BCB(Benzocyclobutene)以其低介电常数、低介电损耗、低吸水率、高热稳定性、化学稳定性以及高薄膜平整度和低固化温度等优良性能,已广泛应用于高级微电子领域[1-3],包括多层布线、应力缓冲/钝化层、GaAs介质内层、高频器件、滤波器、MEMS以及生物芯片等[4-10].特别是在多层布线应用中,BCB介质常被用作为高密度薄膜多层布线基板的层间绝缘介质材料,其介质通孔互连的导通性能直接影响着信号的高速传输,因此,BCB通孔光刻成为该基板制造的关键,可利用其光敏特性实现BCB通孔制作.

传统浸没显影方式进行BCB通孔显影,容易导致通孔的高阻连接甚至互连断路问题,特别是高深宽比的通孔显影,造成信号断路的几率越来越大,为此,必须使用高昂的等离子刻蚀设备,采用O2/C2F6、O2/SF6等特殊气体进行BCB去底膜工艺[11],造成了基板制造过程中工艺周期增加,工艺复杂程度提高,甚至制造成本的大幅上升.基于此,本文提出一种高密度薄膜多层布线基板的间歇旋转喷淋显影新方法,可满足高密度、微小孔径的BCB通孔显影.并通过研究间歇旋转喷淋显影对BCB的通孔形貌、微观结构、导通电阻以及通孔互连剖面的影响,形成形貌良好的BCB通孔及通孔互连图形,实现BCB通孔的低阻性互连,满足高密度薄膜多层布线基板高可靠应用.

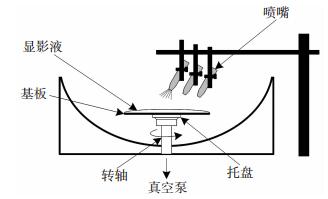

1 间歇旋转喷淋显影方法间歇旋转喷淋显影示意图如图 1所示,间歇旋转喷淋显影方法是显影喷嘴按照一定喷淋压力将显影液喷淋到基板上,借助显影液的表面张力使其均匀铺展在基板表面,停止喷淋,利用离心力以正向和反向交替低速旋转方式进行显影,大大提高显影均匀性;一定工艺时间后,显影喷头再次喷淋新的显影液,并冲走旧的显影液,避免了旧显影液的重复污染;继续显影,重复几次直到显影结束.然后自动切换喷嘴,喷淋定影液进行定影,一定工艺时间后基板高速旋转并氮气吹干.其中喷淋压力、喷嘴角度、转速、显影液温度可调节.

|

图 1 间歇旋转喷淋显影示意图 Figure 1 Schematic diagram of intermittent rotary spray development |

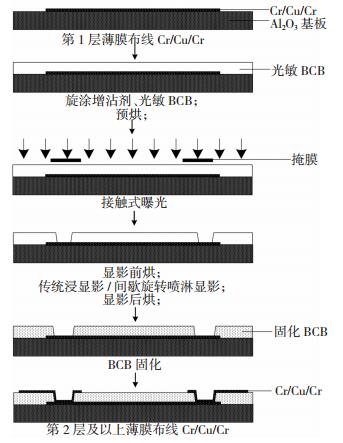

本文采用Cyclotene 4026-46系列光敏BCB介质作为绝缘介质层材料,显影液为DS3000,衬底材料为50 mm×50 mm的Al2O3陶瓷基板,第1、第2层的薄膜布线层采用0.15 μm/1 μm/0.15 μm的Cr/Cu/Cr复合薄膜.光敏BCB通孔互连制作流程如图 2所示.

|

图 2 光敏BCB通孔互连样品制备流程图 Figure 2 Schematic of process for photosensitive BCB via interconnection |

首先在Al2O3陶瓷基板表面制作Cr/Cu/Cr第1层薄膜布线,旋涂增粘剂和BCB胶,转速均为3 000 r/min,30 s,膜厚约10 μm,进行预烘、曝光、显影前烘工艺,分别采用传统浸没显影方式和间歇旋转喷淋显影方式进行通孔显影,传统浸没显影方式是直接将Al2O3陶瓷基板置于DS3000显影液中显影,显影温度40 ℃,然后置于室温下DS3000中浸没定影,氮气吹干;而间歇旋转喷淋显影可一次性完成显影、定影和氮气吹干步骤,显影温度40 ℃,设置喷嘴角度为70°(此时喷液量可100%覆盖Al2O3陶瓷基板,有利于显影均匀性),转速50 r/min,喷淋压力0~20 MPa,两种显影方式的显影终端时间均为50 s,显影时间均为60~100 s,即过显百分比均为10%~100%,对BCB通孔进行显微形貌观察与分析;然后置于210 ℃氮气气氛中固化40 min,在固化后BCB介质层上制作Cr/Cu/Cr第2层薄膜布线(可重复如上操作),形成层间通孔互连,此时对层间通孔互连结构进行通孔导通性能分析.

