摘要

极地低温、高湿、高风速、高盐度、极昼极夜等极端环境易导致船舶、低空飞行器等近海面装备表面结冰,严重影响装备正常运行。为应对极地复杂环境带来的冰害,国内外学者围绕结冰预测探测方法、防除破冰技术等开展了大量对比实验与数理建模研究,对既有涉冰研究进展进行了分析总结。结果表明:结冰预测方法主要基于经验、理论与数值 3 种模型,其中,理论模型准确度小于 50% ,而数值模型准确度大于 60% ;结冰探测主要采用观测与检测两种方法,其中,平均结冰厚度的观测法与检测法测量精度分别可达 ± 0. 038 mm 与 ± 0. 05 mm;极地装备表面的覆冰源自海浪飞沫、雨雾飞沫与大气,其中,海浪飞沫占比高达 90% ;防除冰技术有被动式和主动式两种,前者能耗低且寿命短,后者效率高但装置复杂,两者结合仍是未来发展趋势;极地水上船舶破冰主要采用冲撞、顶撞与首压技术,冰下潜艇破冰则采用机械挤压、鱼雷爆破与激光融冰等直接破冰或 “先弱冰再破冰”的耦合技术。基于本文对极地低温环境结冰预探测方法与防除破冰技术的分析,进一步提出了既有方法与技术的优化方向,以期为复杂低温环境中载运装备及工程设备的冰灾护控技术发展提供参考与借鉴。

Abstract

Extreme environments such as low temperature, high humidity, high wind speed, high salinity, extreme daytime, and extreme nighttime can easily lead to icing on the surface of ships, low-altitude vehicles and other near-sea equipment, which seriously affects the normal operation of such equipment. To cope with the ice hazards brought by the complex environments, scholars both domestically and internationally have conducted numerous comparative experiments and mathematical modeling studies on icing detection and prediction methods, as well as anti-icing, de-icing, and ice-breaking technologies. This paper provides an analysis and summary of the existing research progress in the field of ice-related studies. Results show that icing prediction methods primarily rely on empirical, theoretical and numerical models, with theoretical models having an accuracy below 50% while numerical models achieve an accuracy above 60% . Ice detection mainly adopts two methods of observation and detection, in which the measurement accuracy of the average ice thickness of the observation method and detection method can reach ± 0. 038 mm and ± 0. 05 mm, respectively. Ice cover on the surface of polar equipment originates from wave droplets, rain droplets and the atmosphere, with wave droplets accounting for up to 90% . Ice prevention technologies include passive and active methods, with the former having low energy consumption and short service life, and the latter being more efficient but with complex device setups. The combination of both remains a future development trend. In polar regions, ice-breaking for waterborne vessels primarily involves ramming, crushing, and pressure ridging techniques, while ice-breaking for submarines beneath the ice utilizes mechanical squeezing, torpedo blasting, laser ice melting, and other direct ice-breaking methods or coupled techniques such as " weak ice first, then ice-breaking " coupling techniques. Based on the analysis of icing prediction and detection methods, and anti-icing, de-icing and ice-breaking technologies in polar low-temperature environments, further optimization directions for existing methods and technologies are proposed. These insights aim to provide references for the development of ice disaster protection and control technology for the carrier equipment and engineering equipment in complex low-temperature environments.

Keywords

随着全球气候变暖和海冰融化,极地的资源、地缘政治、军事、科研、航运优势等价值逐渐引起美、俄等大国高度重视[1]。然而,极地区域气候极端,大部分地区常年被冰雪覆盖[2]。南北极与北京气候对比如图1(a)所示。南北两极冬季平均温度低至-50℃和-18℃,远低于北京的-3℃,且风速也较高。此外,极地区域存在高盐度和极昼极夜的情况。极端气候会降低设备可靠性,影响人员工作效率乃至危害生命[3],导致巨大经济损失。如图1(b)所示,冰雪冷冻灾害每年给中国带来高达数十亿元的经济损失[4]。常规应对冰害的技术和设备易受极端环境影响而难以发挥作用,给商业和科考活动等带来了挑战[5]。本文总结了既有各种应对冰害的技术和方法,以期为极端低温环境导致冰害开发应对新技术和方法提供参考。

图1极地气候及冰雪冷冻灾害造成的损失

Fig.1Impacts of polar climate and frozen ice and snow disasters

极地极端环境易造成船舶等载运装备表面结冰,影响装备正常运行[6-7]。如船舶航行时,海水溅到低温的船体或甲板时会凝固,并在表面形成光滑的冰层。此外,空气中的过冷水滴碰到甲板等低温表面也会发生结冰。这些冰会影响设备工作,威胁船舶航行安全。海上平台的积冰很重,积累到一定量后可能引发坍塌事故[8-9]。同时,冰中盐分会腐蚀设备和船体[10-11]。海风吹拂后的表面更加光滑,也易导致工人滑倒和威胁直升机起降安全。

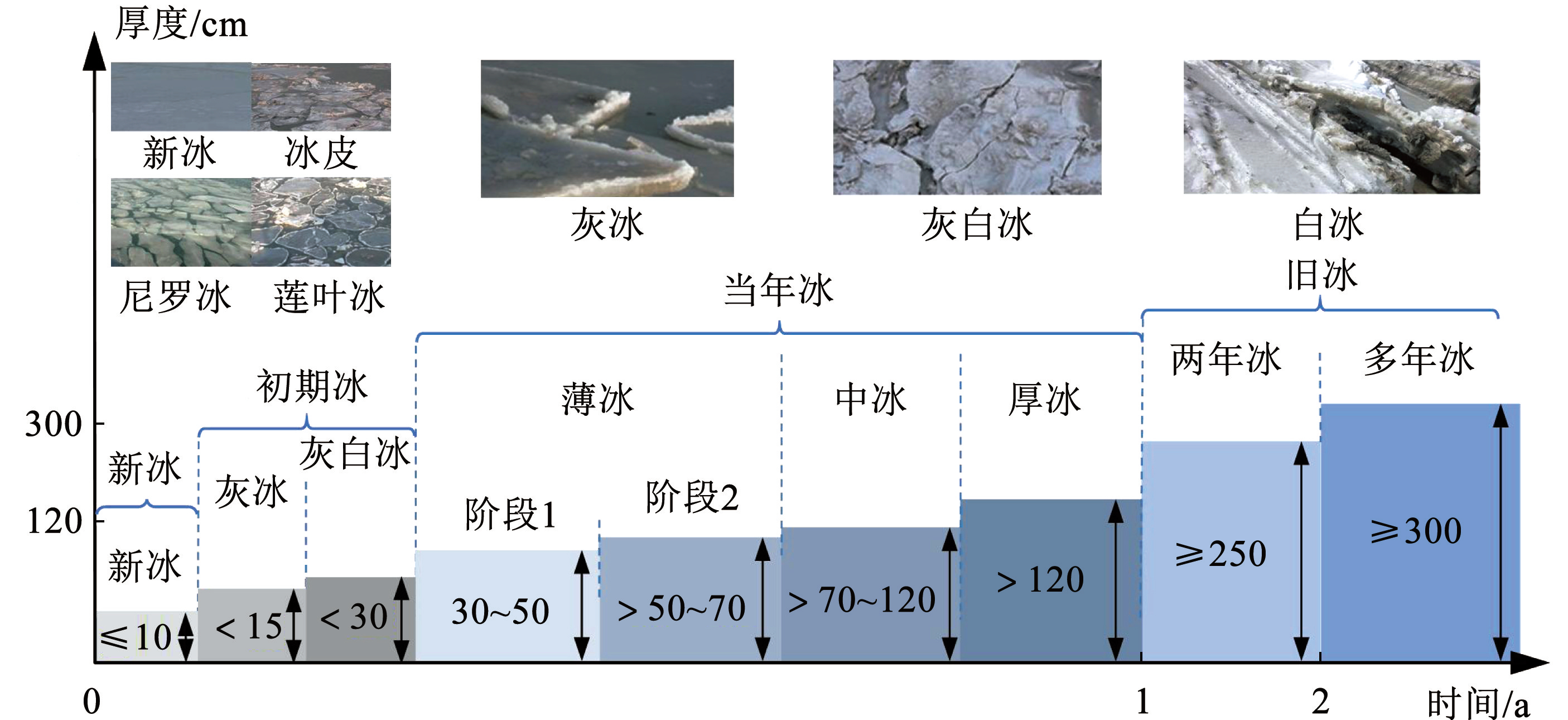

极端低温使海水很容易结冰,有些地区终年被厚实的冰层覆盖。与淡水结冰不同的是,海水温度降至冰点时,部分海水开始成核结冰,然后盐分从冰中析出,在冰中形成蜂窝状结构[12-13]。随着海水结冰和盐分析出,冰中微孔中的海水盐度增加。微孔中海水的盐度高导致凝固温度低,不易冻结。因此,刚形成的海冰内部含有大量气泡、盐水和盐晶体颗粒。在重力和温差的作用下,气泡和盐水会发生迁移导致海冰形态和结构发生变化[14-15]。为表征海冰的成分随着时间推移而发生的动态变化,世界气象组织根据海冰的形成时间和形态对其进行分类。不同的海冰类型和相应的厚度如图2所示[16-17]。

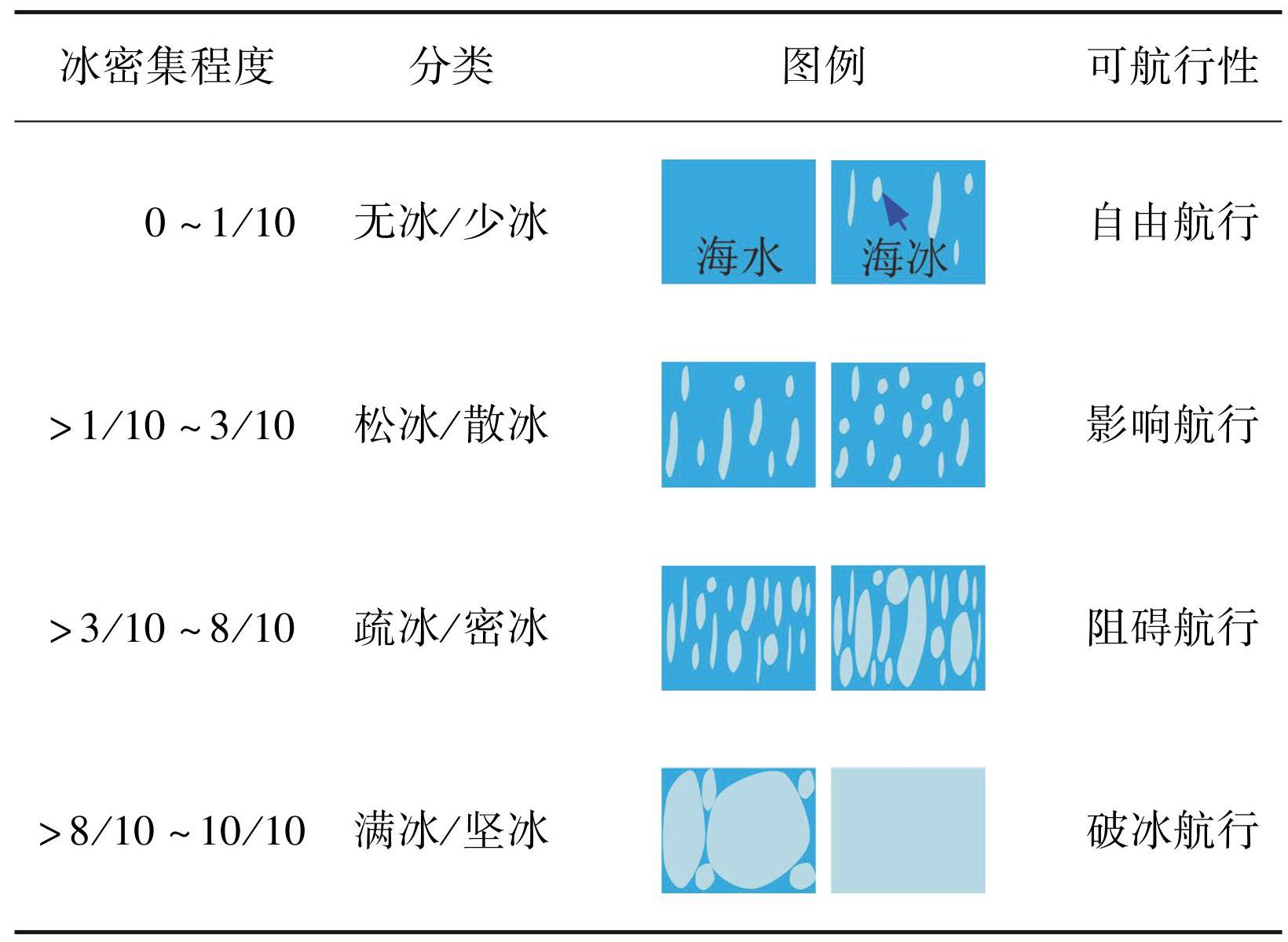

新冰是海冰初始阶段的总称[18],由海水直接冻结或由融雪形成的呈针状、片状、油脂状或海绵状,结构相对松散的冰。冰皮是由新冰冻结或海水直接冻结形成的薄冰层,其表面光滑、湿润、有光泽,厚度约5 cm,并且可随风波动,易被风浪击碎。厚度小于 10 cm 的弹性薄冰壳称为尼罗冰,表面无光泽,在波浪和外力作用下容易弯曲和破碎,并能产生交叉重叠。莲叶冰是一种直径在 30~300 cm、厚度小于 10 cm的圆形冰块,边缘因相互碰撞而凸起。灰冰是由尼罗冰形成的厚度为 10~15 cm、颜色为灰色的平坦冰层,其弹性不如尼罗冰,很容易被波浪击碎。当灰冰的厚度达到 15~30 cm 时,就会变成灰白冰。当灰白冰的积累厚度达到 30 cm 以上时,就会形成表面粗糙、颜色呈乳白色的白冰。除了根据冰的厚度和颜色进行分类外,还可根据冰的形成时间将冰分为新冰、初期冰、当年冰和旧冰[19-20]。为定量衡量海面海冰存在程度对船舶航行的影响,世界气象组织将视野范围内海面上海冰覆盖面积的相对大小定义为冰密集度,并以十分度量[21]。冰密集度的大小和船舶可航行性的关系如表1所示。当密度大于 1 / 10 时,会对通航产生影响。当密度超过 9 / 10 时,就需要破冰航行。

