|

| Abstract: |

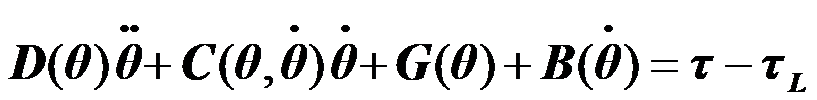

| An adaptive sliding mode control system for the excavator manipulator during straight-line digging operation was presented in this paper. The adaptive laws derived from Lyapunov stability theorem were used to update switching gains and compensate uncertainties. The dynamic model of the excavator manipulator considering link shape and weight was established and the straight-line trajectory of the bucket tooth tip of excavator was transformed into the desired joint angle trajectory for direct control. Finally, simulation results showed the superiority of the proposed control scheme compared with traditional variable structure control with sliding mode. |

| Key words: dynamics adaptive sliding mode control excavator |

| DOI:10.11916/j.issn.1005-9113.18117 |

| Clc Number:TU621 |

| Fund: |

|

| Descriptions in Chinese: |

| 挖掘机滑模自适应轨迹控制研究 徐国胜,吕广明,陆念力 (哈尔滨工业大学 机电学院,哈尔滨 150001) 创新点说明:1) 挖掘机的动力学模型考虑了各机械臂的重量及形状,并给出了动力学各元素的显示表达,  (1) (1)

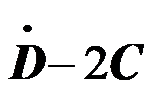

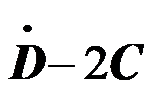

式中,  为斜对称矩阵,这也是考虑挖掘机形状与重量的表达式所具有的。 为斜对称矩阵,这也是考虑挖掘机形状与重量的表达式所具有的。 2) 滑模控制算法的符号函数采用sigmoid 函数代替,通过李雅普诺夫理论得到自适应控制率,调节切换项比例因子,使之跟踪参数误差导致的输入误差,且消除抖振。 3) 轨迹规划,考虑以定切削角进行整平作业生成铲斗轨迹。 研究目的: 挖掘机技术文档参数与装配实机存在误差,该误差不能得到合理估计,但显然是有界的。由于滑模变结构对于模型误差,负载扰动等具有鲁棒性,对于控制处于复杂工作环境的挖掘机轨迹而言非常适用,但滑模切换项容易引起抖振现象,而切换项又是滑模变结构鲁棒适应性所必要的,一般切换项的比例因子要大于模型误差,才能使整体控制系统稳定。但较大的比例因子引起的抖振也愈剧烈,导致对挖掘轨迹自动控制的效果不够理想,为此,探究自适应算法补偿有界误差项进行解决。 研究方法: 首先建立更加符合挖掘机实际情况的动力学模型,其次将滑模控制引入对挖掘机的轨迹控制中。为了低乃至消除抖振,采用sigmoid函数替代切换项符号函数,并通过李雅普诺夫理论得到自适应控制率,自适应调节切换项比例因子,使之补偿挖掘机技术文档参数与实机参数误差导致的控制输入误差,最后与传统滑模控制进行仿真对比。 研究结果: 自适应滑模控制效果达到或优于传统滑模控制,且消除抖振,切换项能很好地补偿参数误差导致的输入误差。 结论: 采用本文自适应滑模控制算法对挖掘机轨迹控制效果相比传统滑模控制消除了抖振现象,取得良好控制效果。该方法摒弃了传统滑模控制需要建模误差界大小的先验知识,对于有界建模误差的系统均能适用。不需估计挖掘机建模误差,符合挖掘机控制实际。 关键词:动力学;自适应滑模控制;挖掘机 |

为斜对称矩阵,这也是考虑挖掘机形状与重量的表达式所具有的。

为斜对称矩阵,这也是考虑挖掘机形状与重量的表达式所具有的。