采用OLS4100激光扫描共聚焦显微镜观察BCB介质通孔表面及三维形貌,测量通孔内台阶高度,并观察层间通孔互连的剖面形貌.采用VERSA 3D扫描电镜观察通孔微观形貌,EDS分析通孔微区成分;采用Model-120四探针测试仪测量Kelvin结构的通孔导通情况.Kelvin结构包含带通孔的两层互连测试结构,以及无通孔的与测试结构布线长度相同的单层薄膜布线参考结构.其通孔导通电阻为两者电阻差,除以相差的通孔个数.

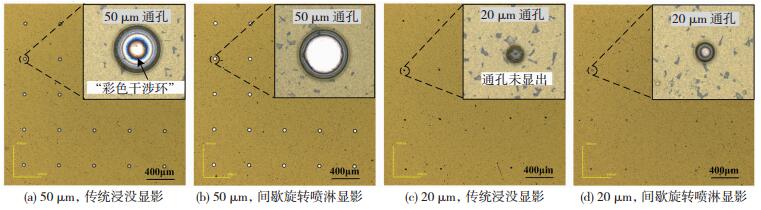

3 结果与讨论 3.1 BCB通孔显微形貌对比分析BCB通孔形貌与BCB通孔显影质量密切相关.通常BCB通孔孔径(通孔孔径≤20 μm)越小越难显影[12],这是由于通孔孔径越小、深宽比越大时,衍射效应越明显,图形畸变程度越严重,不利于通孔光刻.为考察间歇旋转喷淋显影效果及能力,对比分析传统浸没显影和间歇旋转喷淋显影在孔径为20和50 μm时BCB通孔显微形貌,考察其间歇旋转喷淋显影质量.

在显影时间均为75 s,过显百分比为50%,间歇旋转喷淋压力10 MPa时,研究传统浸没显影和间歇旋转喷淋显影方式下20和50 μm通孔光学形貌,结果如图 3所示.从图 3(a)和(c)可以看出,传统浸没显影方式下,50 μm通孔轮廓边缘光滑,通孔内部呈现“彩色干涉环”,20 μm通孔轮廓收缩变形,通孔内部完全被底膜覆盖.由图 3(b)和(d)可以看出,当间歇旋转喷淋显影的喷淋压力为10 MPa时,50和20 μm通孔轮廓边缘光滑,通孔内部中心区域光亮,均未见BCB胶底膜残留,仅在环形边缘位置可见少量侧墙底膜.这是因为传统浸没显影受到显影深度效应影响,显影剂分子的扩散速度逐渐降低,显影液在微小通孔内传质困难,显影速率小,而由于不受到喷淋压力的作用,使得显影液中溶解产物易重新带入通孔内部,从而在微小通孔内产生BCB胶底膜.而通过施加喷淋压力,冲洗掉溶解在显影液中的BCB胶底膜,增加通孔内显影速率,显著降低并清除通孔内部BCB膜底膜,提高了通孔显影均匀性.

|

图 3 不同显影方式20和50 μm通孔的光学形貌图片 Figure 3 Optical micrograph of 20 microns and 50 microns vias of different development modes:(a) 50 μm, traditional immersion development; (b)50 μm, intermittent rotary spray development; (c) 20 μm, traditional immersion development; (d)20 μm, intermittent rotary spray development |