图2世界气象组织对海冰的分类

Fig.2World Meteorological Organization classification of sea ice

表1海面冰密集度分类及对船舶通航能力影响

Tab.1 Effect of ice density on sailing capacity

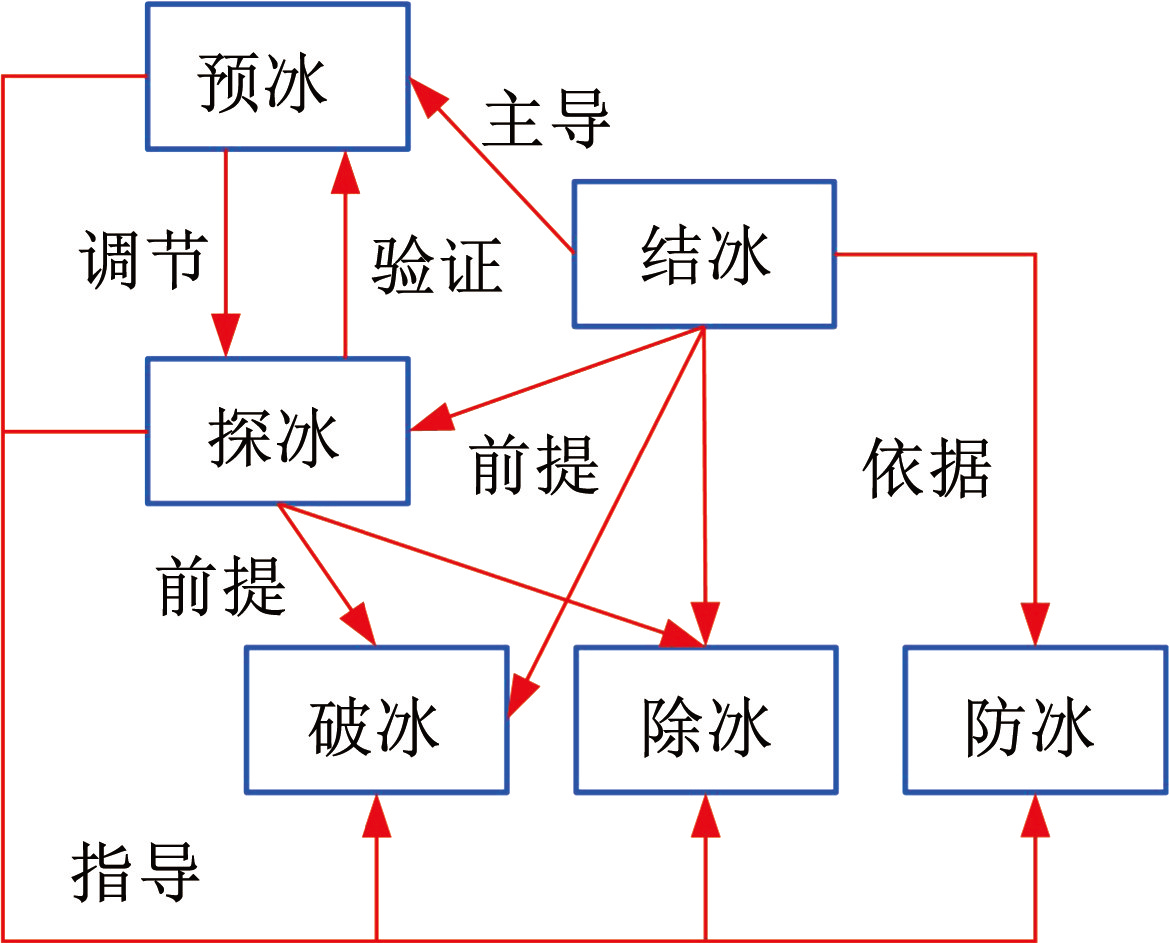

为应对极地环境所导致的冰害问题,本文将从结冰探测和预测技术[22-23]、防除冰方法[24-25]、破冰措施[26-27]三方面总结分析既有研究成果。本研究的思路如图3所示,探测和预测是进行后续操作的前提,了解物体结冰真实情况,为后续的防除冰和破冰操作提供指导。防除冰和破冰是应对冰害的直接手段,对结冰机制的深入研究是开发新技术的前提。因此,了解预探冰、结冰、防除冰和破冰之间关系和他们的技术发展现状可为开发高效应对极地冰害的技术和方法提供参考和借鉴。

图3本研究内容概况

Fig.3Overview of research content

1 结冰预测和探测技术

1.1 结冰预测技术

船舶结冰预测经历了几十年的发展。开发的结冰模型大致可分为经验模型、理论模型和数值模型[28-29]。经验模型是利用基于海洋气象条件参数与实际结冰状况建立的统计关系。最早的船舶结冰预测主要使用半定量分析来估算结冰率,结果以图表形式呈现。根据日本巡逻艇和渔船数据而绘制的结冰示意表明结冰与大气温度和风速有关,但该模型没有考虑海水温度的影响[30]。此后,又有学者根据海上渔船 400 多次结冰数据,绘制了考虑水温、大气温度和海风的结冰厚度预测图[31-32]。此外,船舶结构与尺寸、航向和速度等也会影响结冰情况[30]。考虑船舶自身和气象环境因素可以提高经验模型的结冰预测精度,但经验模型无法给出各因素在结冰中占比,对防除冰的指导作用有限。

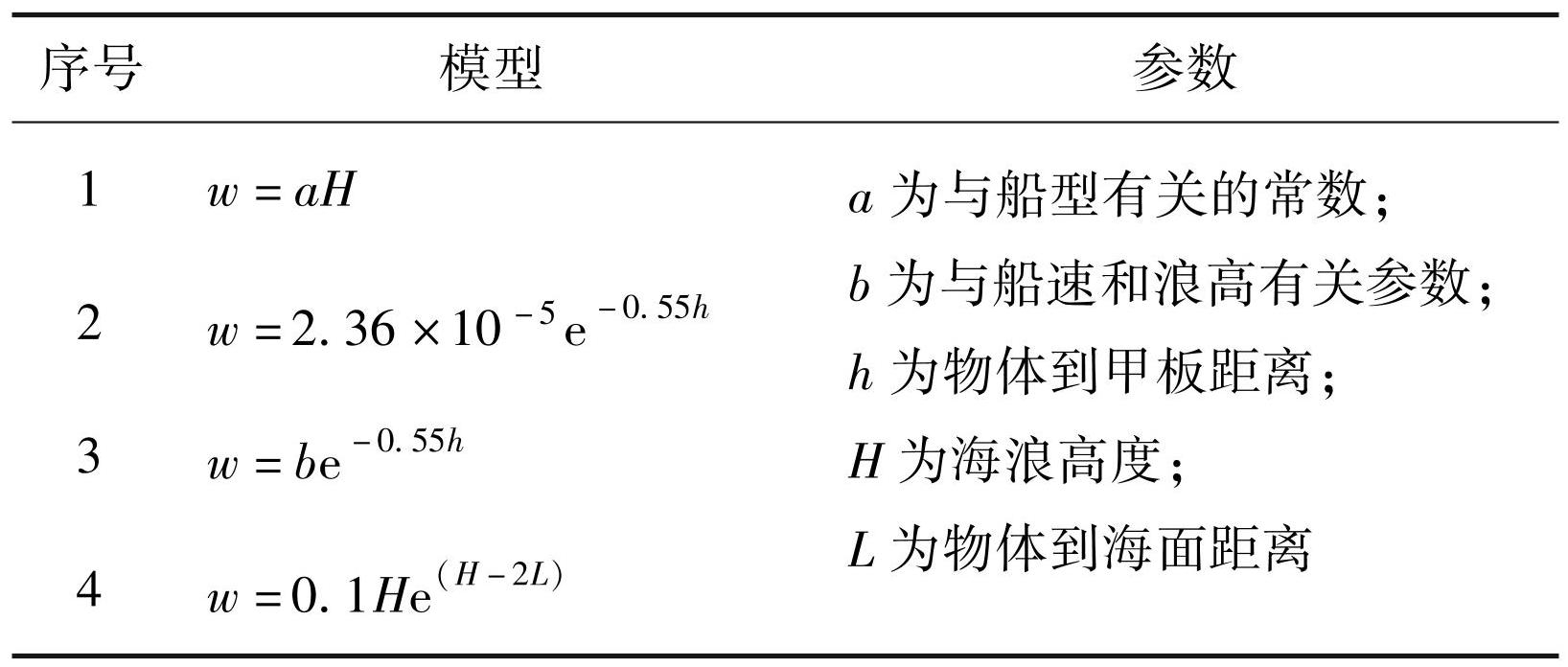

1994 年,一个考虑到大气和海洋参数的理论模型被开发[33]。该模型通过引入有核飞沫的概念来模拟冰积累过程,用于预测不同大小船舶的总体积冰率。 2015 年,一个称为 SHIPIC 的理论模型被开发,该模型利用船舶运动和楔形撞击模型来预估飞沫结冰的概率。然而,该模型的预测精度并不高,误差超过 50% [34]。 2018 年,纪念大学利用最大熵原理开发出一种可预测液滴大小和速度分布的概率分布模型[35]。 2021 年,一种可量化尺寸和飞沫特性的可扩展模型被提出。该模型通过使用半经验分析表达式求解物体运动来估计飞沫频率[36]。在结冰数理模型中液态水质量浓度(w)和最大垂直高度(z)是两个重要参数[37]。学者们对这两个参数进行了大量研究,如表2和表3所示。

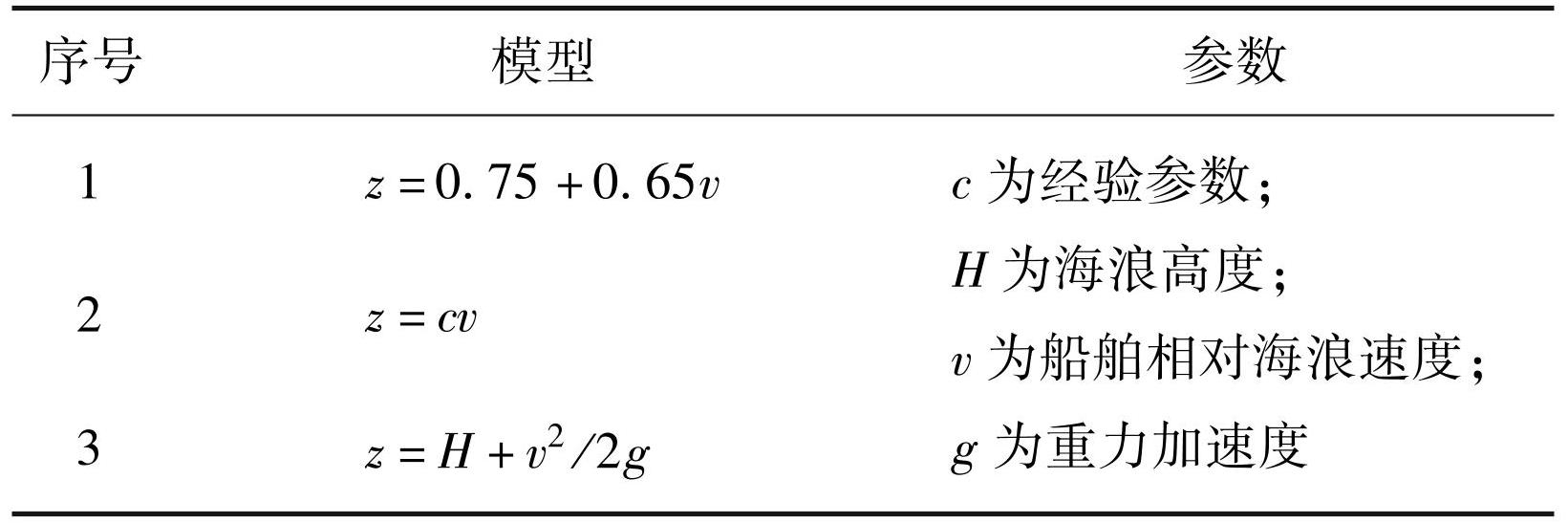

Tab.2 Liquid water content model [38]

Tab.3 Model of maximum vertical height of liquid water [39]

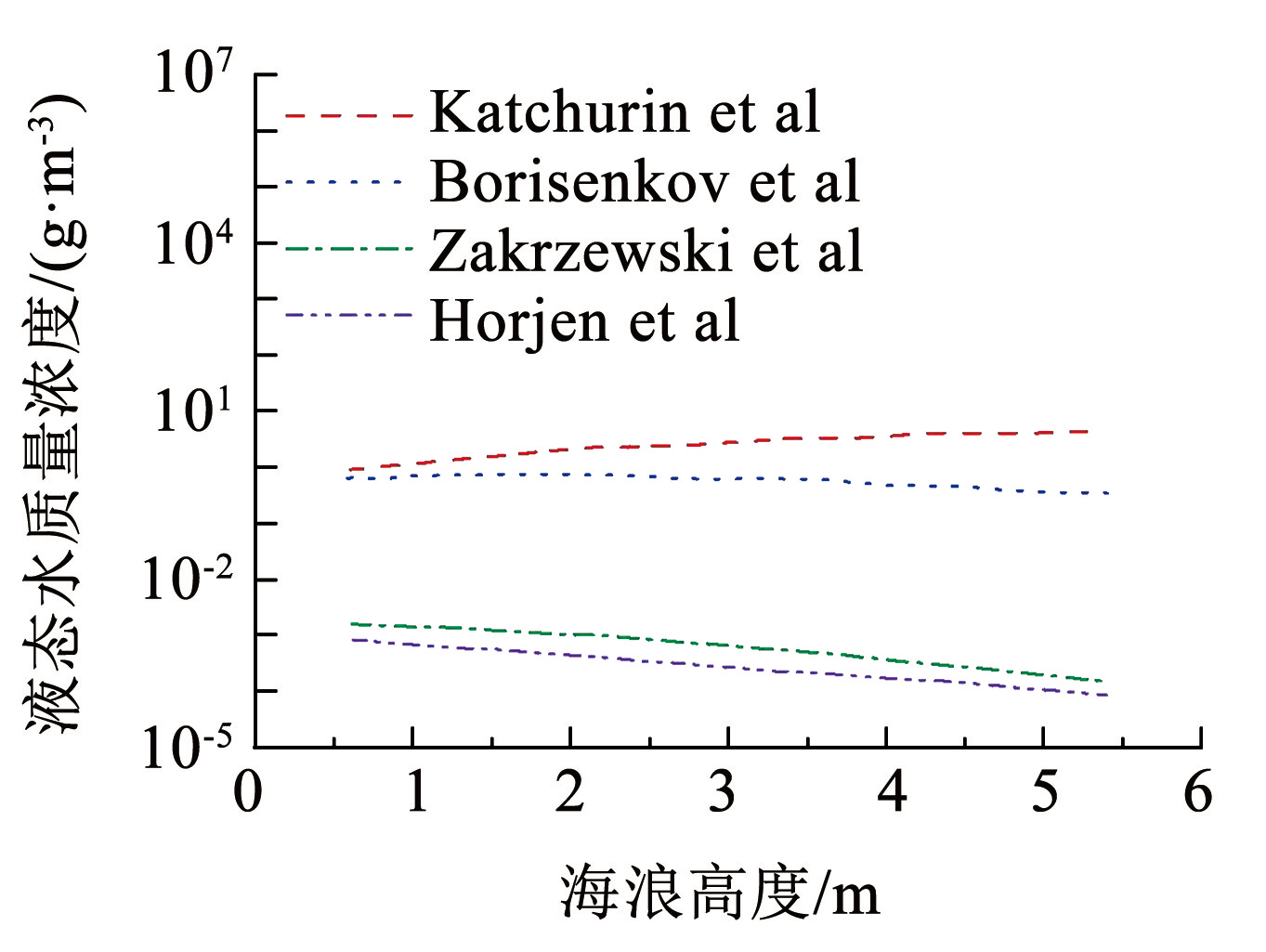

相同工况下不同模型计算的液态水质量浓度随海浪高度的变化如图4所示。由于每个公式考虑的因素不同,不同公式计算得到的结果存在较大差异。这也说明现有结冰预测数理模型还有很大的局限性,无法对复杂海况下的结冰情况进行准确预测。

