1 Introduction

Automation of excavation work has been studied by many researchers. In order to overcome the parameter uncertainties of the excavator and the disturbances due to the interaction with soil and other nonlinearities, Hanh et al.[1] designed a fuzzy self tuning control system with neural network algorithm for the trajectory control of a mini excavator and the experimental results showed the better control performance compared with the conventional PID control. Some researchers[2-3] applied a time-delay control (TDC) with switching action using an integral sliding surface to the straight-line motion control of a hydraulic excavator and the achieved accuracy was mostly within 3 cm or 4 cm for task surfaces with various inclinations through experiments. A contour control algorithm (or cross-coupled pre-compensation algorithm) combined with PI control was applied to the control of a real excavator and was proved effective for improving tracking accuracy in Refs. [4-5]. Ha et al.[6] presented a robust sliding mode controller that implemented impedance control for a backhoe hydraulic excavator and obtained satisfactory results in autonomous excavation with the consideration of bucket-soil interaction. Haga et al.[7] developed the hydraulic excavator with an on-board depth control digging device for the purpose of improving the efficiency of the level digging work. Park et al.[8] employed impedance control and sliding mode control (SMC) in the rigid-body motion control of the excavator, and utilized the echo-state networks online learning method to control the hydraulic servo system. Chiang et al.[9] used model reference adaptive control in the control of excavator path tracking.

Excavators can be regarded as serial robotic manipulators which interact with environment. Many control techniques for robotic manipulators have been applied to the control of the excavators as mentioned above. Variable structure control with sliding mode has been widely used in motion control systems because it is immune to parameter changes and external disturbances[10]. It has also been applied to the control of the excavators in Refs. [3, 6, 8]. However, the main disadvantage of SMC is its high frequency chattering due to the discontinuous switching action used to handle the uncertainties. In order to attenuate or eliminate the chattering, one way is to use the saturation function other than the sign function and the tracking error is then determined by the width of the boundary layer[3, 11]. A second way is the application of the adaptive sliding mode control (ASMC) in which switching gain is reduced by adaptive laws to a minimal admissible level defined by the conditions for the sliding mode to exist since the amplitude of the chattering phenomenon is proportional to the magnitude of the switching part[12-18]. Some other chattering suppression methods use neural network or fuzzy theory to approximate the sign function or tune the switching gain to adapt to the parameter uncertainties and load disturbances[19-25].

In this paper, an adaptive sliding mode controller is designed for the joint angle trajectory tracking control of the excavator manipulator. The adaptive laws derived from Lyapunov stability theorem are used to update the switching gains and compensate the model errors and uncertainties. The rest of the article is organized as follows. Section 2 presents the dynamic model of the excavator manipulator. Section 3 introduces the trajectory generation in joint space of the excavator system. Adaptive sliding mode controller is designed and presented in Section 4. Simulation results of the ASMC and the classical SMC for the trajectory tracking are given in Section 5 and Section 6 provides the brief conclusion.

2 Dynamic Model of the Excavator

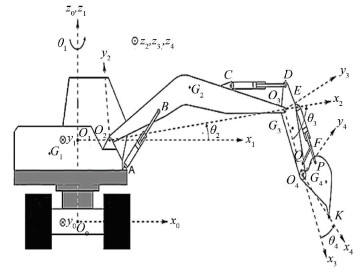

The excavator can be seen as an open-chain manipulator. As shown in Fig. 1, a Cartesian (rectangular and right-handed) coordinate system O0x0y0z0 was chosen as the fixed base frame. Oixiyizi(i=1, 2, …, 4) attached to the revolute axis was defined based on the D-H parameters methodology (Table 1). G1, G2, G3, and G4 are the centers of gravity of the rotating platform with driver's cab, boom, stick, and bucket, respectively.

表 1

Table 1 Kinematic parameters of the excavator

| Link |

di |

ai |

αi |

θi |

| O1O2 |

0 |

a1 |

π/2 |

θ1 |

| O2O3 |

0 |

a2 |

0 |

θ2 |

| O3O4 |

0 |

a3 |

0 |

θ3 |

| O4K |

0 |

a4 |

0 |

θ4 |

|

Table 1 Kinematic parameters of the excavator

|

Since the joint angle θ1 is not changed during the digging operation, the dynamic model for the digging motion of the excavator can be expressed as

|

$

\boldsymbol{D}(\boldsymbol{\theta} ) \boldsymbol{\ddot{\theta } } + \boldsymbol{C}( \boldsymbol{\theta} , \boldsymbol{\dot{\theta }} ) \boldsymbol{\dot{\theta }} + \boldsymbol{G}( \boldsymbol{\theta} ) + \boldsymbol{B}( \boldsymbol{\dot{\theta } }) = \boldsymbol{ \tau} - \boldsymbol{\tau} _{L}

$

|

(1) |

where

|

$

\boldsymbol{D(\theta )} = \left[ \begin{matrix}

{ D_{11}} & { D_{12}}& { D_{13}} \\

{D_{21}} & { D_{22}} & { D_{23}} \\

{D_{31}} & { D_{32}} & { D_{33}} \\

\end{matrix} \right]

$

|

is the inertia matrix, which is symmetric and positive.

|

$

\boldsymbol{\theta } =[ \theta _{2} \;\;\theta _{3}\;\; \theta _{4} ]^{\rm T}

$

|

|

$

\boldsymbol{C}( \boldsymbol{\theta} , \boldsymbol{\dot{\theta }} ) = \left[ \begin{matrix}