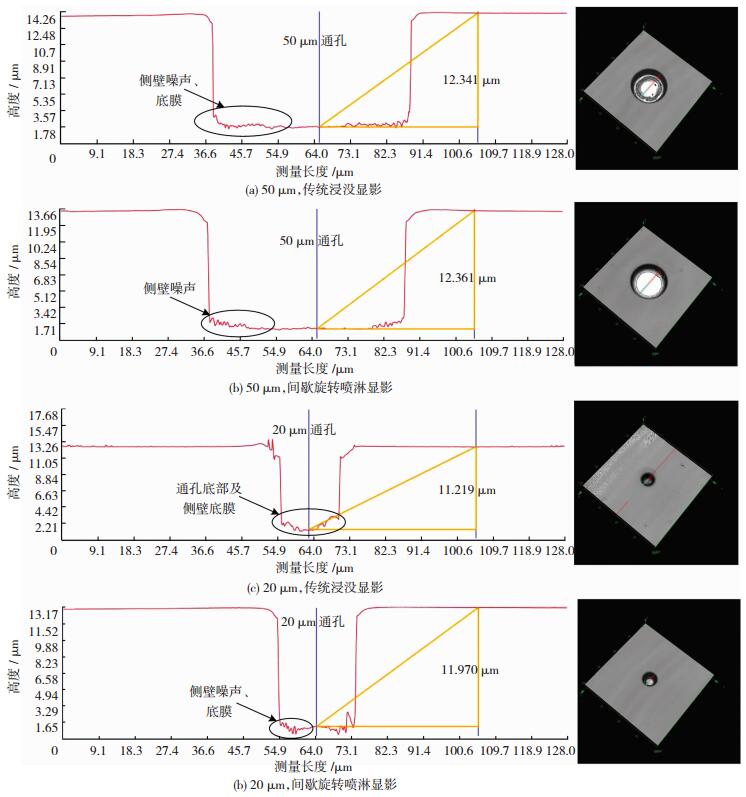

图 4为在显影时间均为75 s,过显百分比均为50%,间歇旋转喷淋压力为10 MPa时,不同显影方式20和50 μm的通孔三维形貌及截面处通孔台阶曲线.从图 4 (a)和(c)可看出,传统浸没显影方式下,50 μm通孔侧壁较陡直,通孔侧壁处被大面积环形BCB胶底膜覆盖,通孔底部中心到膜层表面台阶高度为12.341 μm,20 μm通孔侧壁及中心完全被BCB胶底膜覆盖,其台阶高度为11.219 μm.由图 4(b)和(d)可以看出,当间歇旋转喷淋显影喷淋压力为10 MPa时,50和20 μm通孔侧壁陡直,通孔侧墙覆盖面小,其通孔底部中心到膜层表面台阶高度分别为12.361和11.970 μm,与图 4 (a)和(c)台阶高度相差分别为0.02和0.751 μm,即为BCB胶底膜厚度.这是因为受膜厚影响,前烘易引起BCB胶底部到表面的有机溶剂挥发速度差,造成残留的有机溶剂浓度在深度方向存在梯度[13-14],从而造成底部到表面BCB的热交联程度不同,产生“侧墙效应”,使得通孔底部中心以及侧壁处易产生表面噪声、出现底膜,而当通孔孔径较小时,使残留的底膜从侧壁向底部中心延伸,直至通孔内部完全被覆盖.而间歇旋转喷淋显影方式利用10 MPa的高压喷淋显影,加快新鲜显影液传送到通孔侧壁和溶解产物排出的速度,降低“侧墙效应”对微小通孔内侧壁与通孔底部显影差异性的影响.

|

图 4 不同显影方式20和50 μm通孔三维形貌及台阶曲线 Figure 4 Three-dimensional shape and step curves of 20 microns and 50 microns vias of different development modes: (a) 50 μm, traditional immersion development; (b)50 μm, intermittent rotary spray development; (c) 20 μm, traditional immersion development; (d)20 μm, intermittent rotary spray development |