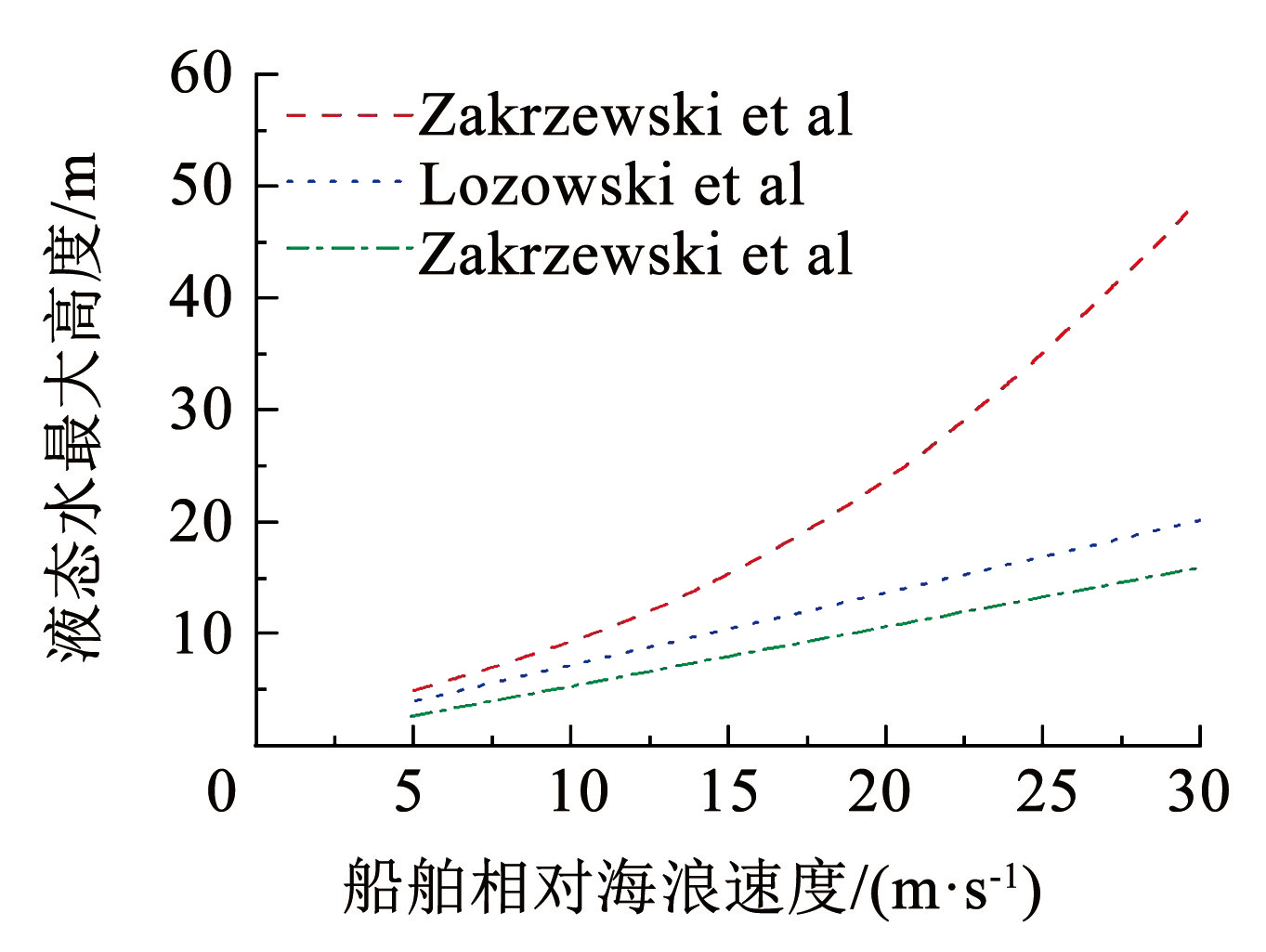

不同模型预测的液态水最大高度如图5所示。不同模型计算的液态水最大高度存在差异,这个差异随着船速的增加而增大。导致不同模型计算结果出现差异的原因可能是这些模型适用的船舶类型不同。船首的差异会直接影响海浪撞击后产生水滴的初始动能和尺寸,进而影响最大垂直高度。

此外,从海浪撞击船首到形成液态水滴的时间也是影响结冰程度的一个重要参数。 Zakrzewski 将这个时间定义为[40]

(1)

式中:c 为与船首结构有关的常数,u 为风速。

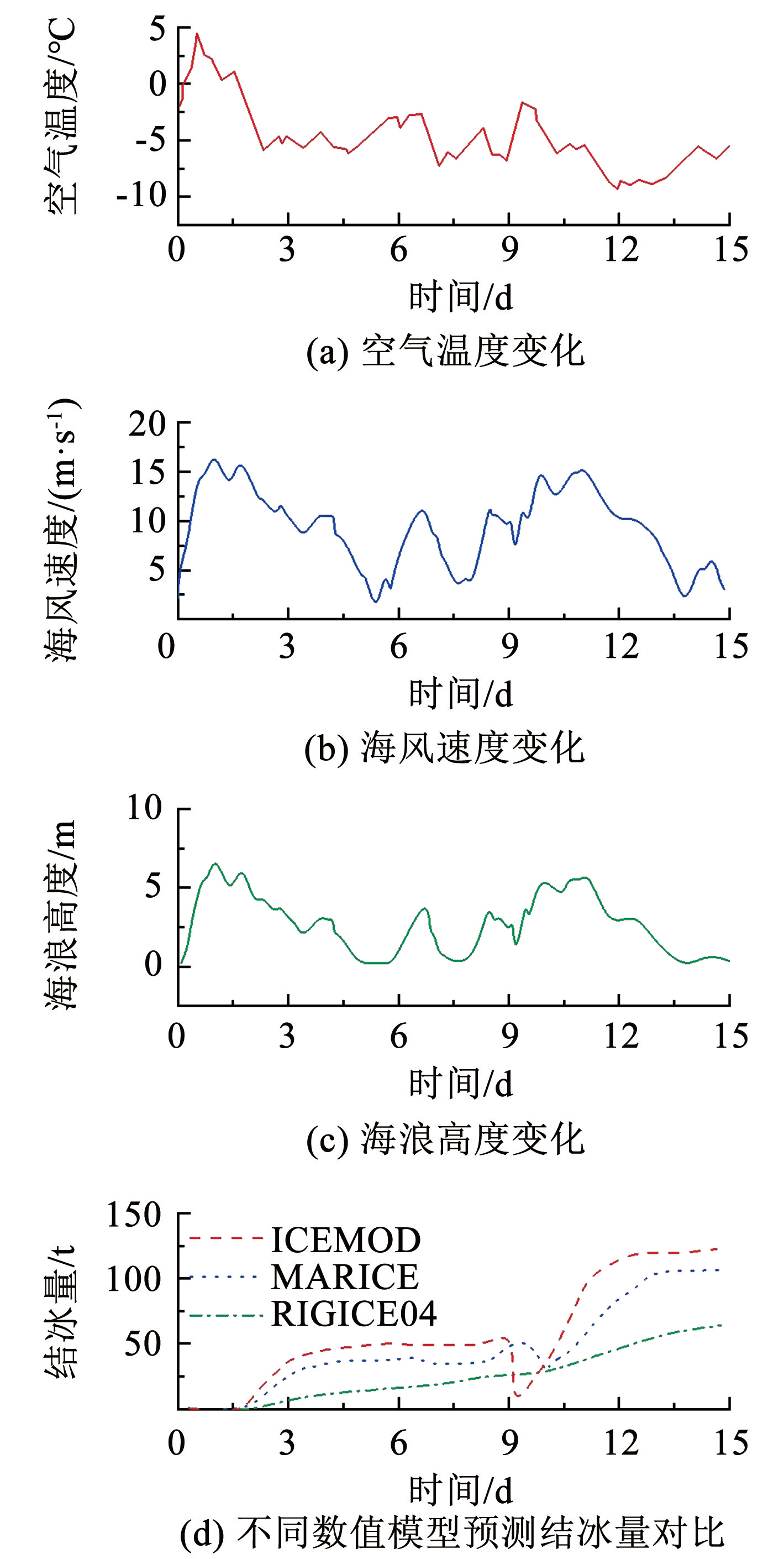

在数值预测结冰方面,RIGICE04 和 ICEMOD 是两种被广泛使用的模型。 RIGICE04 模型预测海上平台的结冰情况,并考虑飞沫生成算法 SPRAY [41]。 ICEMOD 模型由挪威水文实验室于 1986 年开发,并于 1987 年、1988 年、2013 年和 2015 年逐步完善[42-43]。这两个模型对结构进行了简化,将对象分解为圆柱和平面部分,并假定分割部分周围的流场不受其他部分的影响。然而,ICEMOD 和 RIGICE04 都低估了大型结构表面的热传递,导致计算结果与实际存在较大偏差,仅可为工程领域提供参考。此外,为充分考虑传热对结冰的影响,一种借助计算流体力学来解析流动和传热,并跟踪空气中液滴运动的模型 MARICE 被提出[44]。该模型弥补了将结构简化为几何形状导致热传递偏小的问题。不同气象条件下 3 个数值模型预测的积冰量如图6所示。 RIGICE04 模型没有考虑融化,因而得到的结冰量持续增加。 MARICE 和 ICEMOD 计算的积冰量随时间增加具有相同的变化趋势。

图6不同气象条件下不同数值模型预测结冰量对比

Fig.6Comparison of icing amounts predicted by different numerical models under different meteorological conditions

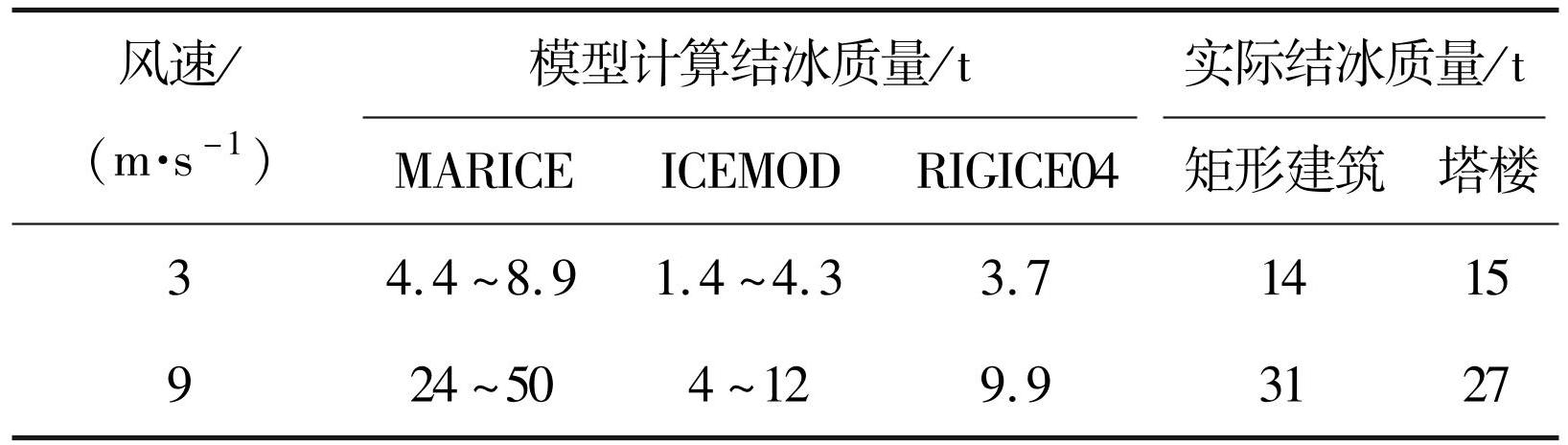

为进一步比较 3 个模型的准确性,将计算结果与实际值进行对比。不同风速下 3 个数值模型计算结冰量和建筑物上实际结冰量对比结果见表4。 MARICE 模型计算的结果与实际值更为接近,准确度大于 60%,而另外两个模型准确度均小于 50%。这可能是由于这两个模型将建筑物简化为几何形状而使表面换热系数减少。将模型简化虽然可降低计算时间和成本,但是也可能会降低预测准确度。

人工智能(Artificial Intelligence,AI)通过自动化和智能化的手段可高效批量处理和分析大量数据,并提供精准的决策支持和预测分析[47-48]。鉴于 AI 具有高效处理大量数据的能力,研究人员将 AI 用在海水结冰情况预测[49]。 2017 年,全连接神经网络和长短期记忆网络被尝试用于预测北极海冰[50]。 2019 年,Johnson 等[51]采用 SEAS5 模型预测了海冰边缘变化情况。 2021 年,Andersson 等[52] 采用 U-Net 模型预测了未来 6 个月二元海冰出现概率。同年,Liu 等[53] 采用卷积网络模型成功预测了未来 6 周的海冰变化。 2022 年,Ren 等[54] 在 U-Net 模型基础上优化得到了 SICNet 模型,该模型可预测未来 28 d 内北极海冰的变化情况。尽管将 AI 用于海冰预测取得了一些进展,但 AI 与海冰预测的整合还处于早期阶段,仍然存在预测精度低、预测范围小等问题。此外,AI 与雷达结合可预测海冰变形[55-56],与飞机结合可预测结冰和故障识别[57-58]。