{ C_{11}} & {C_{12}}& { C_{13}} \\

{C_{21} } & {C_{22}}& { C_{23}} \\

{C_{31}} & {

C_{32}}& { C_{33} } \\

\end{matrix} \right]

$

|

is determined by the Coriolis and centripetal effects. G(θ) = [G2 G3 G4]T represents the gravity, B($\boldsymbol{\dot{\theta } }$)= [Bbo $\dot{\theta }_2$ Bst $\dot{\theta }_3$ Bbu $\dot{\theta }_4$]T signifies friction term, and Bbo, Bst, and Bbu are the viscous friction coefficients of boom, stick, and bucket, respectively. τ = [τ2 τ3 τ4]T represents the torques produced by the hydraulic actuators acting on the joint shafts, and

|

$

\boldsymbol{\tau} _{L}= \left[ \begin{matrix}

{a_{2}[F_{t}\sin (\theta _{2}-\theta _{\rm dg})+F_{n}\cos (\theta _{2}-\theta _{\rm dg})]} \\

{a_{3}[F_{t}\sin (\theta _{23}-\theta _{\rm dg})+F_{n}\cos (\theta _{23}-\theta _{\rm dg})]} \\

{-a_{4}(F_{t}\sin \theta _{\rm b}+F_{n}\cos \theta _{\rm b}) } \\

\end{matrix} \right]

$

|

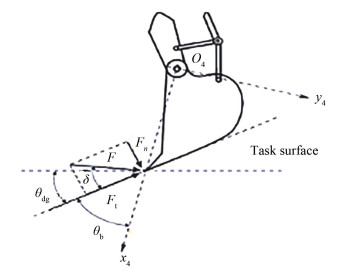

is the interactive torques between the excavator bucket and the ground. Ft, Fn, θb, δ, and θdg are presented in Fig. 2.

The elements in matrix D(θ), C(θ, $\boldsymbol{\dot{\theta }} $), and G(θ) are as follows:

|

$

\boldsymbol{D} _{33}=I_{\rm bu}+M_{\rm bu}r^{2}_{4}

$

|

|

$

\boldsymbol{D} _{22} =D_{33}+I_{\rm st}+M_{\rm st}r^{2}_{3}+\\

\;\;\;\; M_{\rm bu}[a^{2}_{3}+2a_{3}r_{4}\cos (\theta _{4}+α_{4})]

$

|

|

$

\boldsymbol{D} _{11} =D_{22}+I_{\rm bo}+M_{\rm bo}r^{2}_{2}+\\

\;\;\;\;M_{\rm st}[a^{2}_{2}+2a_{2}r_{3}\cos (\theta _{3}+α_{3})]+\\

\;\;\;\;M_{\rm bu}[a^{2}_{2}+2a_{2}a_{3}c_{3}+2a_{2}r_{4}\cos (\theta _{34}+α_{4})]

$

|

|

$

\boldsymbol{D} _{23} =D_{32}=D_{33}+M_{\rm bu}a_{3}r_{4}\cos (\theta _{4}+α_{4})

$

|

|

$

\boldsymbol{D} _{13}=D_{31}=D_{23}+M_{\rm bu}a_{2}r_{4}\cos (\theta _{34}+α_{4})

$

|

|

$

\boldsymbol{D} _{12} =D_{21}=D_{13}+I_{\rm st}+M_{\rm st}[r^{2}_{3}+\\

\;\;\;\;a_{2}r_{3}\cos (\theta _{3}+α_{3})]+M_{\rm bu}[a^{2}_{3}+\\

\;\;\;\;a_{2}a_{3}c_{3}+a_{3}r_{4}\cos (\theta _{4}+α_{4})]

$

|

|

$

\boldsymbol{C} _{11} =-a_{2}\dot \theta _3 [M_{\rm st}r_{3}\sin (\theta _{3}+α_{3})+\\

\;\;\;\;M_{\rm bu}a_{3}s_{3}+M_{\rm bu}r_{4}\sin (\theta _{34}+α_{4})]-\\

\;\;\;\;M_{\rm bu}r_{4}\dot \theta _4 [a_{2}\sin (\theta _{34}+α_{4})+a_{3}\sin (\theta _{4}+α_{4})]

$

|

|

$

\boldsymbol{C} _{12}= -a_{2}\dot \theta _{23}[M_{\rm st}r_{3}\sin (\theta _{3}+α_{3})+\\

\;\;\;\;M_{\rm bu}a_{3}s_{3}+M_{\rm bu}r_{4}\sin (\theta _{34}+α_{4})]-\\

\;\;\;\;M_{\rm bu}r_{4}\dot \theta _4 [a_{2}\sin (\theta _{34}+α_{4})+\\

\;\;\;\;a_{3}\sin (\theta _{4}+α_{4})]

$

|

|

$

\boldsymbol{C} _{13}= -M_{\rm bu}r_{4}\dot \theta _{234}[a_{2}\sin (\theta _{34}+α_{4})+\\

\;\;\;\;a_{3}\sin (\theta _{4}+α_{4})]

$

|

|

$

\boldsymbol{C} _{21}= a_{2}\dot \theta _2 [M_{\rm bu}a_{3}s_{3}+M_{\rm bu}r_{4}\sin (\theta _{34}+\\

\;\;\;\;α_{4})+M_{\rm st}r_{3}\sin (\theta _{3}+α_{3})]-\\

\;\;\;\;M_{\rm bu}a_{3}r_{4}\dot \theta _4 \sin (\theta _{4}+α_{4})