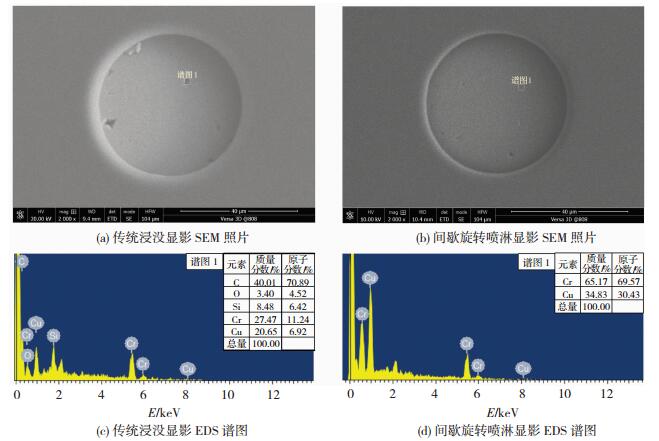

进一步对比分析传统浸没显影和间歇旋转喷淋显影过程中通孔的微观结构和微区成分,对其进行SEM观察和EDS分析.图 5、图 6是在显影时间为75 s,过显百分比为50%,间歇旋转喷淋压力为10 MPa时,不同显影方式下20和50 μm的通孔SEM照片及EDS谱图.从图 5 (a)和(c)可以看出,传统浸没显影的50 μm通孔内部有明显片状残胶残留,通孔内部微区表面含碳、氧、硅、铬和铜成分,其中铬和铜为基板-薄膜界面Cr/Cu/Cr复合薄膜层中所含元素,这表明通孔内部存在少量BCB胶底膜;由图 5 (b)和(d)可以看出,间歇旋转喷淋显影的50 μm通孔内部边界清晰,内部基本没有杂质富集.通孔内部微区表面含铬和铜成分,未见BCB组成成分;从图 6 (a)和(c)可以看出,传统浸没显影的20 μm通孔轮廓收缩变形,通孔内部微区表面含碳、氧、硅成分,而碳、氧、硅为BCB主要组成元素,表明通孔内部已基本被BCB胶底膜覆盖;由图 6 (b)和(d)可以看出,间歇旋转喷淋显影的20 μm通孔内部边界清晰,通孔内部微区表面含铬和铜成分,未见BCB组成成分.这表明与传统浸没显影相比,间歇旋转喷淋显影的通孔内部基本无BCB胶底膜,可满足孔径为50和20 μm的BCB微小通孔显影.

|

图 5 50 μm通孔的SEM照片及EDS谱图 Figure 5 SEM photo and EDS patterns of 50 microns vias: (a)traditional immersion development, SEM photo; (b)intermittent rotary spray development, SEM photo; (c) traditional immersion development, EDS pattern; (d)intermittent rotary spray development, EDS pattern |

|

图 6 20 μm通孔的SEM照片及EDS谱图 Figure 6 SEM photo and EDS patterns of 20 microns vias: (a)traditional immersion development, SEM photo; (b)intermittent rotary spray development, SEM photo; (c) traditional immersion development, EDS pattern; (d)intermittent rotary spray development, EDS pattern |

采用间歇旋转喷淋显影方式形成高密度BCB微小通孔后,需要对其进行基板层间通孔互连工艺研究,考察其间歇旋转喷淋显影方式对层间互连导通性能的影响.

在显影时间为75 s,过显百分比为50%,间歇旋转喷淋压力为10 MPa时,分别选取基板上、下、左、右、中不同位置,不同显影方式下使用四探针测试仪测量Kelvin结构20和50 μm的通孔导通情况,各5组,并通过测试结构及参考结构计算得到通孔导通电阻平均值.不同位置处通孔导通电阻平均值结果如表 1所示.

| 表 1 不同位置区域的通孔导通电阻测试结果 Table 1 Test results of via on-resistance at different locations |

由表 1可看出,传统浸没显影方式下,20 μm通孔导通电阻阻值无穷大,50 μm通孔导通电阻差异性较大,其通孔导通电阻平均偏差大于15 mΩ,不利于微小通孔互连,后续将不作对比分析;而间歇旋转喷淋显影方式下,20和50 μm通孔不同位置处通孔导通电阻差异性均较小,其通孔导通电阻平均偏差均小于1 mΩ,说明间歇旋转喷淋显影可大大降低不同位置处显影差异,通孔导通电阻一致性好,有利于高密度薄膜多层布线基板的通孔互连.

图 7为在显影时间75 s,喷淋压力10 MPa时,不同过显百分比对通孔导通电阻变化情况.采用Kelvin结构分别测量孔径为20和50 μm的通孔导通电阻.从图 7可看出,在过显百分比10%~100%时,50 μm通孔导通电阻随过显百分比的增加呈先下降后基本保持稳定,在过显百分比为30%~80%时,即显影时间为65 s~90 s时,通孔导通电阻较低,且阻值保持稳定,维持在10 mΩ以下.20 μm通孔导通电阻随过显百分比的增加呈先下降后上升趋势,在过显百分比为40%~60%时,通孔导通电阻较低,约为35 mΩ,且阻值保持稳定.这说明间歇旋转喷淋显影有利于通孔导通电阻阻值的显著下降,显影宽容度较大,有利于降低显影的高敏感性和低重复性.

|

图 7 不同过显百分比的50和20 μm通孔导通电阻变化 Figure 7 Variation of 50 microns and 20 microns via on-resistance with different overdevelop percentages |

