镁合金和铝合金是重要的有色金属材料,已广泛应用于航空航天、兵器、电子通讯等领域.在汽车工业中,为了使汽车车身轻量化,高强钢正逐渐被比强度和比刚度更高的镁合金和铝合金所取代[1-3].为了获得可靠的汽车车身结构,镁合金和铝合金的连接受到越来越高的重视.

镁铝异种金属的焊接一直是焊接领域的技术难题.目前,镁和铝采用的焊接方法主要包括钨极氩弧焊、激光焊的熔焊[4-7]和电阻焊、搅拌摩擦焊以及超声波焊接等固相连接方法[8-13].研究表明,无论采取哪种焊接方法,由于镁铝直接接触,都不可避免地在接头结合区形成硬脆的Mg-Al系金属间化合物,降低了接头强度,限制了接头的应用.因此,研究人员提出通过添加中间层控制界面Mg-Al相的大面积形成,以达到提高接头可靠性的目的[14-17].

Al、Sn不会形成金属间化合物,且Sn能够提高镁合金和铝合金焊接时的可焊性[16, 18].本文在铝合金表面化学镀锡后进行铝镁超声波焊接,成功抑制了镁铝超声波焊接头内的Mg-Al脆性相的形成,提高了接头的可靠性.

1 试验试验采用AZ31B镁合金和6061铝合金薄板,厚度均为0.3 mm,尺寸为80 mm×15 mm.试验中,首先对铝合金用50 g/L NaOH溶液浸蚀3 min除油和除氧化膜,然后,采用50%硝酸光亮浸蚀5~15 s,将处理后的铝合金试样采用化学镀锡的方法 (锡酸钠40 g/L,酒石酸钾钠10 g/L,焦磷酸钾10 g/L,十二烷基硫酸钠1 g/L,乙二胺四乙酸二钠1 g/L,55 ℃,4~5 min) 在其表面涂覆一层3 μm的金属锡层.镁合金试样表面用400,600,800,1000号砂纸打磨去除表面氧化膜,用丙酮擦拭表面去油污.将镀锡铝和镁试样搭接后进行超声波焊接.超声波焊头为密齿型,尺寸为10 mm×10 mm,焊接参数:延时时间400 ms,焊接时间90 ms,焊接压力1.8、4.4、7.1、9.8、12.4 MPa.

采用SU8010扫描电镜观察了焊接接头微观形貌.利用TM3000能谱仪 (Energy Dispersive Spectrometer, EDS) 和D8 Advance的X射线衍射仪 (X-Ray Diffractomer, XRD) 分析了接头中各元素的分布情况和相的组成.采用CTM2500万能试验机测试了接头的拉伸剪切强度.

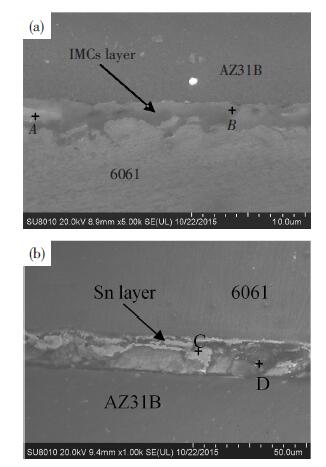

2 结果及讨论图 1为无镀锡层和含镀锡层的镁铝超声波焊接接头截面微观形貌,可见两接头界面均形成了良好的连接,没有裂纹、未焊牢等焊接缺陷.但界面的微观组织形貌发生了明显变化.图 1(a)为无镀锡层铝镁超声波焊接头界面微观组织图,可以看到,接头处两母材之间有一个明显的过渡层,A点和B点的元素含量 (原子分数,%) 分别为68.70Al-29.59Mg和20.05Al-79.95Mg.根据镁铝二元合金相图推测,靠近镁侧的深色区域为扩散反应产生的脆性相Al12Mg17,靠近铝侧的灰色区域为Al3Mg2.有文献对铝镁直接超声波点焊中IMCs层的生长情况进行了详细研究[12],研究发现,通过界面元素相互扩散作用,在焊接界面镁侧将率先形成岛状的Al12Mg17相;随着扩散的进行,Al12Mg17相将形成连续反应层;随后Al3Mg2相在焊接界面铝的一侧形成并快速生长.图 1(b)是含镀锡层的镁铝超声波焊接头界面微观组织照片,可以看到,界面反应层明显比无镀层的界面更厚 (约20 μm).