结冰受到多种因素耦合的影响,并且这种影响往往是非线性的,这就导致对结冰的预测存在较大的困难。使用数值方法对这个非线性的物理过程进行求解,可在一定范围内获得精确结果,但数值模型长时间的预测精度较差。而 AI 可使用深度神经网络捕获预测因子和预测对象之间的高度非线性关系[59-60]。因此,AI 对结冰过程的预测具有天然优势,但是 AI 需要大量数据作为训练样本,如果训练样本数据存在偏差,模型预测精度也会受到影响。

1.2 结冰探测技术

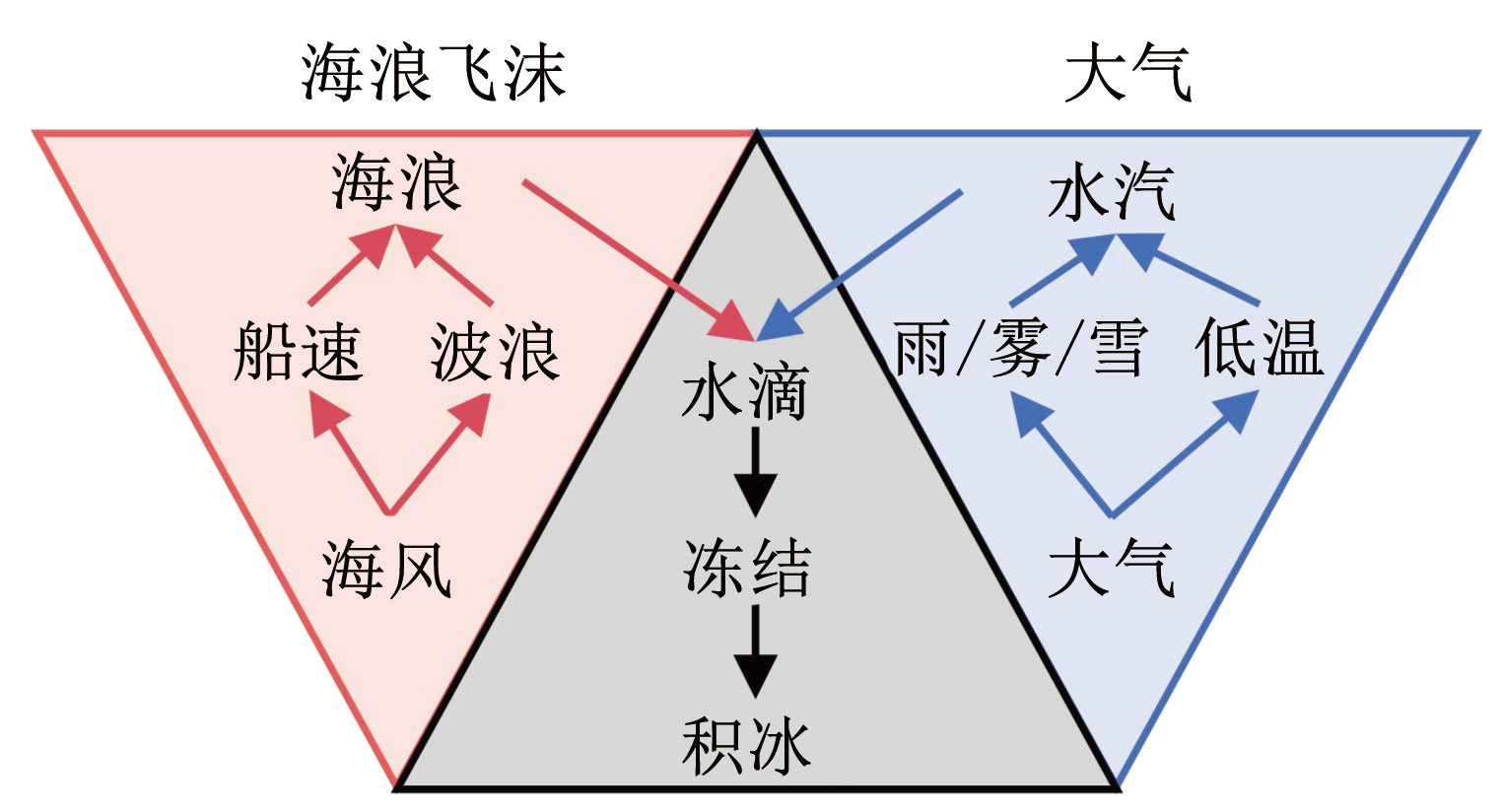

防除冰和破冰的前提是了解结冰条件和冰的累积状况。海浪结冰和大气结冰是甲板和舷窗等结构结冰的主要原因[61-62],这两种结冰类型所包含的要素如图7所示[63]。海浪飞沫携带的水滴撞击并附着在甲板等冷表面时,水滴在低温下迅速凝结成冰[64]。空气冻雨、雾和过冷的大气水滴冻结是导致船舶表面结冰的另一个原因[65-66]。根据大量船舶结冰资料,海浪飞沫结冰占结冰统计总数的 90%、大气结冰占 3%、伴有雨雾的飞沫结冰占 6.4%、降雪占 0.6% [63]。高度低于 16 m 的船舶和设备结冰主要受海浪飞沫影响,高度较高的设备则受到两者的共同影响[67]。

图7海上结冰的两种主要来源和形成原因

Fig.7Two main sources and causes of marine icing

目测法是观测结冰情况时采用的最简单、最直接的方法。英国的 Normalair-Garrett 结冰探测系统的工作原理是在待探测区域使用一个探针,一段时间后再观察结冰情况[68]。尽管这种方法简单方便但其精度和灵敏度都不高。鉴于目测法存在的局限性,摄像法被提出,其原理是将拍下的结冰照片进行处理,使用三维测量方法等对照片中的结冰厚度进行评估,最高测量结果精度为 ± 0.4 mm。该方法的实验装置和原理如图8所示,为提高测量的精度,采用两台相机在不同位置对机翼的结冰区域进行实时拍摄。描述不同时刻照片中冰的轮廓,就可得到不用时刻不同位置的积冰厚度。该方法可解决目测法存在的测量不准和误差大的问题[69]。为进一步提高摄像法测量精度,激光测量冰形方法被提出[70]。激光器产生的激光照射到结冰表面后会反射形成一束激光条,摄像机拍摄该光条后利用图像处理算法可得到冰的三维形貌。该方法可在 2.8 m 范围内自由测量,平均结冰厚度测量精度为 ± 0. 038 mm。该类观测方法可看到结冰轮廓,具有很高的测量精度,但其装置的复杂性限制了其应用场景。此外,在结冰环境中,这些设备表面很容易发生结冰,进而影响工作状态。

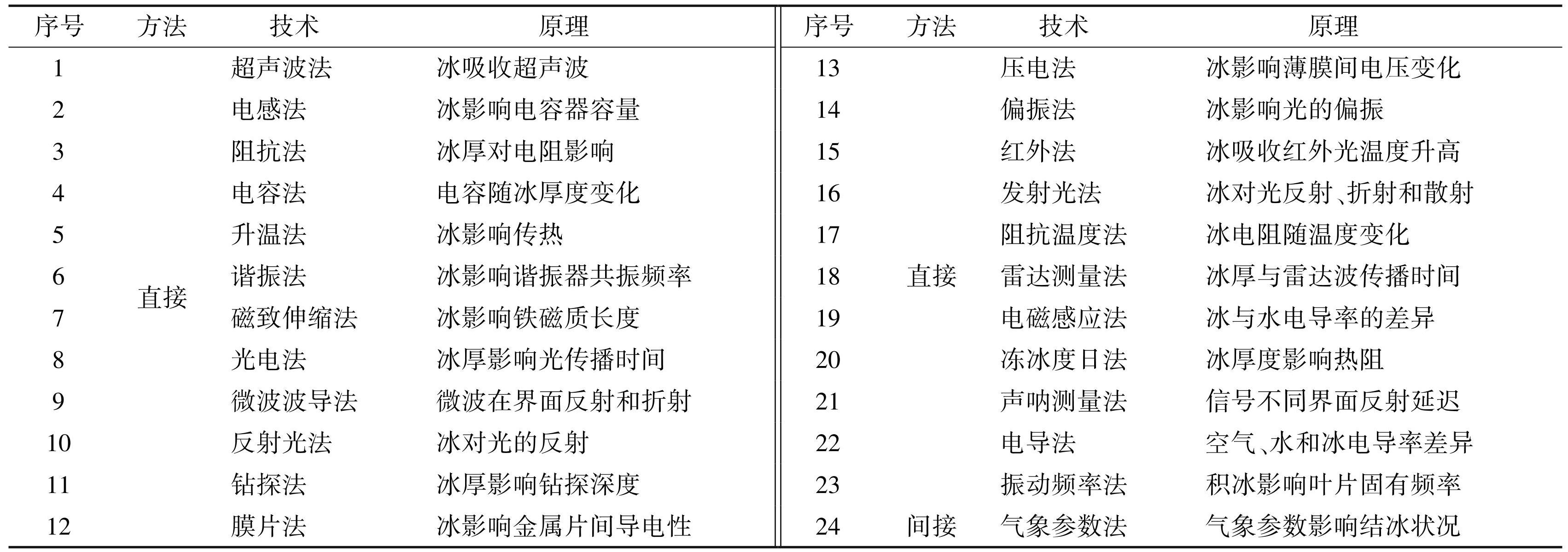

为适用不同场景探冰的需求,准确实时检测结冰厚度的基于电、磁、热等物理原理的传感器检测结冰技术逐渐发展起来。结冰检测器是基于冰会影响传感器测量范围内的物性参数,通过分析参数影响程度反推得到表面结冰厚度。根据是否可直接得到结冰厚度,冰检测方法分为直接法和间接法[71-72],如表5所示。直接检测法是利用传感器监测结冰前后物理参数变化来判断结冰情况,而间接探测法是根据当前气象参数,利用模型推断该条件下的可能结冰情况[73-74]。与间接检测相比,直接检测方法具有高的精度和灵敏性。其中,光纤传感器的测量平均结冰厚度最大误差仅为 ± 0. 05 mm [75]。

图8三维摄像法测量积冰厚度

Fig.8Measurement of ice thickness by 3D method

表5直接和间接结冰探测技术和方法

Tab.5 Direct and indirect ice accumulation detection techniques and methods

2 防除冰技术

随着工业的不断发展,各领域根据自身需求相继提出和开发了多种防除冰技术。根据是否需要额外能量输入,可将这些防除冰技术分为被动式和主动式两种。被动防除冰是指在不需要额外输入能量的情况下通过涂层等功能材料延缓或阻碍成核、降低水或冰对基体黏附力和提高表面温度的技术。主动式防除冰则是在外部能量输入的情况下提高表面温度防止成核发生或融化表面积冰的技术。

2.1 被动防除冰技术

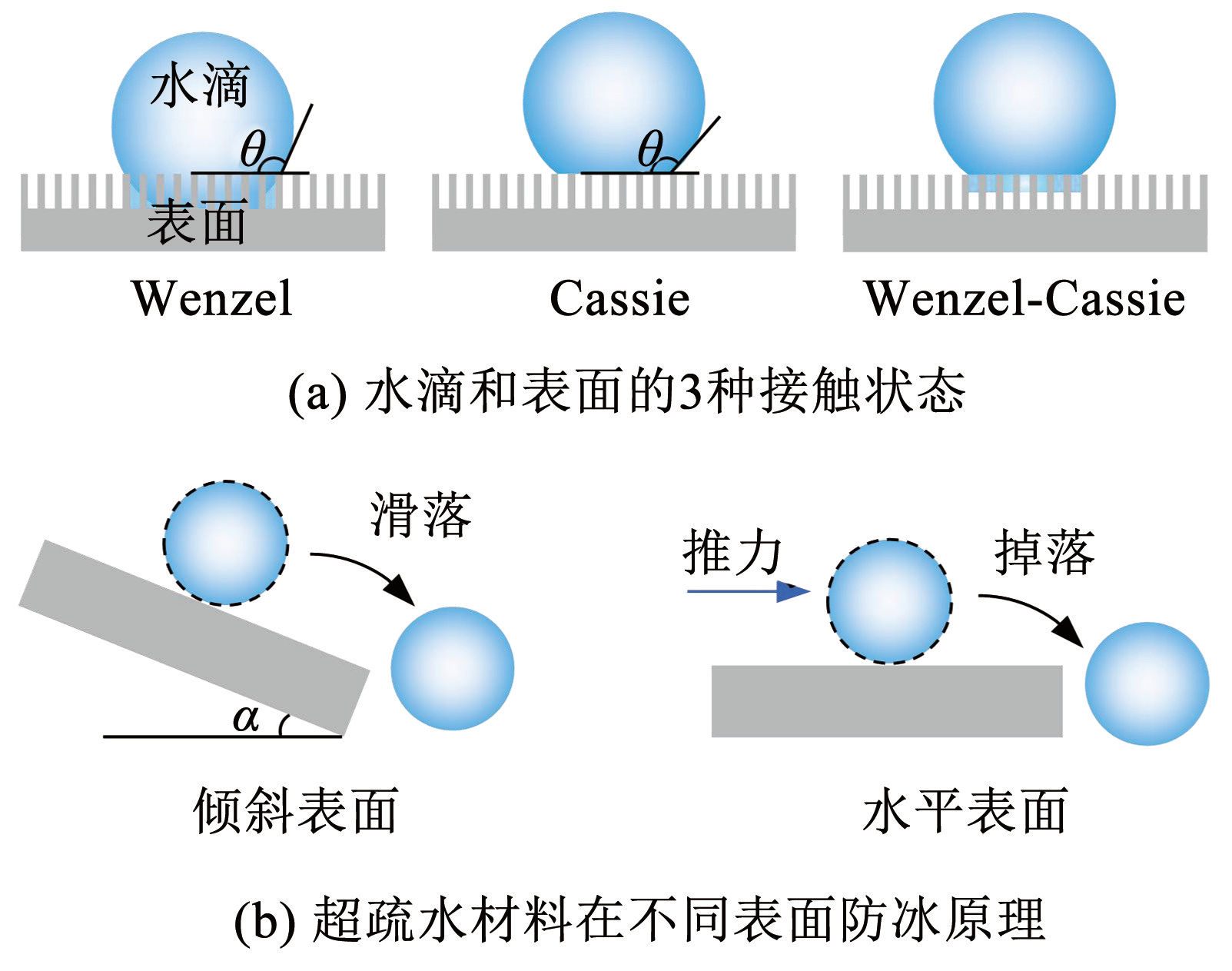

被动防冰是在没有额外能量来源的情况下,采用物理或化学方法阻碍或延缓结冰。超疏水表面是常用的被动式防除冰技术,其可降低水或冰和表面之间的黏附强度。超疏水表面是一类基于荷叶效应的具有纳米结构和低表面能、接触角大于 150°的表面[76]。如图9所示,水滴和表面之间通常有 3 种接触状态,超疏水表面与水滴之间处于 Wenzel-Cassie 状态。固液界面之间的空气层减少了液滴和表面之间的热交换量,减缓液滴生长速率[77-78]。同时,在力作用下液滴极易从表面滑落。