图 8为在显影时间为75 s,过显百分比为50%时,不同喷淋压力对通孔导通电阻变化情况.采用Kelvin结构分别测量孔径为20和50 μm的通孔导通电阻.从图 8可看出,当喷淋压力为0时,即类似于传统浸没显影,50 μm通孔导通电阻阻值达到40 mΩ以上,当喷淋压力在5~20 MPa时,随着喷淋压力的增加,通孔导通电阻迅速降低,阻值维持在10 mΩ以下;而对于20 μm通孔而言,当喷淋压力为0时,通孔导通电阻阻值无穷大,即层间互连断路,当喷淋压力在5~20 MPa时,随着喷淋压力的增加,通孔导通电阻迅速降低,阻值维持在40 mΩ以下.这表明喷淋压力为0时不利于微小通孔的显影,增加喷淋压力可以进一步消除BCB胶体内部高密度平衡态和低密度非平衡态的溶解差异,逐步达到溶解一致,因此,当喷淋压力增加到一定压力时,通孔导通电阻保持稳定.

|

图 8 不同喷淋压力的50和20 μm通孔导通电阻变化 Figure 8 Variation of 50 microns and 20 microns via on-resistance with different spray pressures |

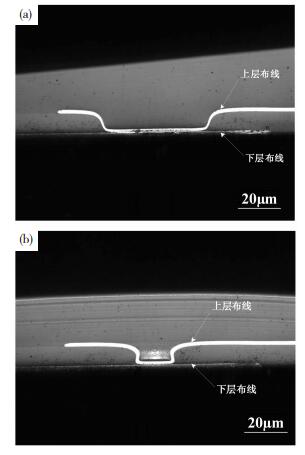

进一步分析间歇旋转喷淋显影方式对层间通孔互连剖面形貌的影响.图 9为50和20 μm通孔互连剖面显微照片.由图 9可知,通孔为50 μm时,通孔周围的上下层布线呈“浅碟形”结构,通孔台阶覆盖良好,通孔底部互连良好;通孔为20 μm时,通孔周围的上下层布线呈“U”形结构,通孔台阶覆盖良好,通孔底部互连良好.这是由于受膜厚的影响,高深宽比的微小通孔容易造成通孔底部吸收减弱和光反射损失[15],使得通孔侧壁上边缘交联程度大于侧壁下边缘交联程度,且随着通孔孔径越小,此趋势越明显.由此可见,采用间歇旋转喷淋显影方式有利于层间微小通孔互连.

|

图 9 50 μm(a)和20 μm(b)通孔互连剖面显微图片 Figure 9 Microscopic images of 50 microns and 20 microns via interconnection profiles |

本文提出一种高密度、微小通孔的间歇旋转喷淋显影新方法,制作出4块50 μm通孔的高密度BCB/Cu薄膜多层布线基板,并对基板内部所有网络互连线进行测试,互连导通率均达到100%(规定导通网络阻值≤50 mΩ),且无互连网络之间短路(规定网络之间阻值≥20 MΩ).

1) 从通孔形貌来看,间歇旋转喷淋显影在喷淋压力为0时,显影不充分,50和20 μm通孔内部存在BCB胶底膜;当喷淋压力为10 MPa时,50和20 μm通孔轮廓边缘光滑,侧壁陡直,通孔内部中心区域光亮,均未见BCB胶底膜残留.

2) 通过通孔微观结构和微区成分分析,20和50 μm通孔内部边界清晰,内部基本没有杂质富集,且通孔内部中心微区表面主要含铬和铜成分,表明通孔内部中心无BCB胶底膜残留,底部为基板-薄膜界面Cr/Cu/Cr复合薄膜层.

3) 从层间通孔导通电阻分析来看,采用Kelvin结构时,50和20 μm通孔在满足一定的过显百分比时,通孔导通电阻下降最快,且阻值保持稳定,显影宽容度大;在喷淋压力5~20 MPa时,通孔导通电阻迅速降低,此时电阻最小,且阻值保持稳定.

4) 通过层间通孔互连剖面分析,50和20 μm通孔台阶覆盖良好,通孔底部互连良好.

| [1] | BU Fan, MA Qing, WANG Zheyao. Delamination of bonding interface between benzocyclobutene (BCB) and silicon dioxide/silicon nitride[J]. Microelectronics Reliability, 2016, 65: 225–233. DOI: 10.1016/j.microrel.2016.08.003 |

| [2] |

张兆华, 崔鲁婧, 李浩, 等. 基于BCB的薄膜多层基板在毫米波T/R组件中的应用[J]. 微波学报, 2017, 33(1): 63–66.

