与传统材料相比较,超细晶材料因其微观结构不同,使得物理性能和力学性能远优于传统材料,具有广泛的应用前景[1-7].铝及其合金具有密度小、导电与导热性能良好、加工性能优良等特点[8],但纯铝的强度较低,限制了其在航空航天、能源技术和军工等领域的应用.通过适当的工艺条件,在不改变纯铝化学成分的前提下改变纯铝微观结构,使其具有超细晶材料特有的优异性能,提高强度等力学性能与耐腐蚀性能,可使纯铝在诸多领域有着更广泛应用.

目前已有很多针对超细晶纯铝性能的研究报道[9-13],但对其耐腐蚀性研究并不多.文献[14]对1050铝合金进行累积叠轧(ARB),得到超细晶材料,与原始退火态相比较显微硬度与耐腐蚀性均提升.文献[15]采用BC路径对Ti进行8道次的ECAP得到超细晶纯钛,通过测试开路电位与极化曲线知其耐腐蚀性能得到改善.文献[16]在室温下通过ECAP得到超细晶纯铝,晶粒有效细化到0.3 μm,力学性能提升,且腐蚀电位正移,腐蚀电流密度降低,耐腐蚀性改善.文献[17]在室温下对工业纯铝ECAP挤压16道次,晶粒细化到0.5 μm,得到的超细晶纯铝较粗晶铝而言,耐腐蚀性提高.目前对超细晶纯铝腐蚀性能的研究主要通过测试其开路电位、极化曲线,只得到其性能改善结果,且实验数据存在一些差别,并未结合电化学阻抗谱进一步证实其晶粒细化对腐蚀性能的影响,解释影响的部分原因.

为此,本文将对ECAP后的超细晶纯铝进行组织观察,研究其力学性能变化,测试其开路电位、极化曲线及电化学阻抗谱,并观察极化后腐蚀形貌,研究其腐蚀性能的变化,以期为超细晶纯铝在海洋、防腐等方面的应用提供借鉴.

1 实验 1.1 实验材料实验材料选用工业纯铝(纯度为99.996%)棒材,尺寸Φ18 mm×70 mm,试样化学成分见表 1.

| 表 1 CP-Al试样化学成分(质量分数/%) Table 1 The chemical composition of CP-Al (wt.%) |

在室温下通过ECPA工艺对CP-Al圆棒料进行BC路径挤压,模具内角为120°,润滑剂为石墨与二硫化钼.根据等效应变公式[18]计算,可知试样每道次挤压的等效应变为0.635.

在室温下利用X射线衍射仪对试样进行分析,采用单色化的Cu Kα射线源,激发的X射线的波长为λ=1.540 6×10-10 m.采用步进测量方式,扫描角度10°~90°,步进角度为0.02°,管电压40 kV,管电流40 mA.采用MID Jade 5.0软件计算ECAP CP-Al样品的平均晶粒尺寸(半高宽补正曲线为软件自带的NBS Silicon-2曲线).

其平均晶粒尺寸计算采用Scherrer[6]公式.

| $ D = K\lambda /[Bx\cos \theta]. $ | (1) |

式中:K为常数; λ为X射线波长; B为衍射峰半高宽; θ为衍射峰角度.

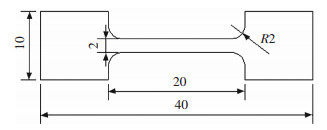

利用德国Zwick/Roell公司生产的仪器化万能硬度试验机Zwick ZHU0.2对试样进行显微维氏硬度测试,分析不同道次ECAP纯铝试样的硬度变化.在室温下采用具有激光引伸计的单轴微拉伸试验机(ZWICK Precisionline Vario)进行单轴微拉伸实验(拉伸速率为0.2 mm/min,预载为5 N),分析试样的抗拉强度、断裂伸长率等力学性能参数.单轴微拉伸试样尺寸如图 1所示.