|

图 1 镁铝超声波焊接头截面微观形貌 Figure 1 Cross section morphology of Mg/Al ultrasonic spot welded joint: (a) without Sn interlayer; (b) with Sn interlayer |

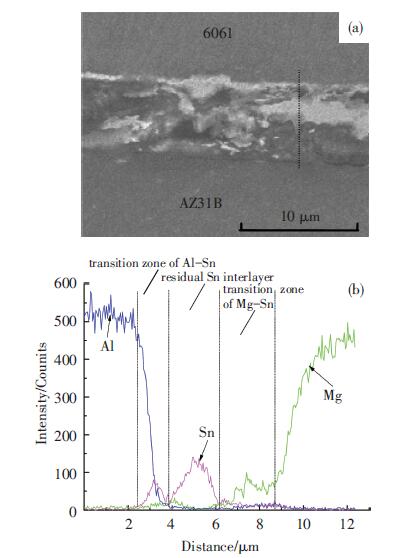

结合图 2能谱线扫描结果发现,反应层内几乎不存在Mg和Al元素的相互混合.这说明镀锡层的加入有效地抑制了Mg和Al在界面的相互扩散.Mg/Sn/Al超声波焊接结合区由Al-Sn反应扩散层、残余锡层和Mg-Sn反应扩散层组成,图 1(b)中C点和D点的元素含量 (原子分数,%) 分别为93.69Sn-6.31Al和9.76Al-85.60Mg-4.64Sn.焊接界面含Sn高的区域呈亮白色,主要存在于Al-Sn扩散层和残余锡层,由Al-Sn二元相图得知,Al、Sn不会形成共晶组织,Al向Sn扩散形成固溶体;含Sn少的区域呈暗黑色,存在于Mg-Sn反应扩散层,Mg、Sn相互扩散析出Mg2Sn金属间化合物.

|

图 2 铝镁超声波焊接头界面EDS分析结果 Figure 2 EDS analysis results of Mg/Al ultrasonic spot welded joint interface: (a) a microstructure of the welded joint; (b) EDS line scan across the welded joint |

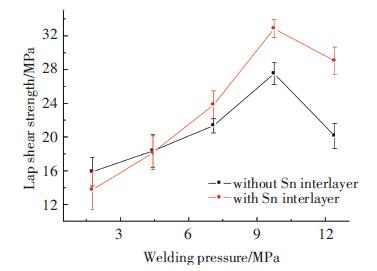

图 3为无镀锡层和含镀锡层的镁铝超声波点焊接头拉伸剪切强度测试结果.如图 2可见,含镀锡层的镁铝超声波焊接头最大拉伸剪切强度为32.9 MPa;而无镀锡层镁铝超声波焊接头的最大拉伸剪切强度为27.5 MPa.可见,镀锡层的添加,有效提高了焊接接头可靠性,即拉伸剪切强度提高了19.6%.值得注意的是,在焊接压力低于4.4 MPa时,无镀锡层接头的强度反而高于含镀锡层接头的强度.这一特殊现象与超声波焊接接头形成的机制有关系.

|

图 3 焊接接头拉伸剪切强度 Figure 3 Lap shear strength of the welded joints |

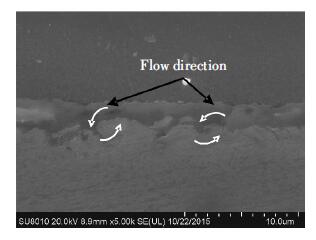

超声波焊接过程中,由摩擦和振动造成焊件间发热和强烈塑性流动,使焊件的接触部分产生严重的塑性变形.这使得焊接区出现涡流状的塑性流动层 (图 4),导致焊件表面之间的机械嵌合并引起物理冶金反应.当焊接压力较小时 (低于4.4 MPa),镀锡层在摩擦和振动阶段起到了润滑剂的作用,改变了镁铝摩擦行为,使得超声波能量不能有效的传递到工件,产生的热量不足以软化或熔化锡层,不能形成有效连接.随着焊接压力增大,振动的传递条件得到了改善,焊件之间产生了足够的摩擦功,产热和塑性流动加剧,界面冶金反应也随之加剧,使得镁铝界面产生了良好的连接.当焊接压力过大时,使摩擦力过大,造成焊件间的相对摩擦运动减弱,甚至会使振幅值有所降低,接头强度也随之降低.

|

图 4 焊接区涡流状塑性流动层 Figure 4 Swirling plastic flow layer on welded zone of ultrasonic welding |