ZHANG Zhaohua, CUI Lujing, LI Hao, et al. Multilayer thin-film substrate using BCB for the integration of millimeter-wave T/R module[J]. Journal of Microwaves, 2017, 33(1): 63–66. |

| [3] |

陈雯芳, 孙浩, 方针, 等. 硅埋置型毫米波系统级封装中光敏BCB工艺改进[J]. 电子器件, 2017, 40(2): 267–271.

CHEN Wenfang, SUN Hao, FANG Zhen, et al. The improvement for photo-BCB progress in silicon based embedding millimeter-wave system-in-package technology[J]. Chinese Journal of Electron Devices, 2017, 40(2): 267–271. DOI: 10.3969/j.issn.1005-9490.2017.02.001 |

| [4] | ZOSCHKE K, WOLF J, EHRMANN O, et al. Copper / benzocyclobutene multi layer wiring-a flexible base technology for wafer level integration of passive components[C]//Electronics Packaging Technology Conference, 2007. Eptc 2007. IEEE, 2007: 295-302. http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=4469803 |

| [5] | SULOCHANA V, AGRAWAL Sunil, SINGH Balwinder. Thermo-mechanical stress induced electromigration in Cu and CNT based TSV surrounding various dielectric layers[J]. Journal of Nanoelectronics and Optoelectronics, 2017, 12(8): 758–765. DOI: 10.1166/jno.2017.2094 |

| [6] | CAI Rongliang, ZHANG Chengrui, ZHOU Liang. Thermal-mechanical analysis of packaged power amplifiers based on heterogeneous integrations using photosensitive BCB[C]//Electrical Design of Advanced Packaging and Aystems, IEEE, 2017: 29-31. |

| [7] | GIBARI M E, BRETIN S, HADJLOUM M, et al. Coplanar waveguide to microstrip transition in thin polymer film for characterization and packaging of microwave photonic components[C]//Telecommunications Forum Telfor, IEEE, 2015, 30 (1) 591-594. |

| [8] |

陈雯芳, 孙浩, 方针, 等. 基于Si-BCB工艺Ka波段双模带通滤波器[J]. 电子测量技术, 2016, 39(11): 26–29.

CHEN Wenfang, SUN Hao, FANG Zhen. Ka-band dual-mode band-pass filter with Si-BCB technology[J]. Electroic Measurement Technology, 2016, 39(11): 26–29. DOI: 10.3969/j.issn.1002-7300.2016.11.007 |

| [9] | Charles-Alix Manier, Kai Zoschke, Hermann Oppermann, et al. Wafer level packaging for hermetical encapsulation of MEMS resonators[C]//Design Test Integration and Packaging of MEMS and MOEMS, IEEE, 2015: 1-6. |

| [10] | LEE Keekeun, HE Jiping, CLEMENT Ryan, et al. Biocompatible benzocyclobutene (BCB)-based Neural implants with micro-fluidic channel[J]. Biosensors & Bioelectronics, 2004, 20(2). |

| [11] | JU Chul-Won, PARK Seong-Su, KIM Seong-Jim, et al. Effects of O2/C2F6 plasma descum with RF cleaning on via formation in MCM-D substrate using photosensitive BCB[C]// Electronic Components and Technology Conference. Orlanclo: IEEE, 2002: 1216-1218. DOI: 10.1109/ECTC.2001.927983 |

| [12] | THALER B J, KUMAR A H, SUSSMAN A, et al. Ceramic/metal composite circuit-board-level technology for application specific electronic modules(ASEMs)[M]. [S.l.]: Advanced Research Projects Agency Electronic Systems Tech Office, 1997. |

| [13] | FLACK Warren W, FAN Warren P, WHITE Sylvia. Optimizationand characterization of ultra-thick photoresist films[C]//Advances in Resist Technology and Processing. [S.l.]: SPIE, 1998, 3333: 1288-1303. DOI: 10.1117/12.312452 |

| [14] | ARTHUR G G. Modifying the surface inhibition layer of thick resists for improved process control[C]// Lithography for Semiconductor Manufacturing Ⅱ.SPIE, 2001: 4404. DOI: 10.1117/12.425229 |

| [15] | Processing Procedures for CYCLOTENE 4000 Series Photo BCB Resins-DS3000 Immersion Develop Process[M].Dow Chemical Company, http://www.microchem.com, 2009: 1-10. |

2018, Vol. 26

2018, Vol. 26