$

|

|

$

\boldsymbol{C} _{22}=-M_{\rm bu}a_{3}r_{4}\dot \theta _4 \sin (\theta _{4}+α_{4})

$

|

|

$

\boldsymbol{C} _{23}=-M_{\rm bu}a_{3}r_{4}\dot \theta _{234}\sin (\theta _{4}+α_{4})

$

|

|

$

\boldsymbol{C} _{31}= M_{\rm bu}r_{4}\dot \theta _2 [a_{2}\sin (\theta _{34}+α_{4})+\\

\;\;\;\;a_{3}\sin (\theta _{4}+α_{4})]+\\

\;\;\;\;M_{\rm bu}a_{3}r_{4}\dot \theta _3 \sin (\theta _{4}+α_{4})

$

|

|

$

\boldsymbol{C} _{32}= M_{\rm bu}a_{3}r_{4}\sin (\theta _{4}+α_{4})(\dot \theta _2 +\dot \theta _3 )

$

|

|

$

\boldsymbol{C} _{33}=0

$

|

|

$

\boldsymbol{G} _{2}= M_{\rm bu}g[a_{2}c_{2}+a_{3}c_{23}+r_{4}\cos (\theta _{234}+α_{4})]+\\

\;\;\;\;M_{\rm st}g[a_{2}c_{2}+r_{3}\cos (\theta _{23}+α_{3})]+\\

\;\;\;\;M_{\rm bo}gr_{2}\cos (\theta _{2}+α_{2})

$

|

|

$

\boldsymbol{G} _{3}= M_{\rm bu}g[a_{3}c_{23}+r_{4}\cos (\theta _{234}+α_{4})]+\\

\;\;\;\;M_{\rm st}gr_{3}\cos (\theta _{23}+α_{3})

$

|

|

$

\boldsymbol{G} _{4}= M_{\rm bu}gr_{4}\cos (\theta _{234}+α_{4})

$

|

where Mbo, Mst, and Mbu are the masses of boom, stick, and bucket, respectively. Ibo, Ist, and Ibu are the moments of inertia of boom, stick, and bucket, respectively.

|

$

r_{2}=O_{2}G_{2}, r_{3}=O_{3}G_{3}, r_{4}=O_{4}G_{4}

$

|

|

$

α_{2}=∠G_{2}O_{2}O_{3}, α_{3}=∠G_{3}O_{3}O_{4}, α_{4}=∠G_{4}O_{4}K

$

|

|

$

c_{3}=\cos (\theta _{3}), s_{3}=\sin (\theta _{3}), c_{23}=\cos (\theta _{2}+\theta _{3})

$

|

|

$

\theta _{34}=\theta _{3}+\theta _{4}, \theta _{234}=\theta _{2}+\theta _{3}+\theta _{4}

$

|

3 Trajectory Generation of the Excavator

The bucket straight-line motion to scrape and flatten the ground is one of the most fundamental tasks of the excavator and an essential element for more complicated tasks[2]. Since the hydraulic actuators generate the desired torques acting on the joint shafts, the bucket straight-line motion should be transformed into the joint angle trajectory for direct control.

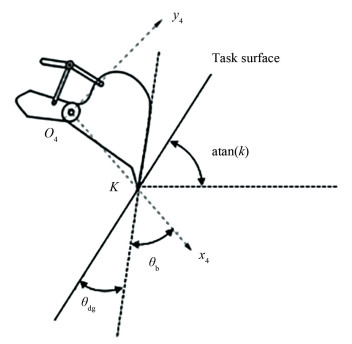

The attachments of the excavator working device, i.e., boom, stick, and bucket, can be seen as planar serial manipulators with 3 degree of freedom(3-DOF). However, the planned straight-line trajectory of the bucket provides only two constraints in O1x1 direction and O1z1 direction, respectively. As the joint angle θ1 is held constant during digging operation, the trajectory is presented in coordinate system O1x1y1z1. In order to get unique joint angle trajectory, the digging angle θdg (the angle between the bottom surface of bucket and the task surface) was kept constant[2]. As shown in Fig. 3, θb is the angle between the bucket bottom and the O4x4 direction, k is the slope of the task surface, φ=θ234=θ2+θ3+θ4 is the attitude angle of the bucket in O1x1y1z1, and the additional constrain can be transformed as follows:

|

$

φ=\arctan(k)+\theta _{\rm b}+\theta _{\rm dg}- \mathsf{π}

$

|

(2) |

From Eq. (2), it can be concluded that the attitude angle φ is constant during straight-line digging operation and the transformed joint angle trajectory presented in O1x1y1z1 is

|

$

\begin{array}{c}

\theta _{3}= -\arccos([(x_{1}-a_{1}-a_{4}\cos φ)^{2}+(z_{1}-\\

a_{4}\sin φ)^{2}-a^{2}_{2}-a^{2}_{3}]/2a_{2}a_{3})

\end{array}

$

|

(3a) |

|

$

α=\arctan( \frac{{ z_{1}-a_{4}\sin φ}}{{ x_{1}-a_{1}-a_{4}\cos φ }})

$

|

(3b) |

|

$

β= \arccos([(x_{1}-a_{1}-a_{4}\cos φ)^{2}+\\

\;\;\;\;(z_{1}-a_{4}\sin φ)^{2}+a^{2}_{2}-a^{2}_{3}]/\\

\;\;\;\;[2a_{2} \sqrt{ (x_{1}-a_{1}-a_{4}\cos φ)^{2}+(z_{1}-a_{4}\sin φ)^{2} }])