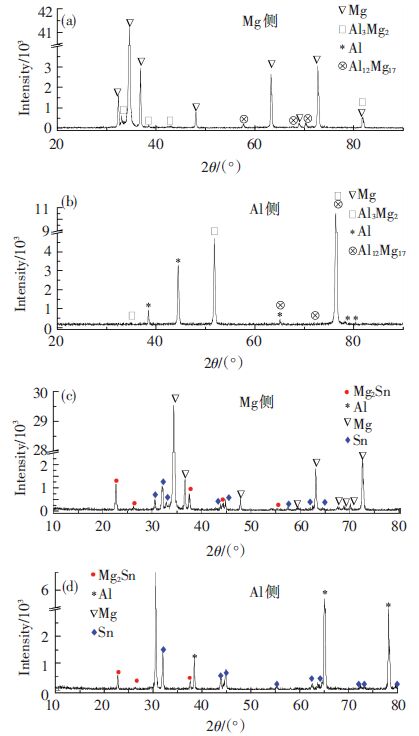

图 5为接头断口的X射线衍射分析结果.

|

图 5 接头断口XRD分析结果 Figure 5 X-ray diffraction patterns obtained from fracture surfaces of (a, b) without and (c, d) with Sn interlayer |

无镀锡层的镁铝超声波焊接头X射线衍射分析结果 (图 5(a)、(b)) 表明,焊接接头断口Mg基体一侧相成分组成中未发现纯铝结构的衍射峰,同样在铝一侧未发现纯镁结构的衍射峰,另外,在断口两侧均含Mg-Al系金属间化合物Al12Mg17和Al3Mg2.由此可以推断,断裂面集中在镁铝反应扩散区,造成断裂的主要原因是呈脆性的金属间化合物的存在.图 5(c)、(d)为含镀锡层镁铝超声波焊接头的X射线衍射分析结果,可以看到,在铝侧和镁侧都存在Sn和Mg2Sn,并没有发现Al12Mg17和Al3Mg2的存在,这与显微形貌分析的结果相同:镀锡层有效地阻隔了镁和铝的直接扩散,抑制了硬脆的Mg-Al金属间化合物的形成.

3 结论1) 镀锡层的加入抑制了镁铝超声波焊接头内脆性Mg-Al金属间化合物的生成,提高了接头的可靠性.

2) 无镀锡层的镁铝超声波焊接头界面出现了大量的Mg-Al相.含镀锡层的镁铝超声波接头界面主要由铝锡固溶体、镁锡固溶体、残余锡层和Mg-Sn金属间化合物组成.

3) 含镀锡层的镁铝超声波焊接头最大拉伸剪切强度为32.9 MPa,而无镀锡层的镁铝超声波焊接头最大拉伸剪切强度仅为27.5 MPa.

| [1] | 江超, 陈辉, 车小莉, 等. 高速列车A6005A铝合金焊接接头断裂韧性研究[J]. 材料科学与工艺, 2013, 21(2): 55–60. JIANG Chao, CHEN Hui, CHE Xiaoli, et al. Fracture toughness of welded joints of A6005A aluminum alloy for high speed train[J]. Materials Science and Technology, 2013, 21(2): 55–60. DOI: 10.11951/j.issn.1005-0299.20130210 |

| [2] | PENNER P, LIU L, GERLICH A, et al. Feasibility study of resistance spot welding of dissimilar Al/Mg combinations with Ni based interlayers[J]. Science and Technology of Welding and Joining, 2013, 18(7): 541–550. DOI: 10.1179/1362171813Y.0000000129 |

| [3] | 宋广胜, 陈强强, 徐勇, 等. AZ31镁合金室温拉伸微观变形机制EBSD原位跟踪研究[J]. 材料工程, 2016, 44(4): 1–8. SONG Gongsheng, CHEN Qiangqiang, XU Yu, et al. Deformation micro-mechanism of AZ31 Mg alloy during tension at room temperature by EBSD in-situ tracking[J]. Journal of Materials Engineering, 2016, 44(4): 1–8. DOI: 10.11868/j.issn.1001-4381.2016.04.001 |

| [4] | BEN-ARTZY A, MUNITZ A, KOHN G, et al. Joining of light hybrid constructions made of magnesium and aluminum alloys[C]//Magnesium Technology 2002. Seattle, WA: TMS, 2002: 295-302. |

| [5] | BORRISUTTHEKUL R, MIYASHITA Y, MUTOH Y. Dissimilar material laser welding between magnesium alloy AZ31B and aluminum alloy A5052-O[J]. Science and Technology of Advanced Materials, 2005, 6(2): 199–204. DOI: 10.1016/j.stam.2004.11.014 |

