracted using these two methods respectively. On this basis, the similarity between manufacturing feature associated entities and rule subject keywords is calculated and a threshold is set for filtering in order to realize keyword-based rule matching. A total of 5 matching experiments were conducted, and 50 models were selected as the experimental dataset for each experiment, including 15 valve bodies, 15 grid wall plates, and 20 rotary hulls. These are representative parts with the high level of complexity and manufacturing difficulty. One typical case form each of these three types is selected, and the types and quantifies of features extracted from them are given in Table 2. The results of precision rate and recall rate are shown in Table 3 and Table 4.

| Table 2 Number of each type of manufacturing feature for typical part models |

| Table 3 Precision rate comparison results |

| Table 4 Recall rate comparison results |

From the results, it can be seen that the knowledge graph-based rule matching method outperforms the natural language-based analysis method in both precision and recall indicators. Plain text methods are not as good as graph search methods with richer knowledge of specialized domains and richer semantics in discriminating the problem of syntactic similarity in specialized domains. Matching methods utilizing the knowledge graph can more accurately capture the relevant information of feature parameters and the feature semantic information of assessment rules, while plain text methods tend to match rules with similar vocabulary and sentence structures used in descriptions. Therefore, knowledge graph-based matching method has better matching performance.

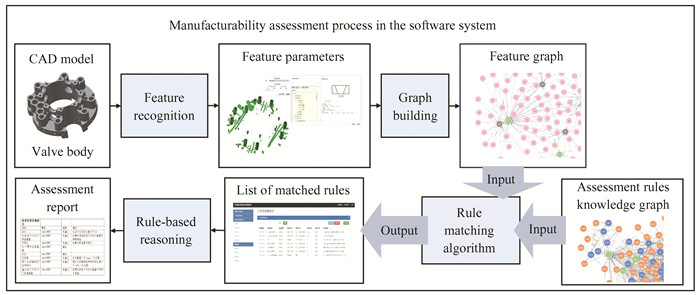

A flowchart for manufacturability assessment in the software system is shown in Fig. 12. The schematic shows the key aspects of the software system, such as model input, graph building, and rule matching. In this process, the input data is the part model, the figure takes a valve body part as an example. The feature parameters of the part model are first extracted by the secondary development plug-in of the CAD software. Then based on the ontology model, the feature parameters are used to construct the feature knowledge graph of the part. The knowledge graphs of manufacturability assessment rules and manufacturing features are used as inputs, and the list of matching rules is calculated using the rule matching algorithm. Finally, the assessment rules are used to reason to get the results and generate a report. Taking the hole feature H3 in the part model M1 as an example, the details of the rules that the feature matches to are shown in Table 5.

|

Fig.12 Manufacturability assessment process in the software system |

| Table 5 Details of assessment rules matched to a hole feature |

5 Conclusions

Due to the poor structure and low reusability of product manufacturing feature information and assessment knowledge in the current aerospace product manufacturability assessment process, it is difficult to realize automated manufacturability assessment. To address these problems, this paper proposes a knowledge graph construction and rule matching method for aerospace product manufacturability assessment knowledge by utilizing the advantages of knowledge graph in knowledge semantics and association representation. The contributions of this research are mainly reflected in three aspects. 1) An ontology model of aerospace product manufacturability assessment is established, which provides a theoretical basis for the construction of knowledge graph pattern layer. 2) A structured representation of manufacturability assessment knowledge is designed, which improves the knowledge expression capability. 3) A rule matching method based on subgraph matching is proposed to improve the precision and recall of assessment rule matching. Based on the practical application of the software platform and matching experiments, this paper verifies that the proposed methods can improve the matching accuracy and efficiency, reduce the dependence on experts, and then reduce the labor cost and design change cost. In the process of subgraph matching, when the complexity of the relationship is high, as well as in the face of large-scale data volume, the number of branches to be searched will increase dramatically. The next step of research can consider the use of deep learning and other methods to develop more efficient matching algorithms under large-scale data.

| [1] |

Liu S, Bao J, Lu Y, et al. Digital twin modeling method based on biomimicry for machining aerospace components. Journal of Manufacturing Systems, 2021, 58: 180-195. DOI:10.1016/j.jmsy.2020.04.014 (  0) 0) |

| [2] |

Gupta S K, Regli W C, Das D, et al. Automated manufacturability analysis: A survey. Research in Engineering Design, 1997, 9(3): 168-190. DOI:10.1007/BF01596601 (  0) 0) |

| [3] |

Shukor S A, Axinte D A. Manufacturability analysis system: Issues and future trends. International Journal of Production Research, 2009, 47(5): 1369-1390. DOI:10.1080/00207540701589398 (  0) 0) |

| [4] |

Gutierrez C, Sequeda J F. Knowledge graphs. Commun. ACM, 2021, 64(3): 96-104. DOI:10.1145/3418294 (  0) 0) |

| [5] |

Lyu M, Li X, Chen C-H. Achieving knowledge-as-a-service in iiot-driven smart manufacturing: A crowdsourcing-based continuous enrichment method for industrial knowledge graph. Advanced Engineering Informatics, 2022, 51: 101494. DOI:10.1016/j.aei.2021.101494 (  0) 0) |

| [6] |

Xiao Y, Zheng S, Shi J, et al. Knowledge graph-based manufacturing process planning: A state-of-the-art review. Journal of Manufacturing Systems, 2023, 70: 417-435. DOI:10.1016/j.jmsy.2023.08.006 (  0) 0) |

| [7] |

Besharati-Foumani H, Lohtander M, Varis J. Intelligent process planning for smart manufacturing systems: A state-of-the-art review. Procedia Manufacturing, 2019, 38: 156-162. DOI:10.1016/j.promfg.2020.01.021 (  0) 0) |