$

|

(3c) |

|

$

\theta _{4}=φ-\theta _{2}-\theta _{3}

$

|

(3e) |

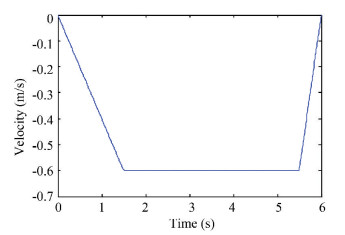

Once the slope of the task surface is obtained, the path of the bucket is determined. According to Refs. [2-3], the planned velocity trajectory is shown in Fig. 4 and the straight-line motion is carried out from a stretched posture to a folded one with the direction tangential to the task surface. Then the planned straight-line displacement and the values of x1 and z1 in Eq. (3) can be obtained by integrating the velocity trajectory, and the joint angle trajectory in Eq. (3) is thus calculated.

4 Design of Adaptive Sliding Mode Controller

4.1 Classical Sliding Mode Controller

Because of the problems such as parameter uncertainties and external disturbances, the excavator manipulator described by Eq. (1) is only an approximation of the real excavator system. Thus, D(θ), C(θ, $ \boldsymbol{\dot{\theta }} $), G(θ), B($ \boldsymbol{\dot{\theta }} $), and τL can be described as

|

$

\boldsymbol{D}(\boldsymbol{\theta} )=\boldsymbol{D}_{0}(\boldsymbol{\theta} )+\boldsymbol{E }_{D}

$

|

|

$

\boldsymbol{C}(\boldsymbol{\theta} , \boldsymbol{\dot \theta} )=\boldsymbol{C}_{0}(\boldsymbol{\theta} , \boldsymbol{\dot \theta} )+\boldsymbol{E }_{C}

$

|

|

$

\boldsymbol{G}(\boldsymbol{\theta} )=\boldsymbol{G}_{0}(\boldsymbol{\theta} )+\boldsymbol{E }_{G}

$

|

|

$

\boldsymbol{B}(\boldsymbol{\dot \theta} )=\boldsymbol{B}_{0}(\boldsymbol{\dot \theta} )+\boldsymbol{E }_{B}

$

|

|

$

\boldsymbol{\tau} _{L}= \boldsymbol{\tau} _{L0} + \boldsymbol{E }_{L}

$

|

where D0(θ), C0(θ, $ \boldsymbol{\dot{\theta }} $), G0(θ), B0($ \boldsymbol{\dot{\theta }} $), and τL0 are the known parts or nominal parameters, and ED, EC, EG, EB, and EL are the errors with the actual values of D(θ), C(θ, $\boldsymbol{\dot{\theta }} $), G(θ), B ($\boldsymbol{\dot{\theta } }$), and τL, respectively.

To design the adaptive sliding mode controller and drive the joint angle position θ to the desired θd, the sliding surface s is defined as

|

$

\boldsymbol{s}=\boldsymbol{ \dot e} +\boldsymbol{\Lambda e}

$

|

where e=θd - θ is the tracking error vector and Λ = diag(λ11, λ22, λ33) is diagonal matrix in which λnn (n=1, 2, 3) is a positive constant. Define the reference states as

|

$

\boldsymbol{\dot \theta} _{r} = \boldsymbol{s}+\boldsymbol{\dot \theta} =\boldsymbol{\dot \theta} _{d} + \boldsymbol{\varLambda e} , \boldsymbol{\ddot \theta} _{r} = \boldsymbol{{\dot s}} +\boldsymbol{\ddot \theta} =\boldsymbol{\ddot \theta} _{d} + \boldsymbol{\varLambda \dot e}

$

|

Then the dynamic model of the excavator described by Eq. (1) can be written as

|

$

\tau = \boldsymbol{D}(\boldsymbol{\theta} )\boldsymbol{\ddot \theta} + \boldsymbol{C}(\boldsymbol{\theta} , \boldsymbol{\dot \theta} )\boldsymbol{\dot \theta} + \boldsymbol{G}(\boldsymbol{\theta} ) + \boldsymbol{B}(\boldsymbol{\dot \theta} ) + \boldsymbol{\tau} _{L} =\\

\;\;\;\; \boldsymbol{D}(\boldsymbol{\theta} )(\boldsymbol{\ddot \theta} _{r} - \boldsymbol{{\dot s} } )+\boldsymbol{C}(\boldsymbol{\theta} , \boldsymbol{\dot \theta} )(\boldsymbol{\dot \theta} _{r} - \boldsymbol{s})+\boldsymbol{G}(\boldsymbol{\theta} )+ \\

\;\;\;\; \boldsymbol{B}(\boldsymbol{\dot \theta} )+\boldsymbol{\tau} _{L}= \boldsymbol{D}(\boldsymbol{\theta} )\boldsymbol{\ddot \theta} _{r} + \boldsymbol{C}(\boldsymbol{\theta} , \boldsymbol{\dot \theta} )\boldsymbol{\dot \theta} _{r} + \boldsymbol{G}(\boldsymbol{\theta} )+ \\

\;\;\;\; \boldsymbol{B}(\boldsymbol{\dot \theta} )+\boldsymbol{\tau} _{L} - \boldsymbol{D}(\boldsymbol{\theta} )\boldsymbol{{\dot s}} -\boldsymbol{C}(\boldsymbol{\theta} , \boldsymbol{\dot \theta} ) \boldsymbol{s}=\boldsymbol{D}_{0}(\boldsymbol{\theta} )\boldsymbol{\ddot \theta} _{r} +\\