| [6] | 刘政军, 宫颖, 苏允海. 镁铝异种金属TIG焊接头性能的研究[J]. 材料工程, 2015, 43(3): 18–22. LIU Zhengjun, GONG Ying, SU Yunhai. Study on characteristics in TIG welded joint of Mg/Al dissimilar materials[J]. Journal of Materials Engineering, 2015, 43(3): 18–22. DOI: 10.11868/j.issn.1001-4381.2015.03.004 |

| [7] | SHANG J, WANG K, ZHOU Q, et al. Microstructure characteristics and mechanical properties of cold metal transfer welding Mg/Al dissimilar metals[J]. Materials & Design, 2012, 34: 559–565. |

| [8] | LIU W, LONG L, MA Y, et al. Microstructure evolution and mechanical properties of Mg/Al diffusion bonded joints[J]. Journal of Alloys and Compounds, 2015, 643: 34–39. DOI: 10.1016/j.jallcom.2015.04.116 |

| [9] | SUHUDDIN U, FISCHER V, KROEFF F, et al. Microstructure and mechanical properties of friction spot welds of dissimilar AA5754 Al and AZ31 Mg alloys[J]. Materials Science and Engineering: A, 2014, 590: 384–389. DOI: 10.1016/j.msea.2013.10.057 |

| [10] | CHOWDHURY S H, CHEN D L, BHOLE S D, et al. Lap shear strength and fatigue behavior of friction stir spot welded dissimilar magnesium-to-aluminum joints with adhesive[J]. Materials Science and Engineering: A, 2013, 562: 53–60. DOI: 10.1016/j.msea.2012.11.039 |

| [11] | MOHAMMADI J, BEHNAMIAN Y, MOSTAFAEI A, et al. Friction stir welding joint of dissimilar materials between AZ31B magnesium and 6061 aluminum alloys: Microstructure studies and mechanical characterizations[J]. Materials Characterization, 2015, 101: 189–207. DOI: 10.1016/j.matchar.2015.01.008 |

| [12] | PATEL V K, BHOLE S D, CHEN D L. Microstructure and mechanical properties of dissimilar welded Mg-Al joints by ultrasonic spot welding technique[J]. Science and Technology of Welding and Joining, 2012, 17(3): 202–206. DOI: 10.1179/1362171811Y.0000000094 |

| [13] | PANYELI A, ROBSON J D, BROUGH I, et al. The effect of high strain rate deformation on intermetallic reaction during ultrasonic welding aluminium to magnesium[J]. Materials Science and Engineering: A, 2012, 556: 31–42. DOI: 10.1016/j.msea.2012.06.055 |

| [14] | 赵丽敏, 刘黎明, 徐荣正, 等. 镁合金与铝合金的夹层扩散焊连接[J]. 焊接学报, 2007, 28(10): 9–12. ZHAO Limin, LIU Liming, XU Rong, et al. Diffusion bonding of Mg/Al alloy with Zn interlayer metal[J]. Transactions-china Welding Institution, 2007, 28(10): 9–12. DOI: 10.3321/j.issn:0253-360x.2007.10.003 |

| [15] | GAO Q, WANG K. Influence of Zn Interlayer on interfacial microstructure and mechanical properties of TIG lap-welded Mg/Al joints[J]. Journal of Materials Engineering and Performance, 2016, 25(3): 756–763. DOI: 10.1007/s11665-016-1899-5 |

| [16] | PATEL V K, BHOLE S D, CHEN D L. Improving weld strength of magnesium to aluminium dissimilar joints via tin interlayer during ultrasonic spot welding[J]. Science and Technology of Welding and Joining, 2012, 17(5): 342–347. DOI: 10.1179/1362171812Y.0000000013 |

| [17] | PANTELI A, ROBSON J D, CHEN Y C, et al. The effectiveness of surface coatings on preventing interfacial reaction during ultrasonic welding of aluminum to magnesium[J]. Metallurgical and Materials Transactions A, 2013, 44(13): 5773–5781. DOI: 10.1007/s11661-013-1928-z |

| [18] | LIU X J, HUANG R S, WANG H Y, et al. Improvement of TIG lap weldability of dissimilar metals of Al and Mg[J]. Science and Technology of Welding & Joining, 2007, 12(3): 258–260. |

2017, Vol. 25

2017, Vol. 25