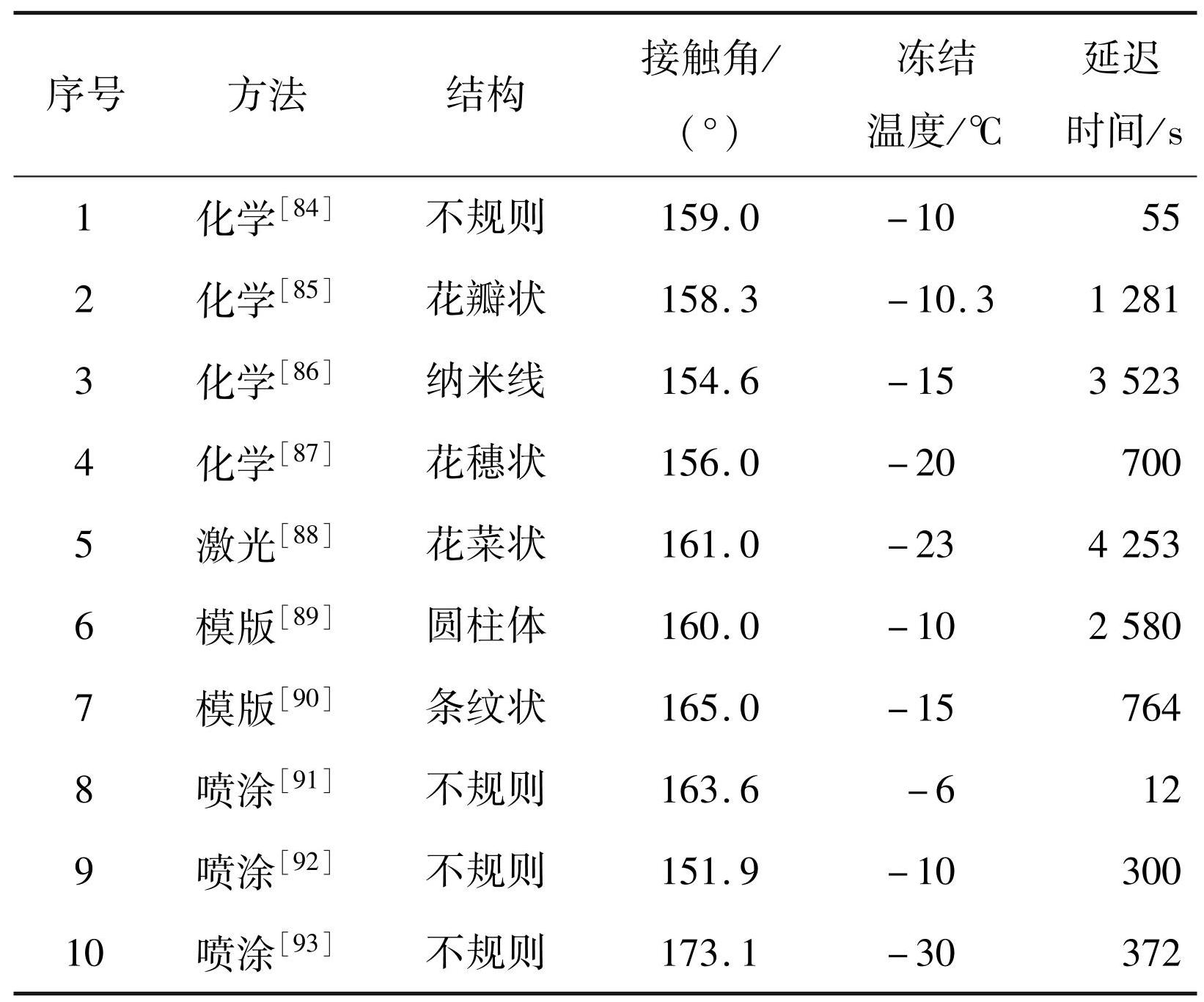

根据 Wenzel-Cassie 模型理论,表面的粗糙结构和化学成分是影响润湿性的两个关键因素[80]。制备超疏水表面首先要在固体表面上构建微米级结构。然后,采用在低表面能聚合物中添加纳米颗粒或在微米结构表面添加低表面能材料的方法使表面具备超疏水性[81]。这两种方法制备的超疏水表面结构存在差异,防结冰效果也不完全相同。防冰效果一般采用冻结过程中水滴过冷阶段到冻结阶段的时间(也称为冻结延迟时间)作为指标。表6比较了不同方法制备超疏水表面的防冰效果。对比发现用激光烧蚀法、模板法和化学蚀刻法制备的具有规则微纳结构的超疏水表面具有更好的抗结冰能力。然而,超疏水表面只能延迟冻结的发生,长时间暴露在低温环境中的表面上仍会结冰[82-83]。

表6不同超疏水表面防冰效果

Tab.6 Anti-icing capability on superhydrophobic surfaces

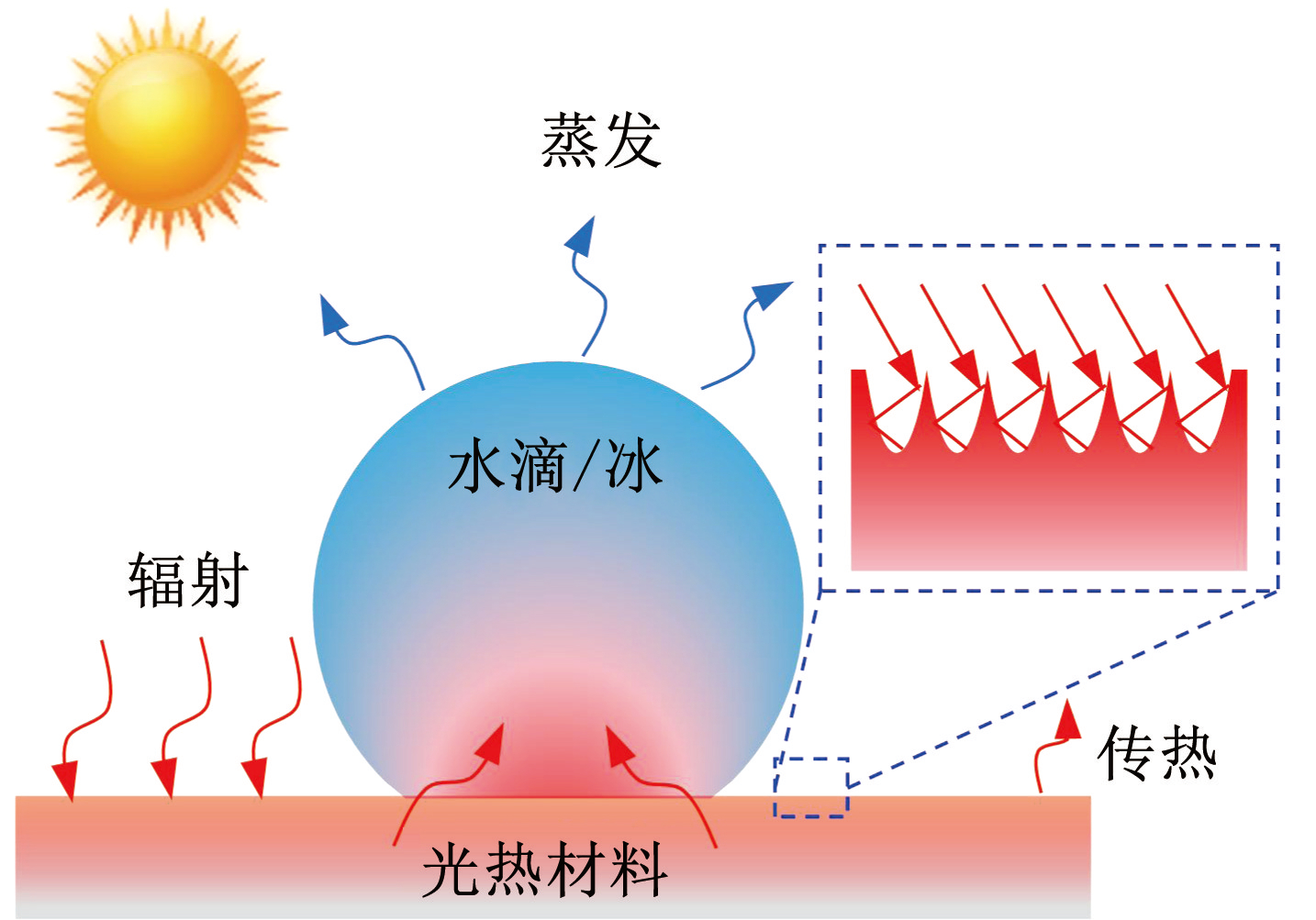

为实现更长时间的防冰,依靠太阳作为热源的光热防冰技术应运而生。光热材料可将太阳能转化为热能,使表面温度高于结冰温度,水蒸气无法在表面冷凝或使表面的水滴蒸发[94]。光热转换是一个复杂而连续的过程,包括光吸收、光子能转化为热能和热传导[95-96],其防冰原理如图10所示。目前,为使水滴从表面脱离,光热材料往往和超疏水材料结合形成光热超疏水表面。光热超疏水材料制备主要通过两种方式:一种是将光热组分引入超疏水材料中,另一种是对光热材料进行超疏水改性。其中,光热材料的改性是最常用的方法。根据光热转换的不同机制,光热材料通常分为碳材料、金属纳米材料、半导体材料和高分子材料[97]。用于光热转换的材料具有波长范围为 300~2 500 nm 的宽带吸收、合适的导热系数和高稳定性等优点[98]。碳材料因来源广泛、工艺简单、易于制造等特点而受到广泛关注。

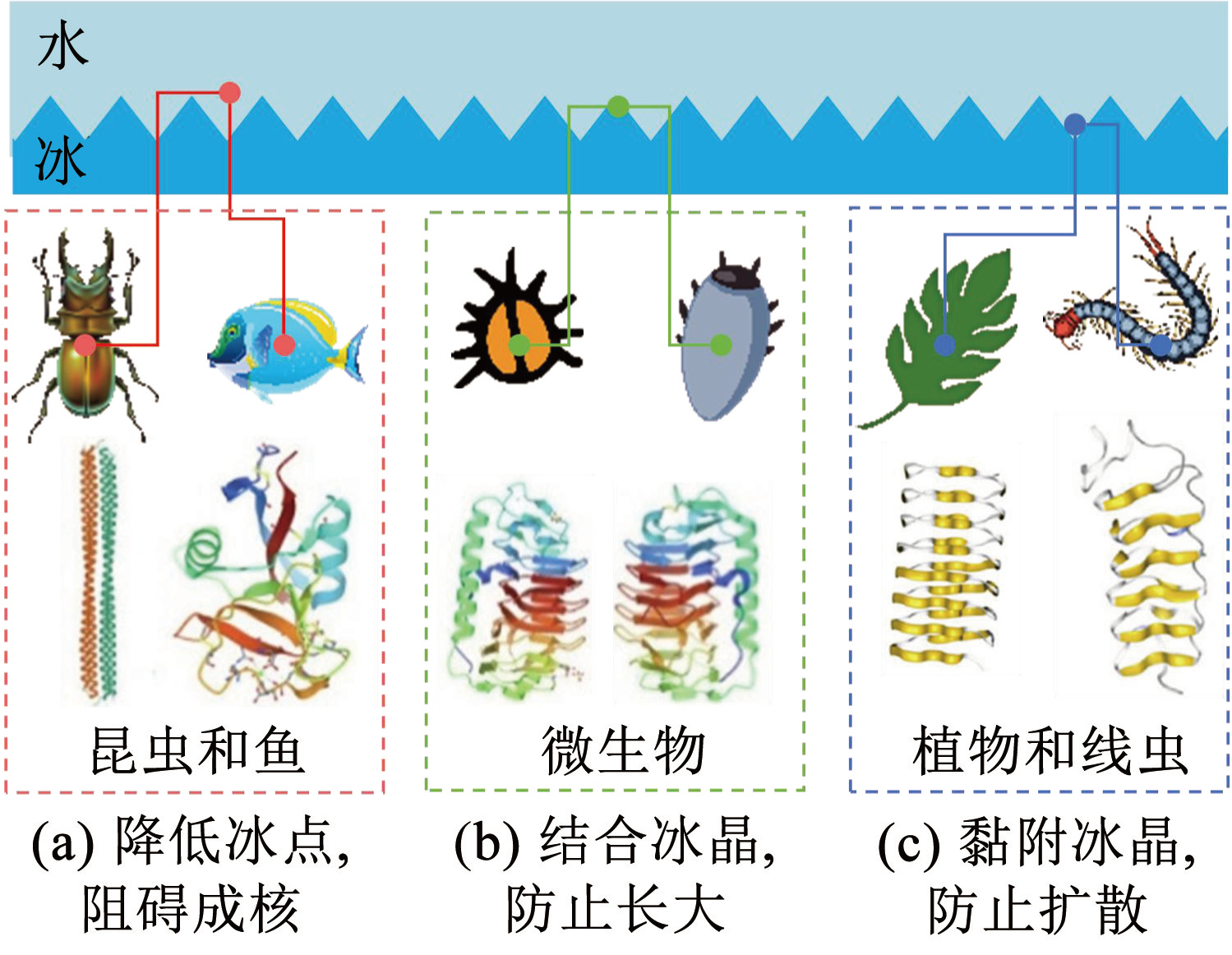

抗冻蛋白(AFPs)是生活在 0℃ 下各种生物所具有的一类特殊蛋白质。 AFPs 具有黏附在冰晶上并阻止其扩增的能力,根据结构组成差异可分为 AFPsⅠ、AFPsⅡ、AFPsⅢ、AFPsⅣ、高活性 AFPs 和抗冻糖 AFPs 6 类[100-101]。如图11所示,不同物种 AFPs 结构不同,导致其防冰机制也不同[102]。 AFPs 的功能受结构和与冰结合位点( IBS)的影响。 IBS 由平坦的疏水结构组成,对 AFPs 的抑制冰再结晶有影响。 AFPs 中存在着相似的重复结构,通过与冰一次的残基结合来促进冰结合面的形成。此外,AFPs 的非冰结合区域可与水分子相互作用,以阻碍冰晶对水的吸收,进而抑制冰晶生长[103]。