\;\;\;\; \boldsymbol{C}_{0}(\boldsymbol{\theta} , \boldsymbol{\dot \theta} )\boldsymbol{\dot \theta} _{r}+ \boldsymbol{G}_{0}(\boldsymbol{\theta} )+\boldsymbol{B}_{0}(\boldsymbol{\dot \theta} )+ \boldsymbol{E}+\boldsymbol{\tau} _{L0}- \\

\;\;\;\; \boldsymbol{D}(\boldsymbol{\theta} ){\dot s} -\boldsymbol{C}(\boldsymbol{\theta} , \boldsymbol{\dot \theta} ) \boldsymbol{s}

$

|

(4) |

where E=ED$\boldsymbol{\ddot{\theta }}_r $ + EC $\boldsymbol{\dot{\theta }}_r $ + EG+ EB+ EL is the matrix that represents model errors or parameter uncertainties.

The control input τ is defined as

|

$

\boldsymbol{\tau} = \boldsymbol{\tau} _{m}+ \boldsymbol{K} _{p} \boldsymbol{s} + \boldsymbol{K} _{i}∫ \boldsymbol{s} {\rm d}t+ \boldsymbol{K} _{s} {\rm sign} ( \boldsymbol{s})

$

|

where τm = D0(θ)$\boldsymbol{\ddot{\theta }} _r$ + C0(θ, $ \boldsymbol{\dot{\theta }} $)$ \boldsymbol{\dot{\theta }}_r $ + G0(θ) + B0($ \boldsymbol{\dot{\theta }} $) + τL0 is the control term based on the nominal parameters of the excavator. Kp=diag(kp1, kp2, kp3), Ki=diag(ki1, ki2, ki3), and Ks=diag(ks1, ks2, ks3) are positive definite diagonal matrices with kpn, kin, and ksn (n=1, 2, 3), all of which are positive constants.

Substitute the control input τ into Eq. (4), we can obtain

|

$

\boldsymbol{D}(\boldsymbol{\theta} ) \boldsymbol{{\dot s}} + \boldsymbol{C}(\boldsymbol{\theta} , \boldsymbol{\dot \theta} ) \boldsymbol{s} + \boldsymbol{K} _{i}∫ \boldsymbol{s} {\rm d}t = \boldsymbol{E }- \boldsymbol{K} _{p} \boldsymbol{s} - \boldsymbol{K } _{s}{\rm sign} ( \boldsymbol{s})

$

|

(5) |

Define the Lyapunov function as

|

$

\boldsymbol{V} = \frac{{1}}{{ 2 }} \boldsymbol{s} ^{\rm T} \boldsymbol{Ds} + \frac{{1}}{{2}} (\int^{t}_{0} \boldsymbol{s} {\rm d}{\tau} )^{\rm T} \boldsymbol{K} _{i}(\int^{t}_{0} \boldsymbol{s} {\rm d}{\tau} )

$

|

Since the matrix $ \boldsymbol{\dot D}$ -2C is skew symmetric

|

$

\boldsymbol{s} ^{\rm T} (\boldsymbol{{\dot D}} -2 \boldsymbol{C}) \boldsymbol{s} =0

$

|

then the differential Lyapunov function is

|

$

\boldsymbol{{\dot V}} =\boldsymbol{s} ^{\rm T} (\boldsymbol{D{\dot s}} + \frac{{1}}{{ 2}} \boldsymbol{{\dot D}} \boldsymbol{s} + \boldsymbol{K} _{i}\int^{t}_{0} \boldsymbol{s} {\rm d}{\tau} )= \\

\;\;\;\; \boldsymbol{s} ^{\rm T} ( \boldsymbol{D{\dot s}} + \boldsymbol{Cs} + \boldsymbol{K} _{i}\int^{t}_{0} \boldsymbol{s} {\rm d}{\tau} )=\\

\;\;\;\;- \boldsymbol{s} ^{\rm T} \boldsymbol{K} _{p} \boldsymbol{s} - \boldsymbol{K} _{s} |\boldsymbol{s} | + \boldsymbol{s} ^{\rm T} \boldsymbol{E }

$

|

If Ksn≥ |En| (n=1, 2, 3), then

|

$

\boldsymbol{{\dot V}} ≤-\boldsymbol{s} ^{\rm T} \boldsymbol{K} _{p} \boldsymbol{s} ≤0

$

|

Since V is a Lyapunov function, so

|

$

λ_{\min} (\boldsymbol{K} _{p})\int^{t}_{0} \boldsymbol{s} ^{\rm T} \boldsymbol{s} {\rm d}{\tau} ≤\int^{t}_{0} \boldsymbol{s} ^{\rm T} \boldsymbol{K} _{p} \boldsymbol{s} ≤V(0)

$

|

where λmin(Kp) is the minimum eigenvalue of the diagonal matrix Kp. Since V(0) and λmin (Kp) are positive constants, it follows that s ∈L2n, e∈L2n∩L∞n, e is continuous and →0 as t→∞, and $\dot e$ ∈L2n. Since $\dot V$ ≤- sTKps ≤0, then 0≤V(t)≤V(0), ∀t≥0. Hence V(t)∈L∞⇒$\int^t_0$sdτ∈L∞. Since e∈L2n∩L∞n, $\dot e$ ∈L2n, and θd, $\dot{\theta }_d $, $\ddot{\theta }_d$∈L∞n, it follows that $\dot{\theta }_r $, $\ddot{\theta }_r$ ∈L∞n. Noting that s ∈L2n and E is bounded, $ \boldsymbol{\dot s}$ ∈L∞n is then obtained from Eq. (5). Since $ \boldsymbol{\dot s}$ ∈L∞n and s is uniformly continuous, then s ∈L2n ⇒ s →0 as t→0⇒$\dot e$ →0[21].

