近年来,环境污染和能源紧缺问题日益严重,太阳能、生物能、氢能、核能、风能、海洋能、地热能等新能源的开发利用越来越受关注[1-3].太阳能作为一种来源丰富且对环境无污染的清洁能源,应用越来越广泛.目前太阳能的利用方式有光热利用、光电利用、光化学利用以及光生物利用等,其中规模化应用最成熟的主要是光热利用和光电利用[4-6].在太阳能的光电利用中,非晶硅太阳能电池以其价格低廉、制备工艺简单、衬底选择灵活等特点,成为薄膜太阳能电池的重点研究方向[7-9].1976年,美国RCA实验室的Carlson等成功研制出转换效率为2.4%的p-i-n结构非晶硅太阳能电池[10].Villar等人利用HWCVD在温度低于150 ℃的条件下制备出效率为4.6%的非晶硅薄膜电池[11].随后,日本的Takeuchi进一步改进了非晶硅太阳能电池的制备工艺,推动了非晶硅电池的批量生产[12].目前,虽然非晶硅太阳能电池的光电转换效率已有较大提高,但与单晶硅太阳能电池相比,其光电转换效率仍然处在较低的水平[13-15].针对这一缺点,人们提出在非晶硅太阳能电池中加入背电极以提高电池对太阳光的利用效率,进而有效改善非晶硅电池的性能[16-17].

Al在地球上含量丰富、易于沉积、可加工性好、电导率和光反射率高,是最为常用的金属背电极材料[18].然而,随着电池使用时间的延长,Al电极中的金属元素会逐渐向非晶硅电池中扩散,造成非晶硅太阳能电池的性质劣化,时间稳定性变差[19].针对这一问题,人们对单层Al电极进行了改进,提出通过设计由透明导电材料(TCO)和Al组成的复合背电极,阻止Al元素的扩散.由于该复合结构不会造成进入非晶硅电池的光透过损失,可以有效增加电池的稳定性,近年来被广泛研究[20-22].

目前,在各种TCO/Al复合背电极的研究中,针对ZnO :Ga(GZO)/Al的研究鲜有报道.本文利用磁控溅射技术,分别制备了ZnO :Ga(GZO)薄膜和GZO/Al复合背电极,并通过调节GZO厚度对复合背电极的性能进行改善,研究了GZO薄膜厚度对GZO层光电性质和对GZO/Al复合背电极性能的影响.

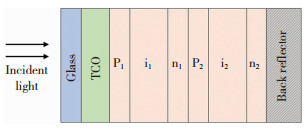

1 实验本实验中,双结非晶硅太阳能电池(面积为1 cm2)由中玻光电有限公司提供.其结构如图 1所示,研究对象为图中灰色阴影部分(Back reflector).实验中,首先将双结非晶硅太阳能电池置于磁控溅射腔体中,将腔体背景真空度抽至8×10-5 Pa.随后,通入Ar气,维持Ar气通入流量为30 sccm,调节工作压力为0.4 Pa.直径为76 mm的GZO靶材(ZnO:Ga2O3 = 98:2 (质量比),纯度99.95%)通过射频(RF)磁控溅射在80 W的条件下于非晶硅电池上首先沉积一层GZO薄膜,并对GZO薄膜的光电性质进行研究.随后,利用直流(DC)磁控溅射通过Al靶(Φ76 mm, 99.95%)在GZO层上镀制Al层,制备GZO/Al复合背电极.

|

图 1 双结非晶硅太阳能电池结构 Fig.1 Structure of double junction amorphous silicon solar cell(this study works on the gray shaded part) |

通过XP-1型台阶仪测量薄膜厚度,利用Rigaku X射线衍射仪对膜层结晶情况进行分析,通过RTS-8型四探针仪对薄膜电学性质进行表征,采用Cary 100紫外-可见分光光度计分析GZO薄膜与GZO/Al复合背电极的光学特性,Keithley-4200 SCS半导体特征测试仪用以表征镀有背电极的非晶硅太阳能电池性能.

2 结果与讨论 2.1 GZO厚度对GZO层结构与光电性质的影响GZO薄膜通过射频磁控溅射镀制,分别制备90,100,120和160 nm的GZO薄膜,研究膜层厚度对GZO薄膜结构与光电性质的影响.图 2为不同厚度GZO薄膜的XRD衍射谱.

|

图 2 不同厚度GZO薄膜的XRD谱图 Fig.2 X-ray diffractograms of GZO thinfilms with different thicknesses |

由图 2可以看出,GZO的结晶以ZnO为主,并表现出沿ZnO(002)晶面较为强烈的择优取向生长.在2θ约为73°附近,可以观察到微弱的ZnO(004)衍射峰,其他晶面的结晶峰在该图中没有得到体现,进一步证明了六角纤维矿结构的ZnO沿c轴取向生长.在不同厚度的样品中,ZnO(002)峰位置相差不大,表明GZO薄膜厚度的变化对薄膜内应力的影响不大.当薄膜厚度为120 nm时,薄膜的衍射峰最强烈,对应薄膜的结晶情况最好.薄膜中的晶粒尺寸可以根据半高宽(FWHM)由谢乐公式计算得到.在本实验中,随着GZO薄膜厚度的变化,ZnO(002)峰的FWHM变化不明显,薄膜晶粒尺寸维持在20~23.6 nm.