此外,基于 AFPs 防冻原理,可降低冰点的防除冰化学药剂被开发[104-105]。防除冰化学药剂可分为氯化盐、醋酸盐、甲酸盐、乙酸盐,即氯化钠和氯化钙、氯化镁、醋酸钙镁、醋酸钾、甲酸钾、乙酸钠和甲酸钠等[106-107]。化学试剂的选择可根据应用场景和受保护面的特性进行。尽管化学试剂已广泛应用在不同的场合,但其会带来的环境污染和腐蚀问题[108]。基于生物质开发的新型糖类防冻试剂可很好地解决腐蚀和污染等问题。糖类抗冻剂种类有很多,包括单糖、寡糖、多糖、变性淀粉等,其抗冻机制并不相同。有些糖类是通过改变蛋白质中水的状态和性质,防止水分子与蛋白质分离,间接地对蛋白质起到保护作用。有些糖类是通过减少自由水的流动,来维持体系的稳定[109]。生物质新型防冻试剂主要是蔗糖,其是由果糖和葡萄糖通过异构体羟基缩合而形成的非还原性二糖。蔗糖具有较高的玻璃化转变温度,对阻止蛋白质二级结构改变、多肽链的伸展和聚集起着作用。但糖类防冻剂使用场合有限、成本高昂都限制其大规模应用[110-111]。

2.2 主动防除冰技术

除不需要额外能量输入的被动防除冰方法外,需要额外输入能量以达到高效快速防除冰目的的主动防冰技术也被广泛采用。既有主动防除冰技术可分为热学法与机械法两类[114]。

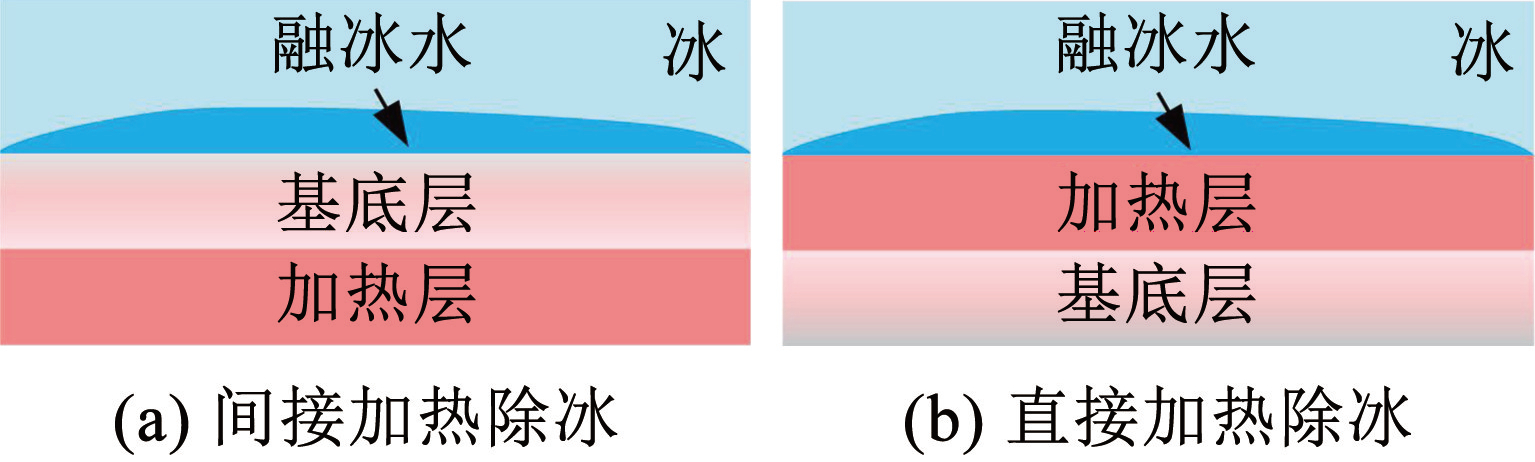

电热防冰是一种简单有效的主动防冰方法,其原理是将电能转化为焦耳热,使物体表面始终保持高于冰点的温度[115]。根据电热材料相对于物体表面的位置,可将其分为内部加热和外部加热,如图12所示[116-117]。内部加热通常是将加热器置于物体内部,然后将产生的热量传递到物体表面。外部加热法是指将加热器直接放置在物体表面,提高表面温度,防止结冰或融化积冰的方法[118]。外部加热比内部加热更加高效,但在恶劣环境中也易发生失效。根据电加热的持续时间,可进一步分为连续加热和间歇加热。对于表面防冰性能要求高或电力资源充足的地方,一般采用连续加热; 而对于表面防冰性能要求低、允许结冰量小、结冰时间短的部件,一般采用间歇加热。

图12电热防冰技术的两种结构和工作原理

Fig.12Two structural and working principles of electrical heating anti-icing technologies

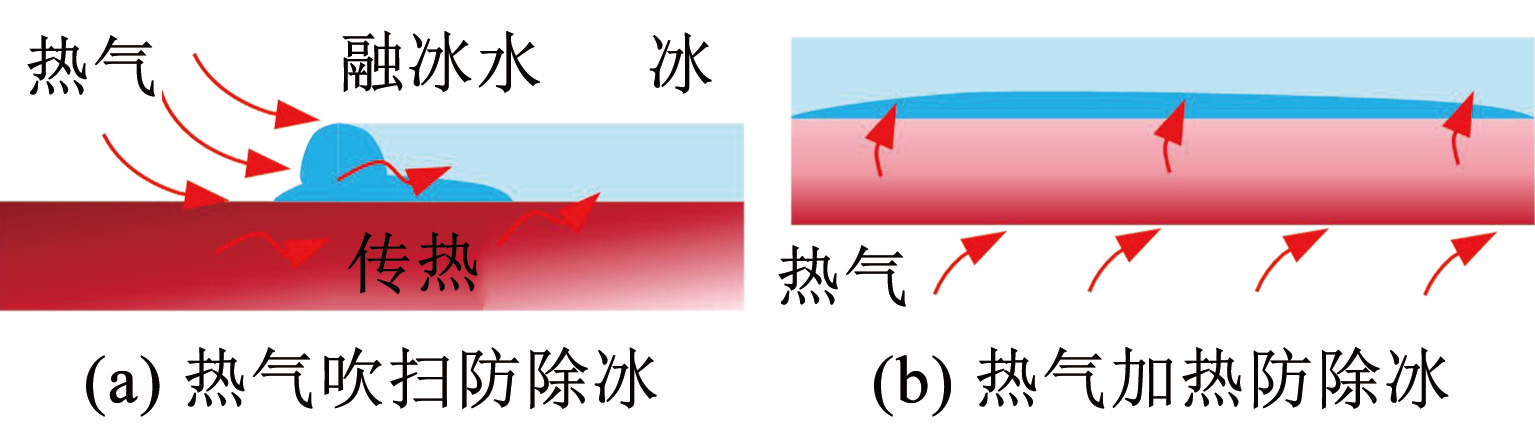

热气除冰是另一种被广泛使用的除冰方法,是利用发动机做功后排出的高温废气作为热源的除冰方法[119-120]。如图13所示,高温热空气可直接吹扫表面提高表面温度,达到防止结冰和融化冰层的目的[121]。不过,这种方法的除冰效率与发动机有关,最大诱导空气量应小于总排气量的 10%,否则会影响发动机的正常工作[122]。热气防除冰的有效性与气象条件和表面尺寸有关[123],同时数值模拟结果也表明,效率随结冰严重程度和表面长度增加而降低[124-125]。此外,还有微波加热和红外线加热的防除冰方法[126-127]。

图13热气除冰技术的两种结构和工作原理

Fig.13Two structural and working principles of heated antiicing technologies

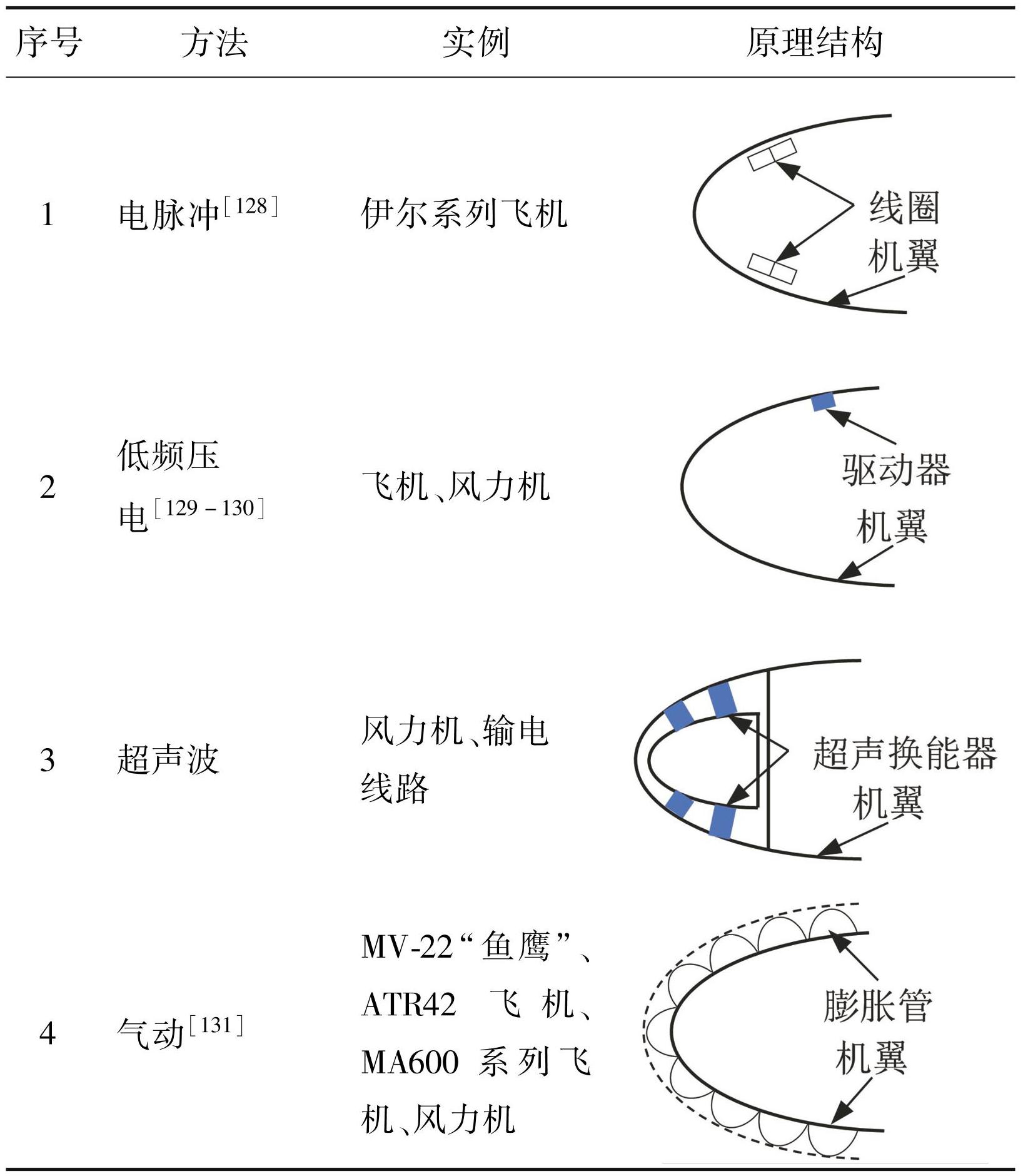

机械防除冰是利用电、气、声波等在物体表面形成机械力,降低冰与物体表面的附着力,使冰在重力或外力的作用下从物体表面脱落。目前,正在研究或已广泛使用的机械除冰方法主要有电脉冲除冰、低频压电除冰、超声波除冰和气动除冰。如表7所示,这些方法被应用在各类装备上。

表7机械除冰技术原理和应用实例

Tab.7 Principles and application examples of mechanical deicing technology

电脉冲除冰系统主要由电源、电容器、晶闸管和线圈 4 部分组成。其基本原理是利用电容器对线圈放电,使线圈产生强磁场,同时物体表面的导电材料产生感应电流和感应磁场[132]。根据电磁感应定律,线圈和感应器之间可瞬间产生几千牛顿的电磁力[133]。电磁力使冰获得较大的瞬时加速度,使冰面破碎[134]。

低频压电除冰系统主要由驱动器、放大器和实验对象等部分组成。该系统利用反向压电原理,在需要除冰保护的区域安装压电驱动器,通过在压电材料表面施加电场,内部正负电荷发生位移,导致材料变形使冰与表面脱离[135-136]。低频压电除冰系统具有结构简单、噪音低、维护性好等优点[137]。

超声波除冰系统主要由超声波发生器、超声波换能器、金属基板、夹持支架等组成[138-139]。该技术是利用了超声波的热效应和机械效应使冰从表面脱离[140]。首先,当换能器激发的超声波在冰中传播时,剪切水平波和 Lamb 波会在基体和冰的界面上产生横向剪切应力。如果剪应力大于黏附强度,冰就会从基底表面脱离。其次,超声波产生热能,导致冰的某些局部区域融化,这时界面上会形成一层薄薄的水层,超声波形成的空化气泡破裂会增强冰的分离效果。

气动除冰系统包括膨胀管、压力调节源和真空源等模块。压力调节源控制进入的压缩空气量,从而控制膨胀管的膨胀程度[141]。真空源控制膨胀管的有效收缩,确保表面光滑而不结冰。当压缩空气注入膨胀管后,会对冰施加剪切力,导致冰破裂,从而使冰从表面脱离[142-143]。该方法具有简单可靠、节省能量等优点,但也存在破坏飞机气动外形问题。