However, the major disadvantage in designing the classical sliding mode controller is that the switching gain Ks in Eq. (5) should be selected larger than the upper bound of the model uncertainties E to guarantee the stability of the control system. A sufficient large switching gain may aggravate the chattering phenomenon and induce a large amplitude jump to the continuous counterpart of the classical SMC.

4.2 Adaptive Sliding Mode Controller

In order to avoid the aforementioned problems in the classical SMC design, an adaptive sliding mode controller is proposed for the trajectory tracking control of the excavator manipulator.

Instead of sign function, shifted sigmoid function Φ(s)=2/(1+e-s)-1 is used in Eq. (5) to eliminate the chattering and the switching gain Ks is updated by the following adaptive law:

|

$

{\dot K} _{sn}=\varGamma _{nn}s_{n}\varPhi (s_{n}), n=1, 2, 3

$

|

(6) |

where Γ =diag(Γ11, Γ22, Γ33) is diagonal matrix and Γnn (n=1, 2, 3) is positive constant. Defining Kd=diag(kd1, kd2, kd3) so that ΚdΦ(s) is the optimal compensation for E and satisfies |KdΦ(s)-E| ≤δ(δ =(δ1 δ2 δ3)T), where δ can be chosen as small as possible.

Define the adaption error as $\boldsymbol{\tilde K}$ =Kd- Ks and choose a Lyapunov candidate as

|

$

V= \frac{{1}}{{2}} \boldsymbol{s}^{\rm T}\boldsymbol{Ds} + \frac{{1}}{{2}} (\int^{t}_{0} \boldsymbol{s} {\rm d}{\tau} )^{\rm T} \boldsymbol{K} _{i}(\int^{t}_{0} \boldsymbol{s} {\rm d}{\tau} )+ \\

\;\;\;\;\;\frac{{1}}{{2}} \sum\limits^3_{n=1} \varGamma ^{-1}_{nn}{\tilde K} _{nn}{\tilde K} _{nn}

$

|

The differential Lyapunov function is calculated as

|

$

\boldsymbol{\dot V} = \boldsymbol{s} ^{\rm T} ( \boldsymbol{D{\dot s}} + \frac{{1}}{{2}} \boldsymbol{{\dot D} s}+\boldsymbol{K} _{i}\int^{t}_{0} \boldsymbol{s} {\rm d}{\tau} )+\sum\limits^3_{n=1} \varGamma ^{-1}_{nn}{\tilde K} _{nn}{\dot {\tilde K}} _{nn} =\\

\;\;\;\boldsymbol{s} ^{\rm T} ( \boldsymbol{D{\dot s}} + \boldsymbol{Cs}+\boldsymbol{K} _{i}\int^{t}_{0} \boldsymbol{s} {\rm d}{\tau} )+\sum\limits^3_{n=1} \varGamma ^{-1}_{nn}{\tilde K} _{nn}{\dot {\tilde K}} _{nn}= \\

\;\;\;\boldsymbol{s} ^{\rm T} \boldsymbol{E}-\boldsymbol{s} ^{\rm T} \boldsymbol{K} _{p} \boldsymbol{s}-\boldsymbol{s} ^{\rm T} \boldsymbol{K} _{s}\varPhi ( \boldsymbol{s}) + \sum\limits^3_{n=1} \varGamma ^{-1}_{nn}{\tilde K} _{nn}{\dot {\tilde K}} _{nn}=\\

\;\;\;- \boldsymbol{s} ^{\rm T} \boldsymbol{K} _{p} \boldsymbol{s}+\boldsymbol{s} ^{\rm T} [ \boldsymbol{E}-\boldsymbol{K} _{d}\varPhi ( \boldsymbol{s})] +\\

\;\;\; \sum\limits^3_{n=1} {\tilde K} _{nn}(-\varGamma ^{-1}_{nn}{\dot K} _{sn}+s_{n}\varPhi (s_{n})) =\\

\;\;\;-\boldsymbol{s} ^{\rm T} \boldsymbol{K} _{p} \boldsymbol{s}+\boldsymbol{s} ^{\rm T} [ \boldsymbol{E}-\boldsymbol{K} _{d}\varPhi ( \boldsymbol{s})]<0

$

|

Hence, s →0 and Ks → Kd in finite time. The tracking error will converge to zero asymptotically and the control system is obviously stable. Then the control input of ASMC is defined as

|

$

\boldsymbol{{\tau}} =\boldsymbol{{\tau}} _{m} +\boldsymbol{K} _{p} s+\boldsymbol{K} _{i}\int \boldsymbol{s} {\rm d}t + \boldsymbol{K} _{s}\varPhi (\boldsymbol{s})

$

|

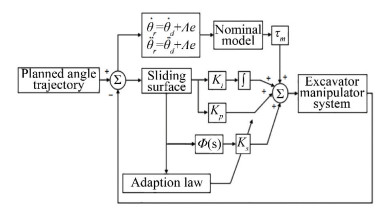

The switching gain Ks is updated by the adaptive law in Eq. (6). Fig. 5 shows the block diagram of the proposed controller.