|

图 1 微拉伸试样尺寸(单位:mm) Figure 1 The size of tensile sample |

采用三电极体系对试样进行电化学腐蚀性能测试,工作电极为试样,辅助电极为铂片, 参比电极为饱和甘汞电极(SCE),质量分数为3.5% NaCl作为测试溶液,如图 2所示.测试仪器为Gamry Interface1000型电化学工作站.OCP测试时间为1 200 s.EIS测试在开路电位下进行,并在幅值为10 mV的正弦交流信号下由高频向低频扫描,频率范围100 kHz~ 10 mHz,并提出相应的等效电路图对数据进行拟合.在电位区间-1~1 V、扫速为2 mV/s下进行极化测试,测试结束后通过SEM观察试样表面形貌.

|

图 2 三电极体系示意图 Figure 2 Schematic diagram of the three-electrode test setting |

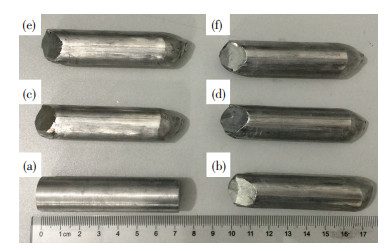

图 3为ECAP变形前的CP-Al试样、不同挤压道次后的ECAP试样的宏观图,可以看出,不同挤压道次下的变形较为顺利,试样表面质量较好,且整体保持完整,并未出现断裂和裂纹等现象.随着挤压道次的不断增加,变形抗力逐渐增大,变形难度逐步增大,因此,试样表面的挤压痕迹越发明显.

|

图 3 纯铝试样及不同道次下ECAP试样图:(a) CP-Al; (b) ECAP 2道次; (c) ECAP 4道次; (d) ECAP 6道次; (e) ECAP 8道次; (f) ECAP 12道次 Figure 3 CP-Al sample and ECAP samples under different passes: (a) CP-Al; (b) ECAP 2 pass; (c) ECAP 4 pass; (d) ECAP 6 pass; (e) ECAP 8 pass; (f) ECAP 12 pass |

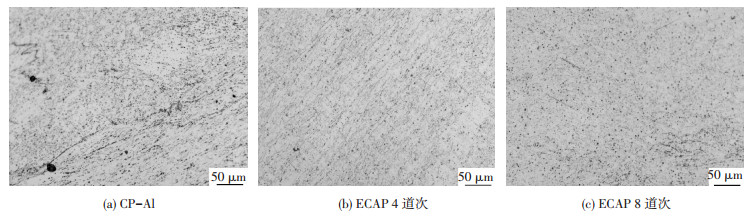

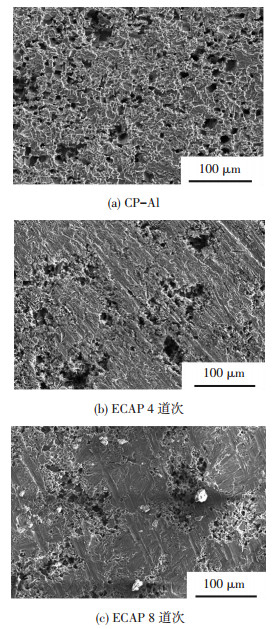

ECAP前后CP-Al试样的微观组织如图 4所示.从图 4可以看出,晶粒在剪切力的作用下,逐渐被拉长,晶粒得到细化.随着挤压道次的增加,晶界变得模糊不清.

|

图 4 ECAP前后CP-Al的微观结构图 Figure 4 Microstructure of different CP-Al samples:(a) CP-Al; (b) ECAP 4 pass; (c) ECAP 8 pass |

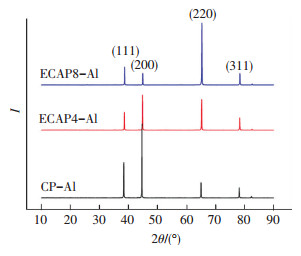

ECAP前后样品采用XRD对其晶粒尺寸进行分析,衍射谱图见图 5.从图 5可以明显看出,CP-Al的晶面具有明显的(111)和(200)晶面取向,而经过8道次的ECAP挤压后,晶面取向发生改变,得到的超细晶纯铝具有明显的(220)晶面取向.用Jade软件和Scherrer公式可得ECAP 4和ECAP 8后样品的平均晶粒尺寸分别为576和482 nm.