3 极地破冰技术

3.1 水面/ 水下直接破冰技术

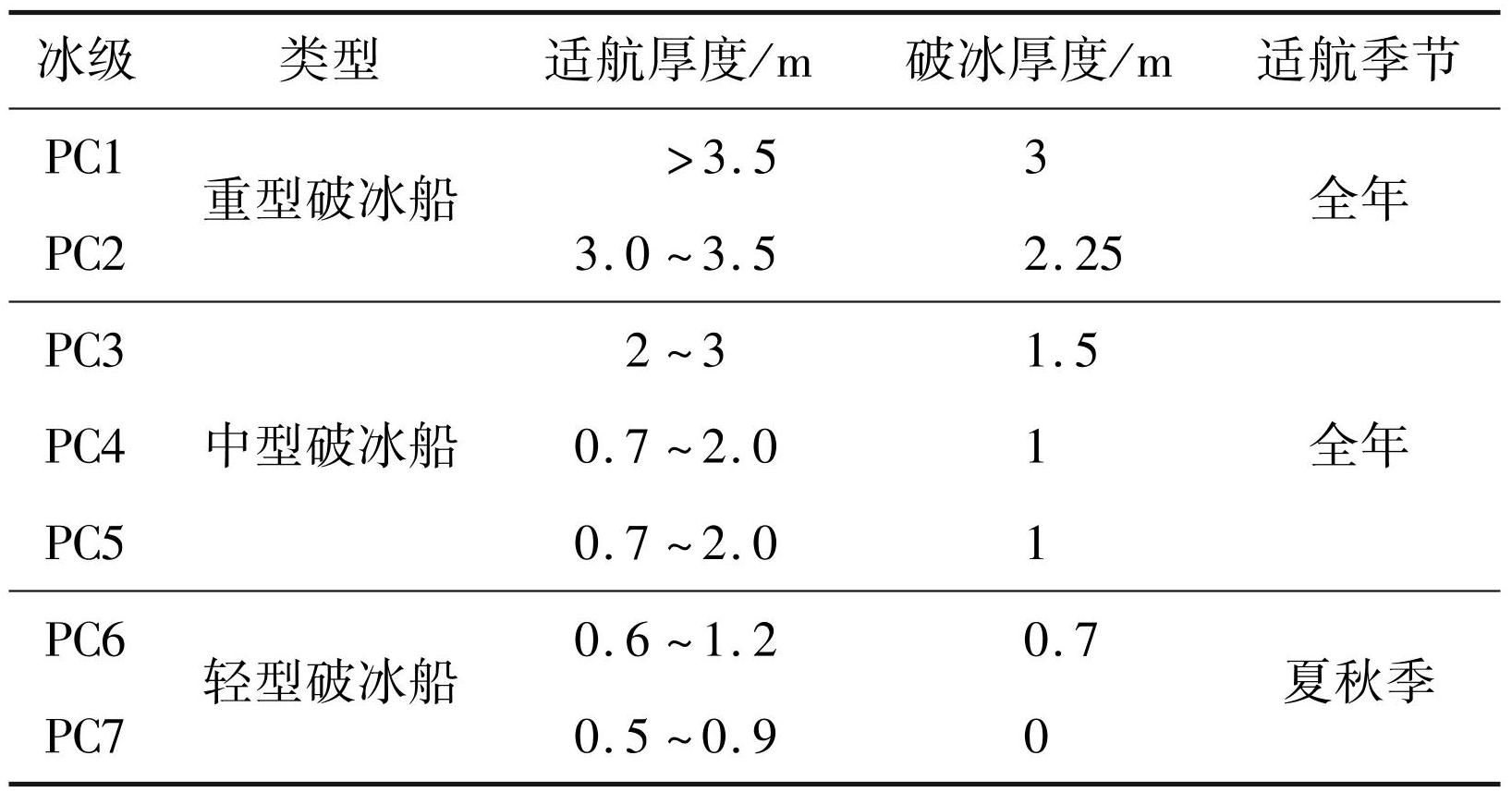

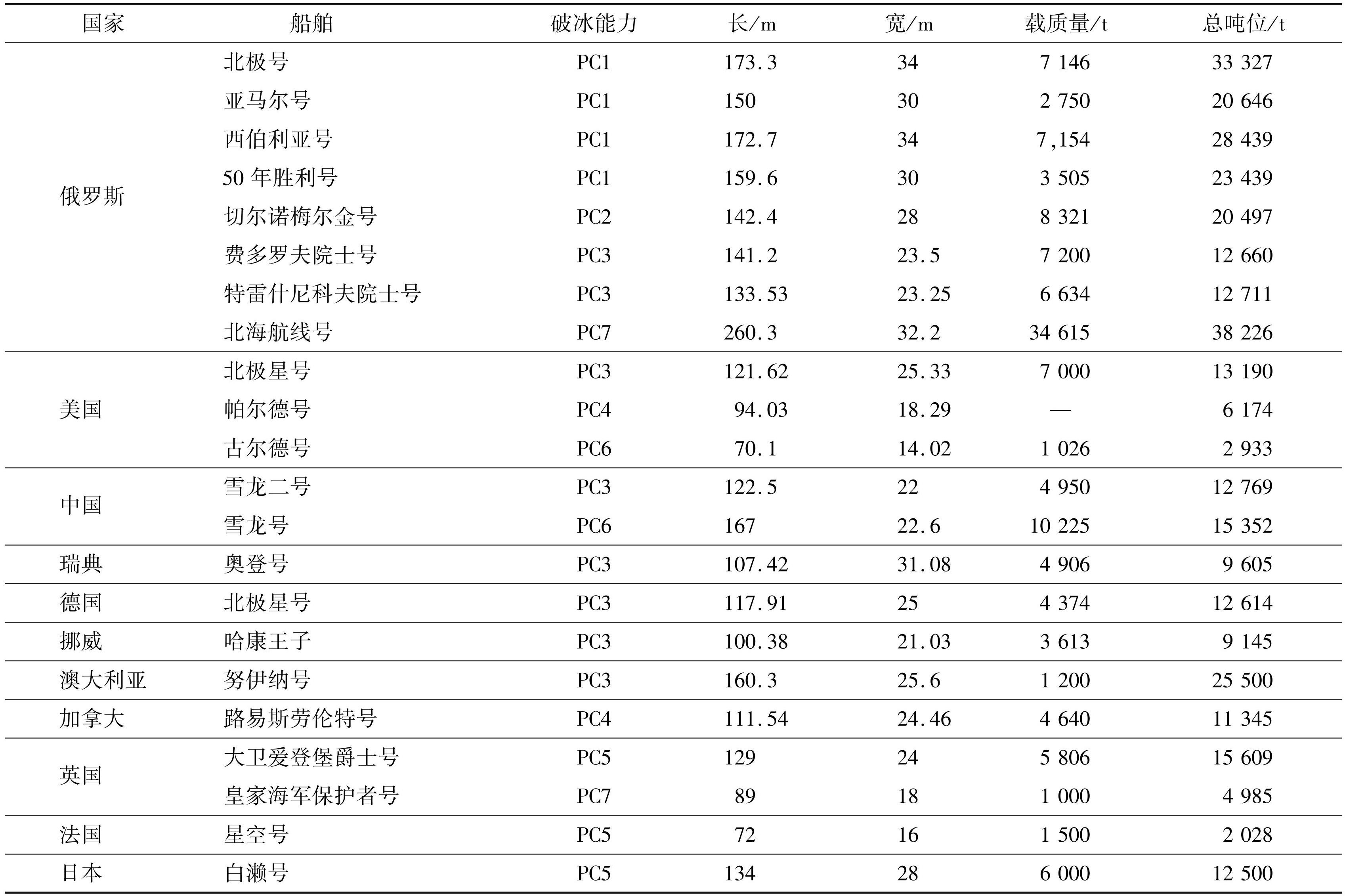

当海面冰密集度大于 8 / 10 时,只有具备破冰能力的船舶才能在极地航行。破冰技术的发展伴随着破冰方法和破冰设备的更新。从柴油动力到功率更大的柴油-燃气轮机联合动力,逐步发展到具有超远航程和破冰能力的核动力系统,破冰动力的更新也推动了破冰能力增加。为定义船舶对于不同冰情的航行适航和破冰能力,2006 年国际船级社协会颁布了《极地船舶统一要求》,将航行船舶分为 PC1~PC7 共 7 个等级,适航能力随破冰厚度增加而依次递减[144]。如表8所示,仅有 PC1 和 PC2 的船舶才可在极地全年安全航行。 2021—2023 年不同国家极地考察的破冰科考船情况如表9所示。在极地科考方面,俄罗斯的破冰船数量和破冰能力,以及载重和总吨位都属于世界领先的地位。此外,俄罗斯拥有在役破冰船超过 40 艘,还拥有世界上唯一一艘核动力破冰船。

表8PC 级破冰船适航能力和破冰厚度

Tab.8 Seaworthiness and ice thickness of PC-class icebreakers

Tab.9 Ice-breaking research vessels of different countries for expeditions to the polar regions during 2021—2023 [145]

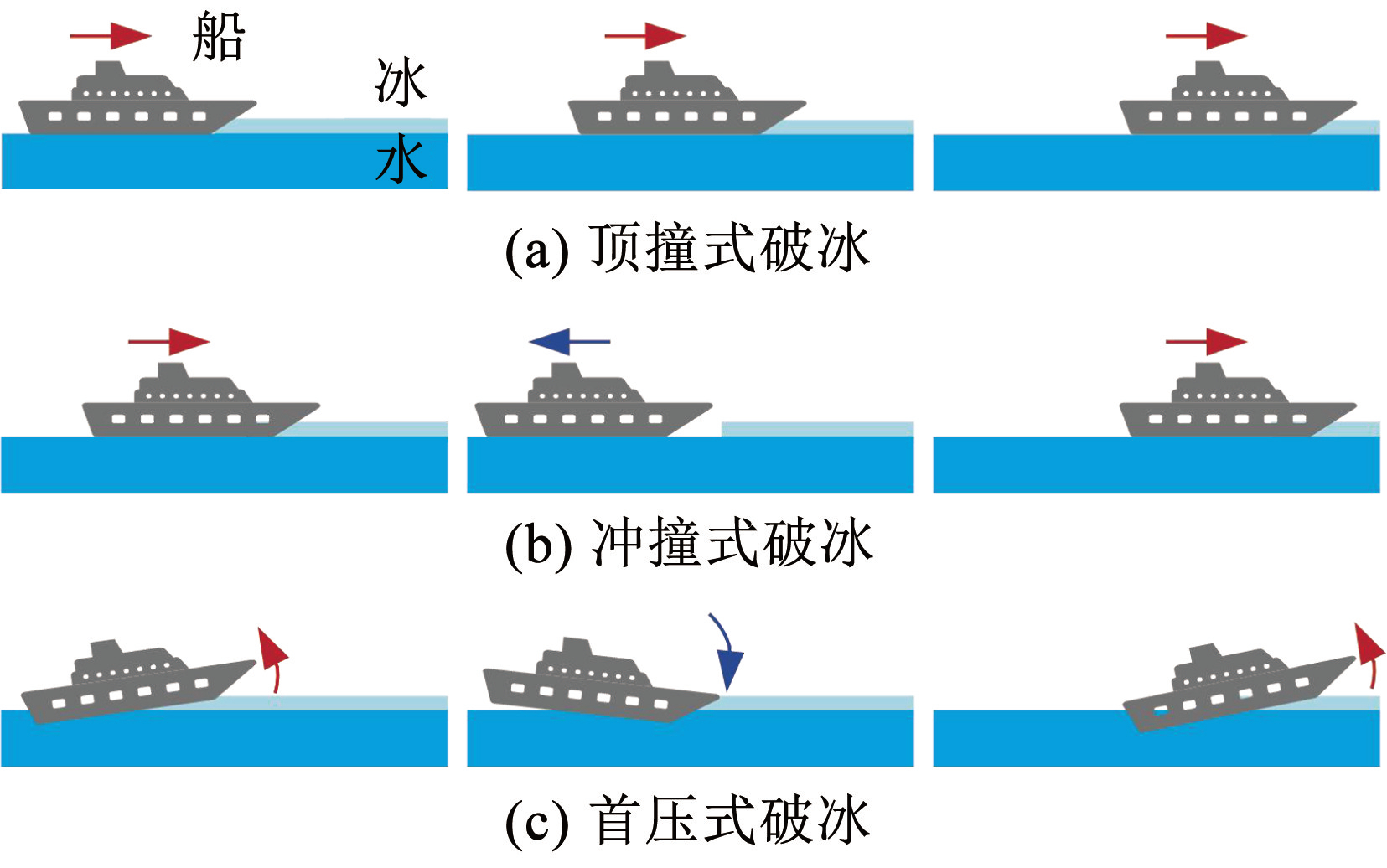

船只破冰时直接接触冰层,依靠自身结构和动力可采用顶撞、冲撞和首压 3 种技术破冰[146-147]。图14(a)是顶撞破冰方式示意,该方式利用船体自重,将船头变成“凿子”依靠自重的巨大惯性和船体动力,连续撞击冰顶破开冰面。图14(b)为冲撞法,通过反复的前进和倒车操作使船只冲破冰层。这种方法操作频繁,速度较低,而且向前反转会面临被厚冰困住的危险。图14( c)为首压破冰法,通过向船头水舱注水增加重量然后抽水减轻重量,反复进行翘头、压冰、注水等动作来实现破冰。这种方法操作复杂,水箱体积大,运行能耗高。此外,还有非对称破冰船、双向破冰船、撬冰船、半潜式破冰船等[148]。