5 Simulation Results

Parameters of the excavator in Refs. [26-27] were used for simulation, where

|

$

a_{1}=0.05\;{\rm m}, a_{2}=5.16\;{\rm m}, a_{3}=2.59\;{\rm m}, a_{4}=1.33\;{\rm m}

$

|

|

$

r_{2}= 2.71\;{\rm m}, r_{3}=0.64\;{\rm m}, r_{4}=0.65\;{\rm m}

$

|

|

$

α_{2}=0.256\;6\;{\rm rad}, α_{3}=0.331\;6\;{\rm rad}

$

|

|

$

α_{4}=0.394\;4\;{\rm rad}, M_{\rm bo}=1\;566\;{\rm kg}

$

|

|

$

M_{\rm st}=735\;{\rm kg}, M_{\rm bu}=432\;{\rm kg}

$

|

|

$

I_{\rm bo}=14\;250.6\;{\rm kg}·{\rm m}^{2}, I_{\rm st}=727.7\;{\rm kg}·{\rm m}^{2}

$

|

|

$

I_{\rm bu}=224.6\;{\rm kg}·{\rm m}^{2}, g=9.8\;{\rm N/kg}

$

|

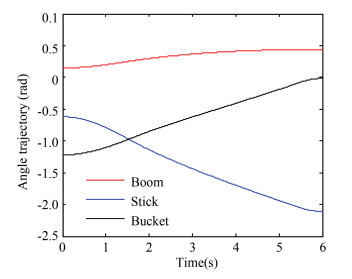

The straight-line motion of the bucket tip K is from the point (7.3 0 -1.74)m to the point (4.3 0 -1.74)m in the coordinate system O1x1y1z1 with the planned velocity trajectory. θdg=π/6, θb=0.925 0 rad, and the slope of the task surface is defined as 0. Then the joint angle trajectories can be obtained from Eq. (3) and is shown in Fig. 6.

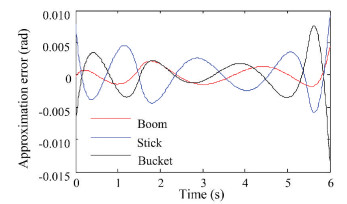

Fifth-order polynomials were used for approximating the boom, stick, and bucket joint angle trajectories[28]. The approximation error curves are shown in Fig. 7. According to the error curves, the maximum approximation error was less than 0.015 rad, which can be neglected.

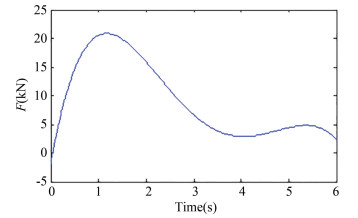

The interactive force between the environment and the bucket is expressed as (Fig. 8)

|

$

F =1.275\;2×10^{-2}t^{5}-6.215\;9×10^{-1}t^{4}+\\

\;\;\;7.088\;1t^{3}-30.507\;7t^{2}+46.316\;1t-\\

\;\;\;1.805\;2 \;{\rm kN}(0≤t≤6 \;{\rm s})

$

|

δ=0.1 rad, and then Fn=Fsinδ and Ft=Fcosδ. The nominal parameters were chosen as

|

$

\boldsymbol{D}_{0}(\boldsymbol{\theta} )=0.9\boldsymbol{D}(\boldsymbol{\theta} )

$

|

|

$

\boldsymbol{C}_{0}(\boldsymbol{\theta} , \boldsymbol{\dot \theta} )=0.9\boldsymbol{C}(\boldsymbol{\theta} , \boldsymbol{\dot \theta} )

$

|

|

$

\boldsymbol{G}_{0}(\boldsymbol{\theta} )=0.9\boldsymbol{G}(\boldsymbol{\theta} ), \boldsymbol{{\tau}} _{L0}=0.95 \boldsymbol{{\tau}} _{L}

$

|

Since the speed of the joint angle trajectory was small enough, the friction term B0($ \boldsymbol{\dot{\theta }} $) can be neglected. The initial pose of the excavator is

|

$

({\theta} _{2} \;\; {\dot \theta} _2 \;\; {\theta} _{3}\;\; {\dot \theta} _3 \;\; {\theta} _{4} \;\; {\dot \theta} _4 )=\\

\;\;(0.1{\rm rad} \;\;0{\rm rad}/{\rm s}\;\; -0.6{\rm rad}\;\; 0{\rm rad}/{\rm s}\;\; -1.2{\rm rad} \;\;0{\rm rad/s})

$

|

|

$

\boldsymbol{\varLambda} ={\rm diag}(5, 5, 5)

$

|

|

$

\boldsymbol{K} _{p}={\rm diag}(100, 100, 100)

$

|

|

$

\boldsymbol{K} _{i}={\rm diag}(100, 100, 100)

$

|

The switching gain

|

$

\boldsymbol{K} _{s}={\rm diag}(20\;000, 1\;500, 1\;200)

$

|

is for the classical SMC. The design parameter of the adaptive law for the switching gain of the proposed ASMC is

|

$

\varGamma = {\rm diag}(1\;500\;000, 100\;000, 100\;000)