| [8] |

Liu M, Li X, Li J, et al. A knowledge graph-based data representation approach for iiot-enabled cognitive manufacturing. Advanced Engineering Informatics, 2022, 51: 101515. DOI:10.1016/j.aei.2021.101515 (  0) 0) |

| [9] |

Bharadwaj A G, Starly B. Knowledge graph construction for product designs from large cad model repositories. Advanced Engineering Informatics, 2022, 53: 101680. DOI:10.1016/j.aei.2022.101680 (  0) 0) |

| [10] |

Hallmann M, Goetz S, Schleich B. Mapping of gd&t information and pmi between 3d product models in the step and stl format. Computer-Aided Design, 2019, 115: 293-306. DOI:10.1016/j.cad.2019.06.006 (  0) 0) |

| [11] |

Sui X L, Zhang G L, Wang Q, et al. Parts information extraction and storage of 3d-capp system oriented virtual manufacturing. Applied Mechanics and Materials, 2013, 427-429: 2645-2649. DOI:10.4028/www.scientific.net/AMM.427-429.2645 (  0) 0) |

| [12] |

Li X, Zhang F, Li Q, et al. Exploiting a knowledge hypergraph for modeling multi-nary relations in fault diagnosis reports. Advanced Engineering Informatics, 2023, 57: 102084. DOI:10.1016/j.aei.2023.102084 (  0) 0) |

| [13] |

Zhou B, Li J, Li X, et al. Leveraging on causal knowledge for enhancing the root cause analysis of equipment spot inspection failures. Advanced Engineering Informatics, 2022, 54: 101799. DOI:10.1016/j.aei.2022.101799 (  0) 0) |

| [14] |

Li X, Zhang S, Huang R, et al. Structured modeling of heterogeneous cam model based on process knowledge graph. The International Journal of Advanced Manufacturing Technology, 2018, 96(9): 4173-4193. DOI:10.1007/s00170-018-1862-8 (  0) 0) |

| [15] |

Ma H, Zhou X, Liu W, et al. A customizable process planning approach for rotational parts based on multi-level machining features and ontology. The International Journal of Advanced Manufacturing Technology, 2020, 108(3): 647-669. DOI:10.1007/s00170-020-05437-0 (  0) 0) |

| [16] |

Hu Z, Li X, Pan X, et al. A question answering system for assembly process of wind turbines based on multi-modal knowledge graph and large language model. Journal of Engineering Design, 2023, 1-25. DOI:10.1080/09544828.2023.2272555 (  0) 0) |

| [17] |

Shen X, Li X, Zhou B, et al. Dynamic knowledge modeling and fusion method for custom apparel production process based on knowledge graph. Advanced Engineering Informatics, 2023, 55: 101880. DOI:10.1016/j.aei.2023.101880 (  0) 0) |

| [18] |

Liu M, Zhou B, Li J, et al. A knowledge graph-based approach for assembly sequence recommendations for wind turbines. Machines, 2023, 11(10): 930. DOI:10.3390/machines11100930 (  0) 0) |

| [19] |

Kim S, Rosen D W, Witherell P, et al. A design for additive manufacturing ontology to support manufacturability analysis. Journal of Computing and Information Science in Engineering, 2019, 19(4): 041014. DOI:10.1115/1.4043531 (  0) 0) |

| [20] |

Dinar M, Rosen D W. A design for additive manufacturing ontology. Journal of Computing and Information Science in Engineering, 2017, 17(2): 021013. DOI:10.1115/1.4035787 (  0) 0) |

| [21] |

Ranjan R, Samant R, Anand S. Design for manufacturability in additive manufacturing using a graph based approach. ASME 2015 International Manufacturing Science and Engineering Conference. New York: ASME, 2015. DOI: 10.1115/msec2015-9448.

(  0) 0) |

| [22] |

Ko H, Witherell P, Lu Y, et al. Machine learning and knowledge graph based design rule construction for additive manufacturing. Additive Manufacturing, 2021, 37: 101620. DOI:10.1016/j.addma.2020.101620 (  0) 0) |

| [23] |

Mayerhofer M, Lepuschitz W, Hoebert T, et al. Knowledge-driven manufacturability analysis for additive manufacturing. IEEE Open Journal of the Industrial Electronics Society, 2021, 2: 207-223. DOI:10.1109/OJIES.2021.3061610 (  0) 0) |

| [24] |

Solano L, Rosado P, Romero F. Ontological-based validation of selected technological resources in integrated machining and inspection process planning. Procedia Engineering, 2015, 132: 1096-1103. DOI:10.1016/j.proeng.2015.12.601 (  0) 0) |

| [25] |

Win N N H, Bao J M, Cui G, et al. Semantic qos ontology and semantic service ranking approach for iot services. Journal of Harbin Institute of Technology (New Series), 2014, 21: 102-112. (  0) 0) |

| [26] |

Zhu L, Jayaram U, Kim O. Semantic applications enabling reasoning in product assembly ontologies—moving past modeling. Journal of Computing and Information Science in Engineering, 2011, 12(1): 011009. DOI:10.1115/1.3647878 (  0) 0) |

| [27] |

Chen Y, Zhang H, Liu R, et al. Experimental explorations on short text topic mining between lda and nmf based schemes. Knowledge-Based Systems, 2019, 163: 1-13. DOI:10.1016/j.knosys.2018.08.011 (  0) 0) |

| [28] |

Song S, Wang Z, Xu S, et al. A novel text classification approach based on word2vec and textrank keyword extraction. Proceedings of the 2019 IEEE Fourth International Conference on Data Science in Cyberspace (DSC). Piscataway: IEEE, 2019: 536-543. DOI: 10.1109/DSC.2019.00087.

(  0) 0) |

2025, Vol. 32

2025, Vol. 32