|

图 5 不同试样的X射线衍射谱图 Figure 5 The X-ray diffraction pattern of different CP-Al samples |

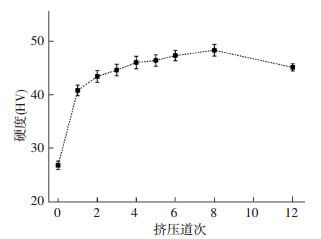

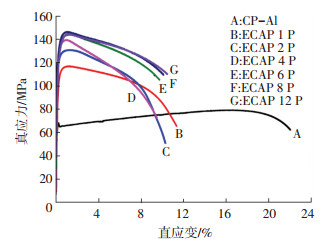

表 2中给出了ECAP变形前的CP-Al试样、不同挤压道次后的ECAP试样的力学性能参数值.从图 6、图 7及表 2可以看出,随着挤压道次的增加,硬度、抗拉强度等力学性能提升,断裂伸长率下降.8道次时达到饱和状态,并随着挤压的继续进行,硬度与抗拉强度略有下降,塑性有所提高.

|

图 6 不同试样的显微硬度 Figure 6 The microhardness of different CP-Al samples |

|

图 7 不同试样微拉伸的真应力-应变曲线 Figure 7 The true stress-true strain curves of different CP-Al samples |

| 表 2 ECAP前后试样的力学性能 Table 2 Mechanical properties of different CP-Al samples |

根据细晶强化原理可知,晶界对位错的滑移运动具有阻滞效应.随着挤压道次的增加,应变量不断增加,位错密度增大,并随着晶粒的不断细化,晶界增多,由于晶界对位错运动具有阻碍作用,位错运动更加困难,使得位错不易穿过晶界塞积在晶界处,产生局部应力,导致试样的显微硬度、强度显著提高,塑性下降.经过8道次挤压后,随着挤压道次的增加,位错的增殖和湮灭达到动态平衡,相应地,显微硬度与抗拉强度的上升趋势也趋于平稳.出现显微硬度略有下降与断裂伸长率有所恢复的情形,是由于位错非常容易被晶界吸收和湮灭,且伴随动态回复和动态再结晶的过程, 位错密度降低, 大量的大角度晶界等轴晶的形成, 使其伸长率有所回升.

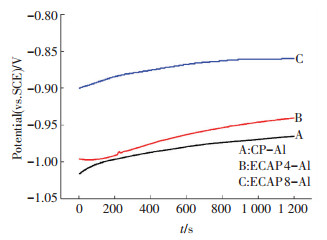

2.3 ECAP后试样腐蚀性能的变化图 8为ECAP前后CP-Al试样开路电位随时间的变化曲线,即腐蚀电位-时间曲线.由图 8可知,CP-Al经过ECAP加工后具有高的自腐蚀电位,并随着ECAP道次的增加,腐蚀电位逐渐变正,从CP-Al的-0.965 V,到ECAP 4道次的-0.941 V以及ECAP 8道次的-0.860 V,说明随着ECAP道次的增加,耐腐蚀性有所改善.

|

图 8 不同试样在3.5%NaCl溶液中的腐蚀电位-时间曲线 Figure 8 Corrosion potential-time curves of different CP-Al samples in 3.5%NaCl solution |

图 9为ECAP前后CP-Al试样在3.5%NaCl溶液中的EIS图,可以看出,在3.5%NaCl溶液中各试样的EIS都具有相似的容抗弧.

|

图 9 不同试样在3.5%NaCl溶液中的EIS与EIS拟合 Figure 9 EIS and EIS fitted of different CP-Al samples in 3.5%NaCl solution |