$

|

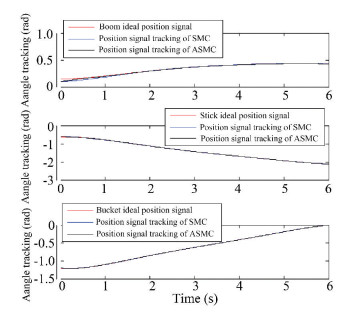

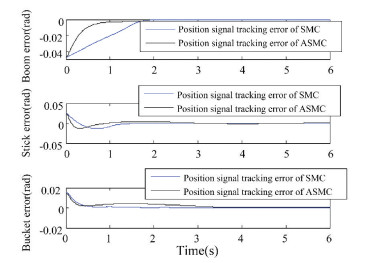

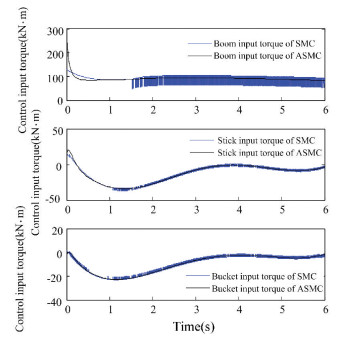

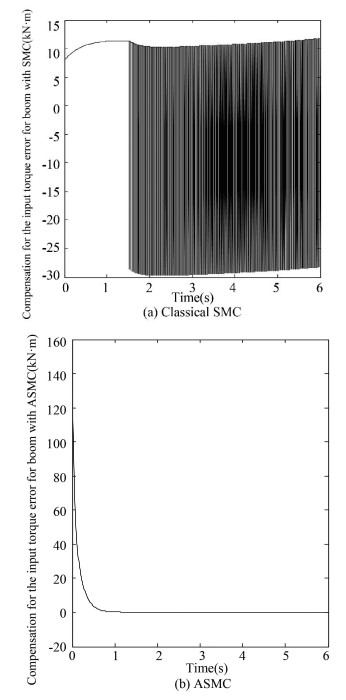

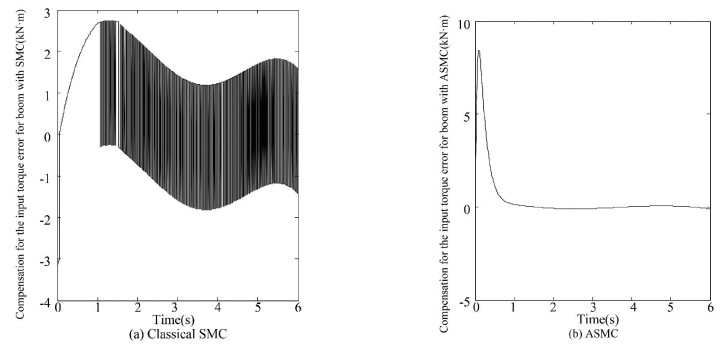

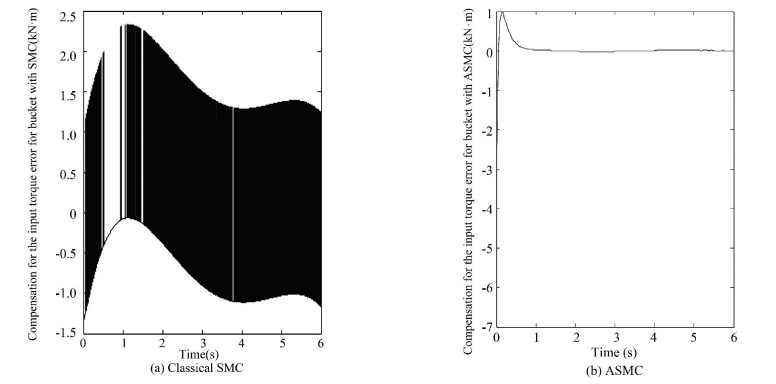

The simulation results are presented in Figs. 9-14. Fig. 9 shows the joint angle trajectories tracking performance of the excavator using classical SMC and ASMC respectively and Fig. 10 shows the angle tracking errors. Results indicate that the proposed ASMC and the classical SMC can both have good control results in trajectory tracking of the excavator. However, the chattering phenomenon in ASMC was eliminated according to the comparison between the control input torque of the classical SMC and that of the ASMC as shown in Fig. 11.

According to Eq. (4) and the parameters set for simulation, the model errors or parameter uncertainties E is

|

$

\boldsymbol{E}= 0.1\boldsymbol{D}(\boldsymbol{\theta} )+0.1\boldsymbol{C}(\boldsymbol{\theta} , \boldsymbol{\dot \theta} )+0.1\boldsymbol{G}(\boldsymbol{\theta} )+0.05 \boldsymbol{{\tau}} _{L}

$

|

Figs. 12-14 show the compensation for the actual model errors or uncertainties E using classical SMC and ASMC. For the classical SMC, Kssign (s) is used to compensate the model errors E with the premise that the boundary of model errors or uncertainties is known. Since Ks is unchanged and usually chosen bigger than the model errors, it may intensify the chattering problem on the sliding surface. Compared with the classical SMC, for the ASMC presented in this paper, KsΦ(s) with Ks updated by the adaptive law in Eq.(6) could successfully track the time-variant model errors or uncertainties E without any prior knowledge of the excavator uncertainties.

6 Conclusions

In this paper, an adaptive sliding mode controller is designed for the straight-line motion control of the excavator manipulator. The dynamic model considering the link shape and weight was presented, and the bucket straight-line motion was transformed into the desired joint angle trajectory for direct control. In general, the nominal parameters or known parts of the dynamic model can be obtained from the design drawings or technical documents of the excavator. The model errors or parameter uncertainties were estimated by the adaptive switching part of the proposed ASMC in this research successfully. Compared with the classical SMC, the prior knowledge of the boundary of the uncertainty is not required in the proposed ASMC, and the chattering phenomenon can be eliminated. Simulation results show the superiority of the adaptive sliding mode controller in the joint trajectory tracking control of the excavator.

0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 0)

0) 2020, Vol. 27

2020, Vol. 27