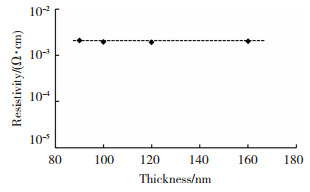

图 3为GZO薄膜电阻率随薄膜厚度的变化.随着薄膜厚度的增加,薄膜电阻率的变化并不明显.在本实验中,薄膜厚度最低为90 nm,远高于薄膜中的晶粒尺寸.因此,在不同薄膜中,晶粒尺寸或微观结构对电阻率的作用较为一致.特别是不同厚度的薄膜中,晶界散射对载流子迁移率造成的影响差距不大.另外,不同厚度的薄膜均是在相同条件下溅射制得的,因而薄膜中Ga的含量及存在形式十分接近,因此,载流子浓度随薄膜厚度的增加变化不大.综上认为,GZO薄膜的电阻率受薄膜厚度变化影响不大.

|

图 3 GZO薄膜电阻率随薄膜厚度的变化 Fig.3 Variation of the resistivity of GZO thinfilms with different thicknesses |

GZO薄膜在可见光区的透光率随薄膜厚度的变化见图 4, 其中,插表为不同厚度薄膜在可见光区的平均透光率.

|

图 4 GZO薄膜透光率随薄膜厚度的变化 Fig.4 Variation of the transmittance of GZO thin films with different thicknesses |

由图 4可见,不同厚度的薄膜均表现出良好的光学特性,可见光区的平均透过率超过93%.随着薄膜厚度的增加,由于光的干涉引起的透过率曲线出现波峰和波谷的迁移.这种迁移是造成薄膜平均透过率变化的主要原因.当薄膜厚度为120 nm时,GZO薄膜表现出相对更好的透光率.结合不同厚度GZO薄膜的电学性质和光学性质,本文推测在该实验条件下制得的GZO薄膜适用于制备GZO/Al复合背电极.

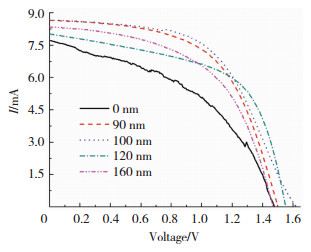

2.2 GZO/Al复合背电极对太阳能电池性能的影响GZO/Al复合背电极通过磁控溅射工艺制备,其中Al层通过直流磁控溅射制备,溅射功率为90 W.具有GZO/Al复合背电极的非晶硅太阳能电池的IV曲线随GZO层厚度的变化如图 5所示.

|

图 5 GZO/Al复合背电极中不同厚度GZO层对应的非晶硅太阳能电池的I-V曲线 Fig.5 I-V curves of amorphous silicon solar cells with various GZO thicknesses in GZO/Al multilayer back reflector |

非晶硅太阳能电池的开路电压(VOC)、短路电流(ISC)以及太阳能电池的最大输出功率(Pm =Im·Vm)和填充因子(FF = Pm/(VOC·ISC))可由IV曲线估读或推导出[23-25].由图 5可知,具有单层铝背电极的电池样品性能不是特别稳定,而具有GZO/Al复合背电极电池样品的I-V曲线均比较平滑.通过图 5中曲线在短路电流与开路电压处的斜率可以看出,具有单层Al背电极电池的并联电阻比具有GZO/Al复合背电极电池样品的并联电阻更小.另外,随着GZO层厚度的变化,太阳能电池的性能参数也发生改变,这种变化结果总结于表 1.电池中的短路电流和开路电压在GZO层厚度为100 nm时达到最大,分别为8.66 mA和1.62 V;而填充因子则是在GZO层厚度为120 nm时达到最佳值(57.8%),GZO厚度为100 nm时太阳能电池的填充因子稍有所降低,为54.7%.对比单层Al背电极的非晶硅太阳能电池(GZO厚度为0),具有GZO/Al复合背电极的非晶硅电池的短路电流、开路电压、填充因子都明显增加.其中GZO层为100 nm时的太阳能电池比单层Al背电极电池样品的短路电流增加了0.95 mA,约增加了12%;开路电压增加了0.14 V,约增加了9.5%,填充因子相应地提高了10%.