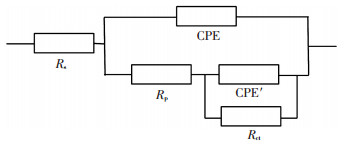

根据各试样阻抗谱图都是由一个容抗弧组成的形状特点,选择合适的等效电路如图 10所示.其中,Rs为溶液电阻,Rct为电荷传递电阻,Rp为腐蚀产物电阻,CPE与CPE′为常相位角元件,Y0和n分别是CPE的相关参数.根据等效电路,对ECAP前后CP-Al试样在3.5%NaCl溶液中的EIS数据进行拟合,拟合结果如图 10所示.从图 10可以看出,拟合结果与实验测量结果比较吻合,说明选择的等效电路是合适的,其拟合结果如表 3所示.随着ECAP道次的增加,电荷传递电阻Rct逐渐增大,表明腐蚀抑制能力逐渐增强,耐腐蚀性能有所改善,与腐蚀电位-时间关系曲线的结果相吻合.

|

图 10 试样在3.5%NaCl溶液中EIS拟合等效电路图 Figure 10 Equivalent circuit used to fit EIS for CP-Al in 3.5%NaCl solution |

| 表 3 不同试样在3.5%NaCl溶液中阻抗谱的等效电路参数 Table 3 Equivalent circuit parameters of impedance spectra of different CP-Al samples in 3.5%NaCl solution |

ECAP前后CP-Al试样在3.5%NaCl溶液中的动电位极化曲线测试结果如图 11所示.极化测试前所有试样均需浸泡在3.5%的氯化钠溶液约10 min,以达到稳定OCP值.从极化曲线中可以明显看出, 3个样品的阴极极化曲线和阳极极化曲线非常相似,说明全部试样的整个反应过程大致相同.此外,随着ECAP道次的增加,阴极电流密度降低.阴极反应是氧化还原,反应式[16]为

|

图 11 不同试样在3.5%NaCl溶液中的极化曲线 Figure 11 Polarization curves of different CP-Al samples in 3.5%NaCl solution |

| $ {\rm{2}}{{\rm{O}}_{\rm{2}}}{\rm{ + }}{{\rm{H}}_{\rm{2}}}{\rm{O + 2e = 2O}}{{\rm{H}}^-}{\rm{.}} $ | (2) |

阳极有明显的钝化区,这是由于在较低的电位下Al阳极表面上钝化膜的生成速度大于溶解速度,因此,表现出钝化状态.当电极电位达到较大值时,Al阳极表面很容易发生点蚀,Al阳极的溶解电流开始随着电位的升高而快速增大.阳极反应为

| $ {\rm{Al = A}}{{\rm{l}}_3} + 3{\rm{e}}. $ | (3) |

点蚀电位、腐蚀电流密度、阳极斜率与阴极斜率等电化学特征参数如表 4所示,可以明显看出,随着ECAP道次的增加,阳极和阴极的斜率有所改变,表明ECAP可以影响阳极和阴极反应.随着ECAP道次增加,腐蚀电流密度逐渐降低,且点蚀电位正移,说明腐蚀速率逐渐降低,耐腐蚀性能改善.

| 表 4 不同试样在3.5%NaCl溶液中的极化曲线参数 Table 4 Electrochemical parameters of polarization curves of different CP-Al samples in 3.5%NaCl solution |

图 12为ECAP前后CP-Al试样在3.5%NaCl溶液中极化测试后腐蚀面的SEM图像.

|

图 12 不同试样在3.5%NaCl溶液中极化测试后SEM形貌 Figure 12 SEM images of different samples after cyclic polarization tests in 3.5%NaCl solution:(a) CP-Al; (b) ECAP 4 pass; (c) ECAP 8 pass |

由图 12可以看出,CP-Al与ECAP CP-Al的腐蚀表面都有明显的腐蚀痕迹.CP-Al的表面腐蚀区数量比ECAP CP-Al多,且CP-Al表面已经呈现均匀腐蚀,而ECAP CP-Al表面仍然是以点蚀扩展形成区域腐蚀,且随着ECAP道次的增加,腐蚀区域数目减少.通过对表面腐蚀形貌比较可以看出,随着ECAP道次的增加,耐腐蚀改善.

随着ECAP道次的增加,晶粒不断细化,耐腐蚀性能改善.这是因为随着晶粒的细化,形成钝化膜的晶粒减小,使得形成的钝化膜相对致密,从而降低其电化学反应.且随着晶粒细化,晶界增多,加速了表面钝化膜的形成,降低了内部晶粒与晶界之间的电偶强度,进而降低了腐蚀速率.挤压道次的增加,粗大的晶粒转化为细小且相对较为均匀的亚晶粒,使得钝化膜的稳定性增强,阻碍了铝的多步溶解过程,从而表现出耐腐蚀性能的增强.

3 结论1) 随着ECAP道次的增加,材料的晶粒细化,显微硬度与抗拉强度等力学性能得到大幅度提升,塑性随之下降.但变形后期,显微硬度与抗拉强度略有下降,塑性有所回复.

2) 随着晶粒的细化,纯铝的腐蚀电位正移(-0.965~-0.860 V)、电荷传递电阻增大(1.741×104~4.798×104 Ω·cm2)、点蚀电位正移(-0.818~-0.734 V)、腐蚀电流密度降低(12.910~3.288 uA/cm2),且腐蚀形貌改善,腐蚀区域数目减少,表明其耐腐蚀性能提高.

3) 晶粒细化后,晶界增多,钝化膜的形成更容易,且形成的钝化膜更加致密,阻碍了铝的多步溶解过程,使腐蚀液更难侵蚀内部金属,是提升耐腐蚀性能的主要原因.

| [1] | TAŃSKI T, SNOPIŃSKI P, PAKIEŁA W. Structure and properties of ultra-fine grained aluminium alloys after laser surface treatment[J]. Materialwissenschaft und Werkstofftechnik, 2016, 47(5/6): 419–427. DOI: 10.1002/mawe.201600517 |

| [2] | MESBAH M, FARAJI G, BUSHROA A R. Characterization of nanostructured pure aluminum tubes produced by tubular channel angular pressing (TCAP)[J]. Materials Science & Engineering A, 2014, 590(1): 289–294. DOI: 10.1016/j.msea.2013.10.036 |

| [3] | PRIMORAC M M, ABAD M D, HOSEMANN P, et al. Elevated temperature mechanical properties of novel ultra-fine grained Cu-Nb composites[J]. Materials Science & Engineering A, 2015, 625: 296–302. DOI: 10.1016/j.msea.2014.12.020 |

| [4] | VALLE J A D, REY P, GESTO D, et al. Mechanical properties of ultra-fine grained AZ91 magnesium alloy processed by friction stir processing[J]. Materials Science & Engineering A, 2015, 628(2): 198–206. DOI: 10.1016/j.msea.2015.01.030 |

| [5] | FARAJI G, ROOSTAE S, NOSRATI A S. Microstructure and mechanical properties of ultra-fine-grained Al-Mg-Si tubes produced by parallel tubular channel angular pressing process[J]. Metallurgical and Materials Transactions A, 2015, 46(4): 1805–1813. DOI: 10.1007/s11661-015-2740-8 |

| [6] |

赵西成, 解摇晨, 杨西荣, 等. 室温90°模具ECAP变形工业纯钛的力学性能[J]. 材料科学与工艺, 2013, 21(2): 113–117.

ZHAO Xicheng, XIE Chen, YANG Xirong, et al. Mechanical properties of commercially pure titanium processed by ECAP at room temperature using a 90° die[J]. Materials Science and Technology, 2013, 21(2): 113–117. DOI: 10.11951/j.issn.1005-0299.20130220 |

| [7] |

罗小萍, 张敏刚, 柴跃生, 等. 铸态AZ81镁合金ECAP态组织与性能研究[J]. 材料科学与工艺, 2012, 20(3): 72–76.

LUO Xiaoping, ZHANG Mingang, CHAI Yuesheng, et al. Microstructure and mechanical properties of cast AZ81 magnesium alloy processed by equal channel angular pressing[J]. Materials Science & Technology, 2012, 20(3): 72–76. DOI: 10.11951/j.issn.1005-0299.20120314 |

| [8] |

李才巨, 张继东, 朱心昆, 等. 高能球磨法制备纯铝纳米晶材料的研究[J]. 粉末冶金技术, 2006, 24(6): 457–459.

LI Caiju, ZHANG Jidong, ZHU Xinkun, et al. Study on the preparation of pure aluminum nanocrystalline materials by high energy ball milling[J]. Powder Metallurgy Technology, 2006, 24(6): 457–459. DOI: 10.3321/j.issn:1001-3784.2006.06.014 |

| [9] | MURASHKIN M, MEDVEDEV A, KAZYKHANOV V, et al. Enhanced mechanical properties and electrical conductivity in ultrafine-grained Al 6101 alloy processed via ECAP-conform[J]. Metals-Open Access Metallurgy Journal, 2015, 5(4): 2148–2164. DOI: 10.3390/met5042148 |

| [10] |

赵润娴, 张建, 王志奇, 等. 等通道转角挤压纯铝的组织结构[J]. 有色金属, 2002, 54(2): 8–11.

ZHAO Runxian, ZHANG Jian, WANG Zhiqi, et al. Microstructure of pure aluminum worked by equal channel angular extrusion[J]. Nonferrous Metals, 2002, 54(2): 8–11. DOI: 10.3969/j.issn.2095-1744.2002.02.003 |

| [11] | JIANG J W, LIU M P, LIU Y, et al. Microstructure and mechanical properties of 6013 aluminium alloy processed by a combination of ECAP and preaging treatment[C]// Materials Science Forum, 2016:6776-82. DOI: 10.4028/www.scientific.net/MSF.877.437. |

| [12] | DUAN Y, TANG L, XU G, et al. Microstructure and mechanical properties of 7005 aluminum alloy processed by room temperature ECAP and subsequent annealing[J]. Journal of Alloys & Compounds, 2016, 664: 518–529. DOI: 10.1016/j.jallcom.2016.01.022 |

| [13] | ABD EL AAL M I, YONG UM Ho, YOO YOON Eum, et al. Microstructure evolution and mechanical properties of pure aluminum deformed by equal channel angular pressing and direct extrusion in one step through an integrated die[J]. Materials Science and Engineering: A, 2015, 625: 252–263. DOI: 10.1016/j.msea.2014.11.089 |

| [14] | FATTAH-ALHOSSEINI A, GASHTI S O. Corrosion Behavior of ultra-fine grained 1050 aluminum alloy fabricated by ARB process in a buffer borate solution[J]. Journal of Materials Engineering and Performance, 2015, 24(9): 3386–3393. DOI: 10.1007/s11665-015-1627-6 |

| [15] | BALYANOV A, KUTNYAKOVA J, AMIRKHANOVA N A, et al. Corrosion resistance of ultra fine-grained Ti[J]. Scripta Materialia, 2004, 51(3): 225–229. DOI: 10.1016/j.scriptamat.2004.04.011 |

| [16] | MOHAMED IBRAHIM ABD EL AAL, SADAWY M M. Influence of ECAP as grain refinement technique on microstructure evolution, mechanical properties and corrosion behavior of pure aluminum[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(12): 3865–3876. DOI: 10.1016/S1003-6326(15)64034-1 |

| [17] | SONG D, AI-BIN M A, JIANG J H, et al. Corrosion behavior of ultra-fine grained industrial pure Al fabricated by ECAP[J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 1065–1070. DOI: 10.1016/S1003-6326(08)60407-0 |

| [18] | VALIEV R Z, LANGDON T G. Principles of equal-channel angular pressing as a processing tool for grain refinement[J]. Progress in Materials Science, 2006, 51(7): 881–981. DOI: 10.1016/j.pmatsci.2006.02.003 |

2018, Vol. 26

2018, Vol. 26