图14船舶 3 种冰面破冰方式示意

Fig.14Schematic diagram of three ice-breaking methods

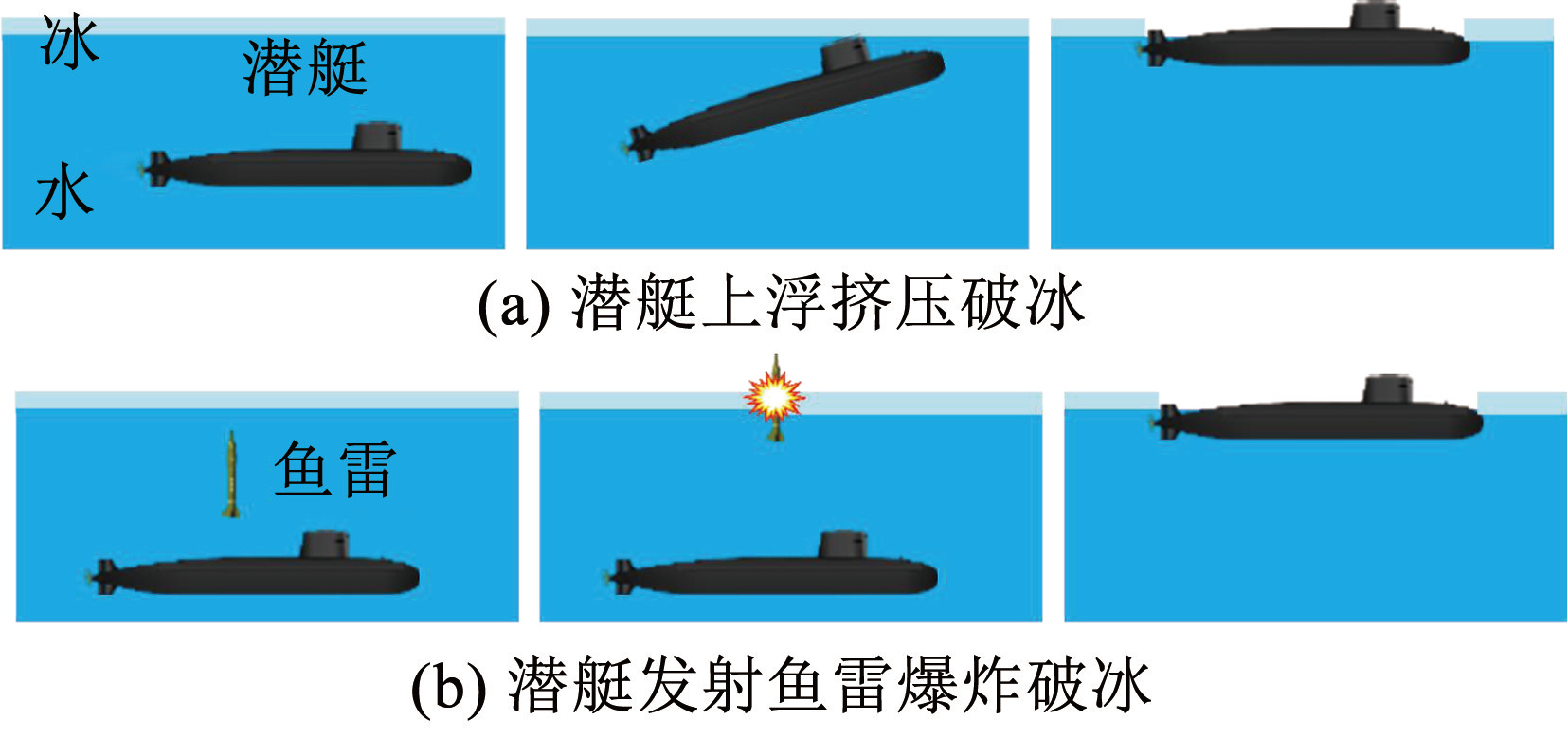

此外,在冰面下巡航的潜艇需要浮出海面时也要进行破冰操作。冰面下破冰主要有机械挤压和鱼雷爆炸两种方法,如图15所示。对于厚度小于 1 m 的冰层,冰下潜艇可以较慢的速度缓慢推开冰层。对于大于 1.5 m 的冰层,这种与冰层直接碰撞的方式是不安全的。为提高潜艇的破冰能力,俄罗斯潜艇模仿鲸鱼破冰的方法,参照鲸鱼的背部,为潜艇设计了一个“鲸背”。潜艇的背部设计了双层外壳,潜艇顶部由硬化的钨钢制成,确保不会被冰层划伤[149]。为进一步降低直接破冰对潜艇结构强度的高要求,鱼雷爆炸破冰方法被提出。先释放鱼雷炸开冰层,然后潜艇破洞中上浮。

图15潜艇两种水下破冰方式示意

Fig.15Schematic diagram of two ice-breaking methods for submarine underwater

3.2 辅助破冰技术

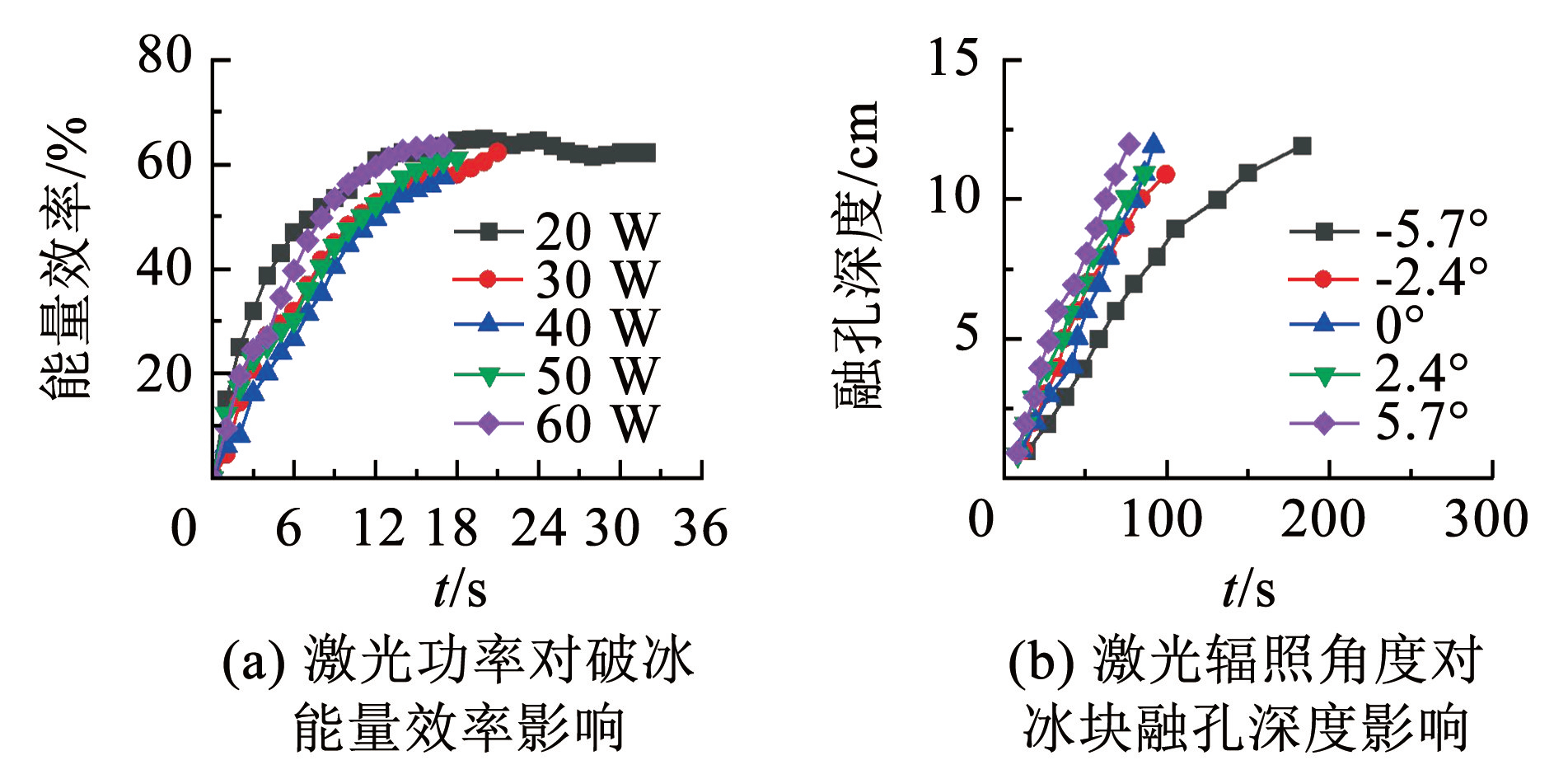

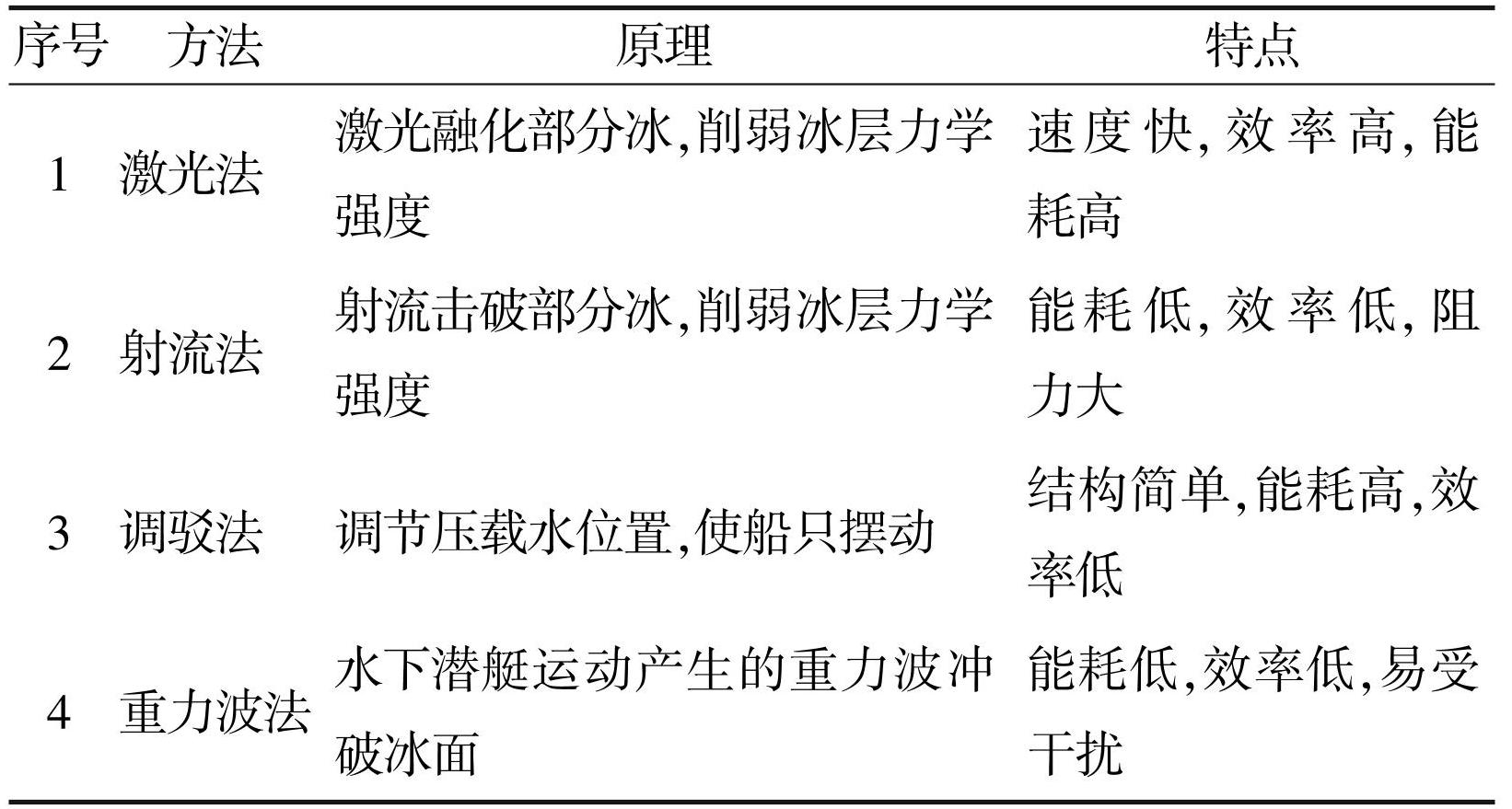

为降低直接机械破冰的能耗和操作难度,“先弱冰再破冰” 的耦合辅助破冰技术逐渐受到关注[150]。如激光融冰和快速倾斜等都是常用的辅助手段。激光具有高能量密度,当照射到物体表面或内部时会导致目标材料融化、断裂甚至蒸发[151],目标物体也可能会发生热汽化,产生的高压蒸汽压力波急剧膨胀,导致材料内部爆炸。烧蚀效应和冲击波效应是激光在短时间内对目标物体定向破坏的主要原因[152]。在破冰之前,首先利用激光对目标冰层进行预处理,在冰层上融孔或切割,以降低冰层强度。此外,激光破冰效率与激光功率[153] 和辐照角度[154] 有关。如图16所示,水平面激光融冰实验中,随着激光功率的增大,能量效率呈现先减小后增大的趋势。辐照角度对融孔深度的影响更为显著,随着辐照角度的增大融孔深度增加。

图16激光功率和辐照角度对融冰影响规律

Fig.16Effect of power and irradiation angle on ice melting

气泡辅助破冰也是常用的破冰技术,其最早由芬兰专家于 1967 年设计,旨在通过气水混合流减少船体与冰块或积雪之间的摩擦[155]。该系统将压缩空气从靠近船体间隔排列的喷嘴喷出,当空气沿着船体上浮时,会把冰块从船体边沿推离,并在冰块和船体中间形成无冰区域。为研究气泡上浮过程中,气泡、水和海冰的相互作用而导致海冰加速破裂的机制,有学者进行了气泡辅助破冰实验。气泡在船壳和冰中间形成了悬臂梁结构,从而减小了破冰的阻力[156]。此外,射流破冰[157]、压载水调驳[158]、弯曲重力波破冰[159]等辅助破冰技术已有研究。其工作原理和特点如表10所示。

表10辅助破冰方法和工作原理

Tab.10 Auxiliary ice-breaking methods and principles

4 结论与展望

1)结冰预测主要基于经验、理论和数值 3 种模型,其中,平均结冰厚度的理论模型预测准确度小于 50%,而数值模型准确度大于 60%。为提高计算速率而对实际模型进行过度简化是数值模型准确度受限的主要原因。通过提高数值模型与实际物体的相似度,充分考虑物体外形和环境的换热量,可提高模型准确度。结合机器学习,使数值模型自我优化调整,可进一步提高结冰预测精度与效率。结冰探测主要采用观测与检测两种方法,前者精度高但装置复杂、适用性低,后者装置简单、准确度低,但较为常用。结冰探测法精度的提高均有赖于对复杂环境结冰特性的掌握,以及对冻结过程中霜冰内部传热传质与流动耦合作用机制的充分理解。

2)既有防除冰技术包含被动式和主动式两种,前者主要有超疏水表面、光热表面、抗冻蛋白与化学试剂涂覆等,该类技术具有能耗低、操作简单、时效短等特点; 后者以热力式和机械式为代表,具有效率高、装置复杂等特点。两类技术在极地低温极端环境中均面临能源紧缺、盐分腐蚀等极端挑战。此类问题的最终解决有赖于化学、传热学、流体力学、机械等多学科协同合作,基于复杂表面与热力或机械耦合的防除冰策略,实现各装备独有的高效防除冰技术。

3)现有极地水面船舶破冰的冲撞、顶撞和首压技术与水下潜艇的挤压上浮破冰技术,均为传统机械破冰技术。尽管既有破冰技术仍以机械式为主,但其存在能效低、操作难度大、破冰厚度有限等诸多问题。为满足实际破冰需求,加大船舶与潜艇壳体厚度不仅造成装备冗余、运行能耗高,也会提高操作难度、降低装备灵活性等,因此,基于激光融冰等辅助方式“先弱冰再破冰”的耦合破冰技术逐步备受关注。