| 表 1 复合背电极中GZO层厚度不同的非晶硅电池的性能参数 Table 1 Properties of the amorphous silicon solar cell with various GZO thicknesses in GZO/Al multilayer back reflector |

非晶硅太阳能电池的光电效率作为太阳能电池的重要参数,直接反应太阳能电池的性能,其变化受到开路电压(VOC)、短路电流(ISC)、太阳能电池的最大输出功率(Pm)和填充因子(FF)的影响.太阳能电池光电转换效率(η)的推导公式为

| $ \eta = {\rm{ }}\frac{{{P_{\rm{m}}}}}{{{p_{{\rm{in}}}}}} \times 100\% = \frac{{{\rm{FF}} \times {V_{{\rm{OC}}}} \times {I_{{\rm{SC}}}}}}{{{P_{{\rm{in}}}}}} \times 100\% . $ |

式中:Pin为入射功率.具有不同背电极的电池转换效率见表 1,可以看出,与单层Al背电极的非晶硅太阳能电池相比,具有GZO/Al复合背电极的太阳能电池转换效率均有不同程度的提高.当GZO层厚度为100 nm时,太阳能电池的转化效率达到最大值7.68%, 与具有单层Al背电极的太阳能电池相比提高了50.6%(相对效率).

3 结论1) 单层GZO薄膜的光电性质在膜厚为90~160 nm之间变化不大,电阻率约为2×10-3Ω·cm,可见光区透过率为93%~95%,适合制备GZO/Al复合背电极.

2) 与具有单层Al背电极的非晶硅太阳能电池相比,具有GZO/Al复合背电极的太阳能电池的短路电流(ISC)、开路电压(VOC)、填充因子(FF)和电池的光电转换效率(η)具有不同程度的提高.

3) 当GZO层厚度为100 nm时,具有GZO/Al复合背电极的非晶硅太阳能电池的转换效率大幅提高50.6%(相对效率).此时,太阳能电池的短路电流(ISC)、开路电压(VOC)和填充因子(FF)分别为8.66 mA,1.62 V和54.7%.

| [1] |

THANH T H, QUANG V L, THANH D H. Determination of the dynamic resistance of the quantum dots solar cells by one Ⅰ-Ⅴ curve and electrochemical impedance spectra[J]. Solar Energy Materials and Solar Cells, 2015, 143: 269-274. DOI:10.1016/j.solmat.2015.07.007 |

| [2] |

KAZMI S A, HAMEED S, AZAM A. Synthesis and characterization of Ag nanowires: Improved performance in dyesensitized solar cells[J]. Recent Trends in Engineering and Material Sciences, 2016, 8: 577-579. DOI:10.1016/j.pisc.2016.06.025 |

| [3] |

LANGFORD J I, WILSON A J C. Scherrer after 60 years:Asurvey and some new results in determination of crystallite size[J]. Journal of Applied Crystallography, 1978, 11: 102-113. DOI:10.1107/S0021889878012844 |

| [4] |

JUNG Kwanghoon, YUN Sunjin, LEE Seonghyun, et al. Double-layered Ag-Al back reflector on stainless steel substrate for a-Si:Hthin film solar cells[J]. Solar Energy Materials and Solar Cells, 2016, 145: 368-374. DOI:10.1016/j.solmat.2015.10.041 |

| [5] |

KNIGHT M W, VAN de Groep J, BRONSVELD P C P, et al. Soft imprinted Ag nanowire hybrid electrodes on silicon heterojunction solar cells[J]. Nano Energy, 2016, 30: 398-406. DOI:10.1016/j.nanoen.2016.10.011 |

| [6] |

LANZ T, FANG L, BAIK S J, et al. Photocurrent increase in amorphous Si solar cells by increased reflectivity of LiF/Al electrodes[J]. Solar Energy Materials and Solar Cells, 2012, 107: 259-262. DOI:10.1016/j.solmat.2012.06.044 |

| [7] |

GUO Yingnan, THIAM M B O, LEVCHENKO I, et al. Inductively and capacitively coupled plasmas at interface: A comparative study towards highly efficient amorphous-crystalline Si solar cells[J]. Applied Surface Science, 2018, 427: 486-492. DOI:10.1016/j.apsusc.2017.08.125 |

| [8] |

KRAJANGSANG T, INTHISANG S, SRITHARATHIKHUN J, et al. An intrinsic amorphous silicon oxide and amorphous silicon stack passivation layer for crystalline silicon heterojunction solar cells[J]. Thin Solid Films, 2017, 628: 107-111. DOI:10.1016/j.tsf.2017.03.010 |

| [9] |

FANG Jia, YAN Baojie, LI Tiantian, et al. Substrate effect on ultra-thin hydrogenated amorphous silicon solar cells[J]. Solar Energy Materials and Solar Cells, 2017, 171: 222-227. DOI:10.1016/j.solmat.2017.06.065 |

| [10] |

CARLSON D E, WRONSKI C R. Amorphous silicon solar-cell[J]. Applied Physics Letters, 1976, 28(11): 671-673. DOI:10.1063/1.88617 |

| [11] |

VILLAR F, ANTONY A, ESCARRE J, et al. Amorphous silicon thin film solar cells deposited entirely by hot-wire chemical vapour deposition at low temperature (< 150 degrees C)[J]. Thin Solid Films, 2009, 517(12): 3575-3577. DOI:10.1016/j.tsf.2009.01.074 |

| [12] |

TAKATSUKA H, YAMAUCHI Y, KAWAMURA K, et al. World's largest amorphous silicon photovoltaic module[J]. Thin Solid Films, 2006, 506: 13-16. DOI:10.1016/j.tsf.2005.08.011 |

| [13] |

QARONY W, HOSSAIN M I, HOSSAIN M K, et al. Efficient amorphous silicon solar cells: Characterization, optimization, and optical loss analysis[J]. Results in Physics, 2017, 7: 4287-4293. DOI:10.1016/j.rinp.2017.09.030 |

| [14] |

STUCKELBERGER M, BIRON R, WYRSCH N, et al. Review: Progress in solar cells from hydrogenated amorphous silicon[J]. Renewable and Sustainable Energy Reviews, 2017, 76: 1497-523. DOI:10.1016/j.rser.2016.11.190 |

| [15] |

DESA M K M, SAPEAI S, AZHARI A W, et al. Silicon back contact solar cell configuration: Apathway towards higher efficiency[J]. Renewable and Sustainable Energy Reviews, 2016, 60: 1516-1532. DOI:10.1016/j.rser.2016.03.004 |

| [16] |

ROCKSTUHL C, FAHR S, LEDERER F. Absorption enhancement in solar cells by localized plasmonpolaritons[J]. Journal of Applied Physics, 2008, 104(12): 123102. DOI:10.1063/1.3037239 |

| [17] |

FERRY V E, VERSCHUUREN M A, LI H B T, et al. Improved red-response in thin film a-Si:Hsolar cells with soft-imprinted plasmonic back reflectors[J]. Applied Physics Letters, 2009, 95(18): 183503. DOI:10.1063/1.3256187 |

| [18] |

WANG G H, SHI C Y, ZHAO L, et al. Improved aluminum-doped ZnO/metal back reflector for p-i-n amorphous silicon germanium thin film solar cells[J]. Thin Solid Films, 2013, 534: 591-593. DOI:10.1016/j.tsf.2013.01.059 |

| [19] |

YI Jangheui, KOO Hyeyoung, KIMJunghyun, et al. Pb-free glass frits prepared by spray pyrolysis as inorganic binders of Al electrodes in Si solar cells[J]. Journal of Alloys and Compounds, 2011, 509(21): 6325-6331. DOI:10.1016/j.jallcom.2011.03.085 |

| [20] |

BRUHAT E, DESRUES T, GRANGE B, et al. TCO contacts for high efficiency c-Si solar cells: influence of different annealing steps on the Si substrates and TCO layersproperties[C]// 7th International Conference on Silicon Photovoltaics, Energy Procedia, ScienceDirect.2017, 124: 829-833. DOI: 10.1016/j.egypro.2017.09.354

|

| [21] |

ZHANG X D, ZHAO Y, GAO Y T, et al. Influence of front electrode and back reflector electrode on the performances of microcrystalline silicon solar cells[J]. Journal of Non-Crystalline Solids, 2006, 352: 1863-1867. DOI:10.1016/j.jnoncrysol.2005.12.047 |

| [22] |

HAN Guifang, ZHANG Sam, BOIX P P, et al. Towards high efficiency thin film solar cells[J]. Progress in Materials Science, 2017, 87: 246-291. DOI:10.1016/j.pmatsci.2017.02.003 |

| [23] |

BETT A J, SCHULZE P S C, WINKLER K, et al. Low temperature perovskite solar cells with an evaporated TiO2 compact layer for perovskite silicon tandem solar cells[C]. 7th International Conference on Silicon Photovoltaics, Energy Procedia, ScienceDirect.2017, 124: 567-576. DOI: 10.1016/j.egypro.2017.09.293

|

| [24] |

SCHILL C, BRACHMANN S, KOEHL M. Impact of soiling on Ⅳ-curves and efficiency of PV-modules[J]. Solar Energy, 2015, 112: 259-262. DOI:10.1016/j.solener.2014.12.003 |

| [25] |

SHAIKH J S, SHAIKH N S, SHEIKH A D, et al. Perovskite solar cells: in pursuit of efficiency and stability[J]. Materials and Design, 2017, 136: 54-80. DOI:10.1016/j.matdes.2017.09.037 |

2019, Vol. 27

2019